BIOLOX - Nanocomposite for Arthoplasty

The Fourth Generation of Ceramics

The Fourth Generation of Ceramics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Tribology and Arthroplasty<br />

Competence in Ceramics<br />

Material Properties<br />

The Strengths of <strong>BIOLOX</strong> ® delta<br />

Key Issues in Hip Arthroplasty<br />

2<br />

Osteolysis and aseptic<br />

loosening are primarily<br />

triggered by wear<br />

particles, mostly of<br />

polyethylene (left).<br />

Osteolysis<br />

Although total hip arthroplasty is one of<br />

the most successful of all surgical procedures,<br />

a number of open questions relating<br />

to implant design and materials remain.<br />

According to the Swedish Register, osteolysis<br />

and aseptic loosening are responsible<br />

<strong>for</strong> more than 75 percent of all revisions.<br />

The bearing materials used and the volume,<br />

size, and biological effects of wear particles<br />

play a decisive role in the development<br />

of these conditions. The second most frequent<br />

complication is dislocation created<br />

by prosthetic impingement and insufficient<br />

joint stability.<br />

Wear Particles<br />

Particle disease, a condition first identified<br />

by Willert, is triggered by polyethylene (PE)<br />

wear particles. Even the new highly crosslinked<br />

polyethylene (XPE) can produce<br />

wear particles, which create a similar condition.<br />

In addition, the fact that the particles<br />

released are significantly smaller than<br />

those associated with standard PE, some<br />

concerns exist over the long-term biological<br />

reaction to these smaller particles and<br />

their increased surface area. In the case of<br />

metal-on-metal articulations, the unavoidable<br />

leaching of metal ions represents an<br />

obvious risk.<br />

Synovial Fluid Lubrication<br />

We know today that there is no permanent<br />

hydrodynamic state of lubrication in<br />

artificial hip joints. The continuous shifting<br />

between motion and rest and the frequent<br />

generation of one-sided stress usually prevent<br />

the <strong>for</strong>mation of a permanent lubricating<br />

film of synovial fluid. This makes the<br />

wear resistance of the articulating materials<br />

even more crucial.<br />

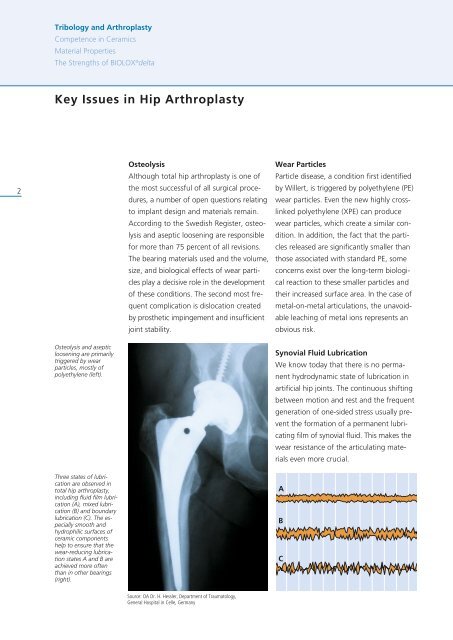

Three states of lubrication<br />

are observed in<br />

total hip arthroplasty,<br />

including fluid film lubrication<br />

(A), mixed lubrication<br />

(B) and boundary<br />

lubrication (C). The especially<br />

smooth and<br />

hydrophilic surfaces of<br />

ceramic components<br />

help to ensure that the<br />

wear-reducing lubrication<br />

states A and B are<br />

achieved more often<br />

than in other bearings<br />

(right).<br />

A<br />

B<br />

C<br />

Source: OA Dr. H. Hessler, Department of Traumatology,<br />

General Hospital in Celle, Germany