Page 2 to 37

Page 2 to 37

Page 2 to 37

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Page</strong> 2 <strong>to</strong> <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a capable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

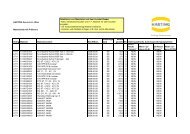

Table of contents<br />

<strong>Page</strong><br />

1. Definition of the specimen<br />

1.1 Contact stripes 3<br />

1.2 Connec<strong>to</strong>rs 3<br />

1.3 Printed Boards 4<br />

2. Preinvestigation of solderability by the wetting balance method.<br />

2.1 Test equipment 7<br />

2.2 Test schedule 8<br />

2.3 Results 9<br />

3. Qualification in the process at the cus<strong>to</strong>mer<br />

3.1 Overview of the test matrix 13<br />

3.2 Test schedule and acceptance criteria 14<br />

3.3 Backward compatibility<br />

3.3.1 Wave soldering process AP 16<br />

3.3.2 Wave soldering process BP 17<br />

3.3.3 Wave soldering process CP 18<br />

3.4 Forward compatibility<br />

3.4.1 Wave soldering process DP 26<br />

3.4.2 Wave soldering process EP 30<br />

3.4.3 Wave soldering process FP 35<br />

4 Summary <strong>37</strong><br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 3 <strong>to</strong> <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a capable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

1. Definition of the specimen<br />

1.1 Contact stripes<br />

Fig.1: BC male contacts<br />

1.2 Connec<strong>to</strong>rs<br />

Fig. 2,3 : DIN Type C male connec<strong>to</strong>r (HARTING Part.No.: 09031966921)<br />

Tin height<br />

Production parameters of the coating:<br />

Surface:<br />

Galvanic<br />

Plating thickness Sn:<br />

Plating thickness Ni:<br />

Base material :<br />

Matt Sn lead-free<br />

HARTING Electronics<br />

6,6µm (average)<br />

2,0µm (average)<br />

CuZn<strong>37</strong><br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 4 <strong>to</strong> <strong>37</strong><br />

1.3 Printed boards<br />

Report <strong>to</strong><br />

Qualification of a capable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Original cus<strong>to</strong>mer PCBs, in separate cases test PCBs, were used for the field trials.<br />

We express our gratitude <strong>to</strong>ward our cus<strong>to</strong>mers for their open and friendly support of our trials at their<br />

premises. To prevent an unauthorized circulation of sensitive or confidential cus<strong>to</strong>mers’ information,<br />

the field trials are recorded in a coded form in this test report. (AP – FP)<br />

The solder conditions are shown in detail for all separate field trials.<br />

Wave soldering test AP<br />

Fig. 4: Cus<strong>to</strong>mer PCB double euro size<br />

Board thickness:<br />

Diameter hole:<br />

Surface:<br />

1,6mm<br />

0,94mm –0,96mm<br />

Ni/Au<br />

Wave soldering test BP<br />

Fig. 5: Cus<strong>to</strong>mer PCB euro size<br />

Board thickness: 1,6mm<br />

Diameter hole: --<br />

Surface:<br />

HAL SnPb<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 5 <strong>to</strong> <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a capable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Wave soldering test CP 1<br />

Fig. 6: Cus<strong>to</strong>mer PCB euro size<br />

Board thickness: 1,6mm<br />

Diameter hole: --<br />

Surface:<br />

HAL SnPb<br />

Wave soldering test CP 2<br />

Fig. 7: Cus<strong>to</strong>mer PCB double euro size<br />

Board thickness:<br />

Diameter hole :<br />

Surface:<br />

1,6mm<br />

0,94mm –0,96mm<br />

Ni/Au<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 6 <strong>to</strong> <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a capable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Wave soldering test DP<br />

Fig. 8:Test PCB (HARTING) double euro size<br />

Type: HARTING leadfree test board 3 (manufactured 2005/01)<br />

Board thickness:<br />

Diameter hole :<br />

Surface:<br />

1,6mm<br />

0,97mm-0,99mm<br />

HAL Sn lead-free<br />

Chem. Sn<br />

Ni/Au<br />

Wave soldering test EP<br />

Fig. 9: Test PCB (HARTING) euro size<br />

Type: HARTING leadfree test board 3 (manufactured 2005/01)<br />

Board thickness: 1,6mm<br />

Diameter hole : 0,97mm-0,99mm<br />

Surface:<br />

HAL Sn leadfree<br />

Chem. Sn<br />

Ni/Au<br />

Wave soldering test FP<br />

Fig. 10: Cus<strong>to</strong>mer PCB, cus<strong>to</strong>m size<br />

Board thickness: 1,6mm<br />

Diameter hole : --<br />

Surface:<br />

Chem. Sn<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 7 <strong>to</strong> <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a capable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

2. Preinvestigation of solderability by the wetting balance method<br />

2.1 Test equipment:<br />

Wetting balance test equipment HARTING ID: 532-060-11<br />

Solder:<br />

Stannol, Sn40Pb40, Sn95.5Ag3.8Cu0.7, Sn99.3Cu0.7<br />

Flux:<br />

Stannol Actiec 5 acc. <strong>to</strong> DIN EN 29453-1 class 1.1.2.A ( IEC class ROL1)<br />

Solid content: 0,125%<br />

Activity level : low<br />

Immersion time :<br />

Immersion speed:<br />

5sec<br />

20mm/sec<br />

Fig.: 11,12 : wetting balance test equipment<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 8 <strong>to</strong> <strong>37</strong><br />

2.2 Test schedule<br />

Report <strong>to</strong><br />

Qualification of a capable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Reference document : in accordance <strong>to</strong> IEC 60068-2-20 (1979/1987) 4.5 Accelerated aging,<br />

IEC 60068-2-54 draft (2003) Solderability by wetting balance method.<br />

Test Requirement Reference-document Sample description<br />

S<strong>to</strong>rage<br />

room<br />

temperature<br />

20°C/60% r.h IEC 60068-2-20<br />

(1979/1987)<br />

dry heat 16h/155°C IEC 60068-2-20<br />

(1979/1987)<br />

steam aging 8h/96°C/100%r h IEC 60068-2-20<br />

(1979/1987)<br />

ANSI/EIA –364-52A<br />

(2003)<br />

Solderability by wetting balance method<br />

Solderability<br />

Solder<br />

Bath temperature<br />

Sn60Pb40 235°C<br />

Sn95,5 Ag3,8<br />

Cu0,7<br />

245°C<br />

Sn99,3 Cu0,7 250°C<br />

IEC 60068-2-54<br />

(draft 2003)<br />

contact stripes<br />

contact stripes<br />

contact stripes<br />

contact stripes<br />

Visual inspection<br />

Visual<br />

inspection<br />

Flux<br />

Actiec 5<br />

min 95% wetting IEC 60068-2-20<br />

(1979/1987)<br />

ANSI/EIA –364-52A<br />

(2003)<br />

contact stripes<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 9 <strong>to</strong> <strong>37</strong><br />

2.3 Results:<br />

Report <strong>to</strong><br />

Qualification of a capable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Overview of the wetting results with the tested BC Male contact stripes (sample surface finish 17)<br />

Solder SnAgCu SnCu SnPb<br />

Flux Actiec 5 Actiec 5 Actiec 5<br />

unloaded ++ + ++<br />

after 16h/155°C dry heat ++ +o ++<br />

after 8h/96°C/100r.h<br />

steam aging<br />

o o o<br />

Definition of the acceptance criteria:<br />

++ = Wetting time < 0,5s / Wetting force = reference force<br />

+ = Wetting time < 1,0s / Wetting force = reference force<br />

+o = Wetting time < 1,5s / Wetting force min. 80% of the reference force<br />

o = Wetting time < 2,0s / Wetting force min. 80% of the reference force<br />

o- = Wetting time < 2,5s / Wetting force min. 50% of the reference force<br />

- = retarded Wetting time > 2,5s, bad Wetting force<br />

-- = retarded Wetting time > 2,5s, very bad Wetting force<br />

Some representative force-time curves:<br />

slow wetting very fast wetting wetting limited unstable wetting<br />

by thermal demand (dewetting)<br />

non wetting poor wetting good wetting retarded wetting<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 10 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Contact stripes unloaded<br />

BC male contact stripes surface matt Sn; solder Sn95,5Ag3,8Cu0,7; Flux: Actiec 5<br />

Diagram 1:<br />

The force-time curve shows a good wetting (fast zero-crossing time (

<strong>Page</strong> 11 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Contacts s<strong>to</strong>red 16h/155°C dry heat<br />

BC male contact stripes surface matt Sn; solder Sn95,5Ag3,8Cu0,7; Flux: Actiec 5<br />

Diagram 2:<br />

The force-time curve shows a good wetting (fast zero-crossing time (

<strong>Page</strong> 12 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Contacts s<strong>to</strong>red 8h/96°C/100%rh steam aging<br />

BC male contact stripes surface Sn; solder Sn95,5Ag3,8Cu0,7; Flux: Actiec 5<br />

Diagram 3:<br />

The force-time curve shows a decelerated wetting, low wetting force.<br />

Fig. 17, 18: Good and complete wetting with no pores at the Sn surface, though the height of the<br />

solder wetting is smaller.<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 13 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

3. Qualification in the process at the cus<strong>to</strong>mer<br />

Field trials at the solder machines of various cus<strong>to</strong>mers of the market<br />

segments machine <strong>to</strong>ols, industrial communication and PCB assembly.<br />

Temperature profile<br />

On of the 4 (in <strong>to</strong>tal) tested<br />

PCBs<br />

One of the 5 (in <strong>to</strong>tal) tested solder<br />

facilities<br />

Evaluation of solder results acc. <strong>to</strong> IPC<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 14 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

3.2 Test schedule and acceptance criteria<br />

Reference document: IPC-A-610-D:2005; Part 5.1 Soldering acceptability requirements;<br />

Part 7.6 plated through holes with component leads.<br />

Test Requirement Reference document Sample description<br />

S<strong>to</strong>rage<br />

room<br />

temperature<br />

20°C/60% r.h IEC 60068-2-20<br />

(1979/1987)<br />

dry heat 16h/155°C IEC 60068-2-20<br />

(1979/1987)<br />

steam aging 8h/96°C/100%r h IEC 60068-2-20<br />

(1979/1987)<br />

ANSI/EIA –364-52A<br />

(2003)<br />

Process capability for Wave soldering<br />

DIN male connec<strong>to</strong>r<br />

Type C<br />

DIN male connec<strong>to</strong>r<br />

Type C<br />

DIN male connec<strong>to</strong>r<br />

Type C<br />

Test 1 AP Test 2 BP Test 3 CP Test 5 DP Test 4 EP Test 6 FP<br />

wave-solder machine<br />

type: SEHO System<br />

8530<br />

wave-solder machine<br />

type: SEHO System,<br />

2035<br />

wave-solder machine<br />

type: Ersa<br />

wave-solder machine<br />

type: EPM<br />

wave-solder machine<br />

type SEHO System<br />

2340<br />

wave-solder machine<br />

type: SEHO System<br />

2340<br />

solder: SnPb solder: SnPb solder: SnPb solder: SnCu solder: SnAgCu solder: SnAgCu<br />

double euro format<br />

Ni/Au<br />

Visual inspection<br />

visual inspection<br />

cross section<br />

euro format<br />

HAL SnPb<br />

acc. <strong>to</strong> IPC A610-D<br />

class 1,2,3<br />

Acc. <strong>to</strong> IPC A610-D<br />

class 1,2,3<br />

euro format<br />

HAL SnPb<br />

double Eurocard<br />

Ni/Au<br />

double euro format<br />

HAL Sn lead-free<br />

Chem. Sn<br />

Ni/Au<br />

IPC-A-610-D<br />

(2005)<br />

IPC-A-610-D<br />

(2005)<br />

double euro format<br />

HAL Sn lead-free<br />

Chem. Sn<br />

Ni/Au<br />

spezial format<br />

Chem. Sn<br />

soldered DIN male connec<strong>to</strong>r<br />

type C<br />

soldered DIN male connec<strong>to</strong>r<br />

type C<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 15 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Acceptability requirements for solder joints with plated-through holes acc. <strong>to</strong><br />

IPC<br />

Criteria Class1 Class2 Class3<br />

A. Wetting on the primary side (solder destination side) Not specified 180° 270°<br />

of lead and barrel<br />

B. Vertical fill of solder Not specified 75% 75%<br />

C. Fillet and wetting on the secondary side (solder<br />

270° 270 330°<br />

source side) of lead and barrel<br />

D. Percent of land area covered with wetted solder on 0 0 0<br />

the primary side (solder destination side)<br />

E. Percent of land area covered with wetted solder on<br />

the secondary side (solder source side)<br />

75% 75% 75%<br />

Evaluation of solder joints with the help of a cross-section<br />

Fig. 19 & 20<br />

Target class 1-3 Acceptable class 1-3<br />

75%<br />

Anzustrebende<br />

Fig. 21 & 22<br />

Target for class 1-3 360° wetting on lead and barrel<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 16 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

3.3 Backward compabtiility<br />

3.3.1 Test 1AP:<br />

Wave soldering (SnPb) with PCB plating Ni/Au<br />

A wave solder machine with a double wave function (manufacturer: SEHO) was used<br />

for the trials. The machine is equipped with a spray flux dispension system and<br />

infrared heating modules. The pcb’s with preassembled components were mounted<br />

in<strong>to</strong> type-specific retaining frames which prevented the overflow of liquid solder on<strong>to</strong><br />

the components on the pcb and protected the connec<strong>to</strong>r mouldings from thermal<br />

stress.<br />

Fig. 23: wave solder machine SEHO system 8530 MPR<br />

Process parameters: Test 1 AP<br />

Wave solder machine SEHO system 8530 MPR<br />

Solder<br />

SnPb<strong>37</strong><br />

Flux<br />

Chemical circuit P880 (Halogen-free and resin-free, no clean,<br />

Solids content 1,9%<br />

Solder temperature 245°C<br />

Wave solder<br />

Atmosphere<br />

Speed<br />

Wave solder contact time<br />

only Chip-wave, 28mm high<br />

normal air<br />

120cm/min<br />

1-1,3s<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 17 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Diagram 4: Temperature profile of the soldering program used. The thermocouple was mounted at the<br />

right angled termination on the secondary side of the PCB (no contact <strong>to</strong> the wave solder).<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 18 of <strong>37</strong><br />

Result: Test AP<br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig. 24: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. 25: secondary side<br />

Fig. 26: primary side<br />

Fig. 27, 28: cross-section , good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 19 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

3.3.2 Test BP:<br />

Wave soldering (SnPb with PCB plating HAL SnPb<br />

The wave solder machine SEHO System 2035 with a double wave function was used for the trials.<br />

The pcb’s with preassembled components were mounted in<strong>to</strong> type-specific retaining frames which<br />

prevented the overflow of liquid solder on<strong>to</strong> the components on the pcb and protected the connec<strong>to</strong>r<br />

mouldings from thermal stress.<br />

Process parameters<br />

Wave solder machine SEHO system 2035<br />

Solder<br />

SnPb<strong>37</strong><br />

Flux Home-made, Isopropanol/Adipinsäure (1,5%)<br />

Solder temperature 260°C<br />

Wave solder<br />

Atmosphere<br />

Speed<br />

Wave solder contact time<br />

main wave<br />

nitrogen<br />

120cm/min<br />

3,8 s<br />

Diagram 5: Temperature profile of used soldering program, only main wave used. Special trial pcb.<br />

The thermocouple (red curve) was mounted at the primary side of the pcb.<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 20 of <strong>37</strong><br />

Result. Test BP<br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig. 29: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. 30: secondary side<br />

Fig. 31 primary side<br />

Fig. 32, 33 cross-section, good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 21 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

3.3.3 Test CP:<br />

Wave soldering (SnPb) with PCB plating HAL SnPb und Ni/Au<br />

The wave solder machine ERSA with a double wave function was used for the trials. The pcb’s were<br />

mounted in<strong>to</strong> retaining frames and the connec<strong>to</strong>r mouldings were covered with heat protection caps.<br />

Fig. 34, 35 Printed board mounted in the retaining frame<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 22 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Process parameters<br />

Wave solder machine ERSA<br />

Solder<br />

SnPb<strong>37</strong><br />

Flux Alphametals E193 (low activated )<br />

Solder temperature 245°C<br />

Wave solder<br />

Chip- und main wave<br />

Atmosphere<br />

nitrogen<br />

Speed<br />

100 cm/min<br />

Wave solder contact time 3,8 – 4,5s<br />

Diagram 6: Temperature profile of the used soldering program, recorded with a special trial PCB. The<br />

thermo sensors were mounted on the primary side of the PCB, see Pic. 65.<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 23 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Diagram 7: Solder wetting profile<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 24 of <strong>37</strong><br />

Result Test CP<br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

PCB plating: HAL SnPb<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig 36: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. <strong>37</strong>: secondary side<br />

Fig. 38: primary side<br />

Fig. 39, 40: cross-section, good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 25 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

PCB plating:<br />

Ni/Au<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig 41: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. 42: secondary side<br />

Fig. 43: primary side<br />

Fig. 44,45: cross-section, good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 26 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

3.4 Forward compatibility<br />

3.4.1 Test DP:<br />

Wave soldering (SnCu) with PCB plating HAL leadfree, chem. Sn and<br />

Ni/Au<br />

Process parameters:<br />

Wave solder machine EPM (extended with IR-pre-heating)<br />

Solder<br />

SnCu(Ni), SN100C BalverZinn<br />

Flux<br />

IF 2009M no clean, low solids, Interflux<br />

Solder temperature 260°C<br />

Wave solder<br />

Atmosphere<br />

Speed<br />

Wave solder contact time<br />

only main wave<br />

normal air<br />

90 cm/min<br />

5 s<br />

Fig. 46 47: PCBs during the wave-solder process<br />

IR pre-heating<br />

Solder wave<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 27 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

PCB plating:<br />

Ni/Au<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig 48: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. 49: secondary side<br />

Fig. 50: primary side<br />

Fig. 51, 52: cross-section, good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 28 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

PCB plating: HAL lead-free<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig 53: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. 54: secondary side<br />

Fig. 55: primary side<br />

Fig. 56, 57: cross-section, good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 29 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

PCB plating: Chem. Sn<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig 58: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. 59: secondary side<br />

Fig. 60: primary side<br />

Fig. 61, 62: cross-section, good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 30 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

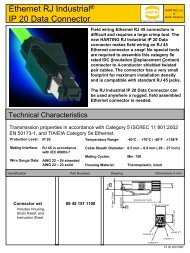

3.4.2 Test EP:<br />

Wave soldering (SnAgCu) with PCB plating HAL leadfree, chem. Sn and<br />

Ni/Au<br />

For these trials, a solder machine with a double wave funcion (manufacturer: SEHO)<br />

was used. Special retaining frames were manufactured <strong>to</strong>r the trial pcb’s.<br />

Fig. 64: Wave solder machine Seho MWS 2340<br />

Fig. 64: PCB during the solder process<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 31 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

Process parameters Test 5 EP<br />

Wave solder machine Seho MWS 2340<br />

Solder<br />

SnAgCu<br />

Flux<br />

Cobar 388, synthetic No-Clean N2-flux<br />

Solder temperature 260°C<br />

Wave solder<br />

Atmosphere<br />

Speed<br />

Wave solder contact time<br />

only main wave<br />

nitrogen<br />

100cm/min<br />

2 s<br />

Diagram 8: Temperature profile of the used soldering program, recorded with a modified PCB. The<br />

thermo sensors were mounted on the primary side of the PCB, see Pic. 65.<br />

Fig. 65: thermocouples at the<br />

connec<strong>to</strong>r and PCB <strong>to</strong> find the right<br />

temperature profile<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 32 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

PCB plating:<br />

Chem. Sn<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig 66: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. 67: secondary side<br />

Fig. 68: primary side<br />

Fig. 69, 70: cross-section, good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 33 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

PCB plating: HAL lead-free (Sn100C)<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig 71: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. 72: secondary side<br />

Fig. 73: primary side<br />

Fig. 74, 75: cross-section, good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 34 of <strong>37</strong><br />

PCB plating: Ni/Au<br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig 76: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. 77: secondary side<br />

Fig. 78: primary side<br />

Bild 79, 80: cross-section, good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 35 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

3.4.3 Test FP:<br />

Wave soldering (SnAgCu) with PCB plating chem. Sn<br />

Test carried out with a Seho 2340 wave solder machine with double wave function<br />

Process parameters<br />

Wave solder machine SEHO 2340<br />

Solder<br />

SnAgCu<br />

Flux<br />

Stannol WF 300S<br />

Solder temperature 260°C<br />

Wave solder<br />

pre-wave3 row nozzle, main wave standard<br />

Atmosphere<br />

nitrogen<br />

Speed<br />

120 cm/min<br />

Wave solder contact time --<br />

Fig. 81: Wave solder machine Seho MWS 2340<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> 36 of <strong>37</strong><br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

PCB plating: Chem. Sn<br />

The visual and microscope inspection shows that the requirements in accordance <strong>to</strong> the IPC<br />

norm IPC-A-610-D:2005; chapter 5.1 Soldering Acceptability Requirements; and chapter 7.6<br />

Plated Through Holes with Component Leads are fulfilled.<br />

Fig 81: Soldered DIN C male connec<strong>to</strong>r secondary side<br />

Fig. 82: secondary side<br />

Fig. 83: primary side<br />

Bild 84, 85: cross-section, good meniscus visible<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp

<strong>Page</strong> <strong>37</strong> of <strong>37</strong><br />

Summary:<br />

Report <strong>to</strong><br />

Qualification of a suitable leadfree termination<br />

surface for wave soldering<br />

No.: F 28-05<br />

To the preinvestigation with the wetting balance:<br />

The optical and microscope investigation of the solder termination pins shows a good wetting<br />

with a homogeneous surface and no defects.<br />

The results of the wetting balance test show very good <strong>to</strong> acceptable results for the contact<br />

stripes in the initial state and after the aging test (16h in dry heat at 155°C) for the three Sn<br />

types used (SnPb, SnAgCu and SnCu) in direct comparison <strong>to</strong> the SnPb surface used<br />

initially. The results after the steam aging (8h at 100r.H. and 96°C) show a delayed wetting<br />

and a lower wetting force for all Sn types used.<br />

To the field tests qualification:<br />

The solder joints comply with the requirements of the Class 3 acc. <strong>to</strong> the IPC 610 D in every<br />

case – the highest requirements whatsoever.<br />

Al<strong>to</strong>gether very good solder results of the extensive field tests show that delayed wetting<br />

observed in the wetting balance tests after steam aging has no negative impact.<br />

.<br />

Corporate Technology Services, HARTING KGaA, Marienwerderstraße 3, 32339 Espelkamp