Info 2 2007 engisch:info 2 2007 - Buderus Edelstahl Gmbh

Info 2 2007 engisch:info 2 2007 - Buderus Edelstahl Gmbh

Info 2 2007 engisch:info 2 2007 - Buderus Edelstahl Gmbh

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

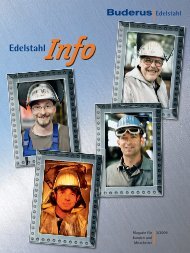

<strong>Edelstahl</strong><br />

Magazine for<br />

customers and<br />

employees<br />

2/<strong>2007</strong>

Inhalt Contents<br />

<strong>Edelstahl</strong><br />

2<br />

5<br />

6<br />

10 years of <strong>Buderus</strong><br />

<strong>Edelstahl</strong> <strong>Info</strong><br />

l The Company<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

Magazin für 1/<strong>2007</strong><br />

Kunden und<br />

Mitarbeiter<br />

Steelmaking and rough machining<br />

move closer together<br />

4 ”Development can never<br />

start too early“<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> donates a total of<br />

€ 10,000 for kindergartens in Wetzlar<br />

5 10 years of <strong>Buderus</strong> <strong>Edelstahl</strong> <strong>Info</strong><br />

A success story<br />

6 Steelmaking and rough machining<br />

move closer together<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> Zerspanungstechnik<br />

GmbH<br />

10<br />

More capacity<br />

to boost output<br />

8 How do fans recognise their team?<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> Style Manual<br />

now available<br />

9 Iron . . . Special steel . . . Heritage<br />

10 More capacity to boost output<br />

Investment and process<br />

improvements continue<br />

l Billets<br />

12 Special gearwheel blanks for<br />

high-speed yacht engines<br />

Quality steel from Wetzlar<br />

for <strong>Edelstahl</strong> Rosswag<br />

12<br />

Special gearwheel blanks for<br />

high-speed yacht engines<br />

l Tool steel/Eengineering alloys<br />

14 Fine Expo design<br />

for a fine material<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> presents<br />

new image at EuroMold<br />

16 <strong>Buderus</strong> <strong>Edelstahl</strong> invited<br />

to a Hindu wedding<br />

An unforgettable experience<br />

18 High level of production with<br />

extreme alternating stress<br />

Substituting forged tool steel for steel<br />

casting for die-casting mould frames

20<br />

Joined-up<br />

safety<br />

l Employees<br />

18<br />

20 Joined-up safety<br />

<strong>Buderus</strong> Works Fire Service and<br />

Works Medical Service<br />

21 New company doctor for<br />

<strong>Buderus</strong> <strong>Edelstahl</strong><br />

22 Minister of Economic Affairs<br />

visits <strong>Buderus</strong> <strong>Edelstahl</strong><br />

Dr Alois Rhiel finds out about<br />

sandwich course provision<br />

22 Aachen University IBF students<br />

at <strong>Buderus</strong> <strong>Edelstahl</strong><br />

23 Award for <strong>Buderus</strong> <strong>Edelstahl</strong><br />

Exemplary integration management<br />

High level of production with<br />

extreme alternating stress<br />

24 “Good luck!”<br />

. . . to all our new apprentices<br />

25 Subsidiary of Schaeffler KG<br />

visits <strong>Buderus</strong> <strong>Edelstahl</strong><br />

25 Long service awards<br />

25 Deaths<br />

l News<br />

26 Steel inspires!<br />

New films by and with<br />

<strong>Buderus</strong> <strong>Edelstahl</strong><br />

27 Imprint<br />

27 Dates for <strong>2007</strong><br />

Dear Readers,<br />

Editorial<br />

<strong>Edelstahl</strong> <strong>Info</strong> is celebrating<br />

its 10th anniversary.<br />

The distribution of our customer<br />

magazine now runs<br />

into five figures, and is well<br />

received all over the world.<br />

Thank you for your interest.<br />

Our mission is still to<br />

present issues and content<br />

in a relevant and lively form, with striking<br />

illustrations.<br />

This issue again examines our new corporate<br />

design as specified in the Style<br />

Manual which has now been issued, to<br />

help maintain <strong>Buderus</strong> <strong>Edelstahl</strong>’s clear<br />

and distinctive profile on the international<br />

market. We introduce the new company<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> Zerspanungstechnik<br />

GmbH, and describe the company’s extensive<br />

investment and process improvements.<br />

You can also read what high-speed<br />

yacht engines have to do with gearwheel<br />

blanks from Wetzlar, with interesting<br />

insights into the use of forged tool steel<br />

for die-casting mould frames used in<br />

automotive engineering. We also want to<br />

share with you our experience of the<br />

Hindu wedding celebration of our longstanding<br />

Indian partners, which was<br />

particularly impressive. The same thing<br />

applies to the visit of the Minister of Economic<br />

Affairs for the State of Hesse, Dr<br />

Alois Rhiel, gathering <strong>info</strong>rmation on the<br />

sandwich study system. We have also<br />

achieved distinction in a quite different<br />

field – for exemplary integration management.<br />

So there is plenty to read – we trust it<br />

will convey the excitement of the world of<br />

<strong>Buderus</strong> <strong>Edelstahl</strong>, and that you enjoy<br />

reading it.<br />

Best wishes,<br />

Christian Jung<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 3

The Company<br />

“Development<br />

can never start<br />

too early”<br />

<strong>Buderus</strong> <strong>Edelstahl</strong><br />

donates a total of<br />

€ 10,000 for kindergartens<br />

in Wetzlar<br />

“A long-established company like <strong>Buderus</strong><br />

<strong>Edelstahl</strong> is devoted to the region and its<br />

population as well as its own economic<br />

success. It is therefore a matter of course<br />

for the company to accept its social<br />

respon sibility in numerous practical ways”,<br />

say Directors Jens Mohr and Karl-Peter<br />

Johann.<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> has the rising generation<br />

in mind, and has donated € 2,500<br />

each to four kindergartens in Wetzlar.<br />

“Development can never start too early, so<br />

we are supporting the kindergartens<br />

instead of giving Christmas presents”, adds<br />

Christian Jung, Marketing and Advertising<br />

Manager, who organised the project.<br />

A “Thank you” from the children<br />

4<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

Inge Kleinhans, Tatjana Züll, Ingrid Müller and Petra Schwarz (from left to right) celebrate donations from<br />

<strong>Buderus</strong> <strong>Edelstahl</strong>. The cheques were presented by the Directors Karl-Peter Johann and Jens Mohr and<br />

Marketing Manager Christian Jung (from right to left)<br />

Good equipment<br />

facilitates development<br />

The Mullewap playgroup in Hermannstein<br />

is using its funds to build a “sludge and<br />

splash” pool, the integrative kindergarten<br />

in Röntgenstraße is building a new outdoor<br />

playground; the Protestant playgroup in<br />

Silhöfer Aue are replacing the insulation,<br />

washroom and windows, and the children<br />

at the Niedergirmes kindergarten in Fröbelstraße<br />

are looking forward to a new play<br />

hill with a Wendy house. The head of the<br />

Niedergirmes kindergarten, Inge Kleinhans,<br />

emphasised the importance of good equipment,<br />

“Children learn better if they get<br />

enough exercise, they overcome language<br />

barriers more quickly, and make better<br />

progress.”<br />

Youth development is<br />

a matter of course<br />

Youth development and education are of<br />

particular concern to the company. This is<br />

evident from the numerous opportunities<br />

for students at <strong>Buderus</strong> <strong>Edelstahl</strong>, and the<br />

high priority given to training generally in<br />

the company. About 50 young people are<br />

currently undergoing training.<br />

The directors Jens Mohr and Karl-Peter<br />

Johann, who presented the cheques to the<br />

kindergartens, are clearly thinking longterm,<br />

“Who knows, perhaps one or two of<br />

these kids will come and work for us. We<br />

certainly intend to maintain our commitment<br />

to young people in the Wetzlar<br />

region.”<br />

This is how the children Joshua, Johannes and Nils imagine their new playground

10 years of <strong>Buderus</strong> <strong>Edelstahl</strong> <strong>Info</strong><br />

A success story<br />

The <strong>Buderus</strong> <strong>Edelstahl</strong> customer magazine<br />

first appeared in 1997. This successful<br />

communication tool quickly<br />

reached a five-digit worldwide circulation<br />

figure. On its 10th anniversary the<br />

picture is that the combination of<br />

factual <strong>info</strong>rmation and interesting<br />

topics with entertainment value has<br />

proved very popular with <strong>Buderus</strong> <strong>Edelstahl</strong>’s<br />

business partners around the<br />

world.<br />

How do we target interesting and important<br />

<strong>info</strong>rmation at customers and potential<br />

customers, without excessive wastage?<br />

What can we do to convey complex material<br />

effectively, whilst also strengthening<br />

the bond between the company and its<br />

customers? Those were the questions to be<br />

answered when the decision was made to<br />

launch the <strong>Buderus</strong> <strong>Edelstahl</strong> customer<br />

magazine in 1997. The advantages clearly<br />

outweighed the costs. One criterion that<br />

applies throughout the industry is that<br />

there is hardly a leading company that does<br />

not now use this attractive channel of<br />

communication with customers. “<strong>Buderus</strong><br />

<strong>Edelstahl</strong> <strong>Info</strong> quickly proved to be a successful<br />

instrument of external communication”,<br />

says Christian Jung, Marketing and<br />

Advertising Manager at <strong>Buderus</strong> <strong>Edelstahl</strong><br />

GmbH. “The magazine promoted business<br />

dialogue from the start, and it is still a<br />

medium that creates goodwill and trust,<br />

and sometimes prompts new ideas or contacts.”<br />

This efficient and effective communication<br />

platform has greatly strengthened<br />

customer loyalty. <strong>Buderus</strong> <strong>Edelstahl</strong> Field<br />

Service staff repeatedly provide positive<br />

feedback from their direct exposure to customer<br />

response.<br />

Multilingual on all continents<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> <strong>Info</strong> appears in German<br />

and in English, and is distributed throughout<br />

Europe as well as in countries such as<br />

Taiwan, China, India, South Africa, Brazil<br />

and the USA. With the integration of the<br />

<strong>Edelstahl</strong> <strong>Info</strong><br />

� Einsatz von Bandstahl in Cabrios<br />

� Gesenkschmiedestücke für den längsten<br />

Eisenbahntunnel der Welt<br />

� Schmieden am Generationenprojekt<br />

� Global Meeting 2004<br />

� Geschmiedeter Baustahl für die Windkraft<br />

The Company<br />

French company Deville Rectification into<br />

the <strong>Buderus</strong> <strong>Edelstahl</strong> family, the magazine<br />

has also appeared in French.<br />

Restructuring within the company has<br />

also changed the range of issues covered by<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> <strong>Info</strong>. First there was the<br />

takeover by Bosch, then the sale to the new<br />

parent company Böhler-Uddeholm, involving<br />

the creation of the three independent<br />

companies <strong>Buderus</strong> <strong>Edelstahl</strong> GmbH,<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> Band GmbH and <strong>Buderus</strong><br />

<strong>Edelstahl</strong> Schmiedetechnik GmbH, and<br />

finally the takeover of Böhler-Uddeholm<br />

by Voestalpine. <strong>Buderus</strong> <strong>Edelstahl</strong> <strong>Info</strong> is<br />

now the customer magazine of <strong>Buderus</strong><br />

<strong>Edelstahl</strong> GmbH, combining technical<br />

innovations and interesting customer<br />

applications with <strong>info</strong>rmation for and<br />

about <strong>Buderus</strong> <strong>Edelstahl</strong> employees. “The<br />

last 10 years must be the most eventful in<br />

the long history of <strong>Buderus</strong> <strong>Edelstahl</strong>”,<br />

comments Christian Jung. “But there is one<br />

consistent theme, the huge positive<br />

response to our customer magazine. That is<br />

a source of satisfaction to us, and reason<br />

enough to pursue our quest to find exciting<br />

new topics.” And that is what the innovative<br />

special steel from Wetzlar offers in<br />

plenty.<br />

Kunden-Magazin<br />

2/2004<br />

EDELSTAHL<br />

Magazin für Kunden<br />

und Mitarbeiter<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 5<br />

3/2005

The Company<br />

Steelmaking and rough machining<br />

come closer together<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> Zerspanungstechnik GmbH<br />

Works building and machine tools at <strong>Buderus</strong> <strong>Edelstahl</strong> Zerspanungstechnik GmbH in Bischoffen-Niederweidbach<br />

6<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

On 1 May <strong>2007</strong>, <strong>Buderus</strong> <strong>Edelstahl</strong><br />

acquired ARRK Zimmermann GmbH in<br />

Bischoffen-Niederweidbach. The<br />

declared joint aim is further enhanced<br />

service for <strong>Buderus</strong> <strong>Edelstahl</strong> customers,<br />

generating significant competitive<br />

advantage.<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> Zerspanungstechnik<br />

GmbH formerly belonged to the ARRK Zimmermann<br />

Group, and has a wide range of<br />

machining facilities, many years’ expe -<br />

rience in machining, and extensive knowhow<br />

to accommodate even the most complex<br />

customer requirements.<br />

The steel pre-machining specialists for<br />

finishing and assembly provide highly<br />

advanced machining appreciated by leading<br />

toolmakers, mould makers and machine<br />

makers. This makes the company an ideal<br />

complement to the products and services<br />

provided by <strong>Buderus</strong> <strong>Edelstahl</strong> GmbH to<br />

meet the specific demands of sophisticated<br />

customers, with a focus on plastic mouldmaking<br />

for the automotive industry to produce<br />

large-format parts such as bumpers,<br />

dashboards and interior trim.<br />

This acquisition further expands<br />

<strong>Buderus</strong> <strong>Edelstahl</strong>’s service provision. With<br />

clear advantages for <strong>Buderus</strong> <strong>Edelstahl</strong><br />

customers – customer-ready supplies for<br />

mould makers, extremely close cooperation<br />

of specialists from steelmaking and rough<br />

machining, reduced travel movements<br />

making for shorter machining times – an

important criterion as regards cost reduction<br />

and securing future prospects in the<br />

European automotive industry.<br />

“Combining machining with steelmaking<br />

is for us a logical response to market<br />

trends in recent years”, says Jens Mohr,<br />

Commercial Director of <strong>Buderus</strong> <strong>Edelstahl</strong>,<br />

and Chairman of the <strong>Buderus</strong> <strong>Edelstahl</strong><br />

Zerspanungstechnik GmbH Supervisory<br />

Board. “Compressing project timescales is<br />

very important in the automotive industry,<br />

as are excellent steel quality and first-class<br />

finish. With the acquisition of ARRK<br />

Zerspanungstechnik GmbH and the associated<br />

expansion of our service provision, we<br />

are even better placed to meet this requirement.”<br />

Bernhard Pauly, General Manager Steel<br />

Bar Sales at <strong>Buderus</strong> <strong>Edelstahl</strong> says,<br />

“<strong>Buderus</strong> <strong>Edelstahl</strong> has always been keenly<br />

responsive to market needs. We have<br />

always taken a wider view. Toolmaking for<br />

vehicle components in Europe has strong<br />

competition from the Asian markets, which<br />

can produce more cheaply. Reducing costs<br />

without sacrificing quality is the way to<br />

secure the future in the European automotive<br />

industry.”<br />

Holger Karches, former Chief Executive<br />

of ARRK Zerspanungstechnik and now CEO<br />

of <strong>Buderus</strong> <strong>Edelstahl</strong> Zerspanungstechnik<br />

GmbH, sees excellent advantages in the<br />

merger. “With a strong parent company like<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> at our side we can<br />

improve the market prospects of both<br />

Contact:<br />

<strong>Buderus</strong> <strong>Edelstahl</strong><br />

Zerspanungstechnik GmbH<br />

Hauptstraße 46<br />

35649 Bischoffen-Niederweidbach<br />

Tel: +49 (0) 64 44/92 46-0<br />

Fax: +49 (0) 64 44/92 46-26<br />

E-mail: <strong>info</strong>-zt@buderus-steel.com<br />

CEO: Holger Karches<br />

Works Manager: Reinhard Tuisl<br />

Holger Karches’ office in the main building<br />

at <strong>Buderus</strong> <strong>Edelstahl</strong> GmbH<br />

Tel: +49 (0) 64 41/3 74-25 06 (Secretariat)<br />

Fax: +49 (0) 64 41/3 74-24 64<br />

E-mail: Holger.Karches@buderus-steel.com<br />

companies, and together we can engage<br />

the future on a progressive basis.” The first<br />

step is to expand <strong>Buderus</strong> <strong>Edelstahl</strong><br />

Zerspanungstechnik GmbH into en effective<br />

steel service centre at the Bischoffen-<br />

Niederweidbach location.<br />

The experienced Reinhard Tuisl remains<br />

Works Manager. Holger Karches has his<br />

main office in the central building of<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> GmbH in Wetzlar, where<br />

he has taken on another task in addition to<br />

heading up <strong>Buderus</strong> <strong>Edelstahl</strong> Zerspa -<br />

nungs technik GmbH – since 1. 7. <strong>2007</strong> he<br />

has been responsible for Purchasing at<br />

The Company<br />

Holger Karches<br />

Reinhard Tuisl<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> GmbH, especially for<br />

scrap and alloys. “Our Works Manager<br />

Reinhard Tuisl is our contact for on-site<br />

machining”, says Holger Karches, “But of<br />

course I will be visiting Bischoffen-Niederweidbach<br />

regularly.”<br />

Combining steelmaking and rough<br />

machining joins two important links in the<br />

production chain. With the new synergies<br />

this creates, <strong>Buderus</strong> <strong>Edelstahl</strong> strengthens<br />

its customers and expands its position as<br />

one of the world's leading producers in this<br />

important field of plastic mouldmaking.<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 7

The Company<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> Style Manual now available<br />

How do fans recognise<br />

their team?<br />

Imagine a football team where every<br />

player wore different kit, and followed<br />

whatever strategy he saw fit – you<br />

would give it a miss, because the beautiful<br />

game would degenerate into a shambles.<br />

A clear approach combined with a<br />

distinctive image, the corporate design,<br />

is crucial for success, in sport as in business.<br />

The new corporate design for the<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> brand represents this<br />

clear profile. It is now set out in the<br />

Style Manual, and is currently being<br />

rolled out worldwide.<br />

A company’s corporate design is part of its<br />

corporate identity, comprising the behaviour,<br />

performance, and the way a company<br />

communicates internally and externally, as<br />

well as the design. When all aspects are<br />

harmonised, a uniform image is created<br />

projecting recognition, trust and distinctive<br />

features. The <strong>Buderus</strong> <strong>Edelstahl</strong> corporate<br />

identity concept has several aims.<br />

Internally it strengthens our team solidarity<br />

and promotes concentration on a common<br />

goal because structures are more<br />

transparent, processes are simpler and<br />

presentation guidelines are uniformly<br />

clear. Externally it helps us to position ourselves<br />

even more successfully on international<br />

markets, and to distinguish ourselves<br />

from the competition in terms of<br />

both style and substance. Positive, clear<br />

and distinctive.<br />

A new corporate design is much more<br />

than just a new logo. It includes the uniform<br />

presentation of all visual components<br />

in all aspects of the business. House<br />

colours, fonts and typography, graphics,<br />

materials and slogos follow prescribed<br />

design formats. Only if the corporate<br />

design is consistently implemented can<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> maintain a uniform<br />

global presence with a high recognition<br />

value. A corporate design functions well<br />

when it permeates all aspects, in all channels<br />

of communication, in all media, on<br />

8<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

Expo stands and trucks, and on hard hats<br />

and work clothes. The smallest variation is<br />

counterproductive. The date in the wrong<br />

place on a business letter, an outdated logo<br />

on an overall, old stocks of sales literature,<br />

old business cards, idiosyncratic presentation<br />

documents and nonstandard exhibition<br />

stands. All this makes for confusion,<br />

and does not convey a clear image of the<br />

company's identity.<br />

The <strong>Buderus</strong> <strong>Edelstahl</strong><br />

Style Manual<br />

Consistent implementation and development<br />

of the new corporate design in existing<br />

and future visual components of<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> as a company is therefore<br />

an important task in all companies and<br />

departments. Help is on hand in the form<br />

of the new <strong>Buderus</strong> <strong>Edelstahl</strong> Style Manual.<br />

It gives a neat overview with clear, read-<br />

Key points:<br />

ily understandable <strong>info</strong>rmation on all the<br />

basic elements of the new corporate<br />

design, with <strong>info</strong>rmation on its theoretical<br />

and practical use. For the three independent<br />

companies <strong>Buderus</strong> <strong>Edelstahl</strong>, <strong>Buderus</strong><br />

<strong>Edelstahl</strong> Band and <strong>Buderus</strong> <strong>Edelstahl</strong><br />

Schmiedetechnik, it forms the common<br />

visual core from which each of the companies<br />

can develop in its own way. And it<br />

projects the essence of the <strong>Buderus</strong> <strong>Edelstahl</strong><br />

brand based on four strong components,<br />

namely quality, competence in technology,<br />

power in innovation and customer<br />

orientation.<br />

That's what fans want, in sport as in<br />

business. Fans adopt teams where you can<br />

see straight away you can trust them<br />

because they make a clear, positive and<br />

promising impression – wherever they may<br />

be in the world.<br />

Corporate identity is the unmistakable identity or personality of the company, both<br />

internal and external.<br />

This includes:<br />

Corporate design – the visual image that reflects the corporate identity and has a<br />

high recognition value.<br />

Corporate communication – company communication including advertising, PR,<br />

sponsorship and sales promotion.<br />

Corporate behaviour – how the company behaves. It is reflected in how employees<br />

interact with each other and with customers, suppliers and shareholders, and in how<br />

the company as a whole behaves in society at large.

Iron . . . Special steel . . . Heritage<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> actively supports the<br />

reconstruction of the medieval hammer<br />

forge in the UNESCO World Heritage<br />

Cistercian monastery in Fontenay,<br />

France.<br />

Monks forge Europe<br />

At the end of the 11th century, Christianity<br />

was finally established in Europe and the<br />

Cistercian order founded hundreds of new<br />

monasteries throughout Central Europe,<br />

starting from Burgundy. This rapidly disseminated<br />

knowledge and new technologies<br />

such as hydropower, constructing<br />

mills, and forging, underpinning and<br />

ensuring the progress and prosperity of<br />

people in the heart of Europe to this day. So<br />

you could well think of the monks of this<br />

order as being the patriarchs of the “European<br />

Idea”.<br />

The Johann-Philipp-Reis School in<br />

Friedberg has been working successfully<br />

since 2005 with students from Poland,<br />

France, the Czech Republic, Italy and<br />

Romania on the Comenius Project, a European<br />

project for researching common roots<br />

and perspectives for a secure future in<br />

peace, freedom and prosperity. The technical<br />

emphasis of the project is on faithful<br />

reconstructions of water driven forges<br />

from the twelfth century in Fontenay<br />

monastery, and on the mediaeval extraction<br />

process in a blast furnace they made<br />

themselves.<br />

"Strike while the iron is hot”<br />

As soon as this worthwhile project was<br />

announced, the General Manager of Open<br />

Die Forging, Ralph Rech, personally committed<br />

himself to implementing it, and<br />

invited the Friedberg class of the School of<br />

Engineering to participate in implementing<br />

their designs. The forging hammer itself<br />

was then made in the <strong>Buderus</strong> <strong>Edelstahl</strong><br />

GmbH open die forge, on the 20 MN press,<br />

and given a hammer eye. The 2000 tonne<br />

hammer is then driven by a wooden water<br />

wheel specially constructed to the students’<br />

own design, like all the components.<br />

Forged hammerhead<br />

made of <strong>Buderus</strong><br />

special steel for<br />

World Heritage<br />

Model of the monastery’s forge<br />

The Company<br />

The hammerhead arrives at the Fontenay monastery<br />

European youth group watch the hammer being<br />

forged in Wetzlar<br />

France is always worth a visit, especially<br />

for the inauguration of the mediaeval<br />

forge in Fontenay on 9 May 2008. <strong>Buderus</strong><br />

<strong>Edelstahl</strong> employees and friends are particularly<br />

welcome when another highlight of<br />

World Heritage is presented to visitors. You<br />

will find further <strong>info</strong>rmation on this exciting<br />

project on www.comenius-fontenay.de<br />

or on www.wikipedia.org/wiki/Fontenay.<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 9

The Company<br />

More capacity to boost output<br />

Investments and process improvements continue<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> is responding to increased customer demand with further extensive<br />

investment and innovative projects relating to the forging furnaces, the new<br />

boiler house, and steam generation in the steel mill. This is also generating environment<br />

protection benefits through the more efficient use of energy.<br />

Forging furnaces renovated and<br />

expanded<br />

As part of the PROFORGE capacity expansion<br />

programme, the company invested in<br />

additional heating capacity both in the<br />

forge and in the 20 MN and 55 MN forging<br />

press areas.<br />

The existing rotary hearth furnace of the<br />

20 MN press was completely overhauled<br />

and is now capable of taking blooms<br />

weighing up to 10 tonnes (previously 7.5).<br />

The furnace has also been fitted with an<br />

automatic charging machine and a new<br />

control system. As well as expanding<br />

capacity and improving efficiency, this has<br />

10<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

also provided computer-aided monitoring<br />

of the heating parameters, giving more<br />

precise control of the relevant process<br />

parameters. Four more bogie hearth furnaces,<br />

each with a capacity of 300 tonnes,<br />

were installed in the 55 MN press section.<br />

The furnaces are equipped with the latest<br />

generation of flat flame burners to prevent<br />

local overheating and ensure even heating<br />

of the ingots.<br />

Technical General Manager Ralph Rech<br />

comments, “These furnaces give us the<br />

capacity for blooms in the 100 to 150<br />

tonne range that customers increasingly<br />

require. Apart from just expanding capaci-<br />

ty, we are also significantly increasing flexibility<br />

in how the forging range is made<br />

up.”<br />

New boiler house increases efficiency<br />

In autumn 2006 a new boiler house was<br />

installed at <strong>Buderus</strong> <strong>Edelstahl</strong>. It replaces a<br />

plant from the 1970s, meeting increased<br />

demand and reducing specific gas consumption<br />

with higher efficiency.<br />

Tobias Besser Head of Central Services,<br />

comments, “It was a major challenge in<br />

terms of technical design and project management<br />

integrating the existing steam<br />

and hot water networks, which had to keep<br />

operating without interruption.”<br />

The core of the plant is a high-pressure<br />

steam boiler made by LOOS, with a thermal<br />

output of 14.5 MW producing 22 tonnes of<br />

steam per hour at 22 bar. The main function<br />

of the boiler is to generate steam for<br />

the steel degassing process in the steel mill.<br />

The boiler is connected to the location’s<br />

hot water circuits by a hydraulic switch.<br />

This system uses steam for works heating<br />

via a heat exchanger, and the return is

linked to the heating circuits by standalone<br />

heat recovery units. The heat recovered<br />

reduces the load on the boiler and reduces<br />

gas consumption.<br />

The design provides for a further stage<br />

of hot cooling in the steel mill to recycle<br />

the process heat that arises there. The control<br />

system will primarily use the heat<br />

from this source once this unit has been<br />

commissioned, and only call on the boiler<br />

for its additional heat requirements. Further<br />

stages will also save energy, such as<br />

avoiding heat loss from the desalination<br />

process, by fitting an upstream reverse<br />

osmosis unit.<br />

Innovative, environment-friendly<br />

steam generation<br />

The exhaust gases created during electric<br />

arc furnace melts reaching temperatures of<br />

1200 °C. have to be cooled down to temperatures<br />

over 120 °C before they can be<br />

fed to the flue gas filter; this is currently<br />

done in a water-cooled pipeline, passing<br />

through cooling towers. Process water is<br />

currently used for cooling, with an input<br />

temperature of about 23 °C. An environment<br />

project is in hand to harness this heat<br />

to save energy, to generate steam for the<br />

vacuum system. The steam needed for vacuum<br />

production (about nine tonnes per<br />

hour) has previously been provided by the<br />

boiler house.<br />

From January 2008, the steam will be<br />

generated from the energy in the exhaust<br />

gas, using the effect of evaporative cooling.<br />

This involves feeding hot water at boiling<br />

temperature from a steam cylinder to<br />

the cooling elements of the new exhaust<br />

duct. Some of the water is evaporated at a<br />

constant temperature by the thermal energy<br />

available there. The steam water mixture<br />

flowing back to the steam cylinder is separated<br />

into saturated steam and water. The<br />

water is returned to the circuit, the steam<br />

is fed to a steam reservoir, and released to<br />

the vacuum system as required.<br />

This plant can generate about 30,000<br />

tonnes of steam a year from the existing<br />

exhaust gas energy. Since no natural gas is<br />

required to generate this steam, there is<br />

also a real CO 2 saving.<br />

New automatic charging machine with rotary hearth furnace<br />

The Company<br />

New boiler house with higher efficiency The core is the new high-pressure steam boiler<br />

Four new bogie hearth furnaces as part of the PROFORGE capacity expansion project<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 11

Billets<br />

Quality steel from Wetzlar for <strong>Edelstahl</strong> Rosswag<br />

Special gearwheel blanks<br />

for high-speed yacht engines<br />

“Steel is where it all starts”, to quote the Rosswag company video. This refers to the<br />

prime grade steel needed for forged products for extreme requirements, which is what<br />

<strong>Edelstahl</strong> Rosswag specialises in. This largest open-die forge in southern Germany will<br />

be celebrating its centenary in four years, and has procured its special steels from<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> for decades.<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> rolled billets in the<br />

Rosswag stockyard Heating the sawn billets to forging temperature The start of forging in the Rosswag forge<br />

12<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong>

Frank Agel, Billet Sales department manager,<br />

visited <strong>Edelstahl</strong> Rosswag GmbH in<br />

Pfinztal in Baden-Württemberg at the end<br />

of April, and witnessed the forging of gearwheel<br />

blanks with a really special requirements<br />

profile for luxury marine trans -<br />

missions. <strong>Buderus</strong> <strong>Edelstahl</strong> supplies rolled<br />

billets to Rosswag (270 square) for this purpose.<br />

The rolled billets are then formed<br />

and forged at a forging temperature of<br />

850–1100 °C to around 635 mm. Rosswag<br />

in turn supplies the gearwheel blanks to ZF<br />

Friedrichshafen AG, where they are finish<br />

machined. They are finally installed in special<br />

marine transmissions for high-powered<br />

engines made by Siemens-MTU, which are<br />

installed in luxury yachts. “Every selfrespecting<br />

yacht owner has his eye on a<br />

good engine when buying a vessel”, says<br />

Alexander Essig, CEO of Rosswag. Alexander<br />

Essig is a smith by trade, and a gra duate<br />

industrial engineer, and is an enthusiastic<br />

sailor himself. He manages this company –<br />

formed in 1911 and now in its fourth generation<br />

– jointly with two other family<br />

members: Ms Kirsten Walezak, who is<br />

responsible for product quality assurance<br />

at Rosswag, and Dr Sven Donisi, who has<br />

taken over as Production Director in the<br />

fifth generation.<br />

Steel made in Wetzlar fabricated and<br />

converted by Rosswag is to be found not<br />

only in some of the finest and fastest<br />

yachts in the world. Rosswag open-die<br />

forged products are also to be found in the<br />

landing flap gear units of the Airbus 380, in<br />

the Ariane space rockets, in Formula 1<br />

bolides, and in the drive units of the ICE 3<br />

high-speed train. And when the bells ring<br />

out in the Frauenkirche in Dresden, in the<br />

Strasbourg Minster or in the Stiftskirche in<br />

Neustadt, <strong>Edelstahl</strong> Rosswag is involved.<br />

Forging bell clappers is one of the company's<br />

traditional activities, and is appreciated<br />

even in Malta, where the Peace Bell in<br />

the town of La Valetta has a clapper forged<br />

in Pfinztal.<br />

Rosswag produces coil, rod, plate and<br />

perforated plate to customer specification<br />

for a very diverse range of industries, as<br />

well as forged special fabrications to order.<br />

Typical orders include prototypes and short<br />

runs. Approaching 400 different materials<br />

are available for the company's customers.<br />

Dressed gearwheel blank Gearwheel blank being machined<br />

Billets<br />

Christiane Rittel, Billet Sales; Jürgen Ludwig, Rosswag Purchasing; Bruno Hosfeld, Rosswag Quality<br />

Assurance; Alexander Essig, Rosswag Chief Executive; Frank Agel, Billet Sales Manager (from left to right)<br />

This includes the quality special steels provided<br />

by <strong>Buderus</strong> <strong>Edelstahl</strong> GmbH. In addition<br />

to various working steels, the Rosswag<br />

forge also machines titanium, aluminium<br />

and other non-ferrous metals. The company<br />

currently has a workforce of 130, and<br />

sales agents in various European countries.<br />

“It all starts with steel”, says Alexander<br />

Essig. “Whether a product delivers what it<br />

promises depends on its quality and outstanding<br />

finish. Only then can you speak of<br />

success. We are linked to <strong>Buderus</strong> <strong>Edelstahl</strong><br />

by such a success story and by mutual trust<br />

that has grown over many decades.”<br />

Gearwheel blank for a special marine transmission<br />

ready for dispatch<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 13

Tool steel/Engineering alloys<br />

Fine Expo design for fine material<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> debuts new image at Euromold<br />

One thing was the concept. Creating the new <strong>Buderus</strong> <strong>Edelstahl</strong> corporate design<br />

and applying it to the various instruments of advertising and communication was<br />

no small undertaking. The other thing was making it happen. The new corporate<br />

design had to prove its worth on the big stage, namely at the Euromold 2006<br />

Expo, the world trade fair for tool and mould making, design and product<br />

development, held this year from 29 November to 2 December in the Frankfurt<br />

Expo complex.<br />

Functional and inviting –<br />

the new exhibition stand<br />

corporate design<br />

It was there for all to see, the sample test<br />

had been successful. “All communication<br />

media were ready bang on schedule”,<br />

observed Christian Jung, Marketing and<br />

Advertising Manager, with satisfaction.<br />

Fresh and radiant, the highly visible exhibition<br />

tower rose up in its special-steel blue<br />

14<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

as the high-visibility key visual on the<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> stand. The steel, once in<br />

glowing, liquid form, and once in solid<br />

form, instantly and vividly illustrates even<br />

to visitors outside the “special steel frater -<br />

nity” what competencies are involved. The<br />

stand was accordingly well visited. The new<br />

CD colours blue and orange offset by white<br />

and silver grey evidently presented a particularly<br />

inviting prospect. Printed canvas<br />

presenting the product range in an interesting<br />

light with key examples conveyed<br />

the impression of openness and transparency,<br />

and also contoured the stand<br />

architecture. No question of trepidation as<br />

visitors approached the stand. Just a few<br />

especially impressive exhibits were displayed<br />

in the entrance area, so as not to<br />

clutter the stand, and to present an accessible<br />

face to visitors. The exhibits included<br />

a core carrier and a mould carrier, a diecasting<br />

mould frame, and machined steel<br />

and aluminium plate from Deville Rectification.<br />

Product <strong>info</strong>rmation on glass plate<br />

helped visitors find their way around. The<br />

Plastics Handbook for Toolmakers likewise<br />

available on the exhibition stand has now<br />

acquired the status of a long seller.

Business was brisk on the exhibition stand<br />

A hammerhead made of <strong>Buderus</strong><br />

special steel, the film release<br />

All this was certainly thought out with<br />

care, and did not fail to achieve its purpose,<br />

that of a functional but pleasant and calm<br />

atmosphere for conducting technical conversations.<br />

One special feature was the<br />

unique spectacular project with a film on<br />

the Africa hammer. It is available as a DVD<br />

entitled “The flaming tree” in German, English,<br />

French and Ewe (see page 26). The 19<br />

tonne work of art has now arrived at its<br />

destination in Togo, forged by the <strong>Buderus</strong><br />

<strong>Edelstahl</strong> open-die forge. The forging artist<br />

Tool steel/Engineering alloys<br />

New sales literature in six languages Active interest in the film about the Africa hammer<br />

Andreas Rimkus was personally present on<br />

the exhibition stand, and proudly explained<br />

how the project came about and how it<br />

was finally realised. Our last detailed report<br />

on this was in <strong>Buderus</strong> <strong>Info</strong> 1/<strong>2007</strong>.<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 15<br />

�<br />

The <strong>Buderus</strong> <strong>Edelstahl</strong> exhibition team

Tool steel/Engineering alloys<br />

Euromold is growing – and <strong>Buderus</strong><br />

<strong>Edelstahl</strong> is growing with it<br />

Such distinctive features help to maintain<br />

visibility in the ever-expanding Euromold<br />

marketplace. More than 60,000 visitors<br />

from 72 countries came to Frankfurt this<br />

year to survey the new trends on show over<br />

an even larger exhibition site extending to<br />

80,050 square metres, especially trends in<br />

tool and mould making, and also in model<br />

and prototype making, in engineering,<br />

design, materials, rapid prototyping and<br />

tooling, in simulation technologies and in<br />

special shows like the one on the possibilities<br />

in the field of plastic. The high proportion<br />

of the international exhibitors and<br />

guests coming from the economic growth<br />

region of Asia was particularly striking. The<br />

exhibition management team attribute the<br />

new record figures to the proven concept<br />

enabling specialists like industrial designers,<br />

product developers, buyers, suppliers<br />

and users to gain an overview of the entire<br />

process chain "from design through prototype<br />

to mass production” within one exhibition<br />

venue.<br />

Investment for greater capacity –<br />

in the service of the customer<br />

Someone with as many years of sales experience<br />

as Bernhard Pauly, the Tool<br />

Steel/Engineering Alloys Sales Manager, is<br />

delighted about the high level of demand<br />

for special steel. “The current challenge in<br />

day-to-day business is to meet the high<br />

demand from existing customers to their<br />

satisfaction, and then acquire new customers.”<br />

To ensure continued success in<br />

this endeavour, <strong>Buderus</strong> <strong>Edelstahl</strong> is investing<br />

in various areas such as the major<br />

expansion of the forging area, the capacity<br />

of which is to be significantly increased.<br />

“This is an important message that should<br />

now be given out from our exhibition<br />

stand,” explains Jens Mohr, the Commercial<br />

Director, “We are investing so we can continue<br />

to serve our customers quickly, flexibly<br />

and with the best quality.”<br />

16<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

An unforgettable experience<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> as a guest<br />

at a Hindu wedding<br />

In Chennai in India, formerly Madras, a wedding celebration of superlatives took place<br />

from the 29 January to 1 February <strong>2007</strong>. The Laxman family, owners of PCK <strong>Buderus</strong><br />

India Special Steels PVT Ltd, issued invitations to the wedding of their son Chidamber,<br />

one of the directors of PCK <strong>Buderus</strong>. Bernhard Pauly and Ulrich Keiner were there from<br />

the start; Jens Mohr, Commercial Director of <strong>Buderus</strong> <strong>Edelstahl</strong>, joined them one day<br />

later.<br />

The ceremonies of this Brahman wedding<br />

with its many rituals and customs, lasted<br />

three whole days. It was a festival of symbols<br />

and flower chains, repeatedly accompanied<br />

by Vedic prayers, song and Indian<br />

wedding music, with instruments we are<br />

not familiar with such as the nadaswaram,<br />

the sound of which wafts through the<br />

wedding room clearly announcing that a<br />

bond is being forged here that is holy and<br />

divine. Unaccustomed sounds to the European<br />

ear, an immense flood of vivid<br />

impressions for the eye.<br />

The married couple<br />

They had hardly arrived, when Bernhard<br />

Pauly, General Manager Steel Bar and<br />

Stockholding Service, and Ulrich Keiner, Far<br />

East Tool Steel Sales, were whisked off to<br />

the first ritual the next morning, a ritual<br />

preparing the bridegroom for his new life<br />

as master of his own house, in which he<br />

takes leave of his bachelor years. Then follows<br />

a further very important ritual in<br />

which the bride’s father enjoins the “still<br />

undecided” bachelor, who comes along in<br />

slippers with an umbrella, bamboo fans and<br />

other artefacts, to no longer adhere to his<br />

ascetic bachelor's life. He finally convinces<br />

him that life as a married man is better, and<br />

promises him his daughter as companion.<br />

Numerous other rituals accompany the<br />

ceremonies, including washing the bridegroom<br />

clean, fertility rituals and symbolic<br />

Ritual on the swing with the mothers of the bride<br />

and groom

acts. For example the bride and groom sit<br />

together on a swing. The swinging symbolises<br />

rocking on the waves of life on which<br />

the couple now move spiritually and physically<br />

in harmony with one another. Then<br />

finally the walk round the sacred fire, seven<br />

steps with seven oaths – the most important<br />

part of the wedding ceremony. It<br />

relates to the belief that if you walk seven<br />

paces with someone, they become your<br />

friend.<br />

“It was a fantastic experience”, says<br />

Bernhard Pauly, “Even if our business<br />

footwear didn't quite fit into the overall<br />

picture.” The black socks and shoes sat<br />

awkwardly with the shirt blouses and fine<br />

silk hip scarves given to the male guests to<br />

wear for the wedding ceremony. Cooks<br />

ladled the purely Indian vegetarian food<br />

from a large pot; the food was served on<br />

banana leaves laid out on the tables, and<br />

eaten with the right hand. This was something<br />

else unfamiliar to the European<br />

guests, like much that they experienced in<br />

the three exciting days.<br />

One day after the wedding ceremony<br />

there were receptions at the houses of the<br />

parents of the bride and groom. Presents<br />

were exchanged, people danced together,<br />

and everyone joined in. A leading light in<br />

this was Robert Chang, Managing Director<br />

The bridegroom with his parents at the Holy Fire<br />

Visiting the new PCK <strong>Buderus</strong> office building and stockholding facility in Chennai<br />

of Wu Jii, Taiwan, who proved an accomplished<br />

dancer. Other <strong>Buderus</strong> business<br />

partners present were Gabriele Pesciera of<br />

Comas S.p.A. Acciai Speciali, who had travelled<br />

from Italy, and David Chen of Metal<br />

System Co. Ltd from Taiwan.<br />

Jens Mohr could only stay for one day,<br />

and used his stay in Chennai to visit the<br />

Tool steel/Engineering alloys<br />

new PCK <strong>Buderus</strong> office building and on<br />

site stockholding facility.<br />

“This impressive wedding left us all with<br />

enduring impressions”, says Bernhard<br />

Pauly. “This delightful private gesture by<br />

the Laxman family has further strengthened<br />

our business relations that have now<br />

existed for almost 50 years.”<br />

Business friends with the bride and groom (from the left): David Chen, Bernhard Pauly, the bride and groom,<br />

Ulrich Keiner, Gabriele Pesciera, Robert Chang, Krishnan Laxman<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 17

Tool steel<br />

18<br />

Substituting forged tool steel for cast steel<br />

in die-casting mould frames<br />

High production level with<br />

extreme alternating stress<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> produces special-steel die-casting mould frames for the light alloy<br />

foundry at the BMW works in Landshut, which are fitted into a die-casting machine<br />

with a clamping force of 4,000 tonnes for producing aluminium crankcases, and fitted<br />

with moulding inserts. The engine block is cast under high pressure and weighs 41 kg.<br />

Relatively rapid cycle times of 2.5 to 3 minutes demand a high production level, and<br />

mould frames must withstand extreme levels of alternating stress.<br />

The light alloy forge at the BMW works in<br />

Landshut had previously been specifying<br />

cast steel for the largest mould frames in<br />

Heavy ingot on the 50MN open-die forging press<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

the forging dimensions 2050 x 1130 x<br />

2430 mm and 2050 x 625 x 2430 mm for<br />

die-casting inserts for producing high-<br />

Moving mould frame part undergoing<br />

pre-machining<br />

quality porefree<br />

aluminium pres -<br />

sure die cast crankcases,<br />

which are now made of hot<br />

working steel. For reasons of quality and<br />

scheduling, one frame pair of the size indicated<br />

consisting of the fixed and the movable<br />

part of the mould was first to be built<br />

in forged tool steel alongside the existing<br />

tool concept. Production at <strong>Buderus</strong> Edel-<br />

Pre-machined fixed mould frame part ready<br />

for heat treatment

Strategic discussion of quality and finish as the basis for costing: Peter Vetter, Volker Lubich, Peter Spielvogel,<br />

Oliver Schaub (from left to right)<br />

stahl had to accommodate the extreme<br />

blank weights of 46 tonnes for the moving<br />

mould frame and 25 tonnes for the fixed<br />

mould frame, and the qualitative finish<br />

with a very tight production timeframe<br />

was discussed in detail with the customer.<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> materials<br />

for high stress states<br />

“You need to know the stress profile of the<br />

complete casting tool during production<br />

exactly in order to determine the most economic<br />

steel grade that is best in terms of<br />

quality”, says Volker Lubich, Tool Steel<br />

Quality Planning Manager at <strong>Buderus</strong> <strong>Edelstahl</strong><br />

(retired at the beginning of <strong>2007</strong>).<br />

“There are thermal stresses acting here due<br />

to preheating of the tool, the casting temperature<br />

and the casting speed. There are<br />

also mechanical stresses due to the clamping<br />

force of the machine, the closing pressure<br />

of the tool and the relatively high<br />

casting pressures of the aluminium up to<br />

850 bar at temperatures up to 700 °C,<br />

which have a cumulative effect on the<br />

casting tool.”<br />

Tool steel<br />

These thermally and mechanically<br />

induced stress states are repeated about<br />

every 2.5 to 3 minutes throughout the production<br />

cycle in the die-casting die, and<br />

require high strength and rigidity with<br />

adequate toughness and ductility of the<br />

mould frames. On the basis of the mechanical<br />

properties required, the Cr-Ni-Mo<br />

alloyed tool steel 2738 ISO-BM was selected<br />

as the tool material.<br />

The initial format of the two forging<br />

blanks involved casting a 100 tonne poly -<br />

gonal raw ingot in a mould for hot forming<br />

under the 5500 tonne forging press. This<br />

made it possible to ensure the two forgings<br />

were adequately formed and thus free of<br />

pores. The production sequence thereafter<br />

through to delivery of the two mould<br />

frames consisted of heat treatment to<br />

establish the correct component strength,<br />

rough pre-machining to contour, and thermal<br />

de-stressing. The piece is then finish<br />

machined according to drawing at a mould<br />

maker engaged by the customer.<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> has been working<br />

successfully for many years with the Aluminium<br />

Diecasting Mould and Injection<br />

Mould departments to produce automotive<br />

plastic parts such as bumpers, spoilers and<br />

mudguards. With the substitution of<br />

forged tool steel for cast steel for die-casting<br />

mould frames, <strong>Buderus</strong> <strong>Edelstahl</strong> offers<br />

its customers attractive new supply<br />

options.<br />

Finished mould frame fixed side Fixed mould side with insert fitted Aluminium die-cast part of the six-cylinder engine<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 19

Employees<br />

The Works Fire Service team<br />

<strong>Buderus</strong> Works Fire Service and Works Medical Service<br />

Joined-up safety<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> has several emergency<br />

departments to avert hazardous situations<br />

and ensure the quickest and best<br />

possible provision. The Works Fire<br />

Service and Works Medical Service are<br />

closely interlinked, and work smoothly<br />

together to provide an emergency<br />

service.<br />

Saving lives, protecting health, avoiding<br />

downtime and breakdown costs are the<br />

tasks of the <strong>Buderus</strong> <strong>Edelstahl</strong> Works Fire<br />

Service. It was formed in 1925, and since<br />

20<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

then it has grown with its tasks. The practised<br />

team is on the spot in minutes,<br />

around the clock, 365 days a year. A total of<br />

33 men and one woman currently belong<br />

to the Works Fire Service, 13 of them fulltime<br />

and 20 volunteers. They are on the<br />

spot immediately with up to eight fire<br />

appliances and emergency vehicles. Their<br />

task ranges from fire prevention by inspections,<br />

tests, etc, to active firefighting and<br />

ambulance work through to handling<br />

unusual emergencies like the one in summer<br />

2006 when a swarm of wild bees had<br />

to be rescued from a facade of the works, a<br />

task the Works Fire Service performed in an<br />

exemplary manner.<br />

Wide range of tasks<br />

In addition to the tasks already indicated,<br />

the full-time fire service staff also perform<br />

activities in the control centre, at reception<br />

and in company security, naturally matching<br />

the rotating shift pattern of <strong>Buderus</strong><br />

<strong>Edelstahl</strong> production, 24/7. The variety of<br />

tasks is very demanding for the team,<br />

which has to be qualified and motivated.

The Works Fire Service has regular practices,<br />

training and special tests, for example<br />

with breathing and chemical protection.<br />

In addition to general firefighting and<br />

fire practices, the everyday work of the<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> Works Fire Service also<br />

includes lifesaving with special equipment.<br />

Modern medical equipment such as the<br />

mobile defibrillator and the artificial respiration<br />

equipment in the new emergency<br />

vehicle must be operated safely and with<br />

no loss of time.<br />

The highest priority is avoiding major<br />

fires and the associated threat of loss and<br />

injury. Every year the works fire service<br />

trains employees in the use of fire extinguishers,<br />

of which more than 900 are distributed<br />

throughout the works premises.<br />

New company doctor for <strong>Buderus</strong> <strong>Edelstahl</strong><br />

From 1 January <strong>2007</strong>,<br />

Heinz-Dieter Schmidt<br />

has taken over the<br />

duties of Dr Ingrid Knell,<br />

our long-serving company<br />

doctor. Heinz-<br />

Dieter Schmidt has<br />

extensive medical training and vocational<br />

experience. He has worked as a specialist in<br />

occupational medicine and as an emergency<br />

doctor. He worked as company doctor<br />

at Hoesch, and was most recently the<br />

lead occupational doctor at the occupational<br />

medical Centre in Haiger.<br />

Heinz-Dieter Schmidt and his team are<br />

available to our workforce for accidents at<br />

work and routine examinations as required.<br />

<strong>Info</strong>rmation and advice and health-related<br />

vocational services are also available from<br />

the company medical service. For example<br />

this year we are offering flu injections to<br />

all employees. Those who are interested can<br />

contact the company medical service up to<br />

the end of November.<br />

Of course the extensive equipment also<br />

has to be maintained regularly, once a<br />

month for respiratory equipment for<br />

example. Also emergency vehicles, hoses,<br />

ladders, ropes, radio communication and<br />

other equipment is checked regularly, subjected<br />

to functional tests, and replaced if<br />

necessary. Fortunately the works fire service<br />

is very rarely deployed for a major incident,<br />

because of the excellent preventive<br />

measures. But the importance of a good<br />

team with excellent equipment became<br />

apparent in May of this year when the<br />

fire-fighting team under the leadership of<br />

Frank Brück was confronted with a fire in<br />

the rolling mill. The incident was successfully<br />

contained, in close cooperation with<br />

the city fire services.<br />

Heinz-Dieter Schmidt is available for consultations<br />

in <strong>2007</strong> at the following times:<br />

Employees<br />

Volunteers always wanted<br />

The volunteers who support the full-time<br />

firefighters are particularly important for<br />

all tasks. The more the better. The <strong>Buderus</strong><br />

<strong>Edelstahl</strong> works fire service is currently<br />

again looking for employees to join as volunteers.<br />

How do you join the works fire<br />

service? It’s easy, just call the works fire<br />

service, or e-mail company security. The<br />

contact person is Oliver Roland. “We<br />

urgently need more volunteers to stay up<br />

to strength”, he says, and looks forward to<br />

your phone call or e-mail.<br />

Monday/Wednesday: 10:00–14:30 hours<br />

Tuesday/Friday: 12:00–16:00 hours<br />

Heinz-Dieter Schmidt with his team: nurse Yvonne Weber, Oliver Roland (works fire service), nurse Barbara<br />

Schliffer, nurse Heike Langner (from left to right), and the new works emergency vehicle<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 21

Employees<br />

Minister of Economic<br />

Affairs visits<br />

<strong>Buderus</strong> <strong>Edelstahl</strong><br />

Dr Alois Rhiel finds out<br />

about the sandwich<br />

course system<br />

When the Minister of Economic Affairs<br />

for the state of Hesse, Alois Rhiel, undertook<br />

his one-week tour of the State on<br />

20. 8. <strong>2007</strong> on the subject of “sandwich<br />

courses in Hesse”, his first visit was to<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> GmbH. Alois Rhiel<br />

visited companies and schools to promote<br />

sandwich courses that combine<br />

training at the workplace and at uni -<br />

versity. “Studying in a sandwich course<br />

format is still not sufficiently well known<br />

to young people at grammar schools and<br />

technical high schools in Hesse, although<br />

this interweaving of theory and practice<br />

is an excellent form of vocational training”,<br />

says Dr Rhiel.<br />

Dr Rhiel took the opportunity at <strong>Buderus</strong><br />

<strong>Edelstahl</strong> to gain practical <strong>info</strong>rmation on<br />

this form of study that the company has<br />

been using successfully since 2001. <strong>Buderus</strong><br />

<strong>Edelstahl</strong> is currently training seven students<br />

under the University sandwich programme<br />

StudyPlus in cooperation with the<br />

Gießen Friedberg University of Applied<br />

Group photo of students and company representatives of <strong>Buderus</strong> <strong>Edelstahl</strong><br />

22<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

Sebastian Best, Minister of Economic Affairs Alois Rhiel, Stefan Luthardt (front, from left to right);<br />

Gerd Hackenberg (Wetzlar/Dillenburg CIC), Detlef Haaske (StudyPlus), Roland Lentz, Jörg E. Feuchthofen,<br />

Jens Paul Mohr, Karl-Peter Johann and Holger Kison (rear, from left to right)<br />

Sciences, making it a good example of the<br />

great success of sandwich courses.<br />

Company Director Karl-Peter Johann<br />

described the company’s growth to illustrate<br />

the importance of qualified managers<br />

in all fields. “We clearly benefit from the<br />

combination of theory and practice, and<br />

develop our own succession with company-specific<br />

knowledge gained on the job<br />

during the practical phases of the course,<br />

who produce usable projects and can start<br />

work as soon as they finish the course”,<br />

adds Mr Johann. The Human Resource<br />

Manager Holger Kison also confirmed the<br />

great success of the sandwich training system,<br />

“The three-year course prepares<br />

promising employees for promotion, having<br />

gained immense specialist knowledge<br />

and also a great deal of social competence<br />

and company ethic.”<br />

Stefan Luthardt is in his fifth semester<br />

studying industrial engineering, specialising<br />

in mechanical engineering, and gave<br />

the minister and the representatives of the<br />

Chamber of Industry and Commerce and<br />

the Union of Company Associations in<br />

Hesse a convincing account of the value of<br />

the <strong>info</strong>rmation tour with an insight into<br />

the syllabus and practical phases. Sebastian<br />

Best is already a StudyPlus graduate, and<br />

used his own career with the company to<br />

illustrate the vocational opportunities that<br />

open up with the course. “You can see there<br />

are always opportunities for further development”,<br />

comments Rhiel.<br />

For <strong>Buderus</strong> <strong>Edelstahl</strong>, the sandwich<br />

course training format is a progressive<br />

instrument to cover the company’s requirement<br />

for highly qualified succession.<br />

Gradu ates are already taking on key functions<br />

in the company, and have excellent<br />

career opportunities.<br />

Students from the Aac<br />

The shortage of skilled manpower in Germany<br />

is becoming ever more apparent, and<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> is no exception. It is<br />

important to enthuse highly qualified<br />

students as early as possible for <strong>Buderus</strong><br />

<strong>Edelstahl</strong> as a company and for the fascinating<br />

world of steel. We do this by providing<br />

work experience and diploma projects,<br />

providing <strong>info</strong>rmation on site at various<br />

graduate job fairs, and organizing works<br />

tours for institutes to familiarize them-

Exemplary company<br />

integration management<br />

Award for <strong>Buderus</strong><br />

<strong>Edelstahl</strong><br />

<strong>Buderus</strong> <strong>Edelstahl</strong> received an award for<br />

its exemplary company integration management,<br />

at an award ceremony on<br />

13. 6. <strong>2007</strong> at Fraport AG in Frankfurt,<br />

presented by the Hesse State Welfare<br />

Association (LWV). Human Resource<br />

Manager Holger Kison received the prize<br />

endowed with € 3,000 on behalf of the<br />

Health Working Group. This makes<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> one of a total of 10<br />

award-winning companies in Hesse that<br />

are committed to integrating sick and<br />

disabled people into work.<br />

The LWV Councillor Dr Peter Barkey presented<br />

the award together with Dr Werner<br />

Scherer, Chief Executive of the Hesse<br />

Employers’ Association Council, saying,<br />

“We are delighted that there are now several<br />

companies in Hesse that have adopted<br />

integration management as a strategic<br />

challenge, setting an example by taking<br />

action for sustained integration of their<br />

disabled and sick employees.”<br />

“Companies in Hesse regard workplace<br />

prevention and integration management<br />

as an expression of a modern company philosophy<br />

whose economic success is based<br />

mainly on the motivation of the workforce”,<br />

emphasised Dr Scherer to the group<br />

of around 200 company representatives.<br />

Together with the agreement between<br />

the Works Council and company management<br />

reached since 2004 for integrating<br />

disabled people, the long-standing practice<br />

of health management at <strong>Buderus</strong> Edel-<br />

hen University IBF at <strong>Buderus</strong> <strong>Edelstahl</strong><br />

selves with our work and the various production<br />

processes.<br />

Students from the Institute of Metal<br />

Forming (IBF) of the Aachen University<br />

of Technology visited us on 31. 5. <strong>2007</strong><br />

under the direction of Professor Gerhart<br />

Hirt to enjoy a varied programme presenting<br />

the world of <strong>Buderus</strong> <strong>Edelstahl</strong>. The<br />

Engineering Director Karl-Peter Johann<br />

greeted the guests and introduced the<br />

company.<br />

The works tour gave the young engineers<br />

a vivid first-hand picture of the production<br />

plant and production processes.<br />

The Works Manager and the Quality Assurance<br />

Manager Dr Frank Hippenstiel provided<br />

additional specific <strong>info</strong>rmation.<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> also organised a tour<br />

through the unique German Museum of<br />

Mathematics, the Mathematikum in Gie -<br />

ßen, where the world of formulae and<br />

numbers becomes an exciting experience.<br />

Employees<br />

Works Council Chairperson Heidi Koster (on the<br />

right), Human Resource Manager Holger Kison<br />

(on the left)<br />

stahl contributes to people with medical<br />

handicaps or long-term illness continuing<br />

or returning to work in the company.<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> takes proactive measures<br />

to make this possible.<br />

The latest example is adapting the crane<br />

cab in the scrap and alloy store area to create<br />

another workplace suitable for disabled<br />

people. Measures such as this have enabled<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> to significantly exceed<br />

its statutory 5 % quota of disabled people<br />

in the workforce. This is quite remarkable<br />

for a company in heavy industry.<br />

The award by the State Welfare Association<br />

is a spur to continue with this work.<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> will donate the prize<br />

money of € 3,000 to the Fröbel School<br />

Development Association in Wetzlar to<br />

improve the learning situation for disabled<br />

people capable of practical training.<br />

Complex mathematical material is presented<br />

in visual terms to make it accessible to<br />

the general public.<br />

The varied day was rounded off in the<br />

evening with a barbeque buffet. The students<br />

and the engineering and management<br />

staff of <strong>Buderus</strong> <strong>Edelstahl</strong> took the<br />

opportunity for more wide-ranging discussion.<br />

This was a networking opportunity to<br />

make contacts that will no doubt be maintained<br />

in future.<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong> 23

Employees<br />

”Good luck!“<br />

to all our new<br />

apprentices<br />

On 1 August <strong>2007</strong>, 19 apprentices started<br />

work in various industrial and engineering<br />

careers at <strong>Buderus</strong> <strong>Edelstahl</strong>.<br />

In the industrial/engineering field the<br />

following young people are being trained<br />

as lathe operator turners: Marcel Oberding,<br />

Nils Ströhmann, Martin Born, Alexander<br />

Veidt and Vitali Wilde. They are learning<br />

to produce or machine workpieces for<br />

machines, equipment and plant by turning<br />

and drilling operations on conventional<br />

and computer-controlled machine<br />

tools. This includes planning the production<br />

processes involved, selecting the necessary<br />

tools, and writing the programs for<br />

computer-aided machines. Setting up the<br />

lathes including tooling and jigs and fixtures,<br />

and monitoring the production<br />

process and checking the quality of the<br />

workpieces also form part of the training,<br />

including maintenance and care of the<br />

machines operated.<br />

There has been a significant increase<br />

this year in the group of apprentices in the<br />

field of materials testing/metal working.<br />

This operation is strengthened with the following<br />

intake, all in their first year of training:<br />

Maurice Dietz, Benjamin Jung, Tobias<br />

24<br />

EDELSTAHL <strong>Info</strong> 2/<strong>2007</strong><br />

Reiss, Lena Seibert und Roman Ulrich. This<br />

training will qualify our young people to<br />

inspect materials and workpieces auto -<br />

nomously, determine their characteristics<br />

and document them. With the knowledge<br />

they acquire of the various production and<br />

machining sections, the materials inspectors<br />

can later analyse precisely the causes<br />

of problems identified. The process of<br />

carrying out test procedures, presenting<br />

results and applying quality assurance<br />

aspects all relates to prescribed standards<br />

and customer specifications.<br />

New trainees in the field of industrial<br />

mechanics maintenance are Jan Bangel,<br />

Tobias Coletta, Ayhan Evli, André Menk,<br />

Janis Schäfer und Albert Schweizer. Over<br />

the next 3 ½ years they will learn how<br />

machines and production plant are<br />

inspected and maintained, and how<br />

machines are dismantled and reassembled,<br />

checked for functionality and put into<br />

service, especially having regard for the<br />

safety rules to be observed.<br />

In the industrial and technical fields we<br />

greet our three new electronics apprentices<br />

specialising in works engineering. Vincenzo<br />