Download - HANSER automotive

Download - HANSER automotive

Download - HANSER automotive

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

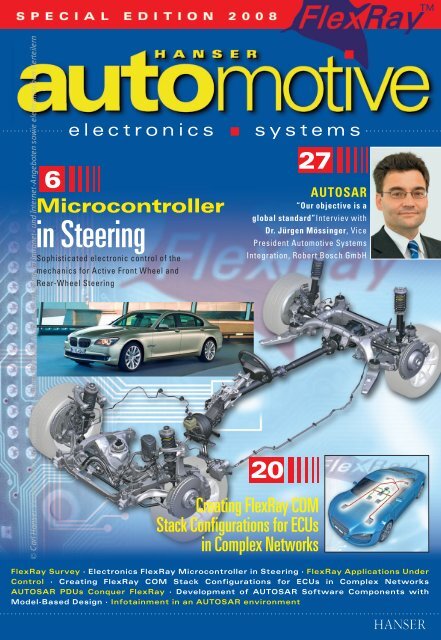

6<br />

electronics<br />

Microcontroller<br />

in Steering<br />

Sophisticated electronic control of the<br />

mechanics for Active Front Wheel and<br />

Rear-Wheel Steering<br />

systems<br />

27<br />

AUTOSAR<br />

“Our objective is a<br />

global standard”Interviev with<br />

Dr. Jürgen Mössinger, Vice<br />

President Automotive Systems<br />

Integration, Robert Bosch GmbH<br />

20<br />

Creating FlexRay COM<br />

Stack Configurations for ECUs<br />

in Complex Networks<br />

FlexRay Survey · Electronics FlexRay Microcontroller in Steering · FlexRay Applications Under<br />

Control · Creating FlexRay COM Stack Configurations for ECUs in Complex Networks<br />

AUTOSAR PDUs Conquer FlexRay · Development of AUTOSAR Software Components with<br />

Model-Based Design · Infotainment in an AUTOSAR environment

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

Measuring in Rough Environments –<br />

Sensor Close, Synchronous, and<br />

Accurate<br />

ES400 Measurement Modules<br />

Compact and rugged for sensor<br />

close installation, IP67 protection,<br />

extended temperature range<br />

-40...120 °C<br />

Powerful time-synchronous data<br />

acquisiton for accurate measurements<br />

of signals from different<br />

sources<br />

Integrated with all established development<br />

and measuring systems:<br />

INCA, CANape, PROVEtech:VA,<br />

MM6, DEWESoft<br />

ES400 modules cover all relevant<br />

applications:<br />

– ES410 – A/D Module<br />

– ES411 – A/D Module with<br />

Sensor Power Supply<br />

– ES420 – Thermo Module<br />

– ES430 – Lambda Module<br />

– ES441 – Counter and Frequency<br />

Module with Sensor<br />

Power Supply<br />

ETAS Group<br />

Whether you’re looking to<br />

shorten your development<br />

times or reduce your warranty<br />

costs – the ETAS Group<br />

has an answer.<br />

We supply a comprehensive<br />

portfolio of standardized<br />

development and diagnostic<br />

tools that cover the entire life<br />

cycle of electronic control<br />

units, from development to<br />

operational use and service.<br />

ETAS GmbH<br />

Borsigstraße 14<br />

70469 Stuttgart, Germany<br />

Phone +49 711 89661- 0<br />

Fax +49 711 89661-106<br />

sales.de@etas.com<br />

www.etas.com

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

ECU<br />

Calibration<br />

Experience with series projects.<br />

Choose proven FlexRay solutions.<br />

Take advantage of our extensive experience with FlexRay series<br />

projects. Use Vector’s comprehensive product portfolio for your<br />

FlexRay networking:<br />

> Simulate and test ECUs and networks with the sophisticated<br />

development environment CANoe and the FlexRay interfaces.<br />

> Profit from standardized ECU software. Vector software<br />

modules can be flexibly configured and easily integrated.<br />

> Ensure advantages in both quality and time: Rely on professional<br />

support during development and training.<br />

Get FlexRay on the road - with series-proven tools, scalable<br />

modules and 20 years of Vector networking know-how.<br />

Get on board: www.flexray-solutions.com<br />

Get the FlexRay Reference<br />

Chart now!<br />

www.flexray-solutions.com<br />

Vector Informatik GmbH<br />

Ingersheimer Str. 24<br />

70499 Stuttgart, Germany<br />

Tel. +49 (0) 7 11/80670-0<br />

www.vector-informatik.com

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

FLEXRAYl AUTOMOTIVE 2008l3<br />

FlexRay<br />

for passenger<br />

cars only?<br />

The next car to feature the fully equipped FlexRay<br />

network in series is on its way – the second time<br />

this technology has gone into series production in<br />

the <strong>automotive</strong> sector. Its capability is proven. This news,<br />

of course, also spreads to other industries: interest in<br />

FlexRay is growing.<br />

Dietmar Millinger<br />

Elektrobit Austria GmbH,<br />

A-1060 Wien<br />

The FlexRay consortium has invested a<br />

great deal in the technology for the <strong>automotive</strong><br />

industry and has therefore done<br />

its bit. Every company in the consortium<br />

is entitled to do its own bit by equipping<br />

their own vehicles. But how shall the consortium<br />

benefit when third parties wish to<br />

use FlexRay? At the very least, it profits<br />

when FlexRay products and solutions are<br />

more widespread so they mature and<br />

improve. At the moment, using FlexRay is<br />

contractually defined for <strong>automotive</strong> applications<br />

only. Many interested parties from<br />

other industries, it is not clear what this<br />

precisely means.<br />

So, I will take a look on the Internet to<br />

find a definition for “<strong>automotive</strong>”.<br />

But, wait, SAE (http://www.sae.org/about/general/history/)<br />

already has a definition for “<strong>automotive</strong>”, maybe this provides<br />

some help . . .<br />

5 Minutes<br />

Should FlexRay be open to other<br />

industries? In our online survey we<br />

want to know, how you think about it.<br />

Join in for the questionnaire on<br />

www.hanser-<strong>automotive</strong>.de.<br />

The survey is completely anonymous<br />

and takes about five minutes.

© Carl Hanser Verlag, München A Uwww.hanser-<strong>automotive</strong>.de T O S A R Nicht zur Verfügung im Intranet- und Internet-Angeboten F L sowie E Xelektronischen R A Y Verteilern<br />

CONTENT<br />

4l SPECIAL EDITION FLEXRAYl AUTOMOTIVE 2008<br />

3 FlexRay, for passenger cars only?<br />

Preface from Dr. Dietmar Millinger, EB<br />

6 NEC Electronics FlexRay Microcontroller in<br />

Steering<br />

Dipl-Ing. Holger Schmerling, Dr. Costas Rente, Dipl-Ing. Sascha Galati<br />

Active (front wheel) Steering and Rear-Wheel Steering demands a<br />

very sophisticated control of torque and rotation of the actuator<br />

motors. Therefore the electronic Control of the Steering Mechanics<br />

with an Active Steering ECU and the Rear-Wheel Steering ECU<br />

10 dSpace: FlexRay Applications Under Control<br />

Dr. Ralf Stolpe, Dipl.-Ing. (FH) Björn Müller, Dipl. Inform. Joachim<br />

Stroop, Dipl.-Ing. André Rolfsmeier, Dipl.-Ing. (FH) Thorsten Hufnagel<br />

Combining FlexRay simulations with XCP on FlexRay<br />

16 Fujitsu: A Distributed Navigation Application<br />

enabled by FlexRay<br />

Fujitsu Microelectronics Europe and University of Applied Sciences<br />

Aschaffenburg (Prof. Dr.-Ing. J. Abke, Christian Eyrich,Matthias<br />

Steeg, Wolfgang Wiewesiek) Is FlexRay suitable for use in a navigation<br />

system? Can FlexRay be used to transfer moving image data<br />

between applications? A feasibility study has been undertaken to<br />

answer these questions in relation to a navigation application.<br />

20 TTTech Computertechnik AG: Creating FlexRay<br />

COM Stack Configurations for ECUs in Complex<br />

Networks<br />

Dipl.-Ing.Georg Stöger The allocation challenge of the FlexRay buffer<br />

memory.<br />

24 Vector Informatik and Audi AG: AUTOSAR PDUs<br />

Conquer FlexRay<br />

Dipl.-Ing. (FH) Wolfgang Brandstätter, Dr. rer. nat. Carsten Böke<br />

FlexRay Tools successfully support developments with PDU-based<br />

communications<br />

27 AUTOSAR: “Our objective is a global standard”<br />

Interview with Dr. Jürgen Mössinger, Vice President Automotive<br />

Systems Integration Robert Bosch GmbH, spokesperson of<br />

AUTOSAR until September 2008.<br />

29 The Mathworks: Development of AUTOSAR Software<br />

Components with Model-Based Design<br />

Guido Sandmann, Joachim Schlosser Top Down and Bottom up:<br />

From an architecture model to an AUTOSAR software component<br />

and reusing legacy models to generate AUTOSAR-compliant code<br />

31 OpenSynergy GmbH: Infotainment in an AUTO-<br />

SAR environment<br />

Dipl.-Ing. Frank-Peter Böhm, Dipl.-Ing. Rolf Morich, Dr. Stefaan Sonck<br />

Thiebaut AUTOSAR can be applied to typical vehicle functions, but it<br />

excludes precisely those areas which are most driven by the entertainment<br />

and telecommunications industries and in which customers<br />

experience innovations most directly and immediately.<br />

6<br />

Two ECUs directly affect the steering characteristics<br />

of the new BMW 7. A very<br />

sophisticated control of torque and rotation<br />

of the actuator motors requires a high<br />

precision closed loop control of the electrical<br />

BLDC motor. This is realized by a<br />

microcontroller that is able at the same<br />

time to frequently update information on<br />

motor currents and position, calculate and<br />

generate the corresponding PWM pattern<br />

required to drive the motor.<br />

This article describes the approach<br />

taken by a tool-based solution to compute<br />

and generate a buffer configuration<br />

and FlexRay Interface (FRIF) layer<br />

schedule that takes into account the<br />

limited resources of communication<br />

buffers and CPU time.<br />

29<br />

20<br />

Companies usually have an<br />

extensive library of mature and<br />

extensively tested models. It is<br />

important that these models<br />

can be reused to target different<br />

platforms such as AUTO-<br />

SAR without any changes to the<br />

models’ blocks.

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

6lA UTOMOTIVE 2008l SPECIAL EDITION FLEXRAY<br />

NEC FlexRay Microcontroller<br />

in Steering<br />

NEC Electronics anticipated the demand for high performance<br />

microcontrollers with embedded FlexRay for chassis applications<br />

and started the development of the V850E/PHO3 in<br />

2004. Consequently, the PHO3 was the world-wide first<br />

microcontroller with embedded FlexRay to successfully pass<br />

the FlexRay Conformance Test at TÜV Nord.<br />

One major highlight of the new BMW 7 Series car<br />

model is its innovative chassis combining comfort,<br />

driving pleasure and active safety. The so-called<br />

Integral Active Steering concept is a symbiosis of electro-hydraulic<br />

power steering controlling the steering force,<br />

Active Steering (AS) controlling the steering angle via an<br />

overriding drive and the optional Rear-Wheel Steering,<br />

Clearly a good coordination of these systems is needed to<br />

ensure an optimum steering behavior in all driving situations.<br />

This is done by the integrated chassis management<br />

(ICM) module and means the ICM needs to have close<br />

communication links to the actor systems.<br />

Actio - reactio: The dynamics of a chassis with its mechanically<br />

coupled components is determined by physics’<br />

laws. Physics occur in real-time and do not care about bottlenecks<br />

such as bus protocols with limited bandwidth, high<br />

bus loads and unpredictable latencies. Therefore the need<br />

to control such a dynamic system via a network requires a<br />

high level of performance communication protocol. It is<br />

vital that it is able to keep pace with real-time requirements<br />

and cope with the amount of sensor data and actuator<br />

instructions.

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

The introduction of FlexRay as the<br />

new high performance <strong>automotive</strong><br />

network protocol has paved the<br />

way for such an integrated chassis<br />

management system to efficiently<br />

control the interaction of distributed<br />

chassis functions (Fig. 1).<br />

Active Steering (AS)<br />

For the Active Steering a special<br />

gear is inserted into the column between<br />

the steering wheel and associated<br />

mechanics. Depending on the<br />

driving situation the impact of the<br />

steering wheel motion on the effective<br />

steering angle of the wheels can<br />

be changed by the AS. At slow city<br />

traffic (e.g at parking) the number of<br />

required steering wheel motions is<br />

reduced in order to make handling<br />

far more efficient. At higher speeds<br />

the steering behavior becomes<br />

more indirect, therefore the driver<br />

does not risk losing control of the<br />

vehicle as a result of unexpected<br />

and sudden steering wheel<br />

motions.<br />

Rear-Wheel Steering<br />

This is managed by means of a concentrically<br />

arranged brushless DC<br />

motor, which is positioned on the<br />

rear axle and moves the track rod<br />

through a spindle drive. The angle of<br />

the rear wheel can be controlled in<br />

a range of 3° maximum in both<br />

directions.<br />

For vehicle speeds of below 60<br />

km/h the rear wheels turn in the<br />

opposite direction of the front<br />

wheels thus enhancing the agility<br />

of the car. When driving at higher<br />

speeds the rear wheels steer in the<br />

same direction as the front wheels thus achieving a better<br />

balance of the side forces between front- and rear-wheels.<br />

This way the stability of the car improves e.g. for an evasive<br />

maneuver whilst driving on the motorway.<br />

Electronic Control of the Mechanics<br />

Both the Active Steering ECU and the Rear-Wheel Steering<br />

ECU directly affect the steering characteristics of the car.<br />

This demands a very sophisticated control of torque and<br />

rotation of the actuator motors. To achieve this a high precision<br />

closed loop control of the electrical BLDC motor is<br />

required. In order to facilitate this a microcontroller is<br />

necessary. This microcontroller is able at the same time to<br />

frequently update information on motor currents and position,<br />

calculate and generate the corresponding PWM pattern<br />

required to drive the motor.<br />

SPECIAL EDITION FLEXRAYl AUTOMOTIVE 2008l7<br />

Fig. 1: Integral Active Steering FlexRay network<br />

Fig. 2: Integral Active Steering ECU<br />

© <strong>automotive</strong><br />

© <strong>automotive</strong><br />

Typically the key components of such an ECU are as follows:<br />

- Main Microcontroller: For AS and Rear-Wheel Steering<br />

this is the NEC Electronics V850E/PHO3, responsible for<br />

the BLDC motor control, sensor evaluation, FlexRay communication<br />

and diagnosis.<br />

- Monitoring microcontroller: required for application monitoring.<br />

- Power MOSFETs to convert the logical PWM output signals<br />

into high currents are required to drive a powerful<br />

BLDC motor.<br />

- Sensor electronics for reading the position of the motor<br />

anchor and the individual phase currents.<br />

- FlexRay bus interface.<br />

- Power supplies.

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

All this had to be realized in a<br />

compact ECU (Fig. 2) that can<br />

operate within harsh environmental<br />

conditions. Some of the<br />

challenging factors are: limited<br />

mounting space, high ambient<br />

temperatures due to the power<br />

dissipation of the MOSFETS and<br />

strict EMC requirements.<br />

Also the software becomes a lot<br />

more complex than before and<br />

requires more memory and<br />

more calculation performance(e.g.<br />

for the Flexray protocol<br />

stack).<br />

8lA UTOMOTIVE 2008l SPECIAL EDITION FLEXRAY<br />

The microcontroller - V850E/PHO3<br />

A microcontroller that is able to satisfy all the above mentioned<br />

requirements is a rare thing. Taking into consideration<br />

NEC’s very well known high level of quality and long<br />

expertise in the chassis field (e.g. several million microcontrollers<br />

sold for electrical power steering) it was decided<br />

to use NEC’s V850E/PHO3 for the Active Steering and<br />

Rear-Wheel Steering projects (Fig. 3).<br />

In a “nutshell” the PHO3 features a high level of calculation<br />

power, a huge memory (1 MB), the capability to control<br />

BLDC motor actuators, an interface to the FlexRay network,<br />

is able to support the extended <strong>automotive</strong> temperature<br />

range (A2 grade) plus excellent EMC performance.<br />

In addition an integrated floating point unit has been implemented<br />

as this is required to support today’s approach of<br />

model based algorithm development.<br />

Many chassis applications have similar requirements to<br />

those above , but require more or less performance, resp.<br />

more or less memory. To cover this, NEC have created a<br />

dedicated product line, named “P” Series. The “P” series<br />

offers strong solutions for low, mid and high-end chassis<br />

applications.<br />

Key parameters of the FlexRay Network<br />

The FlexRay network is the key component which facilitates<br />

the fast exchange of data. This makes it possible for the<br />

actuators to behave in a coordinated way and demonstrate<br />

optimized quick reactions to compliment the physics of<br />

driving.<br />

As the FlexRay protocol was designed to allow a high flexibility<br />

a huge amount of parameters have to be chosen.<br />

One key parameter is the cycle time. As the FlexRay configuration<br />

should be unchanged for all cars within the 7<br />

Series platform and also future car series, it was a very difficult<br />

task to find the optimum balance required between<br />

network throughput and network load.<br />

Initially it was felt beneficial to have a high frequency of<br />

messages. But this would mean that seldomly sent messages<br />

would waste the network capacity. Finally it was<br />

decided to use a 10 Mbit transfer rate and 5 ms cycle time<br />

within the static and dynamic segments over a single channel.<br />

Although a network based purely on a passive bus<br />

would be preferable from cost<br />

point of view, it was finally decided<br />

to use a combination between the<br />

passive bus and star coupler. This<br />

was chosen because too many<br />

FlexRay nodes connected to one<br />

cable would detoriate the signal<br />

quality and hence limit the achievable<br />

bandwidth and quality of the<br />

signal transmission.<br />

V850E/PHO3 with Flex-<br />

Ray is running - What is<br />

next?<br />

Fig. 3: NEC V850E/PHO3 microcontroller<br />

As a result of the successful introduction<br />

of FlexRay into the first<br />

series project, other OEMs are now following and will present<br />

cars with FlexRay over the next couple of years. This<br />

means that FlexRay has been established as the <strong>automotive</strong><br />

high performance communication protocol and will<br />

become a standard interfaces within the <strong>automotive</strong> mass<br />

market. In order to support FlexRay for broader application<br />

areas the topology of the FlexRay network has to become<br />

much simpler. Also more flexible concepts are required<br />

e.g. synchronization. This is already on the way with the<br />

FlexRay protocol specification 3.0.<br />

The next big challenge for future chassis ECU’s will be cost<br />

reduction. High optimization potential still can be found in<br />

simplification of the functional safety concepts, by applying<br />

microcontrollers with enhanced functional safety support.<br />

This could help eliminating or at least simplifying components<br />

such as additional monitoring microcontrollers or<br />

supervision ASICs. But it could also dramatically reduce<br />

the efforts on the SW engineering side.<br />

Why not focus on the actual application SW and have the<br />

HW perform all of the diagnostics still being done in SW<br />

like memory tests, core self tests and plausibility check of<br />

safety-relevant calculation results? And why not reduce the<br />

efforts for functional safety validation and the assessment<br />

process in the same way?<br />

Wouldn’t it be a relief to present an “out-of-the-box” selfsafe<br />

microcontroller with proven safety integrity level rather<br />

than generating a new FMEA for each ECU variant,<br />

even though the same microcontroller is used?<br />

All this could be addressed by a generic functional safety<br />

concept for the microcontroller saving tremendous efforts to<br />

set up and validate a new functional safety concept for each<br />

and every product line. NEC Electronics has already started<br />

designing a new chassis microcontroller family, the Px4<br />

Series to meet these demands. It will be optimized for <strong>automotive</strong><br />

applications targeting IEC 61508 SIL3 certification<br />

and will use a single microcontroller to cover the span between<br />

a high level of functional safety at minimal costs. NEC<br />

has established a close cooperation with TÜV SÜD to monitor<br />

and assess the development of Px4 from the early conceptual<br />

phase to the final implementation in silicon.<br />

V850E/Px4 will feature an integral safety concept based on<br />

two redundant CPU subsystems checking simultaneous<br />

each others’ operation.

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

It will be accomplished by additional hardware diagnostics<br />

addressing those failure modes that need to be addressed<br />

in diagnostic SW or even external hardware today.<br />

From a performance point of view V850E/Px4 will expand<br />

the existing “P” Series roadmap and will feature greater<br />

calculation power due to the new superscalar E2 CPU core,<br />

plus an enhanced peripheral set which is tailored to meet<br />

future chassis application requirements. A full feature list<br />

can be downloaded from Internet:www.eu.necel.com/<br />

applications/<strong>automotive</strong>/040_flexray<br />

Though planned to be manufactured in a state-of-the-art<br />

90nm process, the V850E/Px4 will also use a proven-in-thefield<br />

predecessor device as starting point for the new<br />

design - V850E/PHO3. The realization of this first NEC<br />

microcontroller with embedded FlexRay interface would<br />

not have been possible without the extremely close collaboration<br />

of BMW and the excellent strong team spirit that<br />

prevailed between both parties.<br />

Finally NEC would like to take this opportunity to thank all<br />

of the involved people, particularly the project teams at the<br />

BMW Group – both for a successful introduction of this<br />

device to the market and also for the drive and inspiration<br />

to tackle challenging new <strong>automotive</strong> market requirements.<br />

SPECIAL EDITION FLEXRAYl AUTOMOTIVE 2008l9<br />

Dipl-Ing. Holger Schmerling studied electrical<br />

engineering at the Cologne University of<br />

Applied Sciences specializing in communication<br />

systems. For the past 6 years he has<br />

worked as an application engineer on Flex-<br />

Ray, TTCAN and AUTOSAR in the NEC Electronics<br />

Automotive Business Unit in Düsseldorf.<br />

Dipl-Ing. Sascha Galati studied electrical engineering<br />

at the University of Wuppertal with focus<br />

on automation technology. He gained 4 years<br />

experience as application engineer for <strong>automotive</strong><br />

microcontrollers before joining the NEC Automotive<br />

Business Unit in 2003. Now he is technical<br />

product responsible for <strong>automotive</strong> chassis<br />

microcontroller products.<br />

Dr. Costas Rente studied Physics at the<br />

RWTH Aachen University. In his promotion<br />

thesis he developed semiconductor detectors<br />

for high energy physics. Since 2000 he is<br />

with NEC Electronics and now active in the<br />

project management of chassis products for<br />

the <strong>automotive</strong> market.

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

10lA UTOMOTIVE 2008l SPECIAL EDITION FLEXRAY<br />

COMBINING FLEXRAY SIMULATIONS WITH XCP ON FLEXRAY<br />

FlexRay Applications<br />

Under Control<br />

Following the first successful use of FlexRay in a production application,<br />

numerous further projects are presently approaching production level. The<br />

test functions necessary for verifying these systems are made available by<br />

test systems that have been successfully applied in many projects. Other<br />

FlexRay functions in addition to ones for network verification also came<br />

into operation. Along with FlexRay, the Universal Measurement and Calibration<br />

Protocol, XCP, is also gaining in importance. This paper describes<br />

the methods being used for FlexRay simulations and provides an XCP on<br />

FlexRay application example.<br />

Setting up a FlexRay Simulation<br />

In-vehicle networks are in a state of constant further<br />

development, particularly since the announcement of<br />

FlexRay in the year 2000. dSPACE GmbH was one of the<br />

companies that got involved in developing tools for Flex-<br />

Ray at an early stage, in response to the need for comprehensive<br />

means of testing the new bus system. Vehicles<br />

have now been going into series production with<br />

FlexRay for over a year, and further vehicles and applications<br />

are just one step away from being launched on<br />

the market. It is clear that FlexRay will continue to<br />

advance rapidly.<br />

As the number of applications grows, so do the requirements<br />

on the necessary test tools and infrastructures. Building<br />

on the experience gained from previous applications,<br />

these tools must be given further test execution functions.<br />

The dSPACE solution for testing FlexRay is based on<br />

various hardware platforms and the FlexRay Configuration<br />

Package. It already includes comprehensive test functions<br />

that were also used in the first production project.<br />

The dSPACE tool chain, with its real-time-capable simulation<br />

platforms and with MATLAB/Simulink modeling facilities,<br />

consists of several parts. The resulting workflow for<br />

configuring a test system is shown in Fig. 1.<br />

The dSPACE FlexRay Configuration Package is used to configure<br />

a dSPACE system as simulation or monitoring nodes<br />

in a FlexRay network. The nodes selected by the user are<br />

configured with the dSPACE FlexRay Configuration Tool<br />

according to a FIBEX communication matrix containing<br />

scheduling information for signals and frames. Various<br />

views help in managing the FlexRay configuration. The tool<br />

uses the configuration to generate communication code<br />

and parameters for the FlexRay controllers (called CHI<br />

code). The communication information is extracted and

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

12lA UTOMOTIVE 2008l SPECIAL EDITION FLEXRAY<br />

transferred to MATLAB/Simulink, where the data is used<br />

as parameters for FlexRay communication blocks from the<br />

RTI FlexRay Configuration Blockset. Application-specific<br />

Simulink models can be created using the RTI FlexRay Configuration<br />

Blockset as a basis, with data provided by the<br />

configuration tool. The block attributes are filled with data<br />

generated by the dSPACE FlexRay Configuration Tool. The<br />

blockset contains additional blocks that can be used for<br />

task execution control, interrupt and error handling, status<br />

information, and controller reset. The hardware is connected<br />

via the FlexRay interface to the FlexRay bus, and from<br />

there to the FlexRay ECUs which are the units under test.<br />

The FlexRay Configuration Package is not<br />

only concerned with simple restbus<br />

simulation for mimicking the network<br />

behavior, but also allows target-oriented<br />

failure simulation by checking potential<br />

failure cases. For example, the package<br />

can be used to insert logical corruptions<br />

in FlexRay communication to allow a<br />

cyclic FlexRay frame to be switched in or<br />

out, CRC algorithms to be switched<br />

during run time, etc.<br />

In addition, it is also possible to have a failure<br />

insertion on the physical level by<br />

simulating broken wires, short circuits,<br />

etc., or to vary the termination resistance.<br />

This can be done with suitable failure<br />

insertion hardware for differential<br />

busses.<br />

The dSPACE FlexRay Configuration Tool<br />

can create several kinds of time-triggered<br />

tasks for the various scenarios. In addition<br />

to these test functions for FlexRay<br />

networks, the tool can also be used in<br />

connection with the RTI Bypass Blockset<br />

and the Universal Measurement and<br />

Calibration Protocol (XCP). XCP is the successor to the<br />

much-used CAN Calibration Protocol (CCP). The advantage<br />

of XCP is that it provides strict separation between the protocol<br />

and the transport level, and is therefore open for the<br />

implementation of FlexRay or even future bus systems.<br />

XCP on FlexRay is part of the XCP family standardized by<br />

ASAM. The XCP concept is based on the master/slave principle,<br />

with the electronic control unit (ECU) as the slave.<br />

XCP on FlexRay is already being used in numerous projects,<br />

especially where the CAN bus has been replaced by<br />

FlexRay.<br />

Task-Synchronous Bypassing via XCP<br />

on FlexRay<br />

Due to the complexity of modern electronic control units<br />

(ECUs) and the limited time available for the development<br />

of new ECU generations, the entire ECU software is developed<br />

from scratch in only very few cases. Instead the existing<br />

ECU code is adapted or extended. The external<br />

bypass method is an efficient approach in this context, allowing<br />

new algorithms to be developed on a rapid prototyping<br />

system while the original ECU executes all the functions<br />

that remain unchanged. The input and output variables<br />

of the bypass model are exchanged, and task execution<br />

on the ECU and the prototyping system is synchronized<br />

via existing ECU interfaces such as XCP on FlexRay.<br />

The external bypass approach gives the greatest flexibility<br />

possible during the design phase, since there are almost<br />

no resource constraints such as RAM, ROM, processor<br />

performance, or I/O channels. Real-time behavior is guaranteed<br />

even for complex bypass functions. In addition, the<br />

autoboot options of the prototyping systems allow the<br />

behavior of new functions to be validated in realistic scenarios,<br />

for example during test drives.<br />

Fig. 1: Workflow with dSPACE’s FlexRay solution.<br />

© <strong>automotive</strong><br />

In this configuration example, the dSPACE MicroAutoBox<br />

is used as a real-time prototyping system. The bypass function<br />

is calculated synchronously to an ECU task. As soon<br />

as all the input data of the bypass model is available, an<br />

interrupt is triggered and the bypass task on the MicroAutoBox<br />

is executed. Alternatively, task execution on the two<br />

systems can be synchronized by means of the FlexRay<br />

message schedule. Execution of the bypass task is then<br />

purely time-driven (Fig. 2).<br />

Real-Time ECU Access via XCP on Flex-<br />

Ray<br />

For developing ECU functions by means of the external<br />

bypass approach, it is usually necessary to configure the<br />

bypass interface in the modeling environment and to change<br />

the input and output signals of the bypass model<br />

without ECU code modifications. The RTI Bypass Blockset<br />

provides a generic user interface for this purpose, with the<br />

same look and feel no matter what ECU interface is actually<br />

used for bypassing.<br />

The XCP on FlexRay option of the RTI Bypass Blockset is<br />

based on the dSPACE FlexRay Configuration Package. The

Can you buy electronics system<br />

know-how to save time and money?<br />

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

Yes<br />

With semiconductors, sensors and<br />

Intellectual Property, developed by Bosch<br />

Innovation from Bosch: Share the benefits of 40 years Bosch experience in development<br />

and manufacture of innovative electronic components for the <strong>automotive</strong> market.<br />

Our semiconductors, power semiconductors and sensors cover a wide range of<br />

<strong>automotive</strong> applications. Our IP modules make the integration of communication and<br />

general functions fast and easy. For additional information, please visit our website:<br />

www.bosch-semiconductors.com<br />

Visit our booth at:<br />

Convergence, Detroit: October 20-22, Booth #233<br />

electronica, Munich: November 11-14, Hall A6, Booth #340

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

14lA UTOMOTIVE 2007l 2008l SPECIAL EDITION FLEXRAY<br />

Fig. 2:Task synchronization for bypass scenarios via XCP on FlexRay.<br />

Fig. 3: Workflow for function bypassing via XCP on FlexRay<br />

configuration tool in the package allows users to assign the<br />

XCP master node and to select and configure the XCP slots<br />

of the FlexRay cycle necessary for bypassing, using the<br />

information in the ASAM MCD2 FBX (FIBEX) file. A Simulink<br />

library is generated according to the FlexRay configuration.<br />

After that, the bypass model can be implemented.<br />

The appropriate blocks from the RTI Bypass Blockset are<br />

used for selecting a suitable XCP slot and associating it<br />

with variables to be read from and written to the ECU. The<br />

set of variables available for selection is provided by the<br />

ECU description (ASAP2) file. In addition, the RTI Bypass<br />

Blockset provides configuration dialogs for creating further<br />

ECU variables that were not described in the ASAP2 file<br />

and that can be used for read and write access (Fig. 3).<br />

The synchronization of the ECU and the rapid prototyping<br />

system can be implemented with the help of the FlexRay<br />

Message Schedule or the RTI bypass interrupt mechanism.<br />

© <strong>automotive</strong><br />

If the interrupt mechanism is used, the<br />

calculation of the bypass model is triggered<br />

as soon as all the input values are<br />

available as specified in the model. If<br />

the FlexRay Message Schedule is used,<br />

the calculation of the bypass model is<br />

time-driven regardless of the input<br />

values that were received up to that<br />

point. The RTI Bypass Blockset offers<br />

various mechanisms to ensure data<br />

consistency<br />

Apart from function development<br />

making use of the external bypass<br />

approach, also various hardware-in-theloop<br />

(HIL) test scenarios require realtime<br />

access to ECUs. In these cases,<br />

the RTI Bypass Blockset can also be<br />

used on the HIL platforms: for example,<br />

for real-time tests or to capture the ECU<br />

data for real-time plausibility tests.<br />

© <strong>automotive</strong><br />

Measurement and Calibration via XCP<br />

on FlexRay<br />

Adapting the ECU software to engine and vehicle variants<br />

and validating the vehicle behavior are important milestones<br />

during the ECU development process. These specific<br />

applications are supported by CalDesk, the universal measurement,<br />

calibration and diagnostic tool from dSPACE. For<br />

communication with ECUs via XCP on FlexRay, CalDesk<br />

provides an XCP master implementation that allows users<br />

to measure ECU-internal variables and to adjust calibration<br />

parameters in the ECU software via FlexRay. CalDesk also<br />

lets users record and analyze measurement data from the<br />

vehicle bus, external measurement modules, further ECUs<br />

and dSPACE real-time systems. It is also possible to simultaneously<br />

adjust parameters on different platforms. In addition,<br />

typical diagnostic tasks such as reading and resetting<br />

the ECU’s fault memory via dedicated instruments are sup-

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

FLEXRAYl AUTOMOTIVE 2008l 15<br />

ported. Measurement, calibration and diagnostic tasks can<br />

be remote-controlled via an ASAM MCD3-compliant<br />

COM/DCOM interface: for example, via MATLAB or AutomationDesk<br />

for ECU tests.<br />

Summary<br />

The examples in the previous sections show some basic<br />

concepts for the efficient simulation of FlexRay networks<br />

for ECU tests. The described methods are already being<br />

used in many customer projects and are based on dSPA-<br />

CE’s proven hardware and software simulation solutions.<br />

The capabilities and possibilities of dSPACE’s comprehensive<br />

tool portfolio were explained using an example of<br />

bypassing via XCP on FlexRay. In addition, the paper described<br />

the interaction of the FlexRay configuration tool with<br />

the RTI blocks, as well as with the experiment environments<br />

and tools for test automation.<br />

This high level of performance in customer projects is already<br />

assisting developers as they handle their test, measurement<br />

and calibration tasks in FlexRay projects.<br />

Dr. Ralf Stolpe has been working at dSPACE<br />

GmbH since 2000, and is responsible for projects<br />

pertaining to the development of Flex-<br />

Ray tools.<br />

Dipl.-Ing. (FH) Björn Müller has been a product<br />

engineer in the Hardware-in-the-Loop<br />

Simulator Team since 2006, where he is<br />

responsible for the bus system products of<br />

dSPACE GmbH.<br />

Dipl. Inform. Joachim Stroop is the Lead<br />

Product Manager for System and Function<br />

Design Tools at dSPACE GmbH.<br />

Dipl.-Ing. André Rolfsmeier is Senior Product<br />

Manager for ECU Calibration and Bypassing<br />

at dSPACE GmbH and, as such, is<br />

responsible for measurement and calibration<br />

interfaces in the dSPACE tool portfolio.<br />

Dipl.-Ing. (FH) Thorsten Hufnagel is Project<br />

Leader for ECU Interface and Bypassing<br />

systems at dSPACE GmbH.<br />

Right away –<br />

with FlexRay!<br />

DTS and EDICflex –<br />

the perfect solution for diagnostics and<br />

flash programming of FlexRay ECUs<br />

No matter whether in development, validation<br />

or production – EDICflex hardware interfaces<br />

allow reliable ECU communication at any time.<br />

The Embedded Diagnostic Module guarantees<br />

robust realtime behaviour in diagnostic and<br />

flash programming applications.<br />

Benefit from DTS solutions also in your<br />

applications – flexible user interfaces and<br />

automation APIs are ready for you.<br />

Contact us now!<br />

Tel.: +49 (89) 456 56 420, www.softing.com

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

20lA UTOMOTIVE 2008l SPECIAL EDITION FLEXRAY<br />

Creating FlexRay COM Stack<br />

Configurations<br />

A FlexRay controller typically offers, or addresses via DMA access, several<br />

kilobytes of buffer memory. AUTOSAR defines a comprehensive set of layers<br />

to manage FlexRay communication in an ECU, from high-level signal<br />

management in the COM and handling of large data packets in the Transport<br />

Protocol layer down to the FlexRay Interface Layer for management of<br />

real-time interfaces and the hardware abstraction in the FlexRay Driver<br />

layer. But how can we efficiently allocate the FlexRay buffer memory of an<br />

ECU to the communication frames transmitted and received by an ECU?<br />

How does this affect the CPU load of this ECU, considering that each access<br />

to a communication buffer creates some work for the CPU?<br />

The Allocation Challenge<br />

The challenge itself is illustrated by an example: Assume<br />

a “telephone service” shop where 10 telephone<br />

booths are available for customer use and we are<br />

responsible for assigning customers to phones. Customers<br />

can “transmit” by making phone calls there, or<br />

“receive” by taking incoming calls there. How can we<br />

ensure that the use of the booths is optimized?<br />

Since we know our customers, we try to plan ahead: We<br />

have to exclusively reserve a booth for each of our “very<br />

important” customers. Whenever they require a phone,<br />

for ECUs in Complex<br />

Networks<br />

we need to have a phone booth available for them. Some<br />

customers are known for their short phone calls, usually no<br />

more than a few minutes. With regard to this additional<br />

information or “constraints”, we are able to develop efficient<br />

strategies for allocating phones to the customers.<br />

This illustrates the challenge that needs to be solved for<br />

complex real-time networks: We have a limited number of<br />

buffers (phone booths) and a large number of communication<br />

frames (customers), transmitted or received by the<br />

FlexRay communication controller (the shop) of our ECU.<br />

The buffers have to be allocated to the frames in a way so

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

that no information is lost (this happens if no buffer is free<br />

upon reception) or unduly delayed (this happens if no buffer<br />

is available when a transmission has to be made).<br />

Optimization Goal of AUTOSAR<br />

An additional constraint is related to how AUTOSAR handles<br />

the FlexRay communication: The interface handling the<br />

access to the FlexRay buffers, called the FlexRay Interface<br />

Layer (FrIf), is a software layer executed at certain pre-defined<br />

times and with certain pre-defined actions (“jobs”)<br />

such as packing and unpacking data. It is like the manager<br />

at the phone booth shop: he has some<br />

overhead getting up to assign a customer<br />

to a booth. If there are many booths<br />

and many customers, it would be more<br />

efficient to do several assignments in<br />

one step. These actions correspond to<br />

task activation in an ECU. If the FrIf has<br />

to be activated for each job (e.g. transmission<br />

or reception of a PDU), a lot of<br />

CPU time will be spent just on FrIf activations.<br />

It reduces the overhead significantly<br />

if we can group these jobs.<br />

A FlexRay communication controller<br />

offers dozens or hundreds of buffers,<br />

depending on the hardware and, in some<br />

cases, on the length of the messages.<br />

But several dozens or several hundred<br />

FlexRay frames may have to be transmitted<br />

and received on this node. This is not<br />

a fictional scenario: Some ECUs such as gateways need to<br />

send or receive many of the frames on a network, and a nontrivial<br />

FlexRay system will usually contain hundreds of different<br />

frames. For many of these frames (“static frames”), the<br />

frequency, phase and order are exactly known from the Flex-<br />

Ray communication schedule, while for others (“dynamic<br />

frames”), this is not necessarily so.<br />

Even with a copious amount of communication buffers, the<br />

authors found that it is not a trivial task to find proper allocations<br />

for the buffers when implementing AUTOSAR configurations<br />

for ECUs sending and receiving significant<br />

SPECIAL EDITION FLEXRAYl AUTOMOTIVE 2008l21<br />

amounts of data in large FlexRay networks. As explained<br />

above, the challenge is to define the buffer allocation in a<br />

way that buffers are efficiently used, all frames can be<br />

received and transmitted in time, and the CPU load generated<br />

by the FlexRay Interface layer activations is kept to a<br />

reasonable minimum.<br />

Fig.1:The validity span of the buffers, shown for a period of the green and<br />

the blue PDU. When using 2 buffers for the frames in slot 2, there are just 4<br />

FRIF interrupts necessary.<br />

© <strong>automotive</strong><br />

Several Possibilities for Allocation<br />

The purpose of the buffer allocation is to assign message<br />

buffers to slots and channels, select the buffer direction<br />

(“transmit” or “receive”), and define cycle counter filtering:<br />

Like for CAN, a FlexRay communication buffer can be<br />

programmed to receive only frames with defined identifiers<br />

or identifier ranges, e.g. “receive frame ID 3” or<br />

“receive frame IDs in the range 0x10..0x1F”. FlexRay communication<br />

is organized in (strictly) 64 communication<br />

cycles, and the filtering can refer to these cycles too, e.g.<br />

“receive frame 3 in any communication cycle” or, alternatively,<br />

“receive frame 3 only in communication cycle 20”.<br />

To find a buffer for every frame sent or received by a node<br />

can be a rather simple task when support for the FlexRay<br />

Interface layer is not considered: In this case, one buffer<br />

Mobile drives Automotive.<br />

Today‘s consumers are digital natives who live their life connected<br />

via blogs, communities, and online games. They expect anything,<br />

anywhere, anytime, on any device.<br />

Get mobile in your car. www.tietoenator.com<br />

TietoEnator is a professional service company providing IT, R&D<br />

and consulting services.

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

22lA UTOMOTIVE 2008l SPECIAL EDITION FLEXRAY<br />

Fig. 2: A valid whitelist has to be within the validity span of a buffer.<br />

can be assigned to each slot, independent of the frame<br />

received in that slot. The buffer then needs to be read in<br />

each communication cycle, and the number of buffers is an<br />

upper limit for the number of nodes in a communication<br />

cluster, because a buffer is not allowed to be assigned to<br />

more than one slot. This relaxes constraints quite a bit: we<br />

may have hundreds of frames, but only dozens of slots and<br />

the number of buffers typically is sufficient for this strategy.<br />

But is it always possible?<br />

Validity Spans and Grouping of FrIf Jobs<br />

The following example illustrates how the buffer allocation<br />

can support the optimal FlexRay Interface layer configuration<br />

with respect to CPU load. For demonstration we choose<br />

a single-channel FlexRay network schedule with 8<br />

cycles (instead of the full 64) and 8 static slots (instead of<br />

the several dozens that large FlexRay schedules have). As<br />

shown in the figure 1, there are 2 PDUs sent in this slot –<br />

the first one (green) is sent every odd cycle and the other<br />

one (blue) is sent every even cycle. Initially, all frames of<br />

one static slot for transmission (or reception) could share<br />

one buffer. The disadvantage with this approach is that one<br />

FlexRay Interface interrupt has to be raised in every communication<br />

cycle to copy the PDUs from the system<br />

memory into the controller buffers for transmission (or the<br />

other way round, for reception).<br />

If the real-time constraints for the PDUs allow, one FlexRay<br />

Interface interrupt per two cycles would be sufficient. For<br />

this, two buffers have to be used, and FlexRay controller<br />

configuration specifies when (i.e. in which slot and cycle)<br />

which buffer is to be sent. Such a “cycle filtering” configuration<br />

is specified by a “base cycle” parameter (the first<br />

transmission will occur in cycle N of the 64 cycles) and a<br />

“cycle repetition” parameter (the transmission will reoccur<br />

every N cycles throughout the 64 cycles) for each<br />

buffer. One FlexRay Interface job can now be executed in<br />

the beginning of every odd cycle, copying both PDUs to the<br />

corresponding buffers.<br />

In this example configuration, the “validity span” of each<br />

of these two buffers is “two cycles”: Each buffer can be<br />

updated in a time interval lasting two cycles, before the<br />

transmission is performed by the FlexRay controller, and<br />

new data needs to be provided. It is easier to compute a<br />

schedule for the jobs of a FrIf to operate on buffers with<br />

large validity spans, just as it is easier for humans to enter<br />

a slow-moving merry-go-round than a fast-moving one. And<br />

larger validity spans usually mean that more FrIf jobs can<br />

be grouped together, resulting in lower CPU usage for FrIf<br />

activations/context switches.<br />

Application Constraints and Automatic<br />

Scheduling<br />

A more sophisticated buffer allocation algorithm is required<br />

when the application has additional timing constraints<br />

about “when does the communication have to take place”.<br />

We assume a communication schedule where several relevant<br />

PDUs are transmitted in a single slot (X). As shown in<br />

figure 2,<br />

<br />

<br />

<br />

© <strong>automotive</strong><br />

PDU_A is transmitted with base cycle 0 and cycle<br />

repetition 4,<br />

PDU_B is transmitted with base cycle 0 and cycle<br />

repetition 1,<br />

PDU_C is transmitted with base cycle 1 and repetition<br />

2.<br />

Therefore, each frame in slot X contains 2 PDUs (in one<br />

case, one PDU is missing; this is “currently unused” frame<br />

space that can be used for later extensions to the schedule).<br />

In cycle 0 (with repetition 4), the frame contains PDUs<br />

A and B, in cycle 1 (with repetition 2!) the frame contains<br />

PDUs B and C, and in cycle 2 (with repetition 4), the frame<br />

contains just PDU B. Assuming an application is concerned<br />

with data in PDU_A and PDU_C, FlexRay data for this application<br />

will be received in 3 out of every 4 cycles. However,<br />

let’s say the application requires – here is the additional<br />

constraint (in complex systems there will be several of<br />

these) – that the AUTOSAR COM functions are only executed<br />

at the end of every second communication cycle.<br />

(Such a constraint is typically defined to ensure that legacy<br />

applications are not interrupted by basic software activations).<br />

Allocating one buffer for slot X is now forbidden,<br />

because we get new data in three out of four cycles, but<br />

we are not allowed to schedule one FlexRay Interface activation<br />

per cycle. Hence a smart buffer allocation algorithm<br />

is necessary to maximize the validity span of buffers: two

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

buffers are used for slot X! BUFFER_A holds the frame with<br />

PDUs A and B (validity span: 4 cycles), and BUFFER_B<br />

holds the frame with PDUs B and C (validity span: 2 cycles).<br />

Now the FlexRay Interface activations can be successfully<br />

placed in an interval labeled “whitelist” in figure 2. Whitelists<br />

are used-definable intervals of time in the cycle, specifying<br />

when a PDU may be handled by the FrIf. Whitelists<br />

are often used to formulate application constraints for FrIf<br />

activities, in this case “process the PDUs only every<br />

second cycle”.<br />

In this example, no cycle filter mask can be defined which<br />

contains PDU_A and PDU_C and still meets the application<br />

constraint. Using several buffers for one slot, and configuring<br />

each of these buffers with appropriate cycle filtering,<br />

may be required to meet all constraints encountered in a<br />

typical AUTOSAR FlexRay ECU.<br />

Available Tool Support<br />

The combination of<br />

hardware constraints – how many buffers (and sometimes:<br />

which with restrictions regarding filtering) are<br />

available?<br />

network schedule constraints – when is which PDU<br />

available for reception/when does it have to be provided<br />

for transmission?<br />

application constraints – when, for whatever reason,<br />

shall the FrIf perform its FlexRay handling jobs for specific<br />

PDUs (whitelists) and when is it forbidden to execute<br />

any such jobs (blacklists)? Are there any buffers<br />

that must not be used because they are reserved for<br />

something else (e.g. a FIFO)?<br />

the goal for optimization – group FrIf activities as<br />

much as possible to reduce the CPU load from activations/context<br />

switches<br />

is managed by a scheduling algorithm that automatically<br />

computes at which times during each cycle which FrIf jobs<br />

have to be executed to fulfill all of these constraints. The<br />

tool performing this scheduling algorithm is called TTX-<br />

Build. In order to generate a FrIf schedule for an ECU, the<br />

TTX-Build FrIf scheduler gets as input<br />

<br />

<br />

<br />

<br />

the (often hundreds of) PDUs and frames on the Flex-<br />

Ray network (FIBEX file),<br />

the hardware definition of the FlexRay controller of<br />

the node (ECU definition),<br />

the specification which of the PDUs are to be sent or<br />

received by this ECU (node configuration), e.g. for<br />

AUTOSAR COM (signal based communication interface),<br />

NM (network management) or TP (transport<br />

protocol),<br />

application constraints in the form of time intervals for<br />

“do” and “don’t” execute FrIf actions (blacklists and<br />

whitelists).<br />

The resulting FrIf schedule contains as few as possible (to<br />

minimize the CPU overhead) but as many as necessary FrIf<br />

“tasks”, i.e. definitions of which activities the FrIf has to execute<br />

at certain points in time (referring to the FlexRay network<br />

time).<br />

FLEXRAYl AUTOMOTIVE 2008l 23<br />

A tool for generating and checking specific parts of ECU<br />

software and configuration data needs to support integration<br />

in a development tool chain, where it can be used either<br />

for manual (GUI) or automatic (batch mode) operation.<br />

In the FlexRay ecosystem, this means compatibility to welldefined<br />

input and output file formats to support the workflow<br />

and development processes suggested by AUTOSAR<br />

and established <strong>automotive</strong> electronics development processes.<br />

In case of TTXBuild, it reads the FlexRay cluster<br />

description and network schedule from a FIBEX (Field Bus<br />

Exchange Format) file, takes node configuration data from<br />

a GUI or a user-supplied database (including scripting support<br />

for automatic generation of such a database) and generates<br />

the configuration XML files as described in AUTO-<br />

SAR.<br />

Dipl.-Ing.Georg Stöger studied Realtime<br />

systems at TU Wien. Since 1998 he is working<br />

for TTTech Computertechnik AG, Vienna,<br />

Austria. Today, he is leading the Core Technology<br />

Unit.<br />

FlexConfig - design and<br />

configuration software<br />

for FlexRay.<br />

By Eberspächer Electronics.<br />

Comfortable graphical editors and wizards<br />

Lossless import, export and editing of FIBEX<br />

(1.2.0a, 2.0.0d, 2.0.1 and 3.0.0)<br />

Converter for FIBEX+ to FIBEX 3.0.0,<br />

FIBEX 2.0.1 to FIBEX 3.0.0, CANdb to<br />

FIBEX 2.0.1/3.0.0<br />

Support of PDUs<br />

CHI-exports for all major<br />

communication chips<br />

www.eberspaecher.com

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

24lA UTOMOTIVE 2008l SPECIAL EDITION FLEXRAY<br />

FLEXRAY TOOLS<br />

SUCCESSFULLY SUPPORT<br />

DEVELOPMENTS WITH PDU-<br />

BASED COMMUNICATIONS<br />

AUTOSAR PDUs<br />

Conquer FlexRay<br />

Audi is using FlexRay in their newest vehicles. The developed Flex-<br />

Ray network communication uses PDUs (Protocol Data Units) that<br />

are fully AUTOSAR compatible. PDUs are logical data containers<br />

for exchanging signals between applications and allowing greater<br />

decoupling from the underlying communication system. Audi benefited<br />

immediately from Vector’s CANoe as a bus analysis and simulation<br />

tool which can natively handle PDUs.<br />

With the release of the frame-oriented FIBEX<br />

2.x database format, a new description semantic<br />

was needed to define PDU communications<br />

between network nodes. To overcome this gap,<br />

Audi successfully developed the FIBEX+ description<br />

semantic. Vector was able to immediately support<br />

FIBEX+ in its tools. Profiting from their experiences with<br />

FIBEX+, Audi introduced PDUs into the new FIBEX 3.0<br />

standard from ASAM (Association for Standardisation of<br />

Automation and Measuring Systems [1]).<br />

Continuous feedback from Audi enabled Vector engineers to<br />

integrate important PDU features during the early phases of<br />

tool development. Service Packs were delivered regularly to<br />

Audi, thus, allowing early testing of ECUs with PDU communication<br />

stacks. Audi delivered their latest FIBEX+ database<br />

versions to Vector in order to ensure CANoe’s continuous<br />

compatibility. Close collaboration between Audi and Vector<br />

accelerated the tool development and led to a professional<br />

analysis and development platform for FIBEX+ and the<br />

new FIBEX 3.0 based FlexRay networks.<br />

This article illustrates the impact PDUs have on the internal<br />

structure and features of a FlexRay development tool<br />

CANoe.FlexRay and how Audi engineers benefit from<br />

appropriate tool support.

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

PDU Layer for Network<br />

Analysis<br />

PDUs are managed by tools for analysis,<br />

simulation, and test as high-level communication<br />

data containers (e.g. messages)<br />

containing signals. A FlexRay frame can<br />

contain several PDUs. Since the layout of<br />

a frame can also change from cycle to<br />

cycle, the same PDU can be mapped to<br />

multiple frames. PDUs are uniquely identifiable<br />

by their position in a FlexRay frame<br />

in a specific slot during a specific cycle.<br />

Vector identifies PDUs in CANoe via the<br />

PDU Layer (Figure 1). The PDU Layer<br />

introduces PDU objects and is located<br />

between the bus and the user interfaces,<br />

respectively. The layer is enabled or disabled<br />

according to the assignment of an<br />

appropriate database (FIBEX+ or FIBEX<br />

3.0) to CANoe. If the layer is enabled, then<br />

the complete symbolic database interpretation<br />

(PDU names, signals, timings, etc.)<br />

of the network communication is performed<br />

at PDU level.<br />

The PDU’s main property, which is defined<br />

by the Update Bit, is decoupled from<br />

the frame’s occurrence on the network.<br />

Thus, frames on the network may contain<br />

updated and non-updated PDUs at the<br />

same time. Update Bit values can be visualized<br />

as pre-defined signals or can be<br />

evaluated (e.g. in the graphics window,<br />

see Figure 2). As a default for simple analysis<br />

or simulation received PDUs, which<br />

have not been updated, are ignored. For a<br />

detailed analysis, however, non-updated<br />

PDUs can optionally be displayed and passed<br />

on to the simulated nodes. In addition,<br />

FlexRay frames including their payload<br />

can be displayed and received as socalled<br />

Raw Frames. Such PDU-based analysis<br />

features were heavily used by Audi<br />

during their integration tests.<br />

PDU Layer for Network<br />

Simulation<br />

Although the FlexRay protocol defines frames to be transmitted<br />

cyclically (even without any update), native PDUs do<br />

not have this property. If a PDU is not updated, the receiver<br />

will normally not recognize the PDU. In order to trigger<br />

the receiver cyclically, PDUs must be updated periodically.<br />

If the automatic transmission of PDUs with the Update Bit<br />

set (i.e. without any explicit data update) is required, then<br />

the network designer can define these PDUs to have cyclic<br />

timings. For this reason an Interaction Layer (see Figure 3)<br />

on top of the PDU Layer was developed to handle those<br />

constraints. As an extension to the FlexRay protocol, PDUs<br />

may also be sent cyclically with (nearly) arbitrary periods<br />

with set Update Bit (without being updated).<br />

SPECIAL EDITION FLEXRAYl AUTOMOTIVE 2008l25<br />

Figure 1: CANoe’s Architecture with Abstraction Layers for Signal and PDU Handling<br />

and Sending Behaviour (IL).<br />

© <strong>automotive</strong><br />

Figure 2: CANoe’s visualization of PDU’s Update Bits in Graphics and Trace.<br />

© <strong>automotive</strong><br />

Message counters and check sums were defined by Audi<br />

as additional but optional validity attributes of a PDU. In<br />

fact, the Update Bits, message counters, and check sums<br />

of a PDU are set independently from the application in<br />

CANoe by the Interaction Layer in order to simplify the<br />

remaining bus simulation. Thus, the engineer can concentrate<br />

on setting appropriate signal values. A further use<br />

case is the insertion of explicit failures into the remaining<br />

bus simulation in order to test an ECU’s reaction. Therefore<br />

every automatic feature in CANoe can be disabled and<br />

the Interaction Layer can be used for fault injection.<br />

A simulation of communications with an ECU depends on<br />

the occurrence of specific events (event-based simulation).

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

26lA UTOMOTIVE 2008l SPECIAL EDITION FLEXRAY<br />

Figure 3:The Interaction Layer (IL) of CANoe controls the sending behaviour of PDUs with set Update Bit inclusively<br />

their extended validity attributes (message counter, user CRC).<br />

One of the most important events is the reception of messages<br />

or changes in signal values from the bus. As such,<br />

notification handlers for PDU reception and signal changes<br />

are triggered by the PDU Layer.<br />

Performance Aspects<br />

The additional (but mandatory) PDU Layer does create<br />

some overhead. When receiving FlexRay frames, PDUs<br />

have to be extracted from the frame and then forwarded<br />

to their notification handlers in the application. The same<br />

PDU can be contained in different frames. Thus, a sort of<br />

de-multiplexing of PDUs from frames is implemented by<br />

the PDU Layer. These procedures are highly optimized.<br />

On transmitting PDUs, they must be stored in the appropriate<br />

frame. The PDU can be located in different frames<br />

according to the current (cycle) time or a different set of<br />

PDUs may be contained in the frame. This results in a highly<br />

time-dependent multiplexed mapping of PDUs to Flex-<br />

Ray frames. If this is not fast enough, then frame slot misses<br />

should be expected. For maximum performance, Vector<br />

has implemented those functions to run on the hardware<br />

for the FlexRay bus interfaces of the VN series.<br />

Testing PDU-based Networks<br />

Audi and its Tier1 suppliers also benefited from CANoe’s<br />

AUTOSAR features. This includes a check for communication<br />

conformance in order to test the AUTOSAR communication<br />

stacks (especially the PDU Router) of the ECUs.<br />

Here it is of great importance to be able to compare the<br />

real bus entities (Raw Frames) with the symbolic interpretation<br />

(PDU abstraction level).<br />

Drehzahl erfassen und<br />

zuverlässig überwachen<br />

Vom Geber bis zu jeder Auswertung:<br />

Lösungen aus einer Hand!<br />

BRAUN GMBH<br />

DREHZAHL UND FREQUENZ<br />

D-71301 Waiblingen · Tel: 07151 / 9562- 30<br />

Fax: 07151 / 9562-50 · info@braun-tacho.de<br />

www.braun-tacho.de<br />

This helped the Audi engineers<br />

to identify in early phases<br />

an incorrect PDU or Update<br />

Bit position in the raw Flex-<br />

Ray frames.<br />

Tests can be split into two<br />

categories: First the application’s<br />

transmission behaviour<br />

can be checked with respect<br />

to updated PDUs and secondly,<br />

a signal’s integrity can be<br />

verified according to the application. Audi‘s engineers have<br />

successfully detected incorrect PDU update timings in<br />

early development phases. These tests are fully supported<br />

in CANoe’s Test Feature Set for PDUs. Additionally, for stimulus<br />

and response observations, PDUs can be sent interactively<br />

(PDU Panel) by implicitly manipulating signals<br />

(Input Panels), higher level protocols (transport, diagnostics),<br />

or by a remaining bus simulation (CAPL, MATLAB<br />

models, etc.).<br />

Conclusion<br />

PDU-based communications will not only be used in migration<br />

scenarios, e.g. when porting applications from CAN to<br />

FlexRay networks, but also for new FlexRay developments.<br />

Audi has strongly influenced the development of<br />

FIBEX 3.0 based on lessons learned with FIBEX+. Vector’s<br />

experience with FIBEX+ allowed the quick support of the<br />

new FIBEX 3.0 standard with CANoe. As communications<br />

become more complex and extensive, appropriate modelling<br />

standards (i.e. FIBEX 3.0 and/or AUTOSAR), as well as<br />

their professional tool support, are essential requirements<br />

for an efficient FlexRay development.<br />

Literature:<br />

[1] www.asam.org<br />

© <strong>automotive</strong><br />

Dipl.-Ing. (FH) Wolfgang Brandstätter<br />

is Hardware and Protocol Engineer for<br />

FlexRay;<br />

AUDI AG, 85045 Ingolstadt, Germany<br />

Dr. rer. nat. Carsten Böke is Senior Software<br />

Development Engineer for the “Tools for Networks<br />

and Distributed Systems” product line;<br />

Vector Informatik GmbH, 70499 Stuttgart,<br />

Germany

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />

LOOKING BACK ON NINE MONTHS OF<br />

FORGING THE INITIATIVES GOALS,<br />

DR. MÖSSINGER TALKS ABOUT<br />

ACHIEVMENTS AND CHALLENGES.<br />

“Our objective is a<br />

global standard”<br />

Since the beginning of this year, Dr. Jürgen<br />

Mössinger was spokesperson of the AUTO-<br />

SAR development partnership. The objective<br />

of this initiative is to manage the complexity<br />

of software development by standardization<br />

of basic system functions, scalability and<br />

transferability of functions with consideration<br />

of safety requirements. This results in a<br />

better maintainability, exchangeability and<br />

reuse of software components, easier software<br />

updates and provides a basis for the<br />

use of „Commercail off the shelf“ hardware.<br />

Dr. Mössinger, how has AUTOSAR developed during<br />

the last year?<br />

AUTOSAR began Phase 2 in early 2007. In launching<br />

release 3.0, which was released in late 2007 and published<br />

in February 2008, the consortium has created a stable<br />

basis for the <strong>automotive</strong> industry. This includes the complete<br />

system software, along with the methodology and,<br />

for the first time, also Application Interfaces. On this basis,<br />

vehicles will go into series production on a wide scale. In<br />

August 2008, we concluded the specifications for on-board<br />

diagnostics. OBD is prescribed by law in many countries<br />

and the support for this standard consequently represents<br />

a significant step toward the internationalization of AUTO-<br />

SAR. A subject particularly dear to my own heart.<br />

When can we expect to see products on the road?<br />

Very soon. By 2010, all nine core partners will have<br />

launched AUTOSAR-compliant control units onto the<br />

market.<br />

Have you also received inquiries from other industries?<br />

People are generally interested and, we have naturally also<br />

received inquiries, as has been the case for FlexRay. The<br />

focus at the moment, however, is exclusively on the <strong>automotive</strong><br />

industry.<br />

SPECIAL EDITION AUTOSARl AUTOMOTIVE 2008l27<br />

Dr. Jürgen Mössinger, Vice President Automotive<br />

Systems Integration Robert Bosch<br />

GmbH. He was spokesperson of AUTOSAR<br />

until end of September 2008.<br />

The process of internationalization you are forging<br />

ahead with makes AUTOSAR itself more complex. Isn’t<br />

it more of a hindrance, to have to take requests from<br />

other companies into account?<br />

Experience teaches us that local standards are not the<br />

route to success and would only lead to a further fragmentation<br />

of the subject. We have adopted a global standard<br />

as our objective. In this respect, the consortium offers<br />

various levels of membership. Thanks to internationalization,<br />

the number of members is rising and thus also the<br />

number of companies working with us on the further development<br />

of the standard.<br />

Japan showed interest in AUTOSAR and FlexRay at an<br />

early stage. Have things gotten any closer there?<br />

Japan has a strong <strong>automotive</strong> industry. There are two barriers,<br />

however, that impede the flow of information: on the<br />

one hand, the distance, and on the other, the complex<br />

Japanese language.<br />

By increasing the AUTOSAR presence at conferences and<br />

conventions, we have now succeeded in integrating Asia<br />

and in particular Japan to a greater extent. By way of illustration,<br />

the connection to Jaspar has now also been defined.<br />

JASPAR incorporates the “AUTOSAR/Flexray Standardization”<br />

working group, which performs a bridge function

© Carl Hanser Verlag, München www.hanser-<strong>automotive</strong>.de Nicht zur Verfügung im Intranet- und Internet-Angeboten sowie elektronischen Verteilern<br />