Fort™, FortPlus™ and FortPlus™ Laminated ... - Hansen Group

Fort™, FortPlus™ and FortPlus™ Laminated ... - Hansen Group

Fort™, FortPlus™ and FortPlus™ Laminated ... - Hansen Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

hansen glass processors<br />

<strong>Hansen</strong>Glass<br />

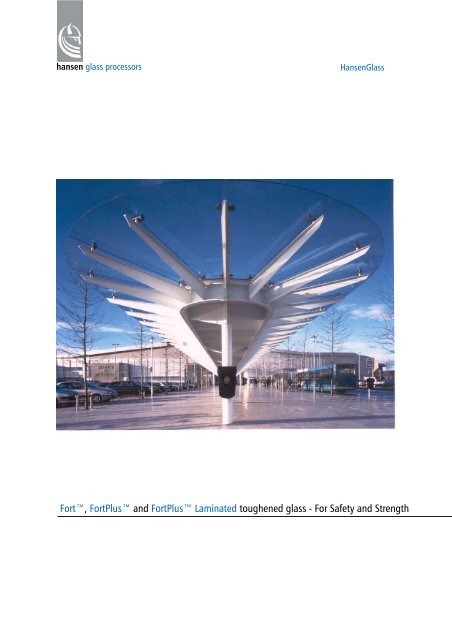

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Introduction<br />

<strong>Hansen</strong>Glass provides three solutions – Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> when specifying<br />

or using glass in critical risk areas or high performance applications such as:<br />

- balustrading, stair treads <strong>and</strong> l<strong>and</strong>ings;<br />

- canopies <strong>and</strong> overhead glazing;<br />

- commercial entrances;<br />

- doors <strong>and</strong> side panels;<br />

- floor panels,<br />

- glass shower/ changing cubicles;<br />

- glass fins;<br />

- glass vanity tops <strong>and</strong> shelving;<br />

- louvers, brise soleil <strong>and</strong> glazed feature elements;<br />

- partitions;<br />

- squash courts;<br />

- street furniture;<br />

- splash backs;<br />

- structural (bolted) glazing <strong>and</strong><br />

- wall cladding<br />

Fort is a high quality toughened glass available in<br />

thicknesses from 4mm to 6mm.<br />

FortPlus is a high quality toughened glass available in<br />

thicknesses from 8mm to 25mm.<br />

FortPlus <strong>Laminated</strong> comprises Fort <strong>and</strong>/or FortPlus<br />

toughened glasses with CIP (cast-in-place) polyester<br />

resin interlayer. Alternatively, <strong>Hansen</strong>Glass can also<br />

supply pvb laminate interlayers. Thicknesses in both<br />

product types are to suit the appropriate design<br />

performance criteria.<br />

All products are available in a wide variety of glass<br />

types which include:<br />

• Clear float glass<br />

• Low iron float glass<br />

• Tinted float glass<br />

• Hard coated low E glass<br />

• Hard coated solar control glass<br />

• Patterned glass<br />

Fort conforms to BS EN 12150, BS 6206 Class A <strong>and</strong><br />

BS EN 12600 Class 1(C)3.<br />

FortPlus conforms to BS EN 12150, BS 6206 Class A<br />

<strong>and</strong> BS EN 12600 Class 1(C)1.<br />

FortPlus <strong>Laminated</strong> conforms to BS EN 12543, BS<br />

6206 Class A <strong>and</strong> BS EN 12600 Class 1(B)1.<br />

2

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Advantages<br />

• Suitable for use in applications requiring safety <strong>and</strong> strength<br />

• Fully tested <strong>and</strong> conform to British <strong>and</strong> International Safety St<strong>and</strong>ards <strong>and</strong> Building Regulations.<br />

• Provide Class A safety impact performance to BS 6206 for use in all critical locations.<br />

• FortPlus <strong>Laminated</strong> gives additional safety characteristics.<br />

• Four to five times stronger than ordinary glass.<br />

• Available as heat soaked toughened glass for added confidence in use.<br />

• Single toughened glass breaks safely into small, blunt edged fragments which reduces the risk of injury<br />

<strong>and</strong> can also be held in place with a laminate interlayer.<br />

• Highly resistant to temperature changes <strong>and</strong> temperature differentials – ideal for use where there are<br />

thermal stress requirements.<br />

• Four decades of proven manufacturing success, utilising a range of thicknesses from 4mm to 25mm.<br />

• Available in a wide range of glass types from all the major basic glass manufacturers.<br />

• Supported by a comprehensive technical advisory service to give guidance on optimum use of the<br />

products.<br />

• Can be used in ThermoSpan, ThermoCool <strong>and</strong> Tempo product ranges.<br />

• For additional safety characteristics, available in cast-in-place <strong>and</strong> pvb laminated versions.<br />

• High visual clarity.<br />

• Kite marked products.<br />

Product Description<br />

Fort <strong>and</strong> FortPlus are manufactured by heating to around 620 o C <strong>and</strong> quenching rapidly to create high<br />

compressive stresses at the surfaces with balancing tensile stresses in the centre. This makes Fort <strong>and</strong><br />

FortPlus four to five times stronger than ordinary glass of the same thickness, <strong>and</strong> they break safely,<br />

conforming to the requirements of BS 6206 Class A.<br />

Their increased strength makes Fort <strong>and</strong> FortPlus<br />

suitable for many structural applications including<br />

balustrade panels, full height glazed partitions <strong>and</strong><br />

ThermoSpan structural glazing.<br />

Fort <strong>and</strong> FortPlus heat soaked toughened glass<br />

are available for use in ThermoSpan structural<br />

glazing <strong>and</strong> where otherwise specified.<br />

FortPlus is used in Tempo frameless glass door<br />

assemblies. St<strong>and</strong>ard door blanks <strong>and</strong> fully fitted<br />

assemblies are available utilising Dorma Glass, Geze<br />

Glass Design <strong>and</strong> door fittings from other major<br />

manufacturers.<br />

3

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Heat soaked toughened glass is used to minimise the risk of spontaneous breakage due to nickel sulphide (NiS)<br />

inclusions, which occur naturally in glass.<br />

It is recommended that Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> heat soaked toughened glass are used in<br />

overhead glazing <strong>and</strong> balustrade panels.<br />

FortPlus <strong>Laminated</strong> is available with cast-in-place<br />

(CIP) interlayer or pvb interlayer. The CIP interlayer<br />

uses a chemically cured polyester resin poured<br />

between two or more panes of glass spaced apart <strong>and</strong><br />

sealed around the edge with a double-sided tape.<br />

FortPlus <strong>Laminated</strong> made with pvb is limited to 3<br />

plies (2 panes of glass with one interlayer) <strong>and</strong> using<br />

panes of FortPlus no more than 12mm thick.<br />

Through heat <strong>and</strong> pressure the pvb sheet bonds the<br />

glasses together.<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> are<br />

available with Ceraphic translucent screen printed<br />

enamel - a range of decorative glasses incorporating<br />

solar control <strong>and</strong> glare reduction properties. Cerocco<br />

s<strong>and</strong>blasting is also available. These two decorative<br />

processes are an ideal way to provide privacy, diffuse<br />

lighting, manifestation, corporate logos, messages<br />

etc.<br />

CeraGrit is a process that gives enhanced non-slip<br />

characteristics <strong>and</strong> is ideal for floor panels <strong>and</strong> stair<br />

treads. When utilised in laminate construction for<br />

stair treads <strong>and</strong> l<strong>and</strong>ing panels the lower panel can be<br />

screen printed or s<strong>and</strong>blasted for additional modesty.<br />

Maximum sizes:<br />

Ceraphic TM<br />

Cerocco<br />

4600mm x 2440mm<br />

3000mm x 2250mm<br />

These two processes can be applied to any clear or<br />

tinted float glass <strong>and</strong> selected patterned glasses.<br />

With Ceraphic, non-st<strong>and</strong>ard single colours can be<br />

provided, although a minimum quantity of ceramic<br />

ink will be required. Other designs <strong>and</strong> cover<br />

percentages, up to 100% <strong>and</strong> graduated cover, can be produced. With both processes specific, decorative <strong>and</strong><br />

corporate designs can be produced from appropriate drawings or artwork. Enquiries should be submitted for<br />

review.<br />

4

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Ceraphic st<strong>and</strong>ard images<br />

Micropoint 4 - 4 mm white points in a 5 spot pattern at 6.4 mm centres giving<br />

31% cover.<br />

Micropoint 6 - 6 mm white points in a 5 spot pattern at 8.5 mm centres giving<br />

39% cover.<br />

Micropoint Contour 4 - 4 mm clear points in a 5 spot pattern at 6.4 mm<br />

centres on a white background giving 69% cover.<br />

Micropoint Contour 6 - 6 mm clear points in a 5 spot pattern at 8.5 mm<br />

centres on a white background giving 61% cover.<br />

Microline 5/5 <strong>and</strong> Microline 10/10 - 5 mm white lines with 5 mm gaps or 10 mm<br />

white lines with 10 mm gaps, both giving 50% cover.<br />

Microline 10/5 <strong>and</strong> Microline 5/10 - 10 mm white lines with 5 mm clear lines<br />

giving 67% cover or 5 mm white lines with 10 mm clear lines giving 33% cover.<br />

Ceraphic <strong>and</strong> Cerocco can be used to resolve manifestation concerns in relation to Safety St<strong>and</strong>ards <strong>and</strong><br />

Building Regulations.<br />

Product Performance<br />

Heat soaked toughened glass<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> are available as heat soaked thermally toughened glass. The heat<br />

soaking processes are: -<br />

• prEN 14179 where the glass temperature at all points is held for a minimum of 2 hours at 290 ± 10 o C,<br />

designed to reduce the incidence of inclusion breakages to less than 1 in 400 tonnes of glass<br />

• DIN 18516-4 where the oven air temperature is held for 8 hours at 290 ± 10 o C, designed to reduce the<br />

incidence of inclusion breakages to less than 1 in 400 tonnes of glass<br />

5

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Technical Description<br />

Normal Dimension Limits<br />

Fort<br />

4mm maximum size<br />

2500mm x 1500mm<br />

5mm maximum size<br />

3100mm x 1900mm<br />

6mm maximum size<br />

4000mm x 2400mm<br />

Minimum size<br />

450mm x 350mm<br />

Aspect ratio: 4 & 5mm maximum 8:1<br />

6mm maximum 12:1<br />

FortPlus<br />

8mm to 15mm maximum size 4600mm x 2440mm<br />

19mm maximum size<br />

10.5m 2 (up to 4600mm long or 2440mm wide)<br />

25mm maximum size<br />

8m 2 (up to 4000mm long or 2440mm wide)<br />

Minimum size<br />

450mm x 350mm<br />

Aspect ratio 8mm maximum 12:1<br />

≥10mm maximum 20:1<br />

FortPlus <strong>Laminated</strong><br />

Maximum size<br />

Minimum size<br />

Aspect ratio<br />

Tolerance on dimensions<br />

4600mm x 2440mm<br />

450mm x 350mm<br />

Dependent on constituent Fort or FortPlus glass<br />

Safety Class A to BS 6206<br />

Fort or FortPlus<br />

up to 1m<br />

over 1m<br />

diagonal difference<br />

FortPlus <strong>Laminated</strong><br />

up to 1m<br />

over 1m <strong>and</strong> up to 3m<br />

over 3m<br />

diagonal difference<br />

edge step<br />

Drilled hole sizes<br />

Minimum diameter<br />

Maximum diameter<br />

± 1mm<br />

± 2mm<br />

≤4mm<br />

± 1.5mm<br />

± 2.5mm<br />

± 3mm<br />

≤4mm<br />

≤4mm<br />

thickness of glass<br />

50mm<br />

Tolerance on drilled holes<br />

Diameter<br />

± 1mm<br />

Position relative to datum<br />

± 2mm<br />

FortPlus <strong>Laminated</strong> misalignment ≤3mm<br />

Tolerance on notches <strong>and</strong> cutouts<br />

Dimensions<br />

± 2mm<br />

Position relative to datum<br />

± 2mm<br />

FortPlus <strong>Laminated</strong> misalignment ≤4mm<br />

Thickness tolerance<br />

Fort <strong>and</strong> FortPlus as BS EN 572<br />

FortPlus <strong>Laminated</strong> sum of component glass<br />

thickness plus 0.5mm per<br />

interlayer<br />

Thermal Insulation<br />

Depending on construction<br />

U value<br />

5.3 - 5.6 W/m 2 K<br />

Sound Reduction<br />

Depending on construction R W C tr<br />

Fort 4mm 29 -3<br />

Fort 6mm 31 -3<br />

FortPlus 10mm 33 -3<br />

FortPlus 12mm 34 -2<br />

FortPlus <strong>Laminated</strong> 13.5mm 37 -3<br />

FortPlus <strong>Laminated</strong> 19.5mm 39 -3<br />

Distortion limits<br />

Bow<br />

2mm/m length<br />

Roller wave <strong>and</strong> edge dip:<br />

Fort 4mm 5mm 6mm<br />

Roller wave 0.3mm 0.2mm 0.15mm<br />

Edge dip 0.5mm 0.3mm 0.25mm<br />

FortPlus<br />

8-10mm ≥12mm<br />

Roller wave 0.10mm 0.05mm<br />

Edge dip 0.25mm 0.25mm<br />

Weight<br />

Maximum weight<br />

Fort or FortPlus<br />

FortPlus <strong>Laminated</strong><br />

2.5kg/m 2 for every mm<br />

thickness of glass<br />

500kg<br />

1000kg<br />

Strength <strong>and</strong> Deflection<br />

Allowable stress 59 N/mm 2<br />

Allowable glass deflection L/65 at design load<br />

Solar <strong>and</strong> Optical Performance<br />

Depending on construction:<br />

Light transmission 89% to 5%<br />

Solar direct energy 82% to 6%<br />

Total solar energy 85% to 29%<br />

6

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Processing<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> must not be cut or worked after manufacture.<br />

Four types of edgework <strong>and</strong> many configurations of holes, cutouts <strong>and</strong> notches can be provided.<br />

belt or wheel finish<br />

as cut<br />

The arrissed edge is the simplest type of edgework <strong>and</strong><br />

consists of removing the sharp edges from as cut glass.<br />

flat ground<br />

Ground edges give a flat profile with a smooth arriss,<br />

both of which may have un-ground areas.<br />

flat ground<br />

Smooth edges give a flat profile with a smooth arriss.<br />

polished<br />

Polishing further refines the edge appearance.<br />

FortPlus <strong>Laminated</strong> has ground, smooth or polished<br />

edges.<br />

All glass thicknesses from 4mm to 25mm can be drilled. The diameter of the holes should be not less than<br />

10mm <strong>and</strong> not less than the thickness of the glass up to a maximum of 50mm. Holes should not be<br />

positioned too close to a corner, to an edge or to each other, in accordance with the minimum distances<br />

shown in figure 1.<br />

The tolerance on hole diameter is ± 1mm <strong>and</strong> the positional tolerance is ± 2mm in relation to the datum.<br />

t = glass thickness<br />

2t<br />

> 2.5t<br />

x > 2t<br />

4t<br />

no holes<br />

in this area<br />

2t<br />

x + y > 6t<br />

y > 2t<br />

Figure 1. Hole positioning<br />

Where there are complex configurations, e.g. more than eight holes in a pane, or more than two holes in close<br />

proximity, or non-rectangular corners, enquiries should be submitted.<br />

7

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

a<br />

B<br />

L<br />

z<br />

x<br />

X<br />

Many configurations of cutouts <strong>and</strong> notches can be supplied,<br />

but enquiries must be submitted. Guidance on limiting sizes<br />

<strong>and</strong> positions is given in the diagram.<br />

B ≤ a/3; L ≤ b/3<br />

D ≤ a/3; D ≤ b/3<br />

X ≥ L/2; x ≥ L/2<br />

X ≥ B/2; x ≥ B/2<br />

Y ≥ D/2 y ≥ D/2<br />

z ≥ B/2 z ≥ D/2<br />

z ≥ L/2<br />

Y<br />

D<br />

y<br />

b<br />

Figure 2. Cutout sizes <strong>and</strong> positions<br />

Re-entrant or internal corners must have a minimum<br />

radius of 10mm <strong>and</strong> not less than the glass thickness.<br />

radius (minimum 10 mm) not less<br />

than glass thickness<br />

Figure 3. Re-entrant <strong>and</strong> internal corners<br />

St<strong>and</strong>ard door blanks can be manufactured.<br />

The tolerance on dimensions <strong>and</strong> hole positions may be higher for complex shapes.<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> can be<br />

manufactured in various geometric or irregular<br />

shapes, based on the supply of<br />

• appropriate computer files; or<br />

• accurate scale drawings; or<br />

• rigid templates – no greater in overall thickness<br />

than 12mm <strong>and</strong> no larger than 1500 x 3000mm<br />

8

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Strength<br />

For normal purposes, the allowable stress of Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> is: -<br />

Short duration loads 59 N/mm 2<br />

Long duration loads 35 N/mm 2<br />

Higher stresses may be allowed in specific designs, e.g. ThermoSpan.<br />

Appearance<br />

The appearance of Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> depends upon the type of glass, the colour <strong>and</strong><br />

the thickness of the glass.<br />

During the toughening process, the heat treatment can produce an overall warp, called bow.<br />

The limit on bow for Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> is 2mm/m length (0.2%).<br />

While the hot glass is in contact with the rollers during the toughening process, a distortion known as ‘roller wave’<br />

is produced, which may be slightly exaggerated (edge dip) at the end of the pane. Roller wave is generally noticed<br />

in reflection.<br />

Table 1 Roller wave <strong>and</strong> edge dip limits<br />

Roller wave Edge dip<br />

Fort 4mm 0.3mm 0.5mm<br />

Fort 5mm 0.2mm 0.3mm<br />

Fort 6mm 0.15mm 0.25mm<br />

FortPlus 8mm <strong>and</strong> 0.10mm 0.25mm<br />

10mm<br />

FortPlus ≥ 12mm 0.05mm 0.25mm<br />

Glass which is thicker than 8mm may show signs of small imprints in the surface (‘roller pick-up’).<br />

The toughening process produces areas of different stress<br />

in the cross section of the glass. These areas of stress<br />

produce a birefringent effect in the glass, which is visible<br />

in polarised light. When toughened glass is viewed in<br />

polarised light, the areas of stress show up as coloured<br />

zones, sometimes known as ‘iridescence’ or ‘leopard<br />

spots’. Polarised light occurs in normal daylight. The<br />

amount of polarised light depends on the weather <strong>and</strong><br />

the angle of the sun. The birefringent effect is more<br />

noticeable either at a glancing angle or through polarised<br />

spectacles.<br />

In FortPlus TM <strong>Laminated</strong> with a cast-in-place interlayer,<br />

although the edge tape is clear, the refractive index of<br />

the tape differs to that of the glass <strong>and</strong> a line appears<br />

at the interface of the two materials. Under some<br />

lighting conditions the line may display a pale blue<br />

interference effect.<br />

FortPlus <strong>Laminated</strong> may have small air bubbles<br />

around holes, cut outs <strong>and</strong> the perimeter where the<br />

resin joins the edge tape, these should be no larger in<br />

size than 1.5mm diameter. A pvb interlayer will also<br />

show similar characteristics.<br />

9

BS 6206 A T<br />

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Safety<br />

All Fort <strong>and</strong> FortPlus break safely <strong>and</strong> conform to Class A of BS 6206. Fort <strong>and</strong> FortPlus are identified<br />

<strong>and</strong> marked as:<br />

BS 6206 A T<br />

T<br />

F O R<br />

F O R<br />

T<br />

P<br />

S<br />

L U<br />

THERMOSPANBS 6206 A T<br />

Fort<br />

FortPlus<br />

Fort or FortPlus<br />

used in ThermoSpan<br />

Sound Reduction<br />

Table 2 gives examples of sound reduction figures.<br />

Thermal durability<br />

Fort <strong>and</strong> FortPlus<br />

Table 2 Sound reduction values<br />

B<strong>and</strong> centre<br />

Sound reduction (dB) for glass thickness<br />

frequency Fort FortPlus FortPlus<br />

<strong>Laminated</strong><br />

(Hz) 4mm 6mm 10mm 12mm 13.5mm 19.5mm<br />

100 17 16 24 24 25 24<br />

125 18 19 21 29 28 28<br />

160 16 20 25 31 27 25<br />

200 19 22 23 28 27 30<br />

250 20 24 28 29 31 34<br />

315 22 25 28 31 31 35<br />

400 25 28 31 29 33 36<br />

500 27 30 33 33 35 37<br />

630 28 32 34 32 37 35<br />

800 30 34 33 31 37 34<br />

1000 32 35 31 32 36 36<br />

1250 33 35 29 32 35 38<br />

1600 34 32 30 36 37 41<br />

2000 34 26 33 39 41 43<br />

2500 31 27 36 42 44 45<br />

3150 24 30 37 45 47 49<br />

4000 26 33 40 47 50 53<br />

R W 29 31 33 34 37 39<br />

C -2 -2 -2 0 -1 -1<br />

C tr -3 -3 -3 -2 -3 -3<br />

The mechanical properties of Fort <strong>and</strong> FortPlus are unchanged for continuous service up to 250 o C <strong>and</strong> are<br />

unaffected by sub-zero temperatures. They are capable of resisting both sudden temperature changes <strong>and</strong><br />

temperature differentials up to 200 K.<br />

FortPlus <strong>Laminated</strong><br />

The maximum working temperature is 100 o C for CIP interlayers <strong>and</strong> 70 o C for pvb interlayers.<br />

10

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Applications<br />

Safety – Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> are ideal for use in the critical locations described in<br />

BS 6262: Part 4 <strong>and</strong> in Building Regulations.<br />

300 mm<br />

800 mm<br />

1500 mm<br />

Critical Locations for Safety Glass<br />

Partitions – because of their safety characteristics <strong>and</strong><br />

strength, Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> are<br />

suitable for use in internal partitions up to the size limits<br />

given in Table 3. The sizes in Table 3 are for partitions,<br />

which are not protecting a drop. Where partitions are<br />

also acting as barriers, the size limits are given in Table<br />

6.<br />

Table 3 Partition Size Limits<br />

4 edge glazed<br />

maximum area<br />

2 edge glazed<br />

maximum span<br />

Fort<br />

4 mm 2m 2 N/A<br />

5 mm 3m 2 N/A<br />

6 mm 4m 2 1.5m<br />

FortPlus<br />

8 mm 6m 2 2.0m<br />

10 mm no limit 2.6m<br />

12 mm no limit 3.2m<br />

≥ 15 mm no limit no limit<br />

FortPlus<br />

Laminate<br />

13.5mm no limit 3.2m<br />

≥ 17.5mm no limit no limit<br />

Barriers <strong>and</strong> guarding – Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> can provide effective barriers complying<br />

with BS 6180 <strong>and</strong> Building Regulations.<br />

Free st<strong>and</strong>ing barriers - Table 4 indicates the thicknesses of FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> generally<br />

appropriate for free-st<strong>and</strong>ing glass barriers. The thickness may alter if the top edge of the clamping detail is<br />

significantly above or below the floor level.<br />

11

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

BS 6399 Part 1<br />

Line Load<br />

Table 4 Free st<strong>and</strong>ing glass barriers<br />

FortPlus<br />

Thickness<br />

FortPlus<br />

<strong>Laminated</strong><br />

Thickness<br />

0.36 kN/m 12mm 13.5mm<br />

0.74 kN/m 15mm 17.5mm<br />

1.5 kN/m 19mm 21.5mm<br />

3.0 kN/m 25mm 25.5mm<br />

Barrier infill panels - Infill panels for barriers can be<br />

supplied for attaching through drilled holes to the<br />

balusters. Table 5 gives the maximum spans for<br />

Fort <strong>and</strong> FortPlus bolted infill panels. It is<br />

suggested that panels should be limited to less than<br />

2000mm, even though longer panels may be<br />

technically within the requirements.<br />

Table 5 Span of infill panels<br />

Infill loading from Span limit (mm) for bolt fixed panes with widths greater than 700mm<br />

BS 6399 Part 1 Fort FortPlus FortPlus <strong>Laminated</strong><br />

UDL Point Load 6mm* 8mm* 10mm 12mm 15mm 11.5mm 13.5mm 17.5mm<br />

(kN/m 2 ) (kN)<br />

0.5 0.25 1400 1800 2150 2450 2900 2100 2400 3000<br />

1.0 0.5 900 1500 1800 2050 2450 1750 2050 2500<br />

1.5 1.5 N/A N/A 1200 1650 2050 1150 1600 2150<br />

* 6mm Fort <strong>and</strong> 8mm FortPlus will not be suitable if the free path perpendicular to the barrier is larger than 1.5m,<br />

since they will not give containment (i.e. remain intact) at Class A of BS 6206.<br />

Full height barriers - In addition to their use in conventional barriers, Fort, FortPlus <strong>and</strong> FortPlus<br />

<strong>Laminated</strong> are suitable for full height barriers, i.e. in fully glazed walls above ground floor or overlooking atria,<br />

as described in BS 6180. Table 6 gives glass areas, which can be used for any type of 4 edge supported<br />

glazing. Larger areas or thinner glass may be used depending on the precise dimensions <strong>and</strong> position of the<br />

glass <strong>and</strong> whether it has additional support by being part of a ThermoCool insulating glass unit. Thicker<br />

glass or smaller sizes may be necessary with 2 edge or bolt fixed glazing systems such as ThermoSpan.<br />

12

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Table 6 Full height barriers<br />

Building use<br />

Domestic<br />

Commercial,<br />

excluding<br />

shops etc. or<br />

places of<br />

assembly<br />

Shops <strong>and</strong><br />

similar usage<br />

Fort, FortPlus or<br />

FortPlus <strong>Laminated</strong><br />

thickness<br />

Area limit m 2<br />

6mm Fort 3.8<br />

8mm FortPlus 6.0<br />

≥ 10mm FortPlus<br />

≥ 11.5mm FortPlus<br />

<strong>Laminated</strong><br />

no limit<br />

6mm Fort 2.4<br />

8mm FortPlus 4.3<br />

10mm FortPlus<br />

11.5mm FortPlus<br />

<strong>Laminated</strong><br />

≥ 12mm FortPlus<br />

≥ 13.5mm FortPlus<br />

<strong>Laminated</strong><br />

6mm Fort<br />

6.0<br />

no limit<br />

N/A<br />

8mm FortPlus 1.8<br />

10mm FortPlus<br />

11.5mm FortPlus<br />

<strong>Laminated</strong><br />

12mm FortPlus<br />

13.5mm FortPlus<br />

<strong>Laminated</strong><br />

≥ 15mm FortPlus<br />

≥ 17.5mm FortPlus<br />

<strong>Laminated</strong><br />

4.2<br />

6.2<br />

no limit<br />

Playing courts - The safety characteristics, strength <strong>and</strong> robustness<br />

of Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> make them ideal for<br />

the viewing walls of courts for squash, pelota <strong>and</strong> trinquette, as<br />

well as any other viewing windows for gymnasia <strong>and</strong> sports halls.<br />

PROSPEC SQUASH COURT??<br />

Shop fronts – Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> can be<br />

used to create shop-front designs to give an impression of space<br />

<strong>and</strong> light. They can be used as simple shop windows or in<br />

conjunction with Tempo doors or as frameless systems supported<br />

by FortPlus fins.<br />

Fins - FortPlus fins are not restricted to shop-fronts, but can be<br />

used to stiffen any frameless glazing. Table 7 shows the thickness<br />

<strong>and</strong> depth of FortPlus fins to span various floor to ceiling heights<br />

when fitted into suitable fin boxes. FortPlus <strong>Laminated</strong> fins are<br />

also available.<br />

13

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Height<br />

of fin<br />

(m)<br />

Table 7 Fin dimensions<br />

Design wind load (N/m 2 )<br />

1000 1250 1500 1750 2000<br />

FortPlus fin thickness (mm)/depth (mm)<br />

2 15/100 15/100 15/110 15/120 15/120<br />

2.5 15/125 15/125 15/130 15/140 15/150<br />

3 15/150 15/150 15/160 15/170 15/180<br />

3.5 15/175 15/175 15/180 15/200 19/190<br />

4 15/200 15/200 19/200 19/200 25/200<br />

Floor panels <strong>and</strong> stair treads – Table 8 indicates<br />

FortPlus Laminate thicknesses for floor, stair l<strong>and</strong>ings<br />

<strong>and</strong> stair treads. As strength <strong>and</strong> safety are the main<br />

characteristics of FortPlus <strong>Laminated</strong> <strong>and</strong> when coupled<br />

with <strong>Hansen</strong>Glass’ CeraGrit product for enhanced slip<br />

resistance, it becomes the ideal product to specify for<br />

walking on.<br />

14

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

Table 8 Typical floor pane thicknesses<br />

Typical<br />

Loads Size of floor<br />

Possible glass type <strong>and</strong> thickness<br />

Application from BS 6399-1 panes 4 edge supported floor<br />

panes<br />

2 shorter edges only<br />

supported floor panes<br />

udl point mm x mm annealed FortPlus FortPlus <strong>Laminated</strong><br />

kN/m 2 kN<br />

laminated <strong>Laminated</strong><br />

Domestic 1.5 1.4 30.5mm 27mm 33mm<br />

Restaurants 2.0 2.7 1000 x 600 35.5mm 27mm 39mm<br />

Offices 2.5 2.7 35.5mm 27mm 39mm<br />

Dance Halls 5.0 3.6<br />

36.5mm 39mm 60mm<br />

Stairs 5.0 4.5 1000 x 300 36.5mm 33mm 78mm<br />

Notes. The above types <strong>and</strong> thicknesses of glass are given as examples only. The glass type <strong>and</strong> thickness<br />

will vary with the size of the pane. In some cases, smaller panes will need thicker glass to resist the<br />

point load. Each case should be checked.<br />

Floor Glazing<br />

The principles of glazing FortPlus <strong>Laminated</strong> floor panes are shown in Figure 5.<br />

Curing<br />

Sealant<br />

10mm to 25mm heat soaked<br />

FortPlus, depending on load<br />

<strong>and</strong> size. All glass to have flat<br />

ground <strong>and</strong> arrissed edges.<br />

Structure<br />

25mm<br />

Silicone<br />

Sealant<br />

Rubber strip 3-5mm thick,<br />

similar in hardness to an<br />

ink eraser<br />

Minimum<br />

bearing<br />

Rubber strip 3-5mm thick similar<br />

in hardness to an ink eraser<br />

50mm Minimum<br />

T, box or solid bar<br />

support<br />

Figure 5. Principles of glazing floor panes<br />

When a floor pane is also required to give thermal insulation, it can be combined into a ThermoCool<br />

insulating glass unit. However, the seal <strong>and</strong> spacer are not capable of sustaining the floor loads in regular use.<br />

It is sensible to step the unit as shown in figure 6, so that all the floor loads are transmitted directly from the<br />

loaded pane to the structure <strong>and</strong> floor loads are not transmitted through the unit seal.<br />

All floor loads taken through<br />

this bearing surface<br />

Glass designed for<br />

walking on<br />

Structure<br />

Soft glazing<br />

material<br />

Structure<br />

Second pane<br />

Figure 6. Principles of floor glazing using ThermoCool insulating glass units<br />

15

hansen glass processors<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> toughened glass - For Safety <strong>and</strong> Strength<br />

H<strong>and</strong>ling <strong>and</strong> Storage<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> should be h<strong>and</strong>led with<br />

great care at all times.<br />

• Stack upright, fully support<br />

at the back<br />

• St<strong>and</strong> on wood or felt<br />

• Store dry at all times<br />

• Store out of sunlight at all<br />

times<br />

• Check for damage<br />

• H<strong>and</strong>le correctly<br />

• Protect from impact<br />

• Avoid contamination<br />

Correctly stacking <strong>and</strong> supporting Fort, FortPlus <strong>and</strong> FortPlus<br />

<strong>Laminated</strong>, in a manner which prevents the glass from sagging, helps<br />

to avoid breakages. To prevent edge damage, the glass must st<strong>and</strong><br />

on strips of material softer than glass, such as wood, rubber or felt.<br />

Water must not be allowed to reach the edges of stacked glass as it<br />

can be drawn between the glass by capillary action <strong>and</strong> cause<br />

damage to the glass surfaces.<br />

Glass should be unpacked on arrival at site <strong>and</strong> checked for<br />

conformity to specification. Any damage should be reported<br />

immediately.<br />

Use protective clothing <strong>and</strong> equipment (a minimum of gloves, safety<br />

shoes <strong>and</strong> safety glasses). Lift Fort, FortPlus <strong>and</strong> FortPlus<br />

<strong>Laminated</strong> in a safe manner using appropriate equipment.<br />

Special care must be taken to protect Fort, FortPlus <strong>and</strong><br />

FortPlus <strong>Laminated</strong>, especially the edges from impact damage<br />

(knocks, abrasions <strong>and</strong> excessive local pressure) which can cause<br />

breakage, scratches, scars, chips or shells.<br />

Before use, the glass should again be checked for damage <strong>and</strong> the<br />

size checked with the frame to ensure that the glazing can be carried<br />

out as specified. Damaged glass should not be glazed.<br />

Fort, FortPlus <strong>and</strong> FortPlus <strong>Laminated</strong> must be protected from<br />

site contamination such as welding spatter, or cementitious or<br />

plaster products, or adhesives.<br />

Glazing<br />

The requirements of BS 6262 <strong>and</strong> BS 8000: Part 7 should be considered.<br />

This publication gives a general description of Fort, FortPlus <strong>and</strong> FortPlus Laminate. It is the responsibility of the customer to ensure that its use is appropriate for the<br />

application <strong>and</strong> complies with all relevant national <strong>and</strong> local legislation, st<strong>and</strong>ards <strong>and</strong> codes of practice <strong>and</strong> any other requirements.<br />

<strong>Hansen</strong> Glass Processing Limited hereby disclaim all liability howsoever arising from any error or omission from this publication <strong>and</strong> of all consequences of relying on it.<br />

Fort, FortPlus, FortPlus <strong>Laminated</strong>, ThermoSpan, ThermoCool, Tempo, Ceramalite, CeramalitePlus, Ceraphic, <strong>and</strong> CeraGrit are all trade marks of <strong>Hansen</strong> Glass<br />

Processing Ltd.<br />

16

hansen glass processors<br />

Product Range<br />

• ThermoSpan Structural<br />

Glazing<br />

• Fort <strong>and</strong> FortPlus Toughened Glass<br />

• Tempo Toughened Glass Doors<br />

<strong>and</strong> Entrance Assemblies<br />

• Thermocool Insulating Glass Units<br />

• Ceramalite Enamelled Sp<strong>and</strong>rel Panels<br />

• Ceraphic Screen Printed Glass<br />

Services<br />

• Glass Processing<br />

• Contract Co-ordination<br />

• Site Deliveries<br />

• ThermoSpan Detailing<br />

• Technical Support<br />

• After Sales Support<br />

Market Sectors<br />

• Commercial<br />

• Leisure<br />

• Community <strong>and</strong> Amenity<br />

• Retail<br />

• Industrial<br />

• Transportation<br />

• Utilities<br />

• Manufacturing<br />

• Institutions<br />

• Military<br />

Technical Services<br />

• Glass Stress Calculations<br />

• Thermal Stress Calculations<br />

• Glass Environmental Properties<br />

• Glass Acoustics Advice<br />

Technical Advisory Service (TAS) available at all <strong>Group</strong> Companies<br />

<strong>Hansen</strong><strong>Group</strong> Mission:<br />

To be the Company in the industry above all others<br />

• from whom our customers choose to buy<br />

• with whom people choose a career<br />

• in whom the professionals have confidence<br />

• whom manufacturers choose to distribute their product.<br />

<strong>Hansen</strong>Glass<br />

Hornhouse Lane<br />

Kirkby<br />

Merseyside<br />

United Kingdom<br />

Tel: (44) 0151 545 3000<br />

Fax: (44) 0151 545 3003<br />

Email: sales@hansenglass.co.uk<br />

<strong>Hansen</strong><strong>Group</strong><br />

Greengate Industrial Park<br />

Greenside Way<br />

Middleton M24 1SW<br />

United Kingdom<br />

Tel: (44) 0161 653 3030<br />

Fax: (44) 0191 653 3031<br />

Email : info@hansengroup.biz