Performance Apparel Markets - Grado Zero Espace Srl

Performance Apparel Markets - Grado Zero Espace Srl

Performance Apparel Markets - Grado Zero Espace Srl

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

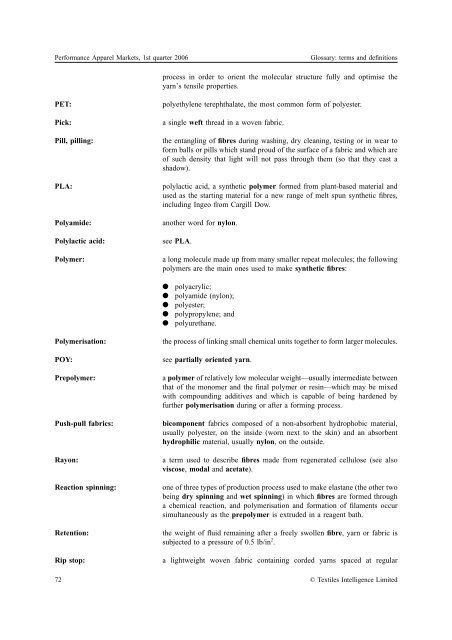

<strong>Performance</strong> <strong>Apparel</strong> <strong>Markets</strong>, 1st quarter 2006<br />

Glossary: terms and definitions<br />

process in order to orient the molecular structure fully and optimise the<br />

yarn’s tensile properties.<br />

PET:<br />

Pick:<br />

Pill, pilling:<br />

PLA:<br />

Polyamide:<br />

Polylactic acid:<br />

Polymer:<br />

polyethylene terephthalate, the most common form of polyester.<br />

a single weft thread in a woven fabric.<br />

the entangling of fibres during washing, dry cleaning, testing or in wear to<br />

form balls or pills which stand proud of the surface of a fabric and which are<br />

of such density that light will not pass through them (so that they cast a<br />

shadow).<br />

polylactic acid, a synthetic polymer formed from plant-based material and<br />

used as the starting material for a new range of melt spun synthetic fibres,<br />

including Ingeo from Cargill Dow.<br />

another word for nylon.<br />

see PLA.<br />

a long molecule made up from many smaller repeat molecules; the following<br />

polymers are the main ones used to make synthetic fibres:<br />

●<br />

●<br />

●<br />

●<br />

●<br />

polyacrylic;<br />

polyamide (nylon);<br />

polyester;<br />

polypropylene; and<br />

polyurethane.<br />

Polymerisation:<br />

POY:<br />

Prepolymer:<br />

Push-pull fabrics:<br />

Rayon:<br />

Reaction spinning:<br />

Retention:<br />

Rip stop:<br />

the process of linking small chemical units together to form larger molecules.<br />

see partially oriented yarn.<br />

a polymer of relatively low molecular weight—usually intermediate between<br />

that of the monomer and the final polymer or resin—which may be mixed<br />

with compounding additives and which is capable of being hardened by<br />

further polymerisation during or after a forming process.<br />

bicomponent fabrics composed of a non-absorbent hydrophobic material,<br />

usually polyester, on the inside (worn next to the skin) and an absorbent<br />

hydrophilic material, usually nylon, on the outside.<br />

a term used to describe fibres made from regenerated cellulose (see also<br />

viscose, modal and acetate).<br />

one of three types of production process used to make elastane (the other two<br />

being dry spinning and wet spinning) in which fibres are formed through<br />

a chemical reaction, and polymerisation and formation of filaments occur<br />

simultaneously as the prepolymer is extruded in a reagent bath.<br />

the weight of fluid remaining after a freely swollen fibre, yarn or fabric is<br />

subjected to a pressure of 0.5 lb/in 2 .<br />

a lightweight woven fabric containing corded yarns spaced at regular<br />

72 © Textiles Intelligence Limited