Performance Apparel Markets - Grado Zero Espace Srl

Performance Apparel Markets - Grado Zero Espace Srl

Performance Apparel Markets - Grado Zero Espace Srl

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

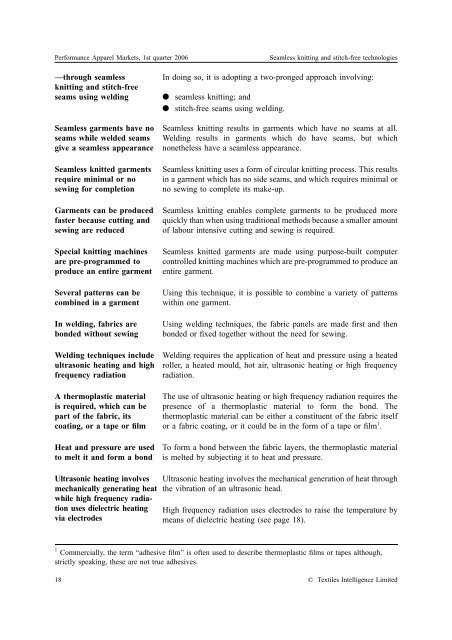

<strong>Performance</strong> <strong>Apparel</strong> <strong>Markets</strong>, 1st quarter 2006<br />

Seamless knitting and stitch-free technologies<br />

—through seamless<br />

knitting and stitch-free<br />

seams using welding<br />

Seamless garments have no<br />

seams while welded seams<br />

give a seamless appearance<br />

Seamless knitted garments<br />

require minimal or no<br />

sewing for completion<br />

Garments can be produced<br />

faster because cutting and<br />

sewing are reduced<br />

Special knitting machines<br />

are pre-programmed to<br />

produce an entire garment<br />

Several patterns can be<br />

combined in a garment<br />

In welding, fabrics are<br />

bonded without sewing<br />

Welding techniques include<br />

ultrasonic heating and high<br />

frequency radiation<br />

A thermoplastic material<br />

is required, which can be<br />

part of the fabric, its<br />

coating, or a tape or film<br />

Heat and pressure are used<br />

to melt it and form a bond<br />

In doing so, it is adopting a two-pronged approach involving:<br />

● seamless knitting; and<br />

● stitch-free seams using welding.<br />

Seamless knitting results in garments which have no seams at all.<br />

Welding results in garments which do have seams, but which<br />

nonetheless have a seamless appearance.<br />

Seamless knitting uses a form of circular knitting process. This results<br />

in a garment which has no side seams, and which requires minimal or<br />

no sewing to complete its make-up.<br />

Seamless knitting enables complete garments to be produced more<br />

quickly than when using traditional methods because a smaller amount<br />

of labour intensive cutting and sewing is required.<br />

Seamless knitted garments are made using purpose-built computer<br />

controlled knitting machines which are pre-programmed to produce an<br />

entire garment.<br />

Using this technique, it is possible to combine a variety of patterns<br />

within one garment.<br />

Using welding techniques, the fabric panels are made first and then<br />

bonded or fixed together without the need for sewing.<br />

Welding requires the application of heat and pressure using a heated<br />

roller, a heated mould, hot air, ultrasonic heating or high frequency<br />

radiation.<br />

The use of ultrasonic heating or high frequency radiation requires the<br />

presence of a thermoplastic material to form the bond. The<br />

thermoplastic material can be either a constituent of the fabric itself<br />

or a fabric coating, or it could be in the form of a tape or film 1 .<br />

To form a bond between the fabric layers, the thermoplastic material<br />

is melted by subjecting it to heat and pressure.<br />

Ultrasonic heating involves<br />

mechanically generating heat<br />

while high frequency radiation<br />

uses dielectric heating<br />

via electrodes<br />

Ultrasonic heating involves the mechanical generation of heat through<br />

the vibration of an ultrasonic head.<br />

High frequency radiation uses electrodes to raise the temperature by<br />

means of dielectric heating (see page 18).<br />

1 Commercially, the term “adhesive film” is often used to describe thermoplastic films or tapes although,<br />

strictly speaking, these are not true adhesives.<br />

18 © Textiles Intelligence Limited