Kap 2.3-5V_120704_us..

Kap 2.3-5V_120704_us..

Kap 2.3-5V_120704_us..

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Hot Runner Nozzles<br />

5 V<br />

Chart for 5 V Hot Runner Nozzles<br />

Application Type Reference Cat. page<br />

Single nozzles<br />

E<br />

SER<br />

DER<br />

2.51<br />

Nozzles<br />

H<br />

SHR<br />

DHR<br />

2.53<br />

Example of nozzle specification on the reverse of this page.<br />

10/03<br />

Subject to technical changes.<br />

<strong>2.3</strong> _ <strong>5V</strong>-a

Hot Runner Nozzles<br />

5 V<br />

Example of a 5 V nozzle designation<br />

Order code:<br />

5 S H R 50 W H<br />

S<br />

S = Special construction<br />

(EVN-Code)<br />

Material tube<br />

diameter<br />

(depending on<br />

article weight +<br />

material)<br />

(see chapter 2)<br />

Nozzle<br />

with tip =<br />

Open<br />

Nozzle =<br />

S<br />

D<br />

W = Optimized temperature profile<br />

(with reduced material tube diameter<br />

for very small shot weights (0.05...2 g)<br />

in conjunction with thermally senitive<br />

material)<br />

Length of the nozzle (Measurement L)<br />

Operating voltage R = 5 V<br />

H =hard metal tip<br />

A = Type C only for open nozzle<br />

C = Type C only for open nozzle<br />

Type of nozzle<br />

E = Single nozzles<br />

H = Nozzles in conjunction<br />

<strong>2.3</strong> _ <strong>5V</strong>-b<br />

Subject to technical changes.<br />

10/03

Gate b<strong>us</strong>hing in the hot runner nozzles<br />

5 V<br />

Gate b<strong>us</strong>hing version A for open Nozzles<br />

See further technical information on the nozzle and nozzle installation page for the<br />

respective nozzle type.<br />

For the nozzle type:<br />

DER,<br />

DHR<br />

+0.02<br />

L<br />

Selection criteria:<br />

• injection on intermediate gate<br />

• direct injection of flat ABS products weighing<br />

more than 100g<br />

• <strong>us</strong>e for shear-sensitive materials<br />

6.3<br />

Note:<br />

6.3<br />

1)<br />

ØD<br />

5...10°<br />

1.2 -0.1<br />

1)<br />

The size of the gate diameter depends on the<br />

processing material and the part weight.<br />

You will find instructions for determining the gate<br />

diameter D in chapter 11 or please contact<br />

our technical support department.<br />

Gate b<strong>us</strong>hing version C for Nozzles with tip an open Nozzles<br />

See further technical information on the nozzle and installation page<br />

for the respective nozzle type.<br />

For the nozzle type:<br />

SER/DER<br />

SHR/DHR<br />

6.3<br />

+0.02<br />

L<br />

Selection criteria:<br />

• injection of small products made of POM<br />

copolymers (please consult our application<br />

engineering department before <strong>us</strong>ing)<br />

• for special applications in which<br />

a flow orientation is to be avoided<br />

and a gate vestige of 1-2 mm is tolerable<br />

(or more with GF material)<br />

6.3<br />

80°<br />

1)<br />

ØD<br />

1.2 -0.1<br />

1)<br />

Note:<br />

The size of the gate diameter depends on the<br />

processing material and the part weight.<br />

You will find instructions for determining the gate<br />

diameter D in chapter 11 or please contact<br />

our technical support department.<br />

<strong>2.3</strong> _ <strong>5V</strong>-d<br />

Subject to technical changes.<br />

Subject to technical changes.<br />

5/03

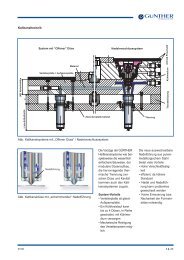

Installation of Hot Runner Nozzles<br />

5 V<br />

Hot Runner Nozzles<br />

5 V<br />

Single Nozzles Type 4SER, 5SER, 6SER/<br />

4DER, 5DER, 6DER<br />

Assembly with Gate B<strong>us</strong>hing (refer to chapter 3)<br />

L<br />

+0.02<br />

30 -0.02<br />

L +0.02<br />

5 +0.02<br />

1x45°<br />

22 -0.02<br />

5 +0.02<br />

1x45°<br />

Ø52<br />

Ø35.5<br />

2)<br />

ØS1<br />

5 V Nozzles with 5 V Manifold<br />

52<br />

ØS1 2)<br />

65<br />

26<br />

Locating ring<br />

(supplied by the c<strong>us</strong>tomer)<br />

Machine nozzle<br />

Adapter<br />

(Page 6.4)<br />

Use single nozzles only<br />

in conjunction with a<br />

machine nozzle adapter<br />

10<br />

5 V Manifold<br />

(Chapter 7)<br />

3)<br />

Cable channel<br />

20 5<br />

7.5<br />

1)<br />

2)<br />

3)<br />

Installation of gate b<strong>us</strong>hing<br />

6.3<br />

R2<br />

Notes:<br />

100°<br />

ØP<br />

H7<br />

H7<br />

ØT1<br />

+0.4<br />

ØS2<br />

R<br />

90°<br />

6.3<br />

1.6<br />

80°<br />

H7<br />

ØS<br />

6.3<br />

4)<br />

1.6 1.6 6.3<br />

1)<br />

ØD<br />

1.6<br />

45°<br />

<strong>2.3</strong><br />

1.2 -0.1<br />

L +0.02<br />

V -0.2<br />

4)<br />

min. t1<br />

The size of the gate diameter depends on the<br />

processing material and the part weight.<br />

You will find instructions for determining the<br />

gate diameter D in chapter 11 or please contact<br />

our technical support department.<br />

The diameter S1 is omitted when installing<br />

without gate b<strong>us</strong>h.<br />

L +0.02<br />

Further information on nozzles with tips and<br />

for open nozzles in the A and C versions can<br />

be found on the <strong>5V</strong>-d page.<br />

We recommend to lay the power and thermocouple<br />

cables in separate channels.<br />

A thermal damage of the thermocouple cables is<br />

therefore avoided.<br />

Single Nozzles Type 4SER, 5SER, 6SER /<br />

4DER, 5DER, 6DER<br />

Nozzle<br />

with tip<br />

Parting line<br />

Open<br />

nozzle<br />

Parting line<br />

L 0.5 L H C<br />

6.5<br />

W=30<br />

ØA<br />

ØB<br />

Ød<br />

ØA-0.05<br />

55°<br />

ØS<br />

ØS<br />

P<br />

P<br />

35<br />

CAD-Reference point<br />

Ø5<br />

52<br />

ca. 600<br />

Ø13<br />

93<br />

Ø3.5<br />

F<br />

14<br />

Type A:<br />

Ø = Not related to the gating<br />

diameter (ØD=1.5 mm)<br />

Type C:<br />

Ø = Related to the gating<br />

diameter (ØD)<br />

flexible cable<br />

G<br />

Plug 146<br />

(or extension plug<br />

142/L)<br />

Order Information:<br />

Example: a nozzle with tip or an open nozzle<br />

in conjunction with a manifold.<br />

Material tube diameter 4.8 mm,<br />

length 50 mm and<br />

Gating diameter 1.0 mm.<br />

Hot Runner Nozzle<br />

5SER50 (Type - nozzle with tip)<br />

5SER50H (Type H - with hard metal tip)<br />

5DDER50A (Type A - open nozzle)<br />

5DER50C-1.0 (Type C - open nozzle)<br />

Note:<br />

For very small shot weights (0.05 to 2 grams)<br />

and thermally sensitive materials (flame<br />

retardant), it is necessary to <strong>us</strong>e nozzles with an<br />

optimized temperature profile and a reduced<br />

material tube diameter.<br />

Example: 5SER50W<br />

5SER50WH (with hard metal tip)<br />

Note:<br />

The measurement L refers to the article surface,<br />

the nozzle expands by 0.5 mm in length<br />

at 250°C (325°F.)<br />

Note:<br />

In the case of small space availability an angle<br />

connector 147 can be <strong>us</strong>ed at the power<br />

connection.<br />

See chapter 8.<br />

Note:<br />

The fit between the nozzle / tool (ØS<br />

H7<br />

) or gate<br />

b<strong>us</strong>hing / tool (Ø T 1H7) has to be consistant<br />

throughout the whole length of the bore.<br />

For Technical Data:<br />

Refer to chapter11.<br />

Delivery in stock<br />

Semi-standard (short delivery time)<br />

Special production (delivery time given on request)<br />

Please Note:<br />

Dimension Ø H7> 10...18 =<br />

Nozzles<br />

with tip<br />

> 18...30 =<br />

> 30...50 =<br />

Open<br />

nozzles<br />

+0.018<br />

0<br />

+0.021<br />

0<br />

+0.025<br />

0<br />

ØP R ØS ØS1 ØS2 ØT1 V t1<br />

4SER 4DER 12 5 15 37 15.5 22 6.7 29<br />

5SER, 5SERW 5DER, 5DERW 12 5 18 39 18.5 26 8.2 28<br />

6SER, 6SERW 6DER, 6DERW 16 8 22 39 22.5 32 9 32<br />

4)<br />

If the nozzle length is 30 mm, the dimensions<br />

t1 and ØS2 are eliminated.<br />

For single nozzles, the locating ring and its<br />

screws m<strong>us</strong>t bear the load from the tool.<br />

Screws and locating rings have to be choosen<br />

careful and the circular pitch has to be as small<br />

as possible.<br />

For specifications see chapter 11.<br />

During assembly the nozzles m<strong>us</strong>t be fitted<br />

with a pre-load of 0.02 mm to 0.05 mm.<br />

Measurements and tolerances herein reference<br />

the tool. It is advisable to <strong>us</strong>e high temperature<br />

grease or spray on the outer surface of<br />

the nozzle barrel.<br />

Nozzles Open<br />

with tip nozzles<br />

4SER<br />

5SER<br />

6SER<br />

5SERW<br />

6SERW<br />

4DER<br />

5DER<br />

6DER<br />

5DERW<br />

6DERW<br />

Nozzle length L<br />

Ød ØA ØB C F G H P ØS 30 40 50 60 70 80 90 100120150180200<br />

4<br />

4.8 37.3 22<br />

6<br />

34.3 22<br />

37.3 24<br />

3.6 37.3 22<br />

4.8 37.3 24<br />

16<br />

16<br />

16<br />

16<br />

16<br />

5.5 10<br />

5.5 10<br />

5.5 10<br />

5.5 10<br />

5.5 10<br />

22<br />

22<br />

22<br />

22<br />

22<br />

19<br />

18<br />

21<br />

18<br />

21<br />

15<br />

18<br />

22<br />

18<br />

22<br />

<strong>2.3</strong> _ 4-6SER/DER Note: All dimensions are given in mm.<br />

Subject to technical changes. 2/04<br />

2/04<br />

Subject to technical changes.<br />

Note: All dimensions are given in mm.<br />

<strong>2.3</strong> _ 4-6SER/DER

Installation of the Hot Runner Nozzles<br />

5 V<br />

Hot Runner Nozzles<br />

5 V<br />

Hot Runner Nozzles Type 4SHR, 5SHR, 6SHR/<br />

4DHR, 5DHR, 6DHR<br />

Hot Runner Nozzles Type 4SHR, 5SHR, 6SHR/<br />

4DHR, 5DHR, 6DHR<br />

Assembly with Gate B<strong>us</strong>hing (refer to chapter 3)<br />

Manifold<br />

height<br />

Manifold<br />

height<br />

Installation without Gate B<strong>us</strong>hing<br />

12<br />

38 -0.02<br />

+0.02<br />

L<br />

12<br />

38 -0.02<br />

+0.02<br />

L<br />

2)<br />

Cable channel<br />

Nozzles<br />

with tip<br />

K<br />

+0.1<br />

5<br />

0.25x45°<br />

7.5<br />

K<br />

+0.02<br />

5<br />

1x45°<br />

0.5x45°<br />

20<br />

5<br />

32 32<br />

Open<br />

nozzles<br />

(20)<br />

105<br />

ØS3<br />

H7<br />

ØS1<br />

1.6<br />

3) See also notes<br />

40<br />

Clamp Plate<br />

Pressure pad<br />

817.250<br />

Manifold<br />

Cavity plate<br />

3) See also notes<br />

Clamp plate<br />

Pressure pad<br />

Manifold<br />

Manifold<br />

enclosure<br />

Cavity plate<br />

ØP R ØS ØS1 ØS2 ØS3 ØT1 V<br />

4SHR, 4SHRW 4DHR, 4DHRW 12 5 15 16 15.5 36 22 6.7 29<br />

5SHR, 5SHRW 5DHR, 5DHRW 12 5 18 19 18.5 39 26 8.2 28<br />

6SHR, 6SHRW 6DHR, 6DHRW 16 8 22 23 22.5 39 32 9.0 32<br />

t1<br />

1)<br />

2)<br />

6.3<br />

R2<br />

Notes:<br />

100°<br />

ØP<br />

H7<br />

H7<br />

ØT1<br />

We recommend to lay the power and thermocouple<br />

cables in separate channels.<br />

A thermal damage of the thermocouple cables is<br />

therefore avoided.<br />

For the expansion coefficient "K" see the<br />

manifold.<br />

Please note:<br />

1.6<br />

+0.4<br />

ØS2<br />

R<br />

90°<br />

80°<br />

H7<br />

ØS<br />

6.3<br />

4)<br />

6.3<br />

1.6 1.6<br />

1)<br />

ØD<br />

1.6<br />

45°<br />

<strong>2.3</strong> -0,1<br />

1.2 -0.1<br />

Dimensions Ø H7 > 10...18 =<br />

> 18...30 =<br />

> 30...50 =<br />

L +0.02<br />

V -0.2<br />

+0.018<br />

0<br />

+0.021<br />

0<br />

+0.025<br />

0<br />

4)<br />

min. t 1<br />

Further information on nozzles with tips and<br />

for open nozzles in the A and C versions can<br />

be found on the <strong>5V</strong>-d page.<br />

The size of the gate diameter depends on the<br />

processing material and the part weight.<br />

You will find instructions for determining the<br />

gate diameter D in chapter 11 or please contact<br />

our technical support department.<br />

3)<br />

The through hole in the clamping plate makes<br />

it possible to tighten the nozzle again after<br />

assembling the mould.<br />

4)<br />

If the nozzle length is 30 mm, the dimensions<br />

t1 and ØS2 are eliminated.<br />

L +0.02<br />

Measurements and tolerances herein reference<br />

the tool.<br />

It is advisable to <strong>us</strong>e high temperature grease or<br />

spray on the outer surface of the nozzle barrel.<br />

In conjunction with a manifold.<br />

Metal o-ring<br />

Nozzle<br />

with tip<br />

Parting line<br />

Open<br />

nozzle<br />

Parting line<br />

Ø32<br />

38<br />

L<br />

0.5<br />

L<br />

W=28<br />

6.2<br />

Nozzles Open<br />

with tip nozzles<br />

4SHR<br />

5SHR<br />

6SHR<br />

4SHRW<br />

5SHRW<br />

6SHRW<br />

4DHR<br />

5DHR<br />

6DHR<br />

4DHRW<br />

5DHRW<br />

6DHRW<br />

4.2<br />

3.5<br />

CAD-<br />

Reference<br />

point<br />

M4<br />

67.5°<br />

Ø37.9<br />

45°<br />

Ød<br />

ØS1<br />

55°<br />

ØS<br />

ØS<br />

P<br />

45°<br />

P<br />

Ø14<br />

52<br />

Ø34<br />

R3<br />

63<br />

Ø13<br />

Ø9<br />

Nozzle length L<br />

9.3<br />

Extension plug 142<br />

(or cable plug 146)<br />

21.7<br />

Flexible cable<br />

Thermo plug CMLK<br />

Ød P ØS ØS1 30 40 50 60 80 100120150180200250<br />

3.8<br />

4.8<br />

6<br />

2.5<br />

3.6<br />

4.8<br />

19<br />

18<br />

21<br />

19<br />

18<br />

21<br />

15<br />

18<br />

22<br />

15<br />

18<br />

22<br />

16<br />

19<br />

23<br />

16<br />

19<br />

23<br />

Type A:<br />

Ø = Not related to the gating<br />

diameter (ØD=1.5 mm)<br />

Type C:<br />

Ø = Related to the gating<br />

diameter (ØD)<br />

Order Information:<br />

Example: a nozzle with tip or an open nozzle<br />

in conjunction with a manifold.<br />

Material tube diameter 4.8 mm,<br />

length 50 mm and<br />

gating diameter 1.0 mm.<br />

Hot Runner Nozzle<br />

5SHR50 (Type - nozzle with tip)<br />

5SHR50H (Type H - with hard metal tip)<br />

5DHR50A (Type A - open nozzle)<br />

5DHR50C-1.0 (Type C - open nozzle)<br />

Order Instructions:<br />

Following parts have to be ordered separately<br />

1.Plug to the thermo b<strong>us</strong>hing<br />

Order No.: CMLK50 (incl. 0.5 m cable)<br />

CMLK100 (incl. 1 m Cable)<br />

CMLK150 (incl. 1.5 m cable)<br />

Examples of applications refer to chapter 8.<br />

Only as replacement<br />

1.Metal o-ring<br />

Order No.: 810.025 for 4SHR, 4DHR<br />

810.027 for 5SHR, 5DHR,<br />

6SHR, 6DHR<br />

2. Extension plug 142 or cable plug 146<br />

Examples of applications refer to chapter 10.<br />

Please note:<br />

For very small shot weights (0.5 to 2 grams) and<br />

thermally sensitive materials (flame retardant) it<br />

is necessary to <strong>us</strong>e nozzles with an optimized<br />

temperature profile and a reduced material tube<br />

diameter.<br />

z.B.: 5SHR50W<br />

5SHR50WH (with hard metal tip)<br />

The measurement L refers to the part surface,<br />

the nozzle expands by 0.5 mm at 250°C.<br />

Insallation guideline:<br />

The hot runner nozzles can be secured to the<br />

manifold in two ways:<br />

1. From the top of the manifold through the<br />

pressure pads (pitch circle Ø32) secured by<br />

two M4 bolts to the nozzle.<br />

2. From the bottom of the manifold secured<br />

by two M5 bolts adjacent to the groves R3<br />

on the nozzle.<br />

If flats (w = 28 mm)are cut into the nozzle<br />

then it can only be secured from the top of<br />

the manifold.<br />

Examples of applications refer to chapter 7.<br />

Technical Information:<br />

Please also see chapter 11.<br />

Delivery - in stock<br />

Semi-standard (short delivery time)<br />

Special production (delivery time upon request)<br />

<strong>2.3</strong> _ 4-6SHR/DHR<br />

Note: All dimensions are given in mm.<br />

Subject to technical changes.<br />

2/04 2/04 Subject to technical changes.<br />

Note: All dimensions are given in mm. <strong>2.3</strong> _ 4-6SHR/DHR