ANNUAL REPORT 2008 - Gorenje Group

ANNUAL REPORT 2008 - Gorenje Group

ANNUAL REPORT 2008 - Gorenje Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

55<br />

3.7 PRODUCTION<br />

The majority of production activities of the household appliances division were carried out in scope<br />

of the parent company. In Velenje 77 % of all appliances were produced and the rest in the cooking<br />

appliance factory in Mora in the Czech Republic and in the factory refrigeration and freezing appliances<br />

in Valjevo, Serbia.<br />

The production was focused on constant quality improvement of products and cost optimisation.<br />

The key challenges in the last months of the year <strong>2008</strong> included maximal adjustment of the scope<br />

of production to the orders. In spite of the exceptional fluctuations in orders and difficult planning<br />

the efficient organisation of production followed the demand in the market.<br />

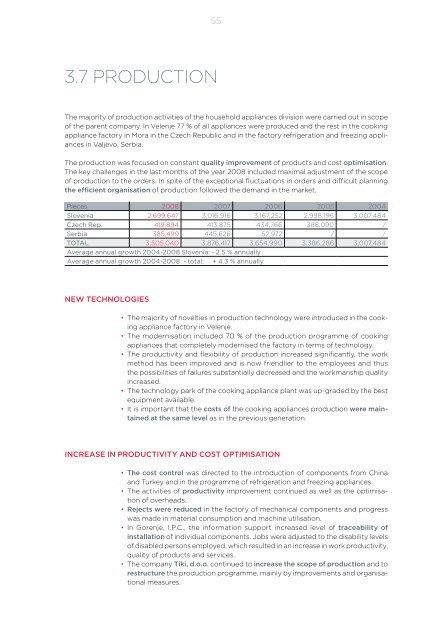

Pieces <strong>2008</strong> 2007 2006 2005 2004<br />

Slovenia 2,699,647 3,016,916 3,167,252 2,998,196 3,007,484<br />

Czech Rep. 419,894 413,875 434,766 388,090 /<br />

Serbia 385,499 445,626 52,972 / /<br />

TOTAL 3,505,040 3,876,417 3,654,990 3,386,286 3,007,484<br />

Average annual growth 2004-<strong>2008</strong> Slovenia: - 2.5 % annually<br />

Average annual growth 2004-<strong>2008</strong> - total: + 4.3 % annually<br />

NEW TECHNOLOGIES<br />

• The majority of novelties in production technology were introduced in the cooking<br />

appliance factory in Velenje.<br />

• The modernisation included 70 % of the production programme of cooking<br />

appliances that completely modernised the factory in terms of technology.<br />

• The productivity and flexibility of production increased significantly, the work<br />

method has been improved and is now friendlier to the employees and thus<br />

the possibilities of failures substantially decreased and the workmanship quality<br />

increased.<br />

• The technology park of the cooking appliance plant was up-graded by the best<br />

equipment available.<br />

• It is important that the costs of the cooking appliances production were maintained<br />

at the same level as in the previous generation.<br />

INCREASE IN PRODUCTIVITY AND COST OPTIMISATION<br />

• The cost control was directed to the introduction of components from China<br />

and Turkey and in the programme of refrigeration and freezing appliances.<br />

• The activities of productivity improvement continued as well as the optimisation<br />

of overheads.<br />

• Rejects were reduced in the factory of mechanical components and progress<br />

was made in material consumption and machine utilisation.<br />

• In <strong>Gorenje</strong>, I.P.C., the information support increased level of traceability of<br />

installation of individual components. Jobs were adjusted to the disability levels<br />

of disabled persons employed, which resulted in an increase in work productivity,<br />

quality of products and services.<br />

• The company Tiki, d.o.o. continued to increase the scope of production and to<br />

restructure the production programme, mainly by improvements and organisational<br />

measures.