Lynne Wong's PhD thesis

Lynne Wong's PhD thesis Lynne Wong's PhD thesis

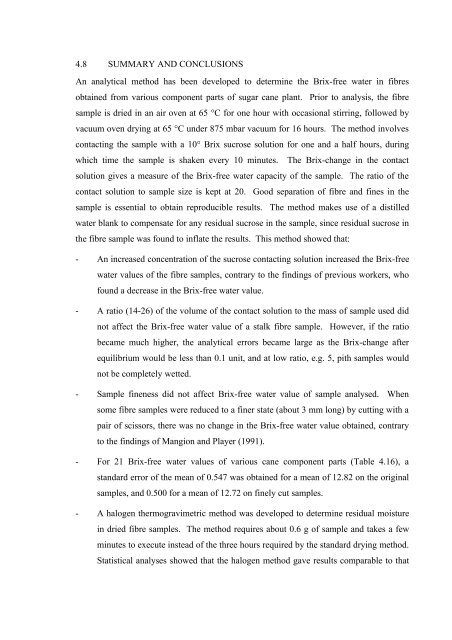

Table 4.28. Predicted Brix-free water of reconstituted dry leaf, green leaf and cane stalk aged 36 weeks. Sample* Mass fraction Experimental Brix-free water/% Predicted Brix-free water/% of Dry leaf Green leaf Rind Stalk Dry leaf Green leaf Rind Stalk reconstituted fibre fines fibre fines fibre fines fibre pith fibre fines fibre fines fibre fines fibre pith Dry leaf Green leaf Cane stalk R 579 1 0.601 0.399 0.745 0.255 0.386 0.158 0.172 0.285 15.57 16.37 13.77 13.17 12.24 15.53 14.42 20.41 16.99 14.72 16.56 2 0.592 0.408 0.685 0.315 0.376 0.158 0.159 0.306 14.77 15.45 14.18 16.04 12.08 17.05 14.36 21.65 16.14 15.86 17.26 3 0.565 0.435 0.699 0.301 0.419 0.224 0.122 0.235 14.36 15.94 13.39 17.44 11.29 19.08 14.05 18.80 16.14 15.70 16.24 Mean 0.586 0.414 0.709 0.291 0.393 0.180 0.151 0.276 14.90 15.92 13.78 15.55 11.87 17.22 14.28 20.29 16.42 15.39 16.61 R 570 1 0.651 0.349 0.719 0.281 0.383 0.224 0.150 0.243 14.44 17.78 12.44 14.88 12.32 16.16 13.50 22.74 16.70 14.23 16.99 2 0.605 0.395 0.673 0.327 0.414 0.266 0.114 0.206 14.85 16.75 12.29 14.55 12.63 13.66 13.23 20.82 16.70 14.13 15.76 3 0.635 0.365 0.711 0.289 0.400 0.304 0.096 0.200 14.51 15.11 12.85 15.87 12.71 13.62 13.07 20.60 15.83 14.82 15.69 Mean 0.631 0.369 0.701 0.299 0.399 0.265 0.120 0.216 14.60 16.54 12.53 15.10 12.55 14.48 13.27 21.38 16.42 14.39 16.16 M 1557/70 1 0.700 0.300 0.742 0.258 0.417 0.241 0.110 0.232 15.30 19.76 13.45 13.41 12.25 16.90 16.36 17.49 17.73 14.54 16.13 2 0.699 0.301 0.689 0.311 0.431 0.261 0.093 0.215 15.27 16.84 13.55 14.67 12.03 13.93 15.90 18.25 16.84 14.99 15.32 3 0.638 0.362 0.674 0.326 0.427 0.247 0.100 0.226 14.69 15.40 13.02 15.68 13.61 13.62 13.04 16.45 16.05 14.98 15.29 Mean 0.679 0.321 0.702 0.298 0.425 0.250 0.101 0.224 15.09 17.33 13.34 14.59 12.63 14.81 15.10 17.40 16.91 14.81 15.59 M 1400/86 1 0.700 0.300 0.691 0.309 0.391 0.236 0.112 0.260 16.07 17.58 13.45 12.86 12.15 14.81 14.53 20.26 17.62 14.37 16.25 2 0.632 0.368 0.719 0.281 0.382 0.262 0.100 0.256 14.87 15.00 12.35 13.13 12.24 13.92 14.99 19.13 16.01 13.67 15.82 3 0.629 0.371 0.717 0.283 0.345 0.214 0.150 0.291 17.06 14.45 12.59 13.94 12.98 15.00 14.02 16.72 17.19 14.07 15.75 Mean 0.654 0.346 0.709 0.291 0.373 0.238 0.121 0.269 16.00 15.67 12.80 13.31 12.45 14.58 14.51 18.70 16.99 14.04 15.99 R 570 (2001) 1 0.582 0.418 0.645 0.355 0.371 0.185 0.179 0.265 13.64 14.79 14.97 14.35 11.77 15.84 9.37 14.09 15.22 15.85 13.80 2 0.548 0.452 0.646 0.354 0.356 0.169 0.201 0.274 15.12 12.80 15.16 15.15 13.68 16.04 14.30 11.76 15.17 16.25 14.77 3 0.496 0.504 0.629 0.371 0.382 0.162 0.207 0.249 14.75 14.07 14.89 15.75 12.75 13.01 10.38 12.27 15.50 16.30 13.28 Mean 0.542 0.458 0.640 0.360 0.370 0.172 0.196 0.263 14.50 13.88 15.01 15.08 12.73 14.96 11.35 12.70 15.32 16.13 13.94 16.41 14.95 15.66 * Samples were harvested in 2003 except where indicated.

4.8 SUMMARY AND CONCLUSIONS An analytical method has been developed to determine the Brix-free water in fibres obtained from various component parts of sugar cane plant. Prior to analysis, the fibre sample is dried in an air oven at 65 °C for one hour with occasional stirring, followed by vacuum oven drying at 65 °C under 875 mbar vacuum for 16 hours. The method involves contacting the sample with a 10° Brix sucrose solution for one and a half hours, during which time the sample is shaken every 10 minutes. The Brix-change in the contact solution gives a measure of the Brix-free water capacity of the sample. The ratio of the contact solution to sample size is kept at 20. Good separation of fibre and fines in the sample is essential to obtain reproducible results. The method makes use of a distilled water blank to compensate for any residual sucrose in the sample, since residual sucrose in the fibre sample was found to inflate the results. This method showed that: - An increased concentration of the sucrose contacting solution increased the Brix-free water values of the fibre samples, contrary to the findings of previous workers, who found a decrease in the Brix-free water value. - A ratio (14-26) of the volume of the contact solution to the mass of sample used did not affect the Brix-free water value of a stalk fibre sample. However, if the ratio became much higher, the analytical errors became large as the Brix-change after equilibrium would be less than 0.1 unit, and at low ratio, e.g. 5, pith samples would not be completely wetted. - Sample fineness did not affect Brix-free water value of sample analysed. When some fibre samples were reduced to a finer state (about 3 mm long) by cutting with a pair of scissors, there was no change in the Brix-free water value obtained, contrary to the findings of Mangion and Player (1991). - For 21 Brix-free water values of various cane component parts (Table 4.16), a standard error of the mean of 0.547 was obtained for a mean of 12.82 on the original samples, and 0.500 for a mean of 12.72 on finely cut samples. - A halogen thermogravimetric method was developed to determine residual moisture in dried fibre samples. The method requires about 0.6 g of sample and takes a few minutes to execute instead of the three hours required by the standard drying method. Statistical analyses showed that the halogen method gave results comparable to that

- Page 167 and 168: solution/fibre ratio was lowered fr

- Page 169 and 170: leave some residual moisture on the

- Page 171 and 172: instead of 150 g of 10° Brix sucro

- Page 173 and 174: Table 4.2. Determination of Brix-fr

- Page 175 and 176: Table 4.3. Comparison of Brix-free

- Page 177 and 178: Table 4.4. Results of the determina

- Page 179 and 180: In order to test for homogeneity of

- Page 181 and 182: Table 4.7. Results of the repeat de

- Page 183 and 184: The experiment was repeated with th

- Page 185 and 186: e any residual moisture in the samp

- Page 187 and 188: By means of the same technique, Won

- Page 189 and 190: was still hot. Since the filter was

- Page 191 and 192: value determined could be corrected

- Page 193 and 194: Qin and White’s finding was confi

- Page 195 and 196: A sample size of 3.5 g with 75 g co

- Page 197 and 198: Figure 4.4. Fibre samples drying in

- Page 199 and 200: - One large fibre sample (rind) of

- Page 201 and 202: Table 4.18. Brix-free water values/

- Page 203 and 204: Table 4.20. Brix-free water values/

- Page 205 and 206: 4.7.3 Statistical analysis It is es

- Page 207 and 208: Table 4.23. Analysis of variance (B

- Page 209 and 210: pointing out that at 52 weeks old,

- Page 211 and 212: The crop of R 570 sampled in 2001 w

- Page 213 and 214: 4.7.4. Estimated Brix-free water co

- Page 215 and 216: The main difference in the two sets

- Page 217: Table 4.27. Predicted Brix-free wat

- Page 221 and 222: component parts, and verify the Bri

- Page 223 and 224: 3) Thermodynamic, water in equilibr

- Page 225 and 226: Langmuir (1916, 1917, 1918) propose

- Page 227 and 228: to determine the moisture sorption

- Page 229 and 230: Table 5.1. Some commonly used isoth

- Page 231 and 232: Lomauro et al. (1985) found that wi

- Page 233 and 234: and on agricultural products such a

- Page 235 and 236: Bruijn (1963) studied the mass incr

- Page 237 and 238: After measuring the EMC of dry corn

- Page 239 and 240: approached, that is, either by adso

- Page 241 and 242: Table 5.4. Water activity (a w ) of

- Page 243 and 244: 5.6.3 Procedure to determine equili

- Page 245 and 246: 5.6.4 Results and discussion An exa

- Page 247 and 248: Table 5.8. Equilibrium moisture con

- Page 249 and 250: Table 5.10. Equilibrium moisture co

- Page 251 and 252: Table 5.12. Equilibrium moisture co

- Page 253 and 254: 30 o C 45 o C 55 o C 60 o C Water w

- Page 255 and 256: m/m of 96% activity, a w (g/100g dr

- Page 257 and 258: vaporisation generally decreases fr

- Page 259 and 260: 30 o C isotherm 45 o C isotherm 55

- Page 261 and 262: 4 0 Stalk fibre 5 0 Stalk pith 5 0

- Page 263 and 264: 5.6.4.4 Fitting of sorption models

- Page 265 and 266: Table 5.19. Parameters of the sorpt

- Page 267 and 268: Table 5.21. Parameters of the sorpt

4.8 SUMMARY AND CONCLUSIONS<br />

An analytical method has been developed to determine the Brix-free water in fibres<br />

obtained from various component parts of sugar cane plant. Prior to analysis, the fibre<br />

sample is dried in an air oven at 65 °C for one hour with occasional stirring, followed by<br />

vacuum oven drying at 65 °C under 875 mbar vacuum for 16 hours. The method involves<br />

contacting the sample with a 10° Brix sucrose solution for one and a half hours, during<br />

which time the sample is shaken every 10 minutes. The Brix-change in the contact<br />

solution gives a measure of the Brix-free water capacity of the sample. The ratio of the<br />

contact solution to sample size is kept at 20. Good separation of fibre and fines in the<br />

sample is essential to obtain reproducible results. The method makes use of a distilled<br />

water blank to compensate for any residual sucrose in the sample, since residual sucrose in<br />

the fibre sample was found to inflate the results. This method showed that:<br />

- An increased concentration of the sucrose contacting solution increased the Brix-free<br />

water values of the fibre samples, contrary to the findings of previous workers, who<br />

found a decrease in the Brix-free water value.<br />

- A ratio (14-26) of the volume of the contact solution to the mass of sample used did<br />

not affect the Brix-free water value of a stalk fibre sample. However, if the ratio<br />

became much higher, the analytical errors became large as the Brix-change after<br />

equilibrium would be less than 0.1 unit, and at low ratio, e.g. 5, pith samples would<br />

not be completely wetted.<br />

- Sample fineness did not affect Brix-free water value of sample analysed. When<br />

some fibre samples were reduced to a finer state (about 3 mm long) by cutting with a<br />

pair of scissors, there was no change in the Brix-free water value obtained, contrary<br />

to the findings of Mangion and Player (1991).<br />

- For 21 Brix-free water values of various cane component parts (Table 4.16), a<br />

standard error of the mean of 0.547 was obtained for a mean of 12.82 on the original<br />

samples, and 0.500 for a mean of 12.72 on finely cut samples.<br />

- A halogen thermogravimetric method was developed to determine residual moisture<br />

in dried fibre samples. The method requires about 0.6 g of sample and takes a few<br />

minutes to execute instead of the three hours required by the standard drying method.<br />

Statistical analyses showed that the halogen method gave results comparable to that