Download (4Mb) - USQ ePrints - University of Southern Queensland

Download (4Mb) - USQ ePrints - University of Southern Queensland

Download (4Mb) - USQ ePrints - University of Southern Queensland

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

During the last decade the harvesting sector has faced an unprecedented cost-price squeeze from<br />

rising capital, parts and fuel costs and labour availability. This has been compounded by a run <strong>of</strong> poor<br />

seasons which has impacted on harvester productivity.<br />

The harvesting sector is responding to these issues through a number <strong>of</strong> alternative design<br />

considerations to the standard Australian machine. These include modifications to suit a number <strong>of</strong><br />

row spacings and wide-swath harvesting.<br />

Sugarcane harvesting is undertaken over a relatively long period (June to December), across a large<br />

geographic area (sub-tropics, dry-tropics, wet-tropics, varied soil types) along a narrow coastal strip<br />

with rainfall averages above 1000 mm per year. Hence, it is inevitable that harvesting will be<br />

conducted during or after periods <strong>of</strong> wet-weather. To cater for this, the sugarcane harvester is<br />

available in tracked configuration.<br />

2.2.1 Row Spacing<br />

In conventional sugarcane farming systems, sugarcane is <strong>of</strong>ten grown on rows 1.5 m apart however<br />

there is significant variance, with large proportions <strong>of</strong> the crop in India, China and the traditional<br />

production areas in Brazil being on 1.0 m row spacing. The Case IH Aust<strong>of</strong>t 7000 and 7700 cane<br />

harvesters have a wheel centre <strong>of</strong> 1860 mm and a track centre <strong>of</strong> 1880 mm respectively. Case IH<br />

7000/7700 machines built prior to 2003 have a throat width <strong>of</strong> 900 mm. Machines built after 2003<br />

have a throat width <strong>of</strong> 1080 mm. The Cameco (2500 series) and John Deere (3500 series) both have a<br />

wheel and track centre <strong>of</strong> 1880 mm. Cameco 2500 series have a throat width <strong>of</strong> 900 mm whilst, John<br />

Deere 3500 series machines have a throat width <strong>of</strong> 1000 mm. Therefore, current machinery is too<br />

much <strong>of</strong> an agronomic compromise for the current 1.5 m system (Figure 2.4).<br />

A number <strong>of</strong> controlled traffic row spacings have been adopted throughout the Australian industry.<br />

There are a number <strong>of</strong> slight variations to these but the most common include 1.85 m wheel spacing<br />

with single row and dual row, 2 m wheel spacing with dual rows at 800 mm centres, 2.4 m wheel<br />

spacing with dual rows at 1200 mm and a 3 m wheel spacing with dual rows at 1.5 m spacing.<br />

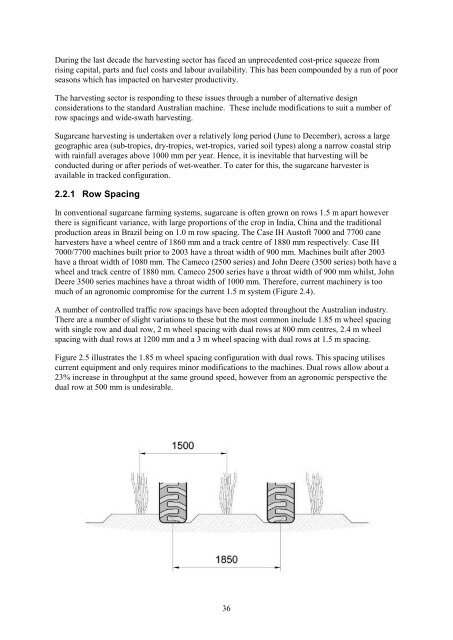

Figure 2.5 illustrates the 1.85 m wheel spacing configuration with dual rows. This spacing utilises<br />

current equipment and only requires minor modifications to the machines. Dual rows allow about a<br />

23% increase in throughput at the same ground speed, however from an agronomic perspective the<br />

dual row at 500 mm is undesirable.<br />

36