Download (4Mb) - USQ ePrints - University of Southern Queensland

Download (4Mb) - USQ ePrints - University of Southern Queensland

Download (4Mb) - USQ ePrints - University of Southern Queensland

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

northern New South Wales (where it is cooler) it takes 18-24 months to grow. Typically, a cropping<br />

cycle comprises one plant crop and 3-4 ratoon (regrowth) crops.<br />

During harvest, the cane harvester drives along each row and cuts the cane stalk <strong>of</strong>f at the bottom <strong>of</strong><br />

the plant. The long stalk is then cut into many shorter lengths called ‘billets’ (around 30 cm).<br />

Another machine known as a cane haulout drives alongside the harvester, collecting all the billets.<br />

The cane haulout collects billets until its full, then drives across the paddock to the road or rail, where<br />

it unloads its contents either into a semi-truck (for road transport) or mill bins at local sidings on the<br />

nearest railway track (for train transport). Once sugarcane has been harvested, it must be transported<br />

to a sugar mill as soon as possible. The longer it takes, the more sugarcane juice stored in the stalks<br />

will evaporate - so it is important that it arrives within 16 hours <strong>of</strong> being cut, to minimise<br />

deterioration.<br />

Australia’s sugarcane is harvested during the drier months in tropical climates – between June and<br />

December each year - depending on the weather.<br />

1.1.6 Farming systems (other crops, field layout, machinery)<br />

Mallee System<br />

The mallee coppice crops are typically grown in belt configurations, commonly in four rows per belt,<br />

but increasingly with two rows, with the inter-belt alleys varying, from 40 to 100 metres or more<br />

across. There is a two metre buffer zone either side <strong>of</strong> the outer rows <strong>of</strong> a belt, and a competition<br />

zone beyond that as shown in Figure 1.4. The width <strong>of</strong> the cropping zone is driven by the cereal<br />

production system (i.e. the seeder and spray boom widths).<br />

An inter-row spacing <strong>of</strong> at least three metres is recommended and the intra-row spacing is typically<br />

two metres to maintain a reasonably consistent flow <strong>of</strong> material into the harvester, which equates to<br />

1,430 mallees per hectare <strong>of</strong> land directly occupied by the belt. The density <strong>of</strong> planting has varied as<br />

the industry has developed, with some very high densities in early plantings, but current indications<br />

are that a wider inter-row spacing not only improves access for harvesting but will improve yield per<br />

kilometre <strong>of</strong> belt. The use <strong>of</strong> more than two rows is not efficient in most circumstances due to the<br />

strong edge effect that develops as competition within the belt increases with age (Peck et al 2011).<br />

The productive capacity <strong>of</strong> the strip <strong>of</strong> land occupied by the belt is captured by two rows, and adding<br />

more rows merely distributes the production <strong>of</strong> biomass across more mallees and increases<br />

competition between them.<br />

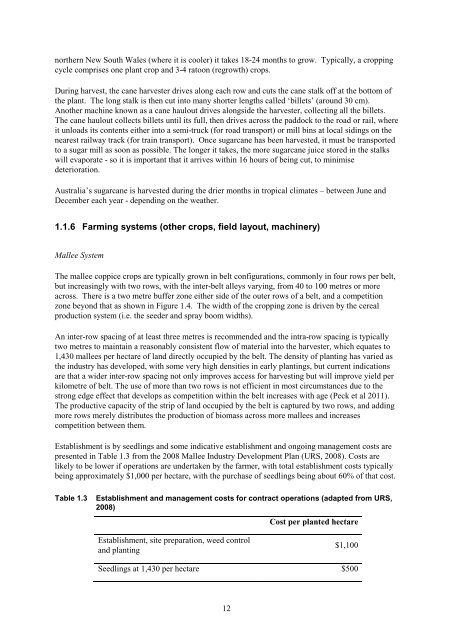

Establishment is by seedlings and some indicative establishment and ongoing management costs are<br />

presented in Table 1.3 from the 2008 Mallee Industry Development Plan (URS, 2008). Costs are<br />

likely to be lower if operations are undertaken by the farmer, with total establishment costs typically<br />

being approximately $1,000 per hectare, with the purchase <strong>of</strong> seedlings being about 60% <strong>of</strong> that cost.<br />

Table 1.3<br />

Establishment and management costs for contract operations (adapted from URS,<br />

2008)<br />

Cost per planted hectare<br />

Establishment, site preparation, weed control<br />

and planting<br />

$1,100<br />

Seedlings at 1,430 per hectare $500<br />

12