Download (4Mb) - USQ ePrints - University of Southern Queensland

Download (4Mb) - USQ ePrints - University of Southern Queensland

Download (4Mb) - USQ ePrints - University of Southern Queensland

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Appendix 1: Comparative Assessment with Sugarcane Supply<br />

Chain<br />

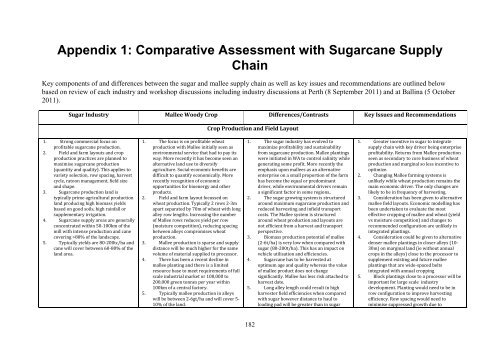

Key components <strong>of</strong> and differences between the sugar and mallee supply chain as well as key issues and recommendations are outlined below<br />

based on review <strong>of</strong> each industry and workshop discussions including industry discussions at Perth (8 September 2011) and at Ballina (5 October<br />

2011).<br />

Sugar Industry Mallee Woody Crop Differences/Contrasts Key Issues and Recommendations<br />

Crop Production and Field Layout<br />

1. Strong commercial focus on<br />

pr<strong>of</strong>itable sugarcane production.<br />

2. Field and farm layouts and crop<br />

production practices are planned to<br />

maximise sugarcane production<br />

(quantity and quality). This applies to<br />

variety selection, row spacing, harvest<br />

cycle, ratoon management, field size<br />

and shape.<br />

3. Sugarcane production land is<br />

typically prime agricultural production<br />

land producing high biomass yields<br />

based on good soils, high rainfall or<br />

supplementary irrigation.<br />

4. Sugarcane supply areas are generally<br />

concentrated within 50-100km <strong>of</strong> the<br />

mill with intense production and cane<br />

covering >80% <strong>of</strong> the landscape.<br />

5. Typically yields are 80-200tc/ha and<br />

cane will cover between 60-80% <strong>of</strong> the<br />

land area.<br />

1. The focus is on pr<strong>of</strong>itable wheat<br />

production with Mallee initially seen as<br />

environmental service that had to pay its<br />

way. More recently it has become seen an<br />

alternative land use to diversify<br />

agriculture. Social-economic benefits are<br />

difficult to quantify economically. More<br />

recently recognition <strong>of</strong> economic<br />

opportunities for bioenergy and other<br />

products.<br />

2. Field and farm layout focussed on<br />

wheat production. Typically 2 rows 2-3m<br />

apart separated by 70m <strong>of</strong> wheat with long<br />

alley row lengths. Increasing the number<br />

<strong>of</strong> Mallee rows reduces yield per row<br />

(moisture competition), reducing spacing<br />

between alleys compromises wheat<br />

production.<br />

3. Mallee production is sparse and supply<br />

distance will be much higher for the same<br />

volume <strong>of</strong> material supplied to processor.<br />

4. There has been a recent decline in<br />

mallee planting and there is a limited<br />

resource base to meet requirements <strong>of</strong> full<br />

scale industrial market or 100,000 to<br />

200,000 green tonnes per year within<br />

100km <strong>of</strong> a central factory.<br />

5. Typically mallee production in alleys<br />

will be between 2-6gt/ha and will cover 5-<br />

10% <strong>of</strong> the land.<br />

1. The sugar industry has evolved to<br />

maximize pr<strong>of</strong>itability and sustainability<br />

from sugarcane production. Mallee plantings<br />

were initiated in WA to control salinity while<br />

generating some pr<strong>of</strong>it. More recently the<br />

emphasis upon mallees as an alternative<br />

enterprise on a small proportion <strong>of</strong> the farm<br />

has become the equal or predominant<br />

driver, while environmental drivers remain<br />

a significant factor in some regions..<br />

2. The sugar growing system is structured<br />

around maximum sugarcane production and<br />

reduced harvesting and infield transport<br />

costs. The Mallee system is structured<br />

around wheat production and layouts are<br />

not efficient from a harvest and transport<br />

perspective.<br />

3. Biomass production potential <strong>of</strong> mallee<br />

(2-6t/ha) is very low when compared with<br />

sugar (80-200t/ha). This has an impact on<br />

vehicle utilisation and efficiencies.<br />

4. Sugarcane has to be harvested at<br />

optimum age and quality whereas the value<br />

<strong>of</strong> mallee product does not change<br />

significantly. Mallee has less risk attached to<br />

harvest date.<br />

5. Long alley length could result in high<br />

harvester field efficiencies when compared<br />

with sugar however distance to haul to<br />

loading pad will be greater than in sugar<br />

1. Greater incentive in sugar to integrate<br />

supply chain with key driver being enterprise<br />

pr<strong>of</strong>itability. Returns from Mallee production<br />

seen as secondary to core business <strong>of</strong> wheat<br />

production and marginal so less incentive to<br />

optimize.<br />

2. Changing Mallee farming systems is<br />

unlikely while wheat production remains the<br />

main economic driver. The only changes are<br />

likely to be in frequency <strong>of</strong> harvesting.<br />

3. Consideration has been given to alternative<br />

mallee field layouts. Economic modelling has<br />

been undertaken to evaluate the most<br />

effective cropping <strong>of</strong> mallee and wheat (yield<br />

vs moisture competition) and changes to<br />

recommended configuration are unlikely in<br />

integrated plantings.<br />

4. Consideration could be given to alternative<br />

denser mallee plantings in closer alleys (10-<br />

30m) on marginal land (ie without annual<br />

crops in the alleys) close to the processor to<br />

supplement existing and future mallee<br />

plantings that are wide-spaced belts<br />

integrated with annual cropping<br />

5. Block plantings close to a processor will be<br />

important for large scale industry<br />

development. Planting would need to be in<br />

row configuration to improve harvesting<br />

efficiency. Row spacing would need to<br />

minimise suppressed growth due to<br />

182