Download (4Mb) - USQ ePrints - University of Southern Queensland

Download (4Mb) - USQ ePrints - University of Southern Queensland

Download (4Mb) - USQ ePrints - University of Southern Queensland

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

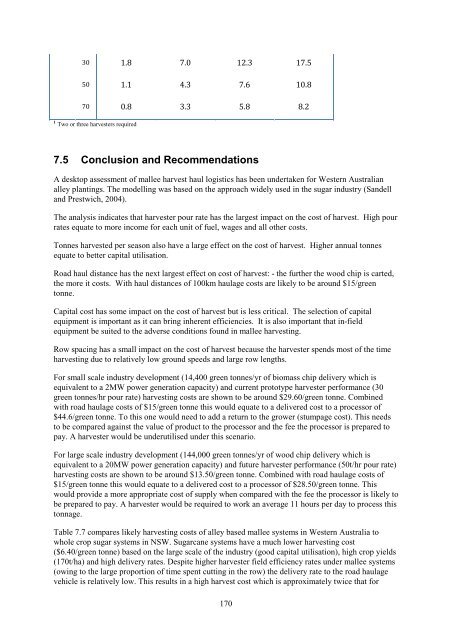

30 1.8 7.0 12.3 17.5<br />

50 1.1 4.3 7.6 10.8<br />

70 0.8 3.3 5.8 8.2<br />

1 Two or three harvesters required<br />

7.5 Conclusion and Recommendations<br />

A desktop assessment <strong>of</strong> mallee harvest haul logistics has been undertaken for Western Australian<br />

alley plantings. The modelling was based on the approach widely used in the sugar industry (Sandell<br />

and Prestwich, 2004).<br />

The analysis indicates that harvester pour rate has the largest impact on the cost <strong>of</strong> harvest. High pour<br />

rates equate to more income for each unit <strong>of</strong> fuel, wages and all other costs.<br />

Tonnes harvested per season also have a large effect on the cost <strong>of</strong> harvest. Higher annual tonnes<br />

equate to better capital utilisation.<br />

Road haul distance has the next largest effect on cost <strong>of</strong> harvest: - the further the wood chip is carted,<br />

the more it costs. With haul distances <strong>of</strong> 100km haulage costs are likely to be around $15/green<br />

tonne.<br />

Capital cost has some impact on the cost <strong>of</strong> harvest but is less critical. The selection <strong>of</strong> capital<br />

equipment is important as it can bring inherent efficiencies. It is also important that in-field<br />

equipment be suited to the adverse conditions found in mallee harvesting.<br />

Row spacing has a small impact on the cost <strong>of</strong> harvest because the harvester spends most <strong>of</strong> the time<br />

harvesting due to relatively low ground speeds and large row lengths.<br />

For small scale industry development (14,400 green tonnes/yr <strong>of</strong> biomass chip delivery which is<br />

equivalent to a 2MW power generation capacity) and current prototype harvester performance (30<br />

green tonnes/hr pour rate) harvesting costs are shown to be around $29.60/green tonne. Combined<br />

with road haulage costs <strong>of</strong> $15/green tonne this would equate to a delivered cost to a processor <strong>of</strong><br />

$44.6/green tonne. To this one would need to add a return to the grower (stumpage cost). This needs<br />

to be compared against the value <strong>of</strong> product to the processor and the fee the processor is prepared to<br />

pay. A harvester would be underutilised under this scenario.<br />

For large scale industry development (144,000 green tonnes/yr <strong>of</strong> wood chip delivery which is<br />

equivalent to a 20MW power generation capacity) and future harvester performance (50t/hr pour rate)<br />

harvesting costs are shown to be around $13.50/green tonne. Combined with road haulage costs <strong>of</strong><br />

$15/green tonne this would equate to a delivered cost to a processor <strong>of</strong> $28.50/green tonne. This<br />

would provide a more appropriate cost <strong>of</strong> supply when compared with the fee the processor is likely to<br />

be prepared to pay. A harvester would be required to work an average 11 hours per day to process this<br />

tonnage.<br />

Table 7.7 compares likely harvesting costs <strong>of</strong> alley based mallee systems in Western Australia to<br />

whole crop sugar systems in NSW. Sugarcane systems have a much lower harvesting cost<br />

($6.40/green tonne) based on the large scale <strong>of</strong> the industry (good capital utilisation), high crop yields<br />

(170t/ha) and high delivery rates. Despite higher harvester field efficiency rates under mallee systems<br />

(owing to the large proportion <strong>of</strong> time spent cutting in the row) the delivery rate to the road haulage<br />

vehicle is relatively low. This results in a high harvest cost which is approximately twice that for<br />

170