Download (4Mb) - USQ ePrints - University of Southern Queensland

Download (4Mb) - USQ ePrints - University of Southern Queensland

Download (4Mb) - USQ ePrints - University of Southern Queensland

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

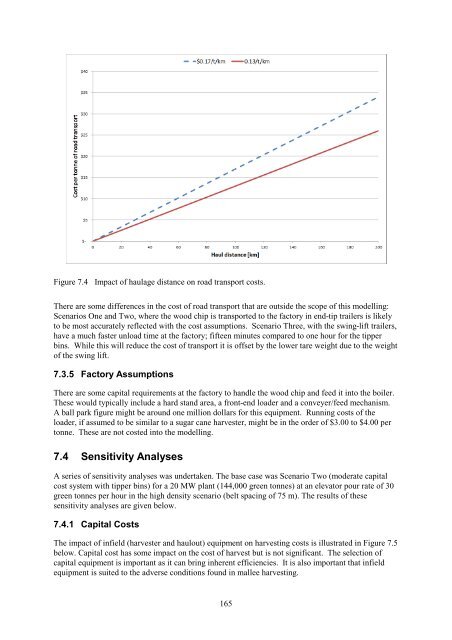

Figure 7.4 Impact <strong>of</strong> haulage distance on road transport costs.<br />

There are some differences in the cost <strong>of</strong> road transport that are outside the scope <strong>of</strong> this modelling:<br />

Scenarios One and Two, where the wood chip is transported to the factory in end-tip trailers is likely<br />

to be most accurately reflected with the cost assumptions. Scenario Three, with the swing-lift trailers,<br />

have a much faster unload time at the factory; fifteen minutes compared to one hour for the tipper<br />

bins. While this will reduce the cost <strong>of</strong> transport it is <strong>of</strong>fset by the lower tare weight due to the weight<br />

<strong>of</strong> the swing lift.<br />

7.3.5 Factory Assumptions<br />

There are some capital requirements at the factory to handle the wood chip and feed it into the boiler.<br />

These would typically include a hard stand area, a front-end loader and a conveyer/feed mechanism.<br />

A ball park figure might be around one million dollars for this equipment. Running costs <strong>of</strong> the<br />

loader, if assumed to be similar to a sugar cane harvester, might be in the order <strong>of</strong> $3.00 to $4.00 per<br />

tonne. These are not costed into the modelling.<br />

7.4 Sensitivity Analyses<br />

A series <strong>of</strong> sensitivity analyses was undertaken. The base case was Scenario Two (moderate capital<br />

cost system with tipper bins) for a 20 MW plant (144,000 green tonnes) at an elevator pour rate <strong>of</strong> 30<br />

green tonnes per hour in the high density scenario (belt spacing <strong>of</strong> 75 m). The results <strong>of</strong> these<br />

sensitivity analyses are given below.<br />

7.4.1 Capital Costs<br />

The impact <strong>of</strong> infield (harvester and haulout) equipment on harvesting costs is illustrated in Figure 7.5<br />

below. Capital cost has some impact on the cost <strong>of</strong> harvest but is not significant. The selection <strong>of</strong><br />

capital equipment is important as it can bring inherent efficiencies. It is also important that infield<br />

equipment is suited to the adverse conditions found in mallee harvesting.<br />

165