Download - Institution of Engineers Singapore

Download - Institution of Engineers Singapore

Download - Institution of Engineers Singapore

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Contents<br />

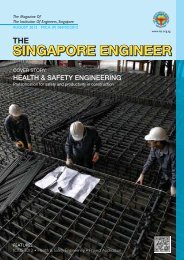

10/2011<br />

Features<br />

Chief Editor<br />

T Bhaskaran<br />

t_b_n8@yahoo.com<br />

Director, Marketing<br />

Roland Ang roland@iesnet.org.sg<br />

Marketing & Publications Executive<br />

Jeremy Chia jeremy@iesnet.org.sg<br />

CEO<br />

Angie Ng<br />

angie@iesnet.org.sg<br />

Publications Manager<br />

Desmond Teo desmond@iesnet.org.sg<br />

Published by<br />

The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong><br />

70 Bukit Tinggi Road<br />

<strong>Singapore</strong> 289758<br />

Tel: 6469 5000 Fax: 6467 1108<br />

Cover designed by Jeremy Chia<br />

Cover image by YWL Engineering Pte Ltd<br />

16 Cover Story: The Sentosa Boardwalk<br />

Design and engineering safety excellence was achieved in spite <strong>of</strong> the challenges<br />

in the project.<br />

24 Project Application: Ferrari World in Abu Dhabi<br />

Mapei’s products have been used for installing floor and wall finishes, as well as<br />

for waterpro<strong>of</strong>ing and sealing <strong>of</strong> surfaces, in this iconic project.<br />

28 Project Application: Digital prototyping s<strong>of</strong>tware helps in<br />

facade engineering projects<br />

Information Technology is helping to create sophisticated architectural and<br />

engineering designs, and build the structures.<br />

29 Project Application: Potain cranes dominate another huge<br />

Saudi Arabian development<br />

The tight time-lines for this major project have resulted in large numbers <strong>of</strong> lifting<br />

machines being deployed.<br />

30 Project Application: Raise boring adopted for dropshafts in<br />

Hong Kong drainage scheme<br />

The technology selected is appropriate, considering the constraints <strong>of</strong> the work<br />

sites.<br />

32 Project Application: Water pipeline in Abu Dhabi gets<br />

underway<br />

Machines for ground compaction achieve the specified results.<br />

33 Project Application: Five Liebherr cranes work in tight<br />

configuration on university campus project<br />

Correct selection <strong>of</strong> equipment prevents conflicting movements and ensures<br />

desired outcomes.<br />

36 Chemical Engineering: Wireless technology: minimising risks<br />

at process plants<br />

A new approach to Health, Safety and Environment challenges is presented.<br />

38 Chemical Engineering: Optimising engineering processes<br />

S<strong>of</strong>tware solutions can help in the design and operation <strong>of</strong> more efficient plants.<br />

NATIONAL ENGINEERS DAY 2011 SUPPLEMENT<br />

(between pages 22 and 23)<br />

A series <strong>of</strong> programmes and activities held over several months will culminate in a Grand<br />

Finale on 11 and 12 November.<br />

Regular Sections<br />

The <strong>Singapore</strong> Engineer is published monthly by The<br />

<strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong> (IES). The publication is<br />

distributed free-<strong>of</strong>-charge to IES members and its affiliates.<br />

Views expressed in this publication do not necessarily reflect<br />

those <strong>of</strong> the Editor or IES. All rights reserved. No part <strong>of</strong><br />

this magazine shall be reproduced, whether mechanical or<br />

electronic, without the prior written consent <strong>of</strong> IES. Whilst<br />

every care is taken to ensure accuracy and honesty in both<br />

editorial and advertising content at press time, IES will not<br />

be liable for any discrepancies. Unsolicited contributions are<br />

welcome but the editor reserves the discretion to use them.<br />

Printed by Print & Print Pte Ltd.<br />

16<br />

2 IES Update<br />

22 IESA Update<br />

34 Products & Solutions<br />

40 Events<br />

41 News<br />

October 2011<br />

THE SINGAPORE ENGINEER · 1

IES Update<br />

Message from the President<br />

Dear Friends<br />

Besides natural disasters, the world has seen, in recent<br />

months and days, a series <strong>of</strong> major accidents including the<br />

crashing <strong>of</strong> airplanes at airshows and the collisions <strong>of</strong> trains.<br />

IES COUNCIL MEMBERS<br />

2011/2012<br />

President<br />

Er. Ho Siong Hin<br />

Deputy President<br />

Er. Pr<strong>of</strong> Chou Siaw Kiang<br />

Vice Presidents<br />

Er. Chong Kee Sen<br />

Er. Edwin Khew<br />

Mr Neo Kok Beng<br />

Er. Ong Geok Soo<br />

Er. Ong See Ho<br />

Honorary Secretary<br />

Er. Ng Say Cheong<br />

Honorary Treasurer<br />

Dr Boh Jaw Woei<br />

Assistant Honorary Secretary<br />

Mr Oh Boon Chye, Jason<br />

Assistant Honorary Treasurer<br />

Mr Kang Choon Seng<br />

Immediate Past President<br />

Er. Lee Bee Wah<br />

Past Presidents<br />

Er. Tan Seng Chuan<br />

Er. A/Pr<strong>of</strong> Foo Say Wei<br />

Er. Ong Ser Huan<br />

Council Members<br />

Er. Dr Chew Soon Hoe<br />

Pr<strong>of</strong> Er Meng Joo<br />

Er. Dr Ho Kwong Meng<br />

Dr Ho Teck Tuak<br />

Er. Jee Yi Yng<br />

Er. Koh Beng Thong<br />

Dr Kwok Wai Onn, Richard<br />

Mr Lee Kwok Weng<br />

Mr Lim Horng Leong<br />

Er. Low Wong Fook<br />

Er. Pr<strong>of</strong> Ong Say Leong<br />

Mr Tan Boon Leng, Mark<br />

Er. Toh Siaw Hui, Joseph<br />

2 · THE SINGAPORE ENGINEER<br />

Er. Ho Siong Hin<br />

President<br />

The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong> (IES)<br />

October 2011<br />

These have resulted in injuries to people and even fatalities.<br />

After the necessary investigations have been conducted,<br />

follow-up actions will be taken, which will include further<br />

increasing the standards <strong>of</strong> engineering safety.<br />

At all stages <strong>of</strong> an engineering project, from design to<br />

construction and completion <strong>of</strong> the infrastructure and facilities, and from start-up to<br />

continued operation, maintenance, and beyond, the human element should have the<br />

greatest importance, followed by the respect for property and capital investments<br />

made.<br />

The increasing focus on the need to reduce the carbon footprint <strong>of</strong> all industrial activities<br />

is also a recognition that the human condition and the consequences to mankind should<br />

be at the centre <strong>of</strong> all engineering decisions.<br />

All this puts a lot more emphasis on the need for continuing education and training <strong>of</strong><br />

employees at all levels, associates, contractors, suppliers, as well as communication with<br />

other stakeholders such as customers, the relevant authorities, and the general public.<br />

With technological advances and new commercial ideas being introduced at tremendous<br />

speeds, it is indeed a challenge to keep abreast <strong>of</strong> developments, in order to ensure the<br />

necessary levels <strong>of</strong> education, training, and communication.<br />

However, the engineering pr<strong>of</strong>ession is up to the task and efforts are being made<br />

continuously, to raise the levels <strong>of</strong> competence in a systematic and efficient manner.<br />

In the face <strong>of</strong> setbacks, the engineering pr<strong>of</strong>ession is known to be resilient and to have<br />

the capacity to overcome adversity and make progress.<br />

And going into the future, it is important that we continue to have good engineers. That<br />

is why IES is focusing on engineering education and accreditation. An example <strong>of</strong> efforts<br />

in this direction is the Inaugural Federation <strong>of</strong> Engineering <strong>Institution</strong>s <strong>of</strong> Asia and the<br />

Pacific (FEIAP) Convention 2011 which IES hosted recently. The event included a oneand-a-half-day<br />

FEIAP International Conference and a 3-day Engineering Accreditation<br />

Workshop.<br />

IES also wishes to see more brilliant students enroll for an engineering education. This<br />

is one <strong>of</strong> the objectives <strong>of</strong> the National <strong>Engineers</strong> Day (NED) which it organised for the<br />

first time, last year.<br />

This year’s event (NED 2011) was launched in late March and has included several<br />

programmes <strong>of</strong> interest to practising engineers as well as to secondary school students<br />

and their teachers.<br />

The Grand Finale <strong>of</strong> NED 2011 will be held on 11 and 12 November. Among the highlights<br />

are a collection <strong>of</strong> inspirational interviews with prominent engineers, which has been<br />

posted on the NED website, as well as an exhibition that will address three themes -<br />

energy, aviation, and defence. The activities at the exhibition include quizzes for students<br />

and other opportunites to win attractive prizes.

IES Update<br />

S<br />

IES celebrates ‘Sapphire’ Anniversary with a ‘bash’<br />

ome 1,100 members and guests<br />

gathered on 9 September 2011<br />

at the Compass West Ballroom, Resorts<br />

World Sentosa, to celebrate IES' 45 th<br />

Anniversary Annual Dinner, aptly<br />

themed the ‘Sapphire’ Anniversary.<br />

Mrs Lim Hwee Hua was the Guest-<strong>of</strong>-<br />

Honour for the occasion.<br />

The evening's programme<br />

commenced with Er. Ho Siong Hin,<br />

IES President, delivering a welcome<br />

speech. In his speech, he outlined the<br />

highlights and achievements <strong>of</strong> IES in<br />

the past year. He also mentioned IES’<br />

building redevelopment project which<br />

aims to realise a clean and green, and<br />

a ‘zero-energy’ building.<br />

Er. Ho thanked partners, including<br />

allied pr<strong>of</strong>essional bodies, educational<br />

institutions, and multinational firms<br />

for providing resources and support<br />

to IES.<br />

The evening also saw the Guest<strong>of</strong>-Honour,<br />

Mrs Lim Hwee Hua, being<br />

conferred the title ‘IES Honorary<br />

Fellow’.<br />

In her acceptance speech, Mrs<br />

Lim highlighted the importance <strong>of</strong><br />

engineering to <strong>Singapore</strong>’s economy<br />

and the benefits it brings. She also<br />

mentioned how she has witnessed the<br />

ideas and concepts <strong>of</strong> engineers being<br />

adapted and implemented, to improve<br />

the lives <strong>of</strong> <strong>Singapore</strong>ans and also to<br />

serve the public at large, in areas such<br />

as transportation which includes the<br />

aerospace and maritime sectors.<br />

At the Sapphire Anniversary<br />

Dinner, for the first time, Past President<br />

Medals were awarded to all the Past<br />

Presidents, for their leadership,<br />

contributions, and sacrifices made<br />

during their tenure as President.<br />

A total <strong>of</strong> 10 Past Presidents were<br />

present to receive their medals.<br />

This was followed by the<br />

presentation <strong>of</strong> certificates to IES<br />

Fellows who are champions with<br />

prominent achievements in their<br />

fields <strong>of</strong> engineering, in <strong>Singapore</strong>, on<br />

the basis <strong>of</strong> the work done by them<br />

and the positions they have attained.<br />

A total <strong>of</strong> five people were selected to<br />

receive the certificates.<br />

Also at the Annual Dinner, IES<br />

Gold Medals were presented to<br />

NTU/NUS engineering graduates. In<br />

Er. Ho Siong Hin delivering his Opening Speech.<br />

Mrs Lim Hwee Hua accepting her conferment as IES Honorary Fellow, from Er. Ho.<br />

The dinner was held at the Compass West Ballroom, Resorts World Sentosa.<br />

Mrs Lim speaking after the conferment.<br />

4 · THE SINGAPORE ENGINEER October 2011

Always secure. Always available.<br />

Anywhere in the world you need power, Schneider Electric is there.<br />

Power loss poses a threat to the equipment, people, and processes you rely on.<br />

And with today’s stricter security and safety regulations, process automation,<br />

and increasing dependence on sophisticated high-tech systems, the need for<br />

uninterrupted power is critical. Add the rising cost <strong>of</strong> energy and environmental<br />

concerns into the mix, and it becomes essential to protect your power with solutions<br />

that not only meet your availability demands, but are energy efficient, too.<br />

Why Schneider Electric is the right power protection choice<br />

You may know us as the market leader in delivering IT power protection. But we also<br />

<strong>of</strong>fer a full range <strong>of</strong> reliable and highly efficient power protection solutions designed<br />

to safeguard business-critical applications and environments outside the IT room.<br />

Our innovative, best-<strong>of</strong>-breed products, services, and solutions provide the secure<br />

and available power you need to keep your systems up and running, while increasing<br />

efficiency, performance, and safety.<br />

Guaranteed availability for business-critical systems<br />

No matter what industry you’re in, our unrivaled portfolio <strong>of</strong>fers a solution that’s<br />

guaranteed to suit your specific business needs and keep your power on. Thanks to<br />

Schneider Electric power and energy management capabilities, in-house expertise,<br />

broad investments in R&D, and global presence, you have a trusted resource for<br />

reliable power, anywhere in the world.<br />

Secure power solutions that deliver the<br />

performance you need<br />

Products:Our complete catalog <strong>of</strong> power solutions,<br />

featuring our leading brands such as APC by<br />

Schneider Electric and GUTOR, <strong>of</strong>fers an unmatched<br />

range <strong>of</strong> single- and three-phase UPS units, rectifiers,<br />

inverter systems, active filters, and static transfer<br />

switches from 1 kVA to several MVAs.<br />

Services:Schneider Electric Critical Power & Cooling<br />

Services can proactively monitor and maintain the<br />

health <strong>of</strong> your systems, protecting your investments,<br />

reducing total cost <strong>of</strong> ownership and operating<br />

expenses, and providing peace <strong>of</strong> mind throughout the<br />

equipment lifecycle.<br />

Solutions:Choosing the right combination <strong>of</strong> products<br />

and services from Schneider Electric gives you the<br />

convenience <strong>of</strong> a total solution – systems, s<strong>of</strong>tware,<br />

and services from a single source.<br />

Speak to a Power Specialist Today, call 6389 6860<br />

The Different Types<br />

<strong>of</strong> UPS Systems<br />

White Paper 1<br />

> Executive summary<br />

Learn more about our secure power solutions.<br />

<strong>Download</strong> our FREE White Paper, “The Different<br />

Types <strong>of</strong> UPS Systems.”<br />

Visit www.SEReply.com Key Code 50990M

IES Update<br />

addition, two Malay/Muslim students<br />

were given the IES Yayasan Mendaki<br />

scholarships.<br />

The night also saw the signing<br />

<strong>of</strong> an MoU between IES and the<br />

Academy <strong>of</strong> Engineering <strong>Singapore</strong><br />

(SAEng), represented, respectively, by<br />

Er. Ho Siong Hin, IES President, and<br />

Pr<strong>of</strong> Cham Tao Soon, President <strong>of</strong><br />

SAEngg; as well as the launch <strong>of</strong> the<br />

SAEng logo.<br />

Certificates <strong>of</strong> appreciation were<br />

also presented to the following for<br />

their ‘pro bono’ services towards the<br />

IES Building redevelopment project -<br />

RSP Architects Planners & <strong>Engineers</strong><br />

Pte Ltd, Squire Mech Pte Ltd, and<br />

Expand Construction Pte Ltd. TSE<br />

Group photo <strong>of</strong> IES Past Presidents.<br />

Er. Ho presented IES Gold Medals to NTU/NUS engineering graduates and IES Yayasan Mendaki Scholarships to Malay/Muslim students.<br />

After the signing <strong>of</strong> the MoU between IES and the Academy <strong>of</strong> Engineering<br />

<strong>Singapore</strong>.<br />

Er. Ho presenting the certificate <strong>of</strong> appreciation to Er. Chang Meng Teng <strong>of</strong><br />

Squire Mech Pte Ltd.<br />

6 · THE SINGAPORE ENGINEER October 2011

Master <strong>of</strong> Science in Urban<br />

Transport Management<br />

Pr<strong>of</strong>essional Certificate Series<br />

To meet the challenges and demands <strong>of</strong> an<br />

increasingly complex land transport system in<br />

today’s urban environment, SIM University<br />

(UniSIM), in collaboration with the LTA Academy,<br />

has developed a unique Master programme in the<br />

management and development <strong>of</strong> land transport<br />

systems.<br />

This pr<strong>of</strong>essional certificate series comprise regular<br />

modules <strong>of</strong> the Master in Urban Transport<br />

Management programme. We invite transport<br />

industry pr<strong>of</strong>essionals to join us and learn about the<br />

latest developments in urban transport<br />

management.<br />

Integrated Transport Policy (11 - 14 Jan 2012)<br />

Delivered by Pr<strong>of</strong>essor Anthony May (University <strong>of</strong><br />

Leeds, U.K.) & Mr. Lew Yii Der (Director <strong>of</strong> LTA<br />

Academy).<br />

Transport Economics (16 - 19 Jan 2012)<br />

Delivered by Pr<strong>of</strong>essor Anthony Chin (National<br />

University <strong>of</strong> <strong>Singapore</strong>)<br />

About the Courses<br />

Both courses are delivered by our distinguished<br />

specialists and conducted at the LTA Academy,<br />

<strong>Singapore</strong>. For details on the courses, please visit<br />

www.unisim.edu.sg/ogs.<br />

Who Should Attend<br />

Public Transport Operators, <strong>Engineers</strong>, Planners,<br />

Architects, Contractors, Consultants, Developers,<br />

Government Officials, Researchers, Academics,<br />

and International Organisations<br />

Fees per Course<br />

<strong>Singapore</strong> Citizen / Permanent Resident : SGD $2,675<br />

Non-Resident : SGD $3,210<br />

* Inclusive <strong>of</strong> GST, Notes, Site Visits, Tea- Breaks<br />

and 1 Networking Lunch<br />

Application<br />

Please visit our website at www.unisim.edu.sg/ogs<br />

to download the application form. Application<br />

deadline is 4 January 2012.<br />

PDUs: Pending<br />

SIM University<br />

CPE/UEN: 200504979Z<br />

Registered: 4 June 2010 to 3 June 2016<br />

Office <strong>of</strong> Graduate Studies<br />

461 Clementi Road <strong>Singapore</strong> 599491<br />

Tel: 6248 5783 / 6248 5787<br />

Email: graddip&master@unisim.edu.sg<br />

Website: www.unisim.edu.sg/ogs

IES Update<br />

Er. Ong See Ho –<br />

Engineer with Education<br />

Affairs at Heart<br />

A<br />

s one <strong>of</strong> the Vice Presidents <strong>of</strong> the<br />

<strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong><br />

(IES), Er. Ong See Ho oversees one <strong>of</strong> the<br />

important areas – the IES Pr<strong>of</strong>essional Group<br />

which is responsible for the pr<strong>of</strong>essional<br />

registries for the ASEAN Engineer, APEC<br />

Engineer, Certified Systems Engineering<br />

Pr<strong>of</strong>essional (CSEP), <strong>Singapore</strong> Certified<br />

Energy Manager, and Project Management,<br />

as well as the <strong>Engineers</strong> Mobility Forum Er. Ong See Ho.<br />

and ACES-IES Joint Registries. The ACES-IES Joint Registries is a<br />

collaboration between the Association <strong>of</strong> Consulting <strong>Engineers</strong><br />

<strong>Singapore</strong> and IES to develop and maintain several registries,<br />

namely those for Resident <strong>Engineers</strong> & Resident Technical<br />

Officers, Qualified Electrical Contractors (QEC) and Qualified<br />

Erosion Control Pr<strong>of</strong>essionals (QECP). The main functions <strong>of</strong> the<br />

various committees looking after these registries are to develop<br />

and maintain an assessment system for registration, to develop<br />

programmes for continuing pr<strong>of</strong>essional development, to audit<br />

compliance by registrants with the conditions <strong>of</strong> registration, and<br />

to administer complaints against registrants.<br />

Er. Ong’s latest assignment in IES was chairing the Organising<br />

Committee for the just concluded Inaugural Federation<br />

<strong>of</strong> Engineering <strong>Institution</strong>s <strong>of</strong> Asia and the Pacific (FEIAP)<br />

Convention 2011. The FEIAP Convention, a week-long series <strong>of</strong><br />

events in <strong>Singapore</strong>, from 2 to 7 October 2011, comprised the<br />

FEIAP International Conference on Engineering Education and<br />

Accreditation, the Engineering Accreditation Workshop on<br />

Developing Sustainable Program Assessment Processes, the<br />

FEIAP 33 rd Anniversary Dinner & Awards Presentation, and the<br />

FEIAP General Assembly.<br />

Er. Ong was instrumental in the formation <strong>of</strong> the Engineering<br />

Accreditation Board (EAB) in 2002, and getting it admitted<br />

as a full signatory <strong>of</strong> the Washington Accord in 2006. The EAB,<br />

which he currently chairs, represents IES as the body to accredit<br />

undergraduate engineering degree programmes that are<br />

delivered and awarded in <strong>Singapore</strong>. The Washington Accord<br />

is an international agreement among bodies responsible for<br />

accrediting engineering degree programmes, and it recognises<br />

the substantial equivalence <strong>of</strong> programmes accredited by<br />

those bodies and recommends that graduates <strong>of</strong> programmes<br />

accredited by any <strong>of</strong> the signatory bodies be recognised by the<br />

other bodies as having met the academic requirements for entry<br />

to the practice <strong>of</strong> engineering.<br />

Er. Ong has been an IES member since 1978 and became an<br />

IES Fellow in 2003. He has been a Council Member since 2007. He<br />

is currently the Deputy CEO (Building Control) <strong>of</strong> the Building<br />

and Construction Authority (BCA) and the Commissioner <strong>of</strong><br />

Building Control. He is also a Board Member <strong>of</strong> the Pr<strong>of</strong>essional<br />

<strong>Engineers</strong> Board (PEB) <strong>Singapore</strong> and the Board <strong>of</strong> Architects<br />

(BOA) <strong>Singapore</strong>. TSE<br />

Er. Ong Ser Huan – Giving<br />

Back as a Way Forward<br />

Er. Ong Ser Huan.<br />

W<br />

When it comes to volunteerism, you could count on Er.<br />

Ong Ser Huan. For the past 20-plus years, he has been<br />

relentless in contributing towards public service voluntarily, as<br />

well as the development <strong>of</strong> engineering pr<strong>of</strong>ession.<br />

His passion towards engineering pr<strong>of</strong>ession saw him chairing<br />

the IES Community Service Committee for seven years prior to<br />

his election as IES President in 1998, which he served till 2000. He<br />

now serves as Past President in the IES Council and Adviser to IES<br />

Mechanical & Electrical Engineering Technical Committee, Clean<br />

Energy Interest Group, IES Overseas Chapter and IES Social and<br />

Community Service Committee.<br />

He is also the Chairman <strong>of</strong> IES/ACES Qualified Electrical<br />

Contractor Registry since its inauguration in 2004<br />

Er. Ong believes that having benefitted from the engineering<br />

pr<strong>of</strong>ession, it makes sense for him to contribute back to the<br />

pr<strong>of</strong>ession and the community voluntarily so that others could<br />

benefit as well.<br />

Apart from his voluntary roles in engineering pr<strong>of</strong>ession,<br />

he also manages to find time to be on the board and advisory<br />

committees <strong>of</strong> various charitable organisations. TSE<br />

ICE President pays visit to IES<br />

Mr Peter Hansford, President, <strong>Institution</strong> <strong>of</strong> Civil <strong>Engineers</strong> (second from<br />

right), visits the IES <strong>of</strong>fice.<br />

10 · THE SINGAPORE ENGINEER October 2011

IES Update<br />

I<br />

The Inaugural FEIAP Convention 2011<br />

ES hosted the Inaugural Federation<br />

<strong>of</strong> Engineering <strong>Institution</strong>s <strong>of</strong> Asia<br />

and the Pacific (FEIAP) Convention 2011,<br />

from 3 to 7 October 2011, at the Furama<br />

RiverFront Hotel in <strong>Singapore</strong>.<br />

The event included a Welcome<br />

Reception (on 2 October) at The Jewel Box<br />

at Mount Faber; the FEIAP International<br />

Conference (on 3 October), the FEIAP<br />

Convention Dinner (on 4 October), the<br />

FEIAP Standing Committee & Workgroup<br />

Meetings (on 5 October), the 19 th FEIAP<br />

General Assembly (on 5 October), and<br />

the Engineering Accreditation Workshop<br />

(from 5 to 7 October), all at the Furama<br />

RiverFront Hotel; as well as a Technical<br />

Visit to Jurong Island.<br />

The convention attracted close to 250<br />

delegates. About 90 <strong>of</strong> them were from 18<br />

countries outside <strong>Singapore</strong>.<br />

FEIAP INTERNATIONAL<br />

CONFERENCE<br />

The Guest-<strong>of</strong>-Honour at the FEIAP<br />

International Conference was Mr Gan Kim<br />

Yong, Minister for Health, <strong>Singapore</strong>.<br />

The conference, which addressed<br />

the theme ‘Engineering Education &<br />

Accreditation’ commenced with a<br />

Welcome Address by Er. Ho Siong Hin,<br />

President, IES.<br />

Er. Ho said that, over the long-term,<br />

<strong>Singapore</strong> aims to develop a vibrant<br />

community <strong>of</strong> educational institutions,<br />

transforming the city-state into a global<br />

talent hub, and that as a major engineering<br />

educational institution in <strong>Singapore</strong>, IES is<br />

working towards fulfilling its role in this<br />

grand master plan.<br />

‘We hope this convention will serve as a<br />

good platform for educators and practising<br />

pr<strong>of</strong>essionals to share information on issues<br />

concerning training <strong>of</strong> future engineers and<br />

accreditation <strong>of</strong> engineering programmes,<br />

continuing pr<strong>of</strong>essional development, and<br />

qualifications <strong>of</strong> engineers’, he said.<br />

Er. Ho highlighted IES’ involvement in<br />

Engineering Accreditation. He said that in<br />

order to ensure local engineering degree<br />

programmes are robust and on par with<br />

international standards, the Engineering<br />

Accreditation Board (EAB) <strong>of</strong> the IES<br />

has been evaluating and accrediting the<br />

programmes <strong>of</strong>fered by local universities.<br />

‘We check that our local programmes<br />

12 · THE SINGAPORE ENGINEER October 2011<br />

are substantially equivalent, in terms <strong>of</strong><br />

training and learning outcomes, to the<br />

internationally recognised Washington<br />

Accord community. This will guarantee<br />

the pr<strong>of</strong>essional competence <strong>of</strong> our<br />

graduates and allow mutual recognition<br />

<strong>of</strong> their qualifications’, said Er. Ho.<br />

He pointed out that as <strong>of</strong> July 2011,<br />

the EAB has accredited 26 engineering<br />

programmes <strong>of</strong>fered by local institutions<br />

<strong>of</strong> higher learning, some in partnership<br />

with renowned foreign universities.<br />

Er. Ho also touched on the importance<br />

<strong>of</strong> Continuous Pr<strong>of</strong>essional Development<br />

for engineers and mentioned the<br />

contribution <strong>of</strong> IES Academy in this area.<br />

‘We have to keep up with technological<br />

changes and embrace new work methods.<br />

In IES, we place strong emphasis on<br />

continuing education and training’, he<br />

said.<br />

‘In the last financial year, more than<br />

The Guest-<strong>of</strong>-Honour, Mr Gan Kim Yong, Minister<br />

for Health, <strong>Singapore</strong>.<br />

Delegates at the FEIAP International Conference.<br />

6,000 engineers have participated in the<br />

Academy’s courses. This is a record. But<br />

we are on course to setting a new record.<br />

In the first four months <strong>of</strong> this financial<br />

year, we have already conducted courses<br />

for more than 2,000 engineers. We are<br />

heartened by the strong demand for our<br />

courses. It is an indication <strong>of</strong> the courses’<br />

quality and relevance. It also demonstrates<br />

our members’ commitment to training<br />

and skills upgrading’, Er. Ho added.<br />

Er. Ho Siong Hin, President, IES.<br />

Er. Tan Seng Chuan, President, FEIAP.

We Achieve Complexity<br />

with Simplicity...

IES Update<br />

In another Welcome Address, Er. Tan<br />

Seng Chuan, President, FEIAP, spoke on<br />

the mobility <strong>of</strong> engineers in the global<br />

market, due to the increasing demand for<br />

expertise and innovation.<br />

‘In order to facilitate mobility <strong>of</strong><br />

engineers in the member economies,<br />

an agreement that covers competence<br />

standards for practising engineers must be<br />

reached to remove any artificial barriers<br />

impeding the free movement and practice<br />

<strong>of</strong> pr<strong>of</strong>essional engineers’, he said.<br />

According to Er. Tan, this can be<br />

systematically achieved through a<br />

framework where substantial equivalence<br />

in ensuring the competence <strong>of</strong><br />

experienced pr<strong>of</strong>essional engineers could<br />

be determined.<br />

He said that in this respect, FEIAP is<br />

moving in the correct direction - to assist<br />

the developing economies in raising their<br />

academic levels and strengthening their<br />

accreditation standards.<br />

‘With the internationally-recognised<br />

accreditation system properly in place,<br />

engineering associations, governments,<br />

and firms worldwide will have confidence<br />

in the abilities, standards, and experience<br />

<strong>of</strong> engineers working across international<br />

boundaries’, Er. Tan said.<br />

The convention also marked the end<br />

<strong>of</strong> Er. Tan’s four-year tenure as FEIAP<br />

President. He is succeeded by Pr<strong>of</strong>. Ir<br />

Chuah Hean Teik from the <strong>Institution</strong> <strong>of</strong><br />

<strong>Engineers</strong>, Malaysia (IEM).<br />

In his Opening Address, the Guest-<strong>of</strong>-<br />

Honour, Mr Gan Kim Yong elaborated on<br />

how engineering can assist in the area <strong>of</strong><br />

healthcare.<br />

‘Healthcare is a huge and growing<br />

sector in all industrialised economies.<br />

Many <strong>of</strong> these economies have something<br />

in common - they are all facing the issue <strong>of</strong><br />

ageing. <strong>Singapore</strong> is not spared either - we<br />

expect to see a doubling <strong>of</strong> the number <strong>of</strong><br />

<strong>Singapore</strong> residents aged 65 and above by<br />

the year 2030’, he said.<br />

‘I head a committee to address this, the<br />

Ministerial Committee for Ageing. One <strong>of</strong><br />

our top priorities is to think through how<br />

we can help prepare <strong>Singapore</strong> to meet<br />

the challenges associated with an ageing<br />

population. Even as the Ministry <strong>of</strong> Health<br />

continues to grow and ramp up the longterm-care<br />

sector to better support ageing,<br />

we are also looking for new and innovative<br />

solutions from beyond the medical<br />

community’, Mr Gan added.<br />

He said that engineering can make<br />

a positive contribution in this aspect,<br />

citing the example <strong>of</strong> bioengineering<br />

which has already produced meaningful<br />

results through the creation <strong>of</strong> important<br />

medical devices, tools and implants that<br />

help doctors treat their patients better<br />

and improve their quality <strong>of</strong> living.<br />

‘Cross-fertilisation and application <strong>of</strong><br />

knowledge from the disciplines <strong>of</strong> science,<br />

engineering and medicine will open new<br />

and exciting opportunities’, Mr Gan said.<br />

He also pointed out that many<br />

universities around the world have started<br />

to look into the area <strong>of</strong> ‘Healthcare<br />

Engineering’, a relatively young branch<br />

<strong>of</strong> engineering, which seeks to address<br />

challenges experienced in healthcare<br />

delivery systems.<br />

‘I see this as a natural evolution in the<br />

development <strong>of</strong> engineering. <strong>Engineers</strong><br />

traditionally have been strong in<br />

optimising efficiency and processes with a<br />

systems engineering approach. Healthcare<br />

engineering takes this forward, applying<br />

well honed and familiar approaches<br />

in systems engineering to bring about<br />

the optimisation <strong>of</strong> various factors in<br />

healthcare systems such as accessibility,<br />

safety, cost and effectiveness <strong>of</strong> care.<br />

Healthcare engineering might be a niche<br />

field today but there is great potential in<br />

such a discipline’, Mr Gan added.<br />

‘FEIAP Engineer <strong>of</strong> the Year 2011’<br />

Awards<br />

Mr Gan later presented the ‘FEIAP Engineer<br />

<strong>of</strong> the Year 2011’ Awards to Er. Pr<strong>of</strong> Su<br />

Guaning, currently President Emeritus<br />

and Pr<strong>of</strong>essor <strong>of</strong> Electrical and Electronic<br />

Engineering at Nanyang Technological<br />

University (NTU), <strong>Singapore</strong>, and to Lt Gen<br />

(Retd) BS Dhaliwal, PVSM, AVSM, VSM, a<br />

decorated soldier, with a distinguished<br />

and chequered career in the Corps <strong>of</strong><br />

<strong>Engineers</strong> <strong>of</strong> the Indian Army, spanning 41<br />

years,.<br />

The citation for Er. Pr<strong>of</strong> Su referred to<br />

his service as President <strong>of</strong> NTU from 2003<br />

to 2011, in raising the university’s pr<strong>of</strong>ile<br />

as a research-intensive global university,<br />

and prior to that, his 30 years <strong>of</strong> dedicated<br />

service to advancing defence science and<br />

technology in <strong>Singapore</strong>.<br />

A <strong>Singapore</strong> President’s Scholar and<br />

Colombo Plan Scholar, Er Pr<strong>of</strong> Su obtained<br />

PhD, MS and BSc degrees in Electrical<br />

Engineering, from Stanford University,<br />

California Institute <strong>of</strong> Technology and<br />

University <strong>of</strong> Alberta.<br />

He served as President <strong>of</strong> IES from<br />

1994 to 1996.<br />

‘Er Pr<strong>of</strong> Su Guaning is awarded the<br />

FEIAP Engineer <strong>of</strong> the Year for lifetime<br />

contributions to the engineering<br />

pr<strong>of</strong>ession and engineering education<br />

in <strong>Singapore</strong>, ASEAN and beyond’, the<br />

citation stated.<br />

The citation for Lt Gen (Retd)<br />

Dhaliwal, referred to his ‘eminent selfmotivation’<br />

that enabled the General<br />

Officer to make a difference, wherever<br />

he served, with a remarkable aptitude for<br />

pragmatic, intuitive and logical deduction.<br />

His deeds and ‘out <strong>of</strong> the box’ ideas have<br />

left an indelible mark in all appointments<br />

he has served in. Throughout his service,<br />

he has utilised his engineering knowledge<br />

and skills, with a capability and capacity to<br />

endure, and to accomplish tasks, in a timebound<br />

manner, during peace and war, and<br />

Er. Pr<strong>of</strong> Su Guaning.<br />

Lt Gen (Retd) BS Dhaliwal.<br />

14 · THE SINGAPORE ENGINEER October 2011

in all terrains.<br />

Summing up, the citation stated,<br />

‘The FEIAP Engineer <strong>of</strong> the Year 2011 is a<br />

Soldier and a Gentleman, and above all, an<br />

Engineer par excellence’.<br />

THE FEIAP CONVENTION DINNER<br />

The highlights <strong>of</strong> the FEIAP Convention<br />

Dinner included a Welcome Speech by<br />

Er. Tan Seng Chuan, FEIAP President;<br />

presentation <strong>of</strong> membership certificates<br />

to members and tokens <strong>of</strong> appreciation to<br />

the chairmen <strong>of</strong> the conference sessions,<br />

as well as the presentation <strong>of</strong> the FEIAP<br />

Special Award to Mr Peter Taylor; and<br />

the signing <strong>of</strong> an MOU between BCA<br />

Academy and IES Academy.<br />

FEIAP CONVENTION 2013<br />

The FEIAP Convention will be held<br />

once every two years. The <strong>Institution</strong> <strong>of</strong><br />

<strong>Engineers</strong>, India (IEI) will be hosting the<br />

2 nd FEIAP Convention in Hyderabad, India,<br />

in 2013.<br />

FEIAP<br />

The Federation <strong>of</strong> Engineering <strong>Institution</strong>s<br />

<strong>of</strong> Southeast Asia and the Pacific (FEISEAP),<br />

an international non-pr<strong>of</strong>it pr<strong>of</strong>essional<br />

organisation, was founded on 6 July 1978.<br />

Its establishment followed an exploratory<br />

meeting, convened and organised by The<br />

Engineering Institute <strong>of</strong> Thailand, under<br />

The King’s Patronage, with the support <strong>of</strong><br />

the United Nations Educational Scientific<br />

and Cultural Organization (UNESCO), on<br />

3 July 1978 in Chiang Mai.<br />

The objectives <strong>of</strong> FEISEAP, being<br />

an independent umbrella organisation<br />

for the engineering institutions in the<br />

Southeast Asian and the Pacific regions,<br />

were to encourage the application <strong>of</strong><br />

technical progress to economic and social<br />

advancement throughout the world, to<br />

advance engineering as a pr<strong>of</strong>ession in the<br />

interest <strong>of</strong> all people, and to foster peace<br />

throughout the world. The federation<br />

was, itself, an international member <strong>of</strong><br />

the World Federation <strong>of</strong> Engineering<br />

Organizations (WFEO) which pursues, on<br />

a global scale, objectives similar to those<br />

<strong>of</strong> FEISEAP.<br />

The constitution <strong>of</strong> the federation has<br />

been amended several times at its biennial<br />

General Assemblies. At the 14 th General<br />

Assembly <strong>of</strong> FEISEAP held in Cebu,<br />

Philippines, on 26 November, 2007, the<br />

question <strong>of</strong> the continuation <strong>of</strong> FEISEAP<br />

was discussed. It was unanimously<br />

agreed at that General Assembly, that<br />

the federation should continue, provided<br />

that its constitution was reviewed to<br />

more clearly define its objectives and to<br />

broaden the scope <strong>of</strong> economies eligible<br />

for membership.<br />

The latest version <strong>of</strong> the constitution is<br />

the result <strong>of</strong> that review and consultation<br />

with all members. It was unanimously<br />

adopted by the Special General Assembly<br />

<strong>of</strong> the federation held in Hanoi, Vietnam,<br />

on 2 June 2008, and incorporates the<br />

change <strong>of</strong> name to the Federation <strong>of</strong><br />

Engineering <strong>Institution</strong>s <strong>of</strong> Asia and the<br />

Pacific (FEIAP). TSE<br />

IES Update<br />

FEIAP Member Economies<br />

• KPEA (Korea Pr<strong>of</strong>essional <strong>Engineers</strong><br />

Association)<br />

• IEM (The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>,<br />

Malaysia)<br />

• IPEJ (<strong>Institution</strong> <strong>of</strong> Pr<strong>of</strong>essional<br />

<strong>Engineers</strong>, Japan)<br />

• EA (<strong>Engineers</strong> Australia)<br />

• EIT (The Engineering Institute <strong>of</strong><br />

Thailand)<br />

• PII (The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong><br />

Indonesia)<br />

• PTC (Philippines Technological<br />

Council)<br />

• IES (The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>,<br />

<strong>Singapore</strong>)<br />

• CAST (China Association <strong>of</strong> Science<br />

<strong>of</strong> Technology)<br />

• HKIE (Hong Kong <strong>Institution</strong> <strong>of</strong><br />

<strong>Engineers</strong>)<br />

• FIE (<strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, Fiji)<br />

• VUSTA (Vietnam Union <strong>of</strong> Science<br />

and Technology Association)<br />

• IEPNG (The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>,<br />

Papua New Guinea)<br />

• IEM (The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>,<br />

Mauritius)<br />

• ASME (The American Society <strong>of</strong><br />

Mechanical, <strong>Engineers</strong>)<br />

• CIE (Chinese Institute <strong>of</strong> <strong>Engineers</strong>,<br />

Chinese Taipei)<br />

• MES (Myanmar Engineering<br />

Society)<br />

• IEI (The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>,<br />

India)<br />

• IEB (The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>,<br />

Bangladesh)<br />

• LUSEA (Lao Union <strong>of</strong> Science and<br />

Engineering Associations)<br />

• BEC (The Board <strong>of</strong> <strong>Engineers</strong>,<br />

Cambodia)<br />

An MOU is signed between BCA Academy and IES Academy. From left: Mr Wong Wai Ching, Deputy<br />

Managing Director (Training & Pr<strong>of</strong>essional Development) and Mr Benedict Tan, Managing Director,<br />

BCA Academy; Er. Ho Siong Hin, President, and Pr<strong>of</strong> Chou Siaw Kiang, Deputy President, IES. The<br />

agreement aims to advance the training and continuous education <strong>of</strong> engineering pr<strong>of</strong>essionals in the<br />

built environment. The MOU is expected to lead to the joint identification, creation and organisation <strong>of</strong><br />

seminars, discussion fora, training programmes, publications, and a repository <strong>of</strong> resources. A relevant<br />

committee will also be formed jointly to set industry standards for the certification <strong>of</strong> competencies<br />

and skill sets. IES members who are involved in the built environment are expected to benefit from<br />

this agreement.<br />

Mr Peter Taylor receives the FEIAP Special<br />

Award from Er. Tan. On left is Ir. Tan Yean Chiu,<br />

Secretary General, FIEAP.<br />

October 2011<br />

THE SINGAPORE ENGINEER · 15

Cover Story<br />

T<br />

he BCA Design and Engineering<br />

Safety Excellence Awards were<br />

instituted as part <strong>of</strong> the efforts by BCA<br />

(Building and Construction Authority) to<br />

ensure high safety standards in the built<br />

environment and inculcate a strong safety<br />

culture in the building industry.<br />

The Award gives recognition to the<br />

efforts taken by the Qualified Person for<br />

Structural Works [QP (ST)], his or her firm<br />

and the project team, for ingenious design<br />

processes and solutions for overcoming<br />

project challenges and ensuring safety in<br />

the design, construction, and maintenance,<br />

<strong>of</strong> building and civil engineering projects,<br />

in <strong>Singapore</strong> and overseas.<br />

The Sentosa Boardwalk<br />

The project was an Award Winner, under the Civil Engineering Category,<br />

at the BCA Design and Engineering Safety Excellence Awards 2011.<br />

Through this Award, BCA hopes to<br />

encourage industry pr<strong>of</strong>essionals to make<br />

a more concerted effort to create a safe<br />

built environment for all.<br />

The assessment criteria covers two key<br />

aspects - safety in design, and safety in<br />

construction.<br />

The Sentosa Boardwalk is a 620 m long<br />

marine structure connecting VivoCity<br />

to Sentosa Island. Built at a cost <strong>of</strong> S$ 70<br />

million, and located near the busy Cruise<br />

Bay, it cuts through the Selat Sengkir sea<br />

channel (which is characterised by high<br />

tidal currents), between Pulau Brani and<br />

Sentosa Island.<br />

With a total deck area <strong>of</strong> approximately<br />

16460 m 2 , the boardwalk accommodates<br />

extensively landscaped gardens, retail and<br />

food & beverage outlets, as well as five<br />

pairs <strong>of</strong> covered travellators ‘to make the<br />

journey a breeze’.<br />

THE CHALLENGES<br />

Construction <strong>of</strong> The Sentosa Boardwalk<br />

was a challenge because <strong>of</strong> several<br />

constraints.<br />

LOCATION<br />

The boardwalk is located within a highly<br />

constrained site, with several stakeholders<br />

including pedestrians commuting to<br />

Vivo City and Sentosa Island, motorists<br />

16 · THE SINGAPORE ENGINEER October 2011

travelling along Sentosa Gateway Avenue,<br />

Sentosa Monorail commuters, and vessel<br />

operators within the busy Cruise Bay.<br />

ENVIRONMENTAL IMPACT<br />

The design had to take into account the<br />

need to minimise the environmental<br />

impact on the Cruise Bay basin.<br />

CONSTRUCTION OPERATIONS<br />

All construction except the above-deck<br />

works had to be executed over water in the<br />

busy Cruise Bay basin and be subjected to<br />

the rapid currents in the Selat Sengkir sea<br />

channel. The capacity <strong>of</strong> the lifting crane<br />

was limited by barge access, headroom<br />

constraints, and proximity <strong>of</strong> the Sentosa<br />

Monorail track.<br />

SHORT CONTRACT PERIOD<br />

In order to complete the project within<br />

15.5 months, a 24/7 fast-track operations<br />

mode was required.<br />

BOARDWALK GEOMETRY<br />

The undulating boardwalk coastline<br />

necessitated the use <strong>of</strong> non-typical edge<br />

slab panels and cantilever beam spans.<br />

VESSEL IMPACT BARRIER SYSTEM<br />

It was necessary to build a vessel impact<br />

barrier that would be able to resist the<br />

exceptionally high, accidental impact from,<br />

for example, a 19,000 gross ton cruise ship<br />

travelling at 3 knots. The impact barrier<br />

system could be sited only in a small<br />

corridor, due to the restriction imposed<br />

by the vessel turning circle nearby.<br />

CREATIVE ENGINEERING<br />

SOLUTIONS<br />

Methods had to be developed to overcome<br />

the constraints and, at the same time,<br />

ensure safety and cost-effectiveness.<br />

Cover Story<br />

SAFETY IN STRUCTURAL DESIGN<br />

The boardwalk development is mainly<br />

a marine construction. Considerations<br />

during the concept development stage<br />

were focused particularly on minimising<br />

on-site activities. Design details and<br />

construction methods were formulated<br />

to facilitate mechanised operations<br />

and constructability, so as to enhance<br />

work efficiency and safety at site. The<br />

boardwalk superstructure, supported on<br />

marine steel and bored piles, consists <strong>of</strong><br />

10 m - 15 m structural grids with primarily<br />

precast prestressed concrete elements.<br />

Special / innovative features<br />

‘Twin’ L-shape prestressed precast beams<br />

The boardwalk supports heavy<br />

superimposed loads due to the<br />

extensive landscaping requirements. This<br />

demanded high capacity primary beams<br />

The Sentosa Boardwalk is a 620 m long marine structure connecting VivoCity to Sentosa Island.<br />

October 2011<br />

THE SINGAPORE ENGINEER · 17

Cover Story<br />

with 10 m - 15 m spans. The maximum<br />

precast cross-sectional area <strong>of</strong> the primary<br />

beam was limited by the lifting capacity<br />

<strong>of</strong> the crane, due to inaccessibility <strong>of</strong> the<br />

barge point between the foundations,<br />

headroom constraints, and proximity <strong>of</strong><br />

the Sentosa Monorail track.<br />

With the constraint <strong>of</strong> segment<br />

weight, a prestressed precast primary<br />

beam was designed, whose peripheral<br />

shell was made up <strong>of</strong> two pieces <strong>of</strong> L-shape<br />

beams. The segment weight was limited<br />

to 15 t. This twin L-shape shell also acted<br />

as formwork to receive the concrete infill<br />

for the final integrated section. It was<br />

detailed and designed with adequate<br />

capacity for all well-defined construction<br />

stages and sequences, to eliminate the<br />

use <strong>of</strong> any temporary formwork during<br />

Infill to L-shape prestressed precast primary<br />

beam supports the T-panels.<br />

L-shape prestressed precast beam installed above piles.<br />

the erection stage.<br />

Due to the asymmetrical shape <strong>of</strong><br />

the beam, careful consideration was<br />

given to the quantity and position <strong>of</strong> the<br />

prestressed strands, in the design, in order<br />

to minimise warping <strong>of</strong> the beams.<br />

One <strong>of</strong> the architectural features <strong>of</strong><br />

the boardwalk is the peripheral pr<strong>of</strong>ile<br />

<strong>of</strong> an ‘undulating wave’ along the deck<br />

coastline. Piles are positioned such that<br />

they are set back from the boardwalk<br />

coastline, resulting in cantilevers <strong>of</strong><br />

variable lengths at the end spans <strong>of</strong><br />

the primary beams. Even though the<br />

cantilever lengths vary significantly, the<br />

precast solution was adopted instead<br />

<strong>of</strong> the cast in-situ option, in order to<br />

eliminate the need for temporary works<br />

and formworks. The main challenge in<br />

the engineering was that long cantilevers<br />

had to be supported by relatively small<br />

recessed sections at the beam-pile head<br />

interface.<br />

The nib <strong>of</strong> the L-shape beams and the<br />

recessed size at the pile head were carefully<br />

detailed so as to cater for pile eccentricity<br />

with a construction tolerance limit <strong>of</strong><br />

200 mm. The twin L-shape concept also<br />

provided flexibility to deal with abnormal<br />

pile eccentricity by opening up the two<br />

precast sections. Pile eccentricity <strong>of</strong> 250<br />

mm was observed in this project due to<br />

the difficulty <strong>of</strong> marine piling in high tidal<br />

currents and the geological complexity.<br />

Erection <strong>of</strong> the precast elements could<br />

have been problematic due to the pile<br />

alignment <strong>of</strong>fsets, if adequate tolerances<br />

had not been provided.<br />

Vessel impact barrier<br />

A ship impact defence system that can<br />

resist the impact <strong>of</strong> a 19,000 gross tonnage<br />

cruise ship at an exceptionally high speed<br />

<strong>of</strong> 3 knots was designed to protect the<br />

Sentosa Boardwalk. The available site area<br />

was limited by the adjacent vessel turning<br />

circle. Due to the high impact energy,<br />

a conventional fender system was not<br />

feasible.<br />

With the independent protection<br />

system, which is separated from the<br />

Sentosa Boardwalk, the impact energy<br />

will be absorbed by plastic hinges in steel<br />

pipe piles with in-filled concrete. Nonlinear,<br />

large deformation plastic analysis<br />

was adopted in the design. The system<br />

demanded no new materials or plant<br />

requirements for the foundation work<br />

for the boardwalk. This yielded a costefficient<br />

solution for the builder and the<br />

impact system required minimal site<br />

area and buffer zone separating it from<br />

the boardwalk deck, when compared to<br />

conventional solutions.<br />

Precast U-beam shell for vessel impact barrier<br />

beam construction.<br />

Advanced structural system for<br />

buildability<br />

Prestressed precast elements<br />

The advantages <strong>of</strong> precast technology<br />

were fully exploited in this project. The<br />

precast solution minimised site activities<br />

in the marine environment and enhanced<br />

safety. The prestressed concrete shell<br />

<strong>of</strong> the primary beam was designed to<br />

function both as the temporary works<br />

and permanent structure, as part <strong>of</strong><br />

the optimisation process. The main<br />

components <strong>of</strong> the structural deck are the<br />

following:<br />

• Main prestressed precast concrete<br />

(twin L-shape) primary beam with<br />

concrete infill, to provide the required<br />

design section capacity.<br />

• Prestressed precast U-secondary<br />

beam with concrete infill, to provide the<br />

required design section capacity.<br />

18 · THE SINGAPORE ENGINEER October 2011

• Prestressed precast T-panels / Double<br />

T-panels for the deck, with a cast-in-situ<br />

topping.<br />

• Precast reinforced edge panels for the<br />

irregular deck at the coastline.<br />

• Cast-in-situ structural concrete<br />

topping.<br />

About 97% <strong>of</strong> the structural deck<br />

is erected with precast elements. All<br />

the precast connections were carefully<br />

detailed for monolithic connection and<br />

provided a robust structural system in the<br />

deck.<br />

All elements were designed for efficient<br />

and safe operations with global and local<br />

stability checks during the manufacturing<br />

stage in the precast yard, handling, and<br />

erection at site. They were also designed<br />

for durability in their performance under<br />

the service conditions.<br />

The precast elements were<br />

standardised so that only four types <strong>of</strong><br />

moulds (for L-primary beam, U-secondary<br />

beam, T panel , and double T panel)<br />

were employed in the casting yard. The<br />

extensive use <strong>of</strong> precasting also provided<br />

the economies <strong>of</strong> scale in this project.<br />

The creative structural system with<br />

a high level <strong>of</strong> standardisation not only<br />

contributed to cost-effectiveness in this<br />

‘design and build’ project, it was also one<br />

<strong>of</strong> the key factors contributing to the high<br />

productivity and the speedy completion<br />

<strong>of</strong> the works.<br />

Cover Story<br />

Collaboration with builder<br />

The builder was actively engaged<br />

throughout the design development.<br />

Constructability details and tolerance<br />

limits were established in the early stages<br />

<strong>of</strong> the project, prior to detailed design. For<br />

example, the use <strong>of</strong> a permanent reinforced<br />

concrete biscuit, as temporary support to<br />

the primary and secondary beams, was an<br />

end product <strong>of</strong> a brainstorming exercise<br />

between the builder and the designer.<br />

The biscuit also served as a safe working<br />

platform at the pile-beam interface zone.<br />

The pile head reinforcement was restricted<br />

so that there would be sufficient space to<br />

mount the reinforced concrete biscuit.<br />

Another example was the integration<br />

L-shape prestressed precast primary beam.<br />

U-shape prestressed precast secondary beam.<br />

Prestressed precast T-panels for the deck with<br />

gaps sealed <strong>of</strong>f to receive concrete toppings.<br />

The completed vessel impact barrier system.<br />

Structural toppings at deck for subsequent<br />

superstructure construction.<br />

October 2011<br />

THE SINGAPORE ENGINEER · 19

Cover Story<br />

<strong>of</strong> the access platform with the precast<br />

elements. The builder’s operational<br />

requirements were identified during<br />

the concept design. The reinforcement<br />

details necessary for mounting the access<br />

platform and temporary railing onto the<br />

primary and secondary precast beams<br />

were incorporated in the yard.<br />

Competent site supervision and<br />

verification<br />

The site supervision team consisted <strong>of</strong><br />

qualified and experienced personnel.<br />

They were deployed both at the overseas<br />

precast casting yards and at the project<br />

site, to oversee the quality and safety <strong>of</strong><br />

the construction works.<br />

Concrete cube strength tests were<br />

carried out on a regular basis throughout<br />

the project, in accordance with the<br />

specifications, both in the overseas<br />

precast casting yards and at an approved<br />

laboratory in <strong>Singapore</strong>, in order to ensure<br />

that the required concrete cube strength<br />

had been achieved before the next stage<br />

<strong>of</strong> activity could proceed.<br />

QUALITY APPROACH IN DESIGN<br />

Comprehensive design analyses and<br />

checks<br />

Comprehensive design analyses and<br />

checks were carried out to ensure safe<br />

erection works and proper performance<br />

<strong>of</strong> the permanent structure in service.<br />

The main design checks covered beam<br />

stresses on the prestressed casting bed and<br />

beam stresses during lifting and handling,<br />

as well as stage-by-stage construction<br />

analyses to include all lock-in forces,<br />

global and local stability checks during<br />

the entire erection and installation phases,<br />

and durability analysis <strong>of</strong> the structure in<br />

service.<br />

DESIGN FOR SAFE OPERATION<br />

AND MAINTENANCE<br />

Safe inspection and maintenance <strong>of</strong><br />

building elements<br />

The durability performance <strong>of</strong> the deck,<br />

under the marine environment, was an<br />

important design consideration. The<br />

foundations for the reinforced concrete<br />

bored piles were protected with sacrificial<br />

outer steel casing, while cathodic<br />

protection was incorporated to protect<br />

the foundations for the steel pipe piles.<br />

All the top sections <strong>of</strong> the piles, which<br />

have the greatest exposure to corrosion,<br />

were coated with corrosion inhibitors and<br />

finished <strong>of</strong>f with anti-corrosion paint on<br />

the steel casing.<br />

The deck structures were cast with<br />

Permanent RC precast biscuit at pile.<br />

Completion <strong>of</strong> RC precast biscuit installation.<br />

Completion <strong>of</strong> precast beams erection.<br />

Launching <strong>of</strong> L-shape prestressed precast<br />

primary beam with safety railing.<br />

Concrete in-fill to secondary beam with working<br />

access platform.<br />

silica fume and corrosion inhibitors and<br />

protected with adequate concrete cover.<br />

Silane coatings were applied to the deck<br />

structures.<br />

With careful consideration given in<br />

the design to durability, it is expected that<br />

the required maintenance work for the<br />

operators will be minimised.<br />

For periodic inspection, the marine<br />

structures can be accessed by boats, at<br />

low tide. The structural level <strong>of</strong> the deck<br />

was designed to allow for maintenance<br />

access from the s<strong>of</strong>fit <strong>of</strong> the structures.<br />

The timber boardwalk is supported<br />

<strong>of</strong>f the structural deck, so that the timber<br />

panels can be easily removed for deck<br />

inspections.<br />

Special designs for occupant safety and<br />

comfort<br />

As discussed above, an independent ship<br />

impact defence system separated from<br />

the boardwalk was designed to protect<br />

the boardwalk.<br />

Spacing <strong>of</strong> the piles for both the<br />

boardwalk and vessel impact barrier was<br />

determined, following an Environmental<br />

Impact Assessment Report. The piles<br />

were aligned to match the boardwalk’s 10<br />

m - 15 m grid with a minimum required<br />

clearance from the deck, so as to mitigate<br />

the encroachment into the Cruise Bay<br />

navigational channel. It was determined<br />

that there will not be any major impact<br />

on the mean current speed within the<br />

Cruise Bay, after completion <strong>of</strong> boardwalk<br />

structure.<br />

CONSTRUCTION QUALITY AND<br />

SAFETY<br />

Design <strong>of</strong> construction methods and<br />

sequence<br />

The builder was required to submit the<br />

method statement for critical activity<br />

at site, for the approval <strong>of</strong> the QP (ST).<br />

Launching <strong>of</strong> U-shape prestressed precast<br />

secondary beam.<br />

20 · THE SINGAPORE ENGINEER October 2011

The critical list <strong>of</strong> method statements<br />

included those for marine bored piling<br />

works, marine pipe piling works, marine<br />

preliminary test pile, test pile installation,<br />

pile dynamic analyser test, launching <strong>of</strong><br />

precast concrete beams, launching <strong>of</strong><br />

precast concrete biscuit, construction <strong>of</strong><br />

concrete deck, construction <strong>of</strong> building<br />

superstructures, construction <strong>of</strong> the<br />

vessel impact barrier, installation <strong>of</strong> steel<br />

structure for gangway, installation <strong>of</strong> steel<br />

structure for metal ro<strong>of</strong> / glass canopies,<br />

and installation <strong>of</strong> steel structures for ro<strong>of</strong><br />

dome <strong>of</strong> ticketing area.<br />

Any deviation from the design/<br />

construction intention agreed on, would<br />

instigate an investigation. The site work<br />

would be put on hold until the revised<br />

method was approved by the QP (ST).<br />

The QP (ST) would then conduct a joint<br />

inspection with the temporary works PE<br />

and the site team, prior to resumption <strong>of</strong><br />

the works.<br />

Supervision and inspection<br />

A 24-hour supervision cycle, with two<br />

work shifts, was needed in this project.<br />

When night works were carried out, the<br />

QP (ST)’s supervision team would always<br />

be in top condition (ie the members<br />

would have had adequate rest) in order to<br />

discharge the duties safely.<br />

The builder implemented a good<br />

QA/QC plan. Joint inspections were<br />

usually carried out by the QP (ST)’s site<br />

supervision team together with the<br />

builder’s supervision team.<br />

The QP (ST) witnessed all critical tests.<br />

The list <strong>of</strong> critical tests included the tremie<br />

trial mix test, concrete trial mix test,<br />

concrete cube strength test, bidirectional<br />

static load test, pile dynamic analyser<br />

test, magnetic particle test, ultrasonic<br />

test, sonic coring test, reinforcement test,<br />

reinforcement coupler test, shear stud<br />

test, and rapid chloride penetration test.<br />

PUBLIC SAFETY<br />

Ensuring safety and a clean<br />

environment<br />

The project is sited in the Cruise Bay, along<br />

Sentosa Gateway Avenue. Public safety<br />

is crucial for the many stakeholders such<br />

as public road users, pedestrians, marine<br />

operators, and Sentosa monorail train<br />

commuters. Careful planning was done<br />

and adequate attention was paid, to<br />

ensure that all lifting operations, especially<br />

for moving the precast elements, were<br />

safely executed.<br />

A total <strong>of</strong> 159 L-shape primary beams,<br />

104 U-shape secondary beams, and 720 T<br />

panels were lifted.<br />

Delivery and launching <strong>of</strong> the precast<br />

segments were done between 2230<br />

and 0600 hours. During this period, the<br />

monorail is shut down, and the road traffic<br />

and number <strong>of</strong> commuters between<br />

VivoCity and Sentosa are lower. The<br />

precast beams were transferred from the<br />

trailer to the barge deck via a 280 t crane<br />

barge. The lifting operation was properly<br />

executed through a carefully planned<br />

lifting plan with the crane boom kept<br />

within 6 m <strong>of</strong> the Sentosa monorail track<br />

protection zone.<br />

A silt control system was provided<br />

to prevent contamination <strong>of</strong> the Cruise<br />

Bay basin (an area that is a tourist<br />

attraction) by silt, due to the drilling for<br />

pile installation. The Environment Impact<br />

Assessment Report concluded that there<br />

was no adverse impact on the recreational<br />

areas in the vicinity.<br />

Minimising impact on the<br />

neighbourhood<br />

Bored piling foundations with temporary<br />

outer steel casing were adopted to<br />

minimise impact on the structures in<br />

vicinity and to prevent any s<strong>of</strong>t soil strata<br />

from collapsing during the course <strong>of</strong><br />

drilling.<br />

Piling rig set up on barge.<br />

The Sentosa Boardwalk at night.<br />

Cover Story<br />

The piles were positioned with an<br />

<strong>of</strong>fset from the adjacent structures, <strong>of</strong><br />

at least 4.5 m, so as to minimise impact<br />

from the foundation work. The structural<br />

elements abutting the adjacent plots were<br />

designed as cantilever structures without<br />

imposing loads onto adjacent existing<br />

structures. Expansion joints were provided<br />

between the boardwalk development and<br />

adjacent foreshore structures.<br />

With the above, the development is<br />

supported independently on a new piling<br />

system and the foundations are located<br />

adequately away from adjacent structures.<br />

The works did not have any adverse effect<br />

on the stability and integrity <strong>of</strong> the existing<br />

foreshore structures.<br />

Precast elements were adopted to<br />

minimise the need <strong>of</strong> cast in-situ works.<br />

This meant fewer concrete trucks along<br />

the busy Sentosa Gateway Avenue. The<br />

use <strong>of</strong> precast elements also increased<br />

productivity and reduced the disturbance<br />

to the neighbourhood during the<br />

construction. TSE<br />

All images by YWL Engineering Pte Ltd.<br />

Qualified Person<br />

Er. Chew Boon Fei<br />

PROJECT CREDITS<br />

C&S Consultant<br />

YWL Engineering Pte Ltd<br />

Builder<br />

Gammon Pte Limited<br />

Developer<br />

Sentosa Development Corporation<br />

Architectural Consultant<br />

Aedas Pte Ltd<br />

October 2011<br />

THE SINGAPORE ENGINEER · 21

IES Academy Update<br />

IES Academy Planned Events 2011 (Partial List)<br />

(Pls refer www.ies.org.sg for details & registration)<br />

Event Description Dates to confirm Accrediation Contact<br />

Events for Resident Technical Offi cer / <strong>Engineers</strong><br />

RE/RTO - Welding Series (Module 1-10), 3 hours / module Jan-Dec 2011<br />

(7pm to 10pm)<br />

3 STU, PDU Karen, 6461 1239<br />

karen@iesnet.org.sg<br />

RE/RTO - Good Concrete Series (Module 1-5), 3 hours /<br />

module<br />

To be advised later<br />

(7pm to 10pm)<br />

3 STU, PDU Vincent, 6461 1240<br />

vincent@iesnet.org.sg<br />

RE/RTO - Structural Steel Series (Module 1-3), 3 hours /<br />

module<br />

To be advised later<br />

(7pm to 10pm)<br />

3 STU, PDU Vincent, 6461 1240<br />

vincent@iesnet.org.sg<br />

RE/RTO - Underground (Module 1-4), 3 hours / module To be advised later<br />

(7pm to 10pm)<br />

3 STU, PDU Vincent, 6461 1240<br />

vincent@iesnet.org.sg<br />

RE/RTO - Paired Natsteel Workshop & Law on Health &<br />

Safety, Environment, Corruption (Module 1-2), 7 hours<br />

Jan-Dec 2011<br />

(1pm to 10pm)<br />

6 STU, 4 PDU Vincent, 6461 1240<br />

vincent@iesnet.org.sg<br />

RE/RTO - Surveying Basic (Module 1-2), 3 hours / module Jan-Dec 2011<br />

(7pm to 10pm)<br />

3 STU, PDU Karen, 6461 1239<br />

karen@iesnet.org.sg<br />

RE/RTO - Concrete: Defects, Repair, Testing (Module 1-3), 3<br />

hours / module<br />

Apr-Dec 2011 3 STU, PDU Karen, 6461 1239<br />

karen@iesnet.org.sg<br />

Certificate <strong>of</strong> Competency (CoC) in Earth Control Measures<br />

(ECM) for Construction Site Personnel<br />

Jan-Dec 2011<br />

(8:30am to 6pm)<br />

8 STU, PDU Rasheedah, 6461 1228<br />

rasheedah@iesnet.org.sg<br />

One Day Course on Working at Height Feb, Apr, Jun, Aug, Oct, Dec 2011<br />

(9am to 5:30pm)<br />

6 STU, 7 PDU, 7 SDU Samuel, 6461 1237<br />

samuel@iesnet.org.sg<br />

Code <strong>of</strong> Pracitise on Risk Management Jul, Sep, Nov 2011<br />

(9am to 5:30pm)<br />

~7 STU, PDU, SDU Samuel, 6461 1237<br />

samuel@iesnet.org.sg<br />

Events for Pr<strong>of</strong>essional <strong>Engineers</strong><br />

Prestressed Concrete in Buildings Mar, Jul, Nov 2011<br />

(9am to 5pm)<br />

Prelimentary Design <strong>of</strong> High-Rise Buildings Jan, May, Sep 2011<br />

(9am to 12:15pm)<br />

Strengthening <strong>of</strong> Reinforced Concrete Structures Jan, May, Sep 2011<br />

(1pm to 4:30pm)<br />

Reinforced Concrete Structures to EC2 Feb, June, Oct 2011<br />

(9am to 4:30pm)<br />

Structural Engineering Failure Apr, Aug, Dec 2011<br />

(9:30am to 5:30pm)<br />

Elements <strong>of</strong> Laboratory BioSafety Jan 2011<br />

(9am to 5:30pm)<br />

Elements <strong>of</strong> Internal Audit for Medical Device Industry Jan 2011<br />

(9am to 5:30pm)<br />

3 Days Course on Design <strong>of</strong> Maritime Structure March 2011<br />

(9am to 6pm)<br />

2 Days Course on Design for Safety Coordinator (DfSC) 15-16 Mar, 8-9 Jul, 21-22 Oct 2011<br />

(9am to 5pm)<br />

Introduction to the Petroleum Downstream Industry Jan 2011<br />

(9am to 5:30pm)<br />

2 Days Course on Green Pump - Centrifugal Feb 2011<br />

(8:30am to 5:30pm)<br />

Technical & Business Writing for Engineering Personnel Mar 2011<br />

(9pm to 6pm)<br />

PDU Rasheedah, 6461 1228<br />

rasheedah@iesnet.org.sg<br />

PDU Rasheedah, 6461 1228<br />

rasheedah@iesnet.org.sg<br />

PDU Rasheedah, 6461 1228<br />

rasheedah@iesnet.org.sg<br />

PDU Rasheedah, 6461 1228<br />

rasheedah@iesnet.org.sg<br />

PDU Rasheedah, 6461 1228<br />

rasheedah@iesnet.org.sg<br />

PDU Rasheedah, 6461 1228<br />

rasheedah@iesnet.org.sg<br />

PDU Rasheedah, 6461 1228<br />

rasheedah@iesnet.org.sg<br />

PDU Karen, 6461 1239<br />

karen@iesnet.org.sg<br />

PDU, CPD, SDU, STU Vincent, 6461 1240<br />

vincent@iesnet.org.sg<br />

PDU Samuel, 6461 1237<br />

samuel@iesnet.org.sg<br />

PDU Samuel, 6461 1237<br />

samuel@iesnet.org.sg<br />