External cladding - Australian Hardwood Network - Timber.net.au

External cladding - Australian Hardwood Network - Timber.net.au

External cladding - Australian Hardwood Network - Timber.net.au

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

AUSTRALIAN HARDWOOD AND CYPRESS<br />

1<br />

A P P L I C A T I O N G U I D E<br />

<strong>External</strong> Cladding<br />

SCOPE<br />

<strong>Timber</strong> <strong>cladding</strong> provides an envelope that<br />

protects and be<strong>au</strong>tifies a building. This guide<br />

covers design and construction advantages,<br />

popular <strong>cladding</strong> systems, detailing<br />

requirements, and regulatory issues.<br />

ADVANTAGES OF TIMBER<br />

Structural Advantages<br />

• can be used on a wide variety of foundation<br />

conditions bec<strong>au</strong>se of its flexibility,<br />

• light weight requires smaller footings,<br />

• clad walls can be supported by posts,<br />

columns or piers, and therefore continuous<br />

sub-floor wall support is unnecessary – thus<br />

reducing costs.<br />

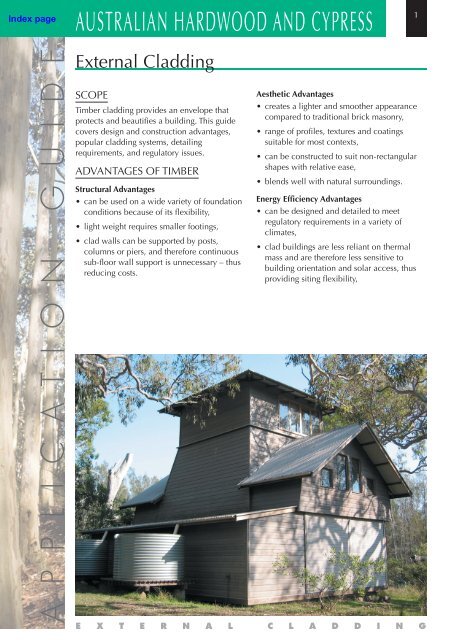

Aesthetic Advantages<br />

• creates a lighter and smoother appearance<br />

compared to traditional brick masonry,<br />

•range of profiles, textures and coatings<br />

suitable for most contexts,<br />

• can be constructed to suit non-rectangular<br />

shapes with relative ease,<br />

• blends well with natural surroundings.<br />

Energy Efficiency Advantages<br />

• can be designed and detailed to meet<br />

regulatory requirements in a variety of<br />

climates,<br />

• clad buildings are less reliant on thermal<br />

mass and are therefore less sensitive to<br />

building orientation and solar access, thus<br />

providing siting flexibility,<br />

E X T E R N A L C L A D D I N G

2<br />

AUSTRALIAN HARDWOOD AND CYPRESS<br />

• reacts quickly to both heating and cooling,<br />

taking little time to warm a cool room, or to<br />

cool a hot one. Insulation will also add to<br />

this by helping to reduce life-cycle energy<br />

consumption and green house gas<br />

emissions.<br />

‘The snug house’<br />

Construction Advantages<br />

•rapid construction,<br />

• reduced material handling and scaffolding -<br />

especially on steep sites,<br />

• no wet trades involved.<br />

GOOD DESIGN PRACTICE<br />

Good design practices help to ensure the best<br />

performance from timber <strong>cladding</strong>. For<br />

example, wide eaves and verandas help to<br />

provide protection.<br />

Flashings at corners, doors, windows and wall<br />

intersections must be detailed to hold a head<br />

of water in harsh weather environments.<br />

Cladding should finish at least 150mm above<br />

finished ground/paving level to avoid moisture<br />

up-take as shown in Figure 1. In conjunction<br />

with this, the bottom edge should be cut to<br />

slope upwards and inwards (i.e. at an angle of<br />

15 degrees) to prevent water tracking back into<br />

the building – as shown in Figure 2.<br />

Figure 1: Ground clearance<br />

‘The breeze house’<br />

Vapour permeable<br />

sarking<br />

150mm<br />

min.<br />

Grade surface<br />

away from house<br />

Figure 2: Drip initiator<br />

SARKING<br />

Sarking is used to direct water that may have<br />

pe<strong>net</strong>rated the <strong>cladding</strong> back to the outside. It<br />

also provides a barrier to prevent drafts, wind<br />

driven rain and dust from entering the wall<br />

cavity. Sarking must be weather proof but<br />

vapour permeable, and is often made from<br />

aluminium foil or bitumen bonded insulation.<br />

This is fixed directly behind the timber<br />

<strong>cladding</strong> – as shown in Figure 3. Additional<br />

detailing may also be necessary where<br />

condensation is a concern. This occurs where<br />

there is a large temperature difference between<br />

the indoor and outdoor environments – as in<br />

very cold climates. Cavity insulation can help<br />

by reducing cold outer air from meeting warm<br />

inner air. In extreme conditions a devoted<br />

vapour barrier on the warm side of the<br />

insulation may also be necessary.<br />

Figure 3: Sarking and vapour barrier<br />

Internal wall<br />

lining<br />

E X T E R N A L C L A D D I N G<br />

Frame<br />

Sarking<br />

15º<br />

Undercut bottom<br />

edge of <strong>cladding</strong><br />

to provide drip<br />

initiator<br />

Cladding<br />

A P P L I C A T I O N G U I D E

AUSTRALIAN HARDWOOD AND CYPRESS<br />

3<br />

A P P L I C A T I O N G U I D E<br />

CLADDING BOARD SELECTION<br />

Solid timber <strong>cladding</strong> boards are available in<br />

either seasoned or unseasoned materials.<br />

Seasoned boards are characterised by being<br />

dressed, having a machined moulded face, and<br />

interlocking tongue and groove (or rebated)<br />

joint. Unseasoned boards are more likely to be<br />

rough sawn, have an unmachined face, and<br />

the absence of any tongue and groove joint.<br />

Cypress can often be supplied unseasoned,<br />

with a machined face and a tongue and groove<br />

joint designed to accommodate the expected<br />

shrinkage. This allows for shrinkage movement<br />

in-situ. The most common options are shown<br />

in Figure 4.<br />

Figure 4: Typical solid timber <strong>cladding</strong> profiles<br />

Weatherboard<br />

30mm<br />

Rebate<br />

Weatherboard<br />

15mm<br />

Species<br />

Cypress<br />

<strong>Hardwood</strong><br />

1 AS2796.2 – <strong>Timber</strong> hardwood – sawn and milled products, Standards Australia.<br />

2 AS1810 – <strong>Timber</strong> – seasoned Cypress – milled products, Standards Australia.<br />

Species used for <strong>cladding</strong> include: Blackbutt,<br />

Cypress, Tallowwood, Spotted Gum, and a<br />

mixture of species generally termed mixed<br />

hardwoods. Each can be purchased in specific<br />

grades defining natural features of the<br />

<strong>cladding</strong>. (Refer to Table 1). For example,<br />

‘Select’ grade contains few knots and gum<br />

veins, while ‘Medium’ and ‘High Feature’<br />

grades contain higher proportions of these<br />

natural features. Ranking for Cypress follows a<br />

similar theme. Specific details for each can be<br />

found in AS2796.2 1 and AS1810 2 respectively.<br />

Table 1: Grade descriptions<br />

Grades<br />

Grade 1<br />

Grade 2<br />

Select Grade<br />

Medium Feature Grade<br />

High Feature Grade<br />

E X T E R N A L C L A D D I N G<br />

Shiplap<br />

16mm<br />

Chamferboard<br />

12 mm

4<br />

AUSTRALIAN HARDWOOD AND CYPRESS<br />

Moisture Content<br />

Moisture content in <strong>cladding</strong> boards influences<br />

overlap requirements. Seasoned boards should<br />

have a moisture content between 10-18% for<br />

hardwood and 10-15% for Cypress which<br />

ensures relatively little movement once the<br />

boards are fitted – thus allowing a small rebate<br />

or overlap.<br />

In contrast, unseasoned boards have in excess<br />

of 18% content and are prone to considerable<br />

shrinkage movement – thus creating the need<br />

for larger rebates or overlaps.<br />

Given this, the following applies 3 :<br />

•For seasoned boards less than 150mm in<br />

width, a 13mm (min.) rebate or overlap is<br />

required. For boards greater than 150mm, a<br />

20mm (min.) rebate or overlap is required.<br />

•For unseasoned boards a 30mm (min.)<br />

overlap is required.<br />

Figure 5: Nailing distances<br />

Unseasoned Cladding<br />

Nail as specified<br />

30mm overlap<br />

Vapour permeable<br />

sarking<br />

35mm approx.<br />

Cladding<br />

Full length packing at<br />

bottom boards and as<br />

necessary over openings<br />

Table 2: Recommended minimum nail sizes<br />

Cladding Thickness<br />

15 to 22mm profiled<br />

Sawn weatherboards<br />

Cypress & <strong>Hardwood</strong> Framing<br />

50 x 2.8mm plain<br />

60 x 2.8mm plain<br />

Nailing<br />

Nailing requirements also vary according to<br />

seasoned or unseasoned states.<br />

For instance, unseasoned boards must be able<br />

to shrink independently of each other.<br />

Therefore nailing through overlaps must be<br />

avoided but must still provide restraint to the<br />

inner board – as shown in Figure 5.<br />

Seasoned boards also should be nailed well<br />

away from edges to avoid splitting of thinner<br />

sections, or where tongue and groove or<br />

rebated overlaps occur. In addition, all board<br />

ends should pre-drilled to prevent splitting and<br />

flat head nails should be used to prevent pullout.<br />

Nails also need to be chosen to suit durability<br />

requirements and hot-dip galvanised nails are<br />

often adequate. Table 2 provides further details<br />

on specific nail sizes for different board<br />

thicknesses.<br />

Seasoned Cladding<br />

Nail Size (mm)<br />

Vapour permeable<br />

sarking<br />

E X T E R N A L C L A D D I N G<br />

25mm<br />

25mm<br />

Nail as specified<br />

Cladding<br />

Softwood other than Cypress Framing<br />

60 x 2.8mm twisted or annular<br />

threaded<br />

65 x 2.8mm twisted or annular<br />

threaded<br />

3 Details are taken from AS2796.1 which applies to hardwoods. No overlap or rebate requirements are given for<br />

Cypress.<br />

A P P L I C A T I O N G U I D E

AUSTRALIAN HARDWOOD AND CYPRESS<br />

5<br />

A P P L I C A T I O N G U I D E<br />

Installation Practices<br />

Installation practices must be undertaken with<br />

weather resistance in mind.<br />

• Boards with grooves must be fixed with the<br />

groove facing downwards.<br />

• Sealants such as mastics should be avoided.<br />

• Butt joints between boards should be<br />

minimised to limit moisture ingress e.g.<br />

single or long lengths should be used on<br />

walls exposed to prevailing weather<br />

conditions, short lengths could be used<br />

between windows or on sheltered parts of<br />

the wall, such as under eaves and verandas.<br />

• Butt joints should be achieved by slightly<br />

over cutting board lengths then snapping the<br />

bowed board into position. For durability,<br />

boards should be end sealed prior to<br />

installation (e.g. with paint or oil based<br />

stain).<br />

HARDBOARD PRODUCTS<br />

Hardboard products represent a special part of<br />

the <strong>cladding</strong> market. Different design and<br />

installation practices are required compared to<br />

solid timber <strong>cladding</strong>.<br />

These products are made of a composition of<br />

fine hardwood fibres held together with natural<br />

lignin in the wood - applied under heat and<br />

pressure. Additives are included during<br />

manufacturing to boost moisture resistant<br />

properties. The end product typically finishes<br />

9.5mm thick and has a factory applied primer<br />

coating to further reduce moisture pe<strong>net</strong>ration<br />

and minimise site painting.<br />

Hardboard products must be fixed using<br />

special fasteners that allow flexibility and<br />

board movement due to ambient moisture<br />

variations.<br />

Options in hardboard <strong>cladding</strong>s include:<br />

boards, shingles or architectural panels<br />

(replicating board patterns). In each instance<br />

the face finish can be either smooth or<br />

textured. Due to the many variations of profile,<br />

size and texture, enquiries about detailed<br />

requirements should be made direct to the<br />

manufacturer.<br />

Hardboard exterior products<br />

E X T E R N A L C L A D D I N G<br />

photos courtesy of: Classic <strong>Australian</strong> Building Products

6<br />

AUSTRALIAN HARDWOOD AND CYPRESS<br />

BCA REQUIREMENTS<br />

The Building Code of Australia (BCA)<br />

influences the ability to use timber <strong>cladding</strong>.<br />

For instance, there are ten classes of building<br />

each requiring ‘A’, ‘B’ or ‘C’ type fire<br />

construction (depending on the rise of the<br />

building in storeys). ‘A’ and ‘B’ require noncombustible<br />

materials thus preventing the use<br />

of timber <strong>cladding</strong>. A large number of other<br />

applications are still possible where ‘C’<br />

construction or less is required. Further details<br />

on this issue should be sought by referring to<br />

the list of publications detailed at the end of<br />

this guide.<br />

RELATED DOCUMENTS<br />

(From this Series of <strong>Timber</strong> Development<br />

Association Publications)<br />

•Fire Requirements for Non-Domestic Fit-Out<br />

(including information on BCA requirements<br />

for fire and other issues).<br />

•Technical & Detailing Guide for <strong>Hardwood</strong>s<br />

and Cypress (including information on<br />

moisture management, durability,<br />

appearance and structural issues).<br />

ACKNOWLEDGMENTS<br />

For additional assistance please contact the<br />

<strong>Timber</strong> Advisory Service<br />

1800 044 529<br />

or visit the following websites:<br />

www.timber.<strong>net</strong>.<strong>au</strong><br />

www.<strong>au</strong>stralianhardwood.<strong>net</strong><br />

•<strong>Timber</strong> Manual, National Association of<br />

Forest Industries Ltd., Canberra.<br />

• Cypress and <strong>Hardwood</strong> Claddings, <strong>Timber</strong><br />

Research and Development Advisory<br />

Council, Brisbane.<br />

T DA<br />

<strong>Timber</strong> Development<br />

Association (NSW) Ltd<br />

Sponsored by the NSW Native <strong>Timber</strong> Industry Marketing and Development Fund<br />

E X T E R N A L C L A D D I N G<br />

A P P L I C A T I O N G U I D E