Annual Review 2006 - Grohe

Annual Review 2006 - Grohe

Annual Review 2006 - Grohe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Annual</strong> <strong>Review</strong> <strong>2006</strong>

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

In this review<br />

GROHE <strong>2006</strong>: A record year 02<br />

Introduction by David Haines 03<br />

The sanitary products industry 08<br />

Understanding our business 10<br />

Our winning team 12<br />

Our brand value worldwide 14<br />

WaterCare 16<br />

Performance review 18<br />

Sales 20<br />

Cost of Sales 22<br />

Expenses 23<br />

Profitability 24<br />

Cash Management 24<br />

Liquidity and Funding 25<br />

Investing for Growth 25<br />

Sustainable and profitable growth 26<br />

Innovation, inspired by demand 28<br />

Design 30<br />

Quality 32<br />

Technology 34<br />

Sales and customer relationships 36<br />

Heritage, corporate responsibility<br />

and sustainability 38<br />

Global recognition<br />

As the world’s leading single-brand<br />

manufacturer and supplier of sanitary<br />

fittings, our brand gives us an invaluable<br />

edge in a highly competitive market.<br />

Details on page 14<br />

GROHE WaterCare<br />

Water is a precious resource and<br />

sustainability is increasingly important.<br />

We deliver better shower experiences<br />

and our products use up to 30% less<br />

water than our competitors.<br />

Details on page 16<br />

Award-winning<br />

Our products have been publicly<br />

recognised for design and innovation,<br />

receiving 30 design awards since 2004.<br />

Details on page 31<br />

Financial summary 40<br />

Summary consolidated operating<br />

information 40<br />

Summary cash flow information 41<br />

Notes 42<br />

Our global presence<br />

IBC

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong> 01<br />

Who we are<br />

€939m<br />

Revenue +12%<br />

€171m<br />

EBITDA +12%<br />

GROHE is the global market leader and the world’s<br />

largest single-brand manufacturer and supplier of<br />

sanitary fittings, offering a broad range of products<br />

for handling water in bathrooms and kitchens.<br />

We focus on the medium to high-end mass market<br />

for sanitary fittings and sell our products in 130<br />

markets through 23 sales subsidiaries, 15 branch<br />

offices and more than 80 unaffiliated sales agents<br />

worldwide. We are the market leader in Germany,<br />

France and the Benelux countries, Austria, Russia<br />

and many Middle Eastern countries and for<br />

European-style sanitary fittings in many markets<br />

including the United States and Japan.<br />

Established in 1948 and headquartered in Hemer,<br />

Germany, GROHE currently employs 5,200 people<br />

worldwide, including 3,200 in Germany. We<br />

operate six production facilities, which are located<br />

in Germany (three), Portugal, Canada and Thailand<br />

as well as an assembly plant in China.<br />

We operate four business categories: Bath and<br />

Special Fittings; Showers and Shower Systems;<br />

Kitchen Fittings; and Sanitary Systems. Over 90%<br />

of our sales are from products marketed under<br />

the GROHE brand, which is renowned worldwide<br />

for product quality, technical leadership and<br />

innovation and superior design.<br />

Find out more at www.grohe.com

02<br />

David J. Haines, CEO & Chairman of the Management Board

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

03<br />

GROHE <strong>2006</strong>:<br />

A record year<br />

1<br />

2<br />

3<br />

4<br />

5<br />

12% growth across all<br />

regions and categories<br />

39% revenue from<br />

products launched<br />

since 2004<br />

More than €100m<br />

in costs saved through<br />

restructuring<br />

11% productivity<br />

increase in factories<br />

15% increase in<br />

cash generated<br />

from operations<br />

before exceptionals<br />

and financing<br />

Dear stakeholder,<br />

Under the leadership of our new management team,<br />

we have now largely completed our restructuring<br />

programme and have built a leaner, stronger global<br />

company that is fit for the challenges that lie ahead.<br />

In <strong>2006</strong> we delivered a record year with sales<br />

growing 12% to €939 million, operational EBITDA<br />

growing 12% to €171 million and €133 million in<br />

cash generated from operations before exceptionals<br />

and financing. This clearly demonstrates that our Fit<br />

for the Future strategy, which we began two years<br />

ago, is on track and producing excellent results.<br />

Our sustainable competitive advantage<br />

is our single global GROHE brand,<br />

which allows us to connect with<br />

installers, trade customers, wholesalers<br />

and consumers in 130 markets<br />

worldwide. We are one brand and<br />

we are the preferred brand.<br />

We are proud of the changes GROHE<br />

has made over the past three years<br />

and we expect our performance will<br />

continue to improve in 2007 and<br />

beyond. Our recent €800 million<br />

senior floating rate note issuance in<br />

January 2007 was welcomed by our<br />

investors, priced competitively and<br />

had an order book that was more than<br />

two times over-subscribed.<br />

As we embark on the next stage of<br />

our profitable growth, I am pleased<br />

to report that GROHE is positioned as<br />

a leaner, more efficient global market<br />

leader in the sanitary industry.<br />

When we look at the year in more<br />

detail, <strong>2006</strong> was characterised by<br />

two distinct halves:<br />

In the first six months, we completed<br />

the two-year major restructuring of<br />

our teams and factories, delivering<br />

more than €100 million in cost savings<br />

since 2004. We re-launched the<br />

GROHE brand worldwide and<br />

successfully replaced a majority<br />

of our core product lines. In the<br />

second half of the year, we increased<br />

revenue 14% compared with the<br />

second half of 2005, with growth<br />

coming in most markets due to our<br />

revitalised sales team supported<br />

by our new product lines. We also<br />

successfully brought our global<br />

production footprint up to full capacity,<br />

operating to a consistent and<br />

world-class level of GROHE quality<br />

performance across all our plants.<br />

At the end of the year, we had<br />

generated €133 million in cash from<br />

operations due to the successful<br />

implementation of our GROHE Lean<br />

Cash Management Programme.

04 Fit for the future<br />

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Turnover<br />

€ million<br />

05 838<br />

06 939 12%<br />

In <strong>2006</strong> we delivered<br />

a record year with sales<br />

increasing 12%.<br />

05 06<br />

In <strong>2006</strong>, the unprecedented rises<br />

in the costs of our raw materials,<br />

particularly brass, have caused a<br />

fundamental change in the way our<br />

industry operates. We endured almost<br />

a threefold increase in our hedged<br />

brass cost, adding approximately<br />

€50 million to our costs. We were able<br />

to counter this through our ongoing<br />

cost restructuring programme and a<br />

successful 5% price increase in July.<br />

Because of our actions, we were able<br />

to increase operational EBITDA by<br />

€18 million (12%) to €171 million.<br />

Our Competitive Strengths<br />

We believe the following four<br />

strengths differentiate us from our<br />

competitors and make us unique,<br />

special and better:<br />

1 Strong Global Brand<br />

The global strength of the GROHE<br />

brand is one of our key competitive<br />

advantages. In many markets around<br />

the world, GROHE benefits from high<br />

levels of brand awareness and loyalty,<br />

not only from consumers but also from<br />

the professionals and trade customers<br />

who buy, fit and supply our products.<br />

In <strong>2006</strong>, we generated over 90% of<br />

our sales from products marketed<br />

under the GROHE brand. Furthermore,<br />

we achieved the highest worldwide<br />

sales for fittings in terms of value<br />

under one single brand, and we have<br />

more non-domestic sales than any<br />

of our competitors.<br />

2 Established Reputation for Product<br />

Quality, Design and Innovation<br />

Only with GROHE can you get the<br />

perfect balance of quality, technology<br />

and design. Over the past 70 years<br />

GROHE has acquired a reputation<br />

for delivering products of the highest<br />

quality that exceed our customers’<br />

expectations. Our expertise in the field<br />

of water technology shines through<br />

in every product we produce: they<br />

not only look beautiful but also function<br />

to perfection for a lifetime. We are<br />

innovation leaders and invest to<br />

develop new technical features that<br />

are superior to our competition. We<br />

define these benefits as “Moments<br />

of Truth” where professionals and<br />

end users can physically witness the<br />

superior performance of GROHE<br />

products. Our products have been<br />

publicly recognised for their design<br />

and innovation, winning 30 design<br />

awards since 2004.<br />

3 Scale – Leading Market Positions<br />

and Global Presence<br />

We are the global leader and largest<br />

single-brand manufacturer and supplier<br />

of sanitary fittings. We focus on the<br />

medium and high-end segments of<br />

the sanitary fittings market, and we<br />

are the market leader for these<br />

products in Germany, France, the<br />

Benelux countries, Austria, Russia and<br />

many Middle Eastern countries. We<br />

also hold leading positions in the<br />

market for European style sanitary<br />

fittings in many overseas markets,<br />

including the United States and Japan.<br />

We sell our products in 130 markets<br />

through a global sales organisation of<br />

over 1,150 employees.<br />

4 High Customer Loyalty<br />

We have strong relationships with<br />

wholesalers, showroom owners,<br />

installers, designers, planners and<br />

architects, who choose us as their<br />

preferred provider of sanitary fittings.<br />

We believe this is primarily attributable<br />

to our single global brand, the quality of<br />

our products and our comprehensive<br />

relationship management. We<br />

invest significantly in understanding<br />

our customers’ requirements,<br />

communicating our brand effectively,<br />

maintaining our personal relationships<br />

and offering a broad range of services.<br />

We believe these strong customer<br />

relationships translate into significant<br />

repeat business.

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Fit for the future 05<br />

25%<br />

Renewal rate target<br />

leading to the freshest<br />

portfolio<br />

Best of the Best<br />

Strategy and our Five Objectives<br />

Our vision is to become the leading<br />

global premier brand for water<br />

technology products. We will<br />

achieve our vision by focusing on the<br />

following five strategic objectives:<br />

1 Strengthen and Leverage the<br />

GROHE Brand<br />

We are further strengthening the<br />

GROHE brand with a new brand<br />

strategy. The enhanced GROHE<br />

brand essence of “Performance you<br />

can enjoy” is communicated with a<br />

new claim, “Enjoy Water ® ”, and we<br />

are highlighting key performance<br />

characteristics of GROHE products<br />

through “Moments of Truth”, such as<br />

GROHE SilkMove ® enhanced water<br />

control and GROHE TurboStat ® water<br />

temperature control for safety.<br />

We aim to improve awareness,<br />

increase our reputation and strengthen<br />

customers’ preferences for our<br />

products. By doing so, we aim to<br />

increase our market share and<br />

to expand into new distribution<br />

channels and geographic regions.<br />

2 Enhance Demand-Led Innovation<br />

to Deliver the Freshest Portfolio<br />

in the Industry<br />

Over the past two years, we have<br />

introduced a new ‘demand-led<br />

innovation’ process that has improved<br />

the appeal of our newest products,<br />

reduced their time-to-market and<br />

increased our throughput efficiency.<br />

Our primary focus is to enhance<br />

customer utility by adding innovative<br />

functions and features, creating water<br />

and energy saving solutions, facilitating<br />

the installation process and optimising<br />

the use of bathroom space.<br />

We have increased our investment<br />

in R&D significantly and reduced<br />

our time-to-market by more than<br />

half. We aim to reduce this still further,<br />

accelerating the development of<br />

our faster-growing and higher-margin<br />

product lines.<br />

We are committed to having the<br />

freshest portfolio in our industry and<br />

we have set an internal benchmark<br />

of a 25% renewal rate – meaning<br />

that 25% of our sales will come from<br />

products less than two years old. In<br />

<strong>2006</strong> we launched more than 20 new<br />

product lines and we will launch over<br />

50 in 2007. We plan to continue this<br />

rate of innovation in the future.<br />

3 Capitalise on Growth Opportunities<br />

in Advanced and Emerging Markets<br />

We intend to capitalise on a variety<br />

of growth opportunities in both<br />

advanced and emerging markets,<br />

further strengthening our presence<br />

geographically and across all relevant<br />

sectors of demand and distribution.<br />

In advanced markets where we have<br />

a leading position, we plan to grow our<br />

sales by addressing increasing demand<br />

for certain styles, functionality, water<br />

saving and efficient use of bathroom<br />

space and by developing new<br />

distribution channels (including selective<br />

do-it-yourself retailers and kitchen<br />

studios). In North America, we intend<br />

to further broaden our customer base<br />

and distribution network, introduce<br />

more local style products and expand<br />

our position in the project business.<br />

In emerging markets, in particular in<br />

Eastern Europe, the Middle East and<br />

the Far East, we intend to expand our<br />

business by broadening our distribution<br />

network, strengthening our customer<br />

relationships (for example, in <strong>2006</strong> we<br />

added close to 100 sales professionals<br />

to our team in China) and introducing<br />

products tailored to local tastes<br />

and requirements.<br />

4 Become the Leanest Company<br />

in our Industry<br />

GROHE Lean Production:<br />

When we began our restructuring<br />

programme two years ago, our cost<br />

footprint was 80% German while<br />

our revenue footprint was just 20%<br />

German. Over the course of our<br />

corporate transformation, we have<br />

changed this balance, transforming<br />

our operations from a German to<br />

a global footprint.

06 Fit for the future<br />

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Operational EBITDA<br />

€ million<br />

05 154<br />

06 171 12%<br />

Cash from operations before<br />

exceptionals and financing<br />

€ million<br />

05 116<br />

06 133 15%<br />

05 06<br />

05 06<br />

Our lean mentality now encompasses<br />

everything we do, from procurement<br />

and production to distribution and<br />

delivery. We aim to improve our<br />

operational performance with the<br />

ongoing standardisation and<br />

modularisation of components, the<br />

further development of the skill levels<br />

of our workforce and by increasing<br />

working hours flexibility.<br />

Since 2004, we have invested<br />

approximately €60 million equally in<br />

our manufacturing facilities inside and<br />

outside Germany, closing one of our<br />

German factories. In our remaining<br />

three German plants we have increased<br />

our capability to manufacture more<br />

technically complicated products and<br />

increased our production flexibility.<br />

In our factories located in Thailand,<br />

Canada, Portugal and China, we have<br />

invested in new capacity and also<br />

ensured all our factories now meet<br />

exactly the same standards for<br />

GROHE quality and reliability.<br />

We have made excellent progress and<br />

by the end of <strong>2006</strong> we had achieved<br />

over €100 million of cost savings.<br />

This new global manufacturing<br />

footprint has enabled us to reduce our<br />

manufacturing costs by 11% in <strong>2006</strong>.<br />

Through further lean initiatives and<br />

investments in additional equipment,<br />

we believe we can increase our total<br />

production capacity a further 5-10%<br />

per year. Additionally, we have reduced<br />

the headcount of our German plants<br />

by 30% from 2,953 to 2,062 while<br />

investing in a new global sourcing team<br />

with expert procurement specialists<br />

now located in Germany (43),<br />

China (35), Canada (5), Thailand (5)<br />

and Portugal (4). As a result, we have<br />

increased the share of our components<br />

sourced from low-cost countries to<br />

over 20% of our total purchase costs.<br />

We have reduced the number of<br />

products we make by almost 60%<br />

to focus on those that deliver the right<br />

mix of volume and margin. Although<br />

we have reduced our supplier network,<br />

we do not rely on any single-source<br />

supplier, with our 10 largest suppliers<br />

accounting for approximately 26%<br />

of our total purchasing. Additionally,<br />

we have invested significantly in our<br />

e-procurement capabilities and the<br />

ongoing migration of our information<br />

technology systems to SAP R/3.<br />

GROHE Lean Cash Management:<br />

During <strong>2006</strong>, our cash management<br />

situation was also a story of two<br />

halves. In the first half, we required<br />

cash to fund our restructuring<br />

programme, to increase inventories<br />

as we transferred production to lowercost<br />

countries, upgrade our product<br />

portfolio and fund our sales growth.<br />

In the second half, we generated cash<br />

as we completed the restructuring<br />

and introduced the GROHE Lean Cash<br />

Management Programme, which<br />

reduced our inventories, reduced<br />

markets and head office expenditure,<br />

reduced our Days Sales Outstanding<br />

(DSO) performance and improved our<br />

Days Payable Outstanding (DPO)<br />

performance. Overall in <strong>2006</strong>, we<br />

generated €133 million in cash from<br />

our operations before exceptionals and<br />

financing. This is a 15% increase on<br />

2005. The GROHE Lean Cash<br />

Management Programme will continue<br />

to produce results into 2007.<br />

5 People, people, people<br />

Over the past year, we have<br />

strengthened our senior management<br />

team with world class professionals<br />

to lead GROHE into the future. In<br />

October, Eckehard Betz was appointed<br />

Executive Director of Operations<br />

responsible for all our production.<br />

Eckehard previously worked for Magna<br />

International Inc in the automotive<br />

industry. In February 2007, Thorsten<br />

Knopp was appointed Chief Financial<br />

Officer. He previously worked at<br />

Diageo plc.<br />

We have continued to rebuild and<br />

update the quality of our teams<br />

at all levels in GROHE including a<br />

comprehensive strengthening of<br />

most of our sales teams around the<br />

world. Our team now benefits from<br />

an unprecedented breadth and depth<br />

of talent and experience from some

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Fit for the future 07<br />

5 Priorities going forward<br />

Lean working capital<br />

1 ›<br />

2<br />

Improve Days Sales Outstanding<br />

(DSO)<br />

› Reduce inventory<br />

› Improve Days Purchasing<br />

Outstanding (DPO)<br />

3<br />

›<br />

›<br />

›<br />

›<br />

›<br />

›<br />

Sustainable profitable growth<br />

Manage pricing<br />

Increase profitable volume<br />

Introduce new sales practices<br />

Mix and margin improvement<br />

Improve product mix<br />

Reduce unit costs<br />

Introduce new manufacturing<br />

processes<br />

4<br />

5<br />

›<br />

›<br />

›<br />

›<br />

›<br />

Productivity improvement<br />

Reduce current factory costs run rate<br />

Increase sourcing productivity<br />

Reduce complexity in components<br />

Overhead reduction<br />

Keep overheads flat in 2007<br />

Reduce in 2008<br />

of the world’s largest and most<br />

successful consumer and professional<br />

services companies, including Nestlé<br />

S.A., Mars, Incorporated, The Procter<br />

& Gamble Company, The Coca-Cola<br />

Company, Bain & Company, McKinsey<br />

& Company, The Black & Decker<br />

Corporation, Motorola, Inc., Diageo plc<br />

and Honeywell International Inc.<br />

This upgrading of our talent base<br />

is already playing a significant role in<br />

enhancing our growth opportunities<br />

and our operational effectiveness,<br />

providing the foundations for further<br />

development in the years to come.<br />

Besides improving our talent, we<br />

have installed new human resource<br />

processes with linkage between<br />

performance and rewards, supported<br />

by tailored coaching, to ensure we<br />

can improve the performance of our<br />

people and help us all achieve our<br />

full potential. I am fully confident this<br />

stronger management team will work<br />

closely with me to implement our<br />

strategy with energy and consistency.<br />

How We Behave<br />

In <strong>2006</strong> we implemented new risk<br />

controls and compliance programmes<br />

supported by an increased investment<br />

in our global audit function. All of our<br />

top 50 managers were trained in<br />

these new GROHE compliance rules<br />

and regulations. In early 2007, we<br />

implemented a GROHE Code of<br />

Business Conduct. This Code embodies<br />

the standards of behaviour we<br />

expect from our employees and the<br />

commitments we share with our<br />

stakeholders and the environment.<br />

As part of this Code, we have installed<br />

a confidential telephone number where<br />

employees can report any misconduct.<br />

We have experienced an EU-wide<br />

investigation into the sanitary fittings<br />

industry in connection with enquiries<br />

of alleged cartel law infringement<br />

through to 2004. We are co-operating<br />

fully with the investigation, evaluating<br />

the objections carefully and will respond<br />

as appropriate.<br />

Our 2007 Priorities<br />

Looking ahead to 2007, we are<br />

prepared for the challenges and<br />

opportunities we face as a leader<br />

in the global sanitary fittings market.<br />

We will continue to implement our<br />

Fit for the Future strategy focusing<br />

on the five priorities listed above. We<br />

have appointed a management board<br />

member to lead each of these projects<br />

to ensure successful delivery. These<br />

five priorities should continue to drive<br />

sales in 2007 and 2008, improve our<br />

gross margins and EBITDA margin<br />

while generating excess cash.<br />

We are pleased that the study by<br />

Germany’s Federal Ministry of Finance<br />

compiled by the European Business<br />

School, TU Munich, confirmed that<br />

“GROHE is an example of a successful<br />

restructuring which is now generating<br />

value sustainably. Following the<br />

restructuring, GROHE is able to drive<br />

the globalisation of its brand and<br />

assure its long-term future”.<br />

It is with satisfaction that I look back<br />

on <strong>2006</strong> and ahead to 2007. GROHE<br />

is successfully executing its strategy<br />

for profitable growth. The Management<br />

Board would like to thank all GROHE<br />

staff for their contribution to our<br />

achievements in <strong>2006</strong>, and their<br />

dedication and commitment to our<br />

success. I look forward to reporting<br />

back to you in 2008 with equally<br />

strong achievements.<br />

David J. Haines<br />

CEO & Chairman<br />

of the Management Board

08 Fit for the future<br />

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

The sanitary<br />

products<br />

industry<br />

Global Market for Sanitary Products and Water Technology Products <strong>2006</strong><br />

Global Market for Sanitary Products €48 billion<br />

Global Market for Water Technology Products €12.7 billion (27%)<br />

Bathroom Equipment Products €20.2bn<br />

1. Most of BEP market €19.6bn<br />

2. Shower Panels €0.6bn<br />

3. Sanitary Fittings Products €11.4bn<br />

4. Sanitary Systems €1.3bn<br />

5. Most of STP market €15.1bn<br />

Sanitary Technology Products €16.4bn<br />

Bathroom Equipment Products (BEP)<br />

Sanitary Technology Products (STP)<br />

Water Technology Products (WTP)<br />

4<br />

5<br />

STP<br />

WTP<br />

3<br />

BEP<br />

2<br />

1<br />

›<br />

›<br />

›<br />

We compete in the sanitary<br />

products industry, which is<br />

generally classified into three<br />

product categories as follows:<br />

bathroom equipment products,<br />

such as bath tubs, whirlpools,<br />

ceramics, bathroom furniture and<br />

accessories, shower enclosures<br />

and cubicles, and shower panels;<br />

sanitary fittings products,<br />

such as bathroom and kitchen<br />

faucets, showerheads and related<br />

accessories; and<br />

sanitary technology products,<br />

such as flushing and installation<br />

systems, water pipes and<br />

plumbing fittings.<br />

GROHE offers products from each of<br />

these three product categories which<br />

are used for handling water at all water<br />

outlets in residential bathrooms and<br />

kitchens as well as in commercial,<br />

industrial and institutional sanitary<br />

installations. We refer to our offerings<br />

as “water technology products”.<br />

€48 Billion Industry<br />

We estimate that the total value of<br />

the global sanitary products market<br />

in <strong>2006</strong> was approximately €48 billion,<br />

including a total value of the global<br />

market for water technology products<br />

of approximately €12.7 billion. Of the<br />

water technology market, we estimate<br />

that approximately €11.4 billion was<br />

attributable to sanitary faucets and<br />

›<br />

›<br />

›<br />

showerheads, approximately<br />

€0.6 billion to bathroom equipment<br />

(shower panels) and approximately<br />

€1.3 billion to sanitary technology.<br />

Europe accounted for approximately<br />

39% of the global market for water<br />

technology products, followed by<br />

North America, excluding Mexico (33%)<br />

and the rest of the world (28%).<br />

Drivers of Growth<br />

We estimate that both the global<br />

sanitary products market and the<br />

market for water technology products<br />

have on average grown by approximately<br />

6% per year over the past 10 years.<br />

We estimate that global volume<br />

demand for sanitary products grew<br />

by approximately 2% during the same<br />

period whereas price increases and<br />

product mix improvements accounted<br />

for approximately 4% of the growth.<br />

From a global perspective, the industry<br />

is characterised by strong, consistent<br />

and sustainable growth. Quantitative<br />

drivers of this growth include:<br />

a growing number of households<br />

and rising disposable income;<br />

an increasing focus on the bathroom<br />

and kitchen, resulting in expanded<br />

room space and more water outlets<br />

(for example, showers in addition<br />

to bathtubs);<br />

increasing renovation activities<br />

associated with the aging of building<br />

stock and changes in design;<br />

Global Market Water Technology<br />

Products €12.7billion (27%)<br />

1. Bathroom Faucets €7.3bn<br />

2. Kitchen Faucets €2.2bn<br />

3. Showerheads & Shower Panels €1.9bn<br />

4. Sanitary Systems €1.3bn<br />

3<br />

2<br />

4<br />

Global Market Water Technology<br />

Products €12.7billion (27%)<br />

1. Europe €5bn<br />

2. North America €4.1bn<br />

3. Rest of the World €3.6bn<br />

3<br />

2<br />

1<br />

1

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong> Fit for the future 09<br />

Sanitary Industry Demand<br />

By volume ‘000 pieces<br />

• New residential<br />

• New commercial<br />

• Residential R&R<br />

• Commercial R&I<br />

130<br />

120<br />

110<br />

100<br />

90<br />

80<br />

92 93 94 95 96 97 98 99 00 01 02 03 04 05 06<br />

Source: GROHE estimate based on EUROCONSTRUCT figures<br />

Ref: Western Europe excluding Scandinavia and Switzerland<br />

›<br />

›<br />

›<br />

›<br />

the introduction of innovative product<br />

types, styles and features (such as<br />

shower panels and thermostatic<br />

control of water temperature), resulting<br />

in accelerated renovation cycles and<br />

improvements in product mix;<br />

increasing demand for water- and<br />

energy-saving products and systems;<br />

the growth of urban professional<br />

middle classes in rapidly urbanising,<br />

large-scale emerging economies<br />

(combined with a growing popularity<br />

of Western sanitary standards);<br />

the growth in tourism.<br />

Sources of Demand<br />

Demand for sanitary products is driven<br />

by private households (worth about<br />

70% of the global market value)<br />

and project business (30%). New<br />

construction activities account for<br />

about 30% of purchases, while<br />

replacement and renovation activities,<br />

which are less cyclical in nature,<br />

account for about 70%.<br />

Purchasing decisions for sanitary<br />

products to be used for private or<br />

residential purposes are typically<br />

influenced by end-users, installers,<br />

and showroom sales personnel,<br />

while decisions for larger scale projects<br />

are commonly made by planners,<br />

designers, architects and builders.<br />

The vast majority of the distribution<br />

of sanitary products – around 75% – is<br />

still via traditional channels of sanitary<br />

wholesale merchants selling to installers<br />

or retailers. Professionals in this channel<br />

are characterised by a high level of<br />

loyalty to trusted brands they are familiar<br />

with in their everyday work practice.<br />

Three Major Industry Trends<br />

We foresee three major trends<br />

influencing our industry in the future:<br />

1 Scarcity of Water vs Increased<br />

Demand<br />

Water is scarce. In many parts of the<br />

world, water is more expensive than oil.<br />

In our homes and offices, the usage of<br />

water is increasing. At the same time,<br />

the increasing scarcity of water requires<br />

us to act more responsibly, reducing<br />

and conserving our usage. At GROHE<br />

we have recognised this dilemma for<br />

some time and we have responded.<br />

All our products are designed and<br />

built to minimise waste through<br />

leakage and maximise effectiveness<br />

through technology.<br />

2 Premiumisation and<br />

Commodisation<br />

Over the last 10 years, the market for<br />

sanitary fittings has grown overall at<br />

a sustainable annual rate of 6%. Yet<br />

on closer analysis, the premium end<br />

of the market is growing faster driven<br />

by the increased demand for higher<br />

quality, better designed total bathroom<br />

and kitchen solutions. The lower end<br />

of the market is also growing faster<br />

than 6% but not as rapidly as the top<br />

end, driven by lower-priced products<br />

coming from China. The mid-market<br />

is in decline as consumers either tradeup<br />

or down. GROHE is well positioned<br />

to capitalise on this trend with most<br />

of our products targeting the mass<br />

premium segment. However, we<br />

have also witnessed fast growth in<br />

our lower-priced entry level products.<br />

3 Consolidation and Globalisation<br />

Currently, the overall global sanitary<br />

market is relatively fragmented with<br />

several hundred manufacturers<br />

of sanitary products, most of<br />

which concentrate on a particular<br />

geographic region. Globally, the top<br />

six manufacturing groups in the<br />

sanitary industry only account for<br />

an estimated 26% of sales.<br />

However, the past decade has seen<br />

an accelerating pace of consolidation,<br />

as manufacturers and wholesalers<br />

alike seek greater economies of scale.<br />

The emerging, larger and more<br />

professional wholesale players are<br />

seeking to reduce their portfolio of<br />

suppliers. As the sanitary fittings<br />

industry continues to consolidate,<br />

we believe there are opportunities<br />

for growth among high-performing<br />

manufacturers like ourselves with<br />

established premium brand names,<br />

global distribution capabilities and<br />

long-standing relationships with<br />

wholesalers and trade affiliations.

10 Fit for the future<br />

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Understanding our business<br />

We focus on the<br />

premium mass market<br />

for sanitary fittings. 90%<br />

We generate more than 90%<br />

of our sales from products<br />

marketed under the GROHE brand<br />

GROHE is the global market leader<br />

and the world’s leading singlebrand<br />

manufacturer and supplier of<br />

sanitary fittings for bath and kitchen.<br />

The GROHE brand is renowned<br />

for product quality and durability,<br />

technical innovation and<br />

superior design.<br />

We focus on the premium mass<br />

markets for sanitary fittings and<br />

sell our products in 130 markets<br />

through 23 sales subsidiaries,<br />

15 branch offices and more than<br />

80 unaffiliated sales agencies<br />

worldwide.<br />

Headquartered in Hemer, Germany,<br />

we operate six production facilities<br />

located in Germany (three),<br />

Portugal, Canada and Thailand,<br />

and one assembly plant in China.<br />

Our Brand and Heritage<br />

We generate more than 90% of our<br />

sales from products marketed under<br />

the GROHE brand, making us the<br />

largest single-brand manufacturer in<br />

the sanitary fittings industry. Our brand<br />

is associated with premium fittings<br />

distinguished by innovative design, high<br />

quality and leading technology. We are<br />

committed to supplying one of the<br />

broadest portfolios in the industry with<br />

one of the highest renewal rates of new<br />

products every year.<br />

Since the company was founded in<br />

1948, the name GROHE has stood for a<br />

commitment to tradition and innovation,<br />

for high durability and functionality,<br />

sustainable, balanced design and<br />

reliable, long-term partnership with<br />

professional customers.<br />

Our Market Positions<br />

We are the market leader for sanitary<br />

fittings in Germany, France, the Benelux<br />

countries, Austria, Russia and many<br />

Middle Eastern countries. We hold<br />

leading positions for our European-style<br />

sanitary fittings in many overseas<br />

markets, including the United States<br />

and Japan. Approximately 82% of our<br />

sales are currently generated outside<br />

our home market of Germany.<br />

Our Channels<br />

We primarily sell our products<br />

to wholesalers, who sell them to<br />

professional customers such as<br />

developers, architects, designers,<br />

retailers and installers including<br />

plumbers, who in turn sell our products<br />

to both residential and commercial endusers.<br />

We provide a comprehensive<br />

and professional service and support<br />

that helps build loyalty from our<br />

professional customers. We also<br />

sell our products direct to consumers<br />

through upmarket showrooms<br />

and boutiques.<br />

Our Products<br />

Our products are used for handling<br />

water at all water outlets in residential<br />

bathrooms and kitchens as well as in<br />

commercial, industrial and institutional<br />

sanitary installations.<br />

The majority of our product offerings<br />

are bathroom and kitchen faucets,<br />

showerheads and related accessories<br />

as well as shower panels and flushing<br />

and installation systems. We refer<br />

to our product offerings as ‘‘water<br />

technology products’’.

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Fit for the future 11<br />

Sales by region<br />

%<br />

1. Other European countries 53%<br />

2. Germany 18%<br />

3. Middle East and Asia 15%<br />

4. Americas 14%<br />

3<br />

2<br />

4<br />

1<br />

Sales by category<br />

%<br />

1. Bath & Special Fittings 41%<br />

2. Showers & Shower Systems 32%<br />

3. Kitchen Faucets 13%<br />

4. Sanitary Systems 11%<br />

5. Other GROHE products 3%<br />

3<br />

4<br />

2<br />

5<br />

1<br />

Where we operate:<br />

Germany<br />

Americas<br />

Other European countries<br />

Middle East & Asia<br />

Our business categories:<br />

Bath<br />

Showers<br />

Kitchen<br />

Sanitary<br />

Our products are divided into four<br />

strategic product groups: Bath and<br />

Special Fittings, Showers and Shower<br />

Systems, Kitchen Faucets, Sanitary<br />

Systems; and a smaller division<br />

specialising in private label products.<br />

The GROHE Bath and Special Fittings<br />

division, which includes a wide range<br />

of premium bathroom faucets and<br />

specialty electronic fittings, represents<br />

our largest division accounting for<br />

41% of our sales in <strong>2006</strong>.<br />

Our market-leading range of<br />

Showers and Shower Systems,<br />

which includes hand-held and<br />

wall-mounted showerheads and<br />

integrated shower systems aimed<br />

at a premium audience, is our<br />

second largest division, accounting<br />

for 32% of our sales in <strong>2006</strong>.<br />

Our Kitchen Faucets division,<br />

which includes single-lever and<br />

two-handled faucets aimed at<br />

the premium residential market,<br />

accounted for 13% of our sales<br />

in <strong>2006</strong>.<br />

The GROHE Sanitary Systems<br />

division, which represents our<br />

mechanical and electronic flushing<br />

systems for toilets and urinals<br />

as well as concealed installation<br />

systems, accounted for 11% of<br />

our sales in <strong>2006</strong>.<br />

›<br />

›<br />

›<br />

›<br />

GROHE offers distributors, installers<br />

and consumers value-added products<br />

characterised by high functionality,<br />

including simple, intuitive operation<br />

and installation. Our products are<br />

renowned for their durability and sparepart<br />

availability for years to come.<br />

Our Competitive Strengths<br />

We have developed four sustainable<br />

competitive strengths:<br />

Strong global brand with high level<br />

of brand awareness, preference and<br />

loyalty of professionals and end-user<br />

customers around the world.<br />

Established reputation for product<br />

quality, design and innovation,<br />

recognised by numerous awards.<br />

Leading market positions in many<br />

markets around the globe, including<br />

market leadership in Germany, France,<br />

the Benelux countries, Austria, Russia<br />

and many Middle Eastern countries<br />

as well as leading positions in the<br />

market for European-style sanitary<br />

fittings in many overseas markets<br />

(including the United States and Japan).<br />

Long-term business relationships and<br />

high customer loyalty with numerous<br />

wholesalers, showroom owners,<br />

installers, designer, planners and<br />

architects around the globe.<br />

Our Five Principles<br />

1 Quality<br />

Always best value<br />

2 Responsibility<br />

Take the monkey<br />

3 Lean<br />

Spend the company’s money<br />

as you would your own<br />

4 Mutuality<br />

Win-win<br />

5 Freedom<br />

Cash allows us to control<br />

our destiny

12 Fit for the future GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

David Haines<br />

Gerald Mulvin<br />

Hans-Gerd Füchtenkort<br />

Our<br />

winning<br />

team<br />

A key part of GROHE’s recovery has<br />

been to revitalise our management<br />

team by hiring leading talent with<br />

valuable experience from across<br />

the business spectrum.<br />

We now have a proven and multinational<br />

leadership that is driving<br />

GROHE to compete on the global<br />

stage with world-class lean<br />

efficiency. We have installed<br />

new business processes and<br />

systems to support and improve<br />

decision-making.<br />

GROHE’s board of management<br />

now consists of six members,<br />

each bringing an array of<br />

knowledge, skills and experience<br />

gained within and outside the<br />

water-products industry.<br />

David Haines<br />

Chief Executive Officer<br />

and Chairman of the Management Board<br />

Year appointed: 2004<br />

David J. Haines is Managing Director<br />

of GROHE Holding GmbH and GROHE<br />

Beteiligungs GmbH. He has been<br />

Chief Executive Officer and Chairman<br />

of the Management Board of<br />

GROHE AG and its predecessors<br />

since September 2004.<br />

David is also Chairman of the Board<br />

of Directors of VimpelCom, the NYSE<br />

listed leading Russian mobile phone<br />

operator. He has held this position<br />

since July 2005. Prior to joining<br />

GROHE, he served as Global<br />

Marketing Director at Vodafone Group<br />

Plc (2000-2004) and led many of<br />

the marketing successes of that era.<br />

Before David joined Vodafone, he was<br />

Deputy Division President of The Coca-<br />

Cola Company Germany (1998-2000).<br />

From 1989 to 1998, he held a number<br />

of executive positions with Mars,<br />

Incorporated, including CEO of Mars,<br />

Incorporated in Sweden and Vice<br />

President of Mars in the C.I.S. in the<br />

growth period 1995-1998. David holds<br />

a first class honours degree from the<br />

University of Greenwich, London.<br />

Gerald Mulvin<br />

Chief Marketing Officer<br />

Year appointed: 2004<br />

Gerald Mulvin joined GROHE as Chief<br />

Marketing Officer in September 2004.<br />

Previously, he was a Partner at the<br />

management consulting firm Bain &<br />

Company (1995-2004). Before his<br />

career in consulting he was a software<br />

design engineer. He holds bachelor<br />

and master degrees in electronic<br />

engineering from University College,<br />

Dublin, and an MBA from INSEAD.<br />

Hans-Gerd Füchtenkort<br />

Executive Director of Global Sales<br />

Year appointed: 2005<br />

Hans-Gerd Füchtenkort joined GROHE as<br />

Executive Director of Global Sales in May<br />

2005. For the five years prior to joining<br />

GROHE, he was a Managing Partner<br />

of Dr Rochus Mummert & Partner and<br />

owner of his own consulting firm. From<br />

1996 -1999 Hans-Gerd was a Member<br />

of the Global Management Board and<br />

President of Europe, Middle East and<br />

Africa for AC Nielsen. From 1994-1995<br />

he was Chairman of the Management<br />

Board of CJ van Houten AG, Zurich. From<br />

1976-1994 he held a number of executive<br />

positions with Mars, Incorporated<br />

including CEO of Mars, Incorporated<br />

Denmark, CEO of Mars, Incorporated<br />

Germany and a Member of the<br />

Management Board Mars Confectionary<br />

Europe. Hans-Gerd holds a masters<br />

degree in business administration.

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Fit for the future 13<br />

Eckehard Betz Thorsten Knopp Detlef Spigiel<br />

Eckehard Betz<br />

Executive Director of Operations<br />

Year appointed: <strong>2006</strong><br />

Eckehard Betz joined GROHE in<br />

October <strong>2006</strong> as Executive Director of<br />

Operations, responsible for purchasing,<br />

production and supply chain<br />

management. Previously, he was<br />

Executive Vice President of the<br />

Closures Group Europe, a subsidiary<br />

of Magna International Inc where he<br />

was responsible for a complex lean<br />

production system. He also has<br />

extensive experience in the automotive<br />

industry, working in the UK, the US<br />

and Germany where he implemented<br />

TQM and lean productivity practices.<br />

He holds a degree in production<br />

engineering from the Technical<br />

University of Munich and wrote a<br />

thesis on lean management<br />

at Imperial College, London.<br />

Thorsten Knopp<br />

Chief Financial Officer<br />

Year appointed: 2007<br />

Thorsten Knopp joined GROHE as<br />

Chief Financial Officer in February<br />

2007. Prior to joining GROHE, Thorsten<br />

held senior positions at Diageo plc<br />

(2002-2007). His experience includes<br />

CFO Africa, he was also Senior Vice<br />

President Strategy and Vice President<br />

Finance Supply Chain, North America.<br />

Prior to joining Diageo plc, Thorsten<br />

worked at The Procter & Gamble<br />

Company (P&G) from 1989-2002<br />

where he held senior finance and<br />

management positions including<br />

a leading role in the restructuring<br />

of P&G, based in the US, in the<br />

late 90s and early 2000s. Prior to<br />

working in the US, he held various<br />

financial and business strategy<br />

positions for various brands across<br />

Europe. From 1987-1989, Thorsten<br />

worked at Philips Medical Systems<br />

as a development manager.<br />

He holds a first class PhD degree in<br />

Industrial Science from the University<br />

of Herisau, Switzerland and a degree<br />

in Strategic Management and Logistics<br />

from the Wirtschaftsakademie,<br />

Hamburg.<br />

Detlef Spigiel<br />

Executive Director of Personnel<br />

Year appointed: 2000<br />

Detlef Spigiel joined GROHE in<br />

August 2000. In November <strong>2006</strong><br />

he took up his current position as<br />

Executive Director of Personnel.<br />

Detlef has held various R&D and<br />

operations positions in the automotive<br />

industry and has also served on the<br />

board of a ThyssenKrupp subsidiary,<br />

responsible for production, sales,<br />

human resources and controlling.<br />

He graduated from the University of<br />

Dortmund with degrees in production<br />

engineering and business studies.<br />

Importing New Talent<br />

– Throughout the Company<br />

Our philosophy of invigorating<br />

our management with experience<br />

and expertise from outside the<br />

water-products sector is particularly<br />

evident in our sales leadership team,<br />

where the majority of our country<br />

and regional sales managers have<br />

been replaced by experienced<br />

business leaders from some of<br />

the world’s best-known consumerproducts<br />

companies, including:<br />

Mars, Incorporated, Nestlé S.A.,<br />

The Procter & Gamble Company,<br />

Motorola, Inc., The Coca-Cola<br />

Company, Honeywell International Inc.,<br />

Kohler Mira Ltd, Villeroy & Boch AG,<br />

Hasbro, Inc. and The Black & Decker<br />

Corporation.<br />

A Balanced and<br />

Productive Workforce<br />

In 2005, we closed our production<br />

facilities in Herzberg and reduced<br />

our workforce in our German plants.<br />

Despite this reduction in our workforce,<br />

we did not suffer any work stoppages<br />

or decreases in productivity. In fact,<br />

we have not suffered material work<br />

stoppage or a strike within the<br />

past seven years.<br />

We now have a workforce that is<br />

geographically balanced to reflect<br />

the global nature of our business,<br />

significantly increasing our workforce<br />

in Thailand, Portugal and China<br />

during <strong>2006</strong>.

14 Fit for the future<br />

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

“I love surprises.<br />

But not under my shower.”<br />

Dr. Ármann Höskuldsson,<br />

President of the Geoscience Society of Iceland<br />

“Either you control water,<br />

or water controls you.”<br />

Micah Lester,<br />

Surfing Pro, Mermaid Beach, Australia<br />

Our brand value worldwide<br />

Our global brand gives us an<br />

invaluable edge in a crowded<br />

and highly competitive market.<br />

We combine outstanding design<br />

with a unique combination of<br />

quality and innovative technology<br />

to build a unique, special and<br />

better position compared to<br />

our global competitors.<br />

Pre-eminent Brand Position<br />

We achieve the largest worldwide<br />

sales under one global brand. We<br />

achieve the highest proportion of sales<br />

outside our domestic market of any<br />

competitor, making us the most<br />

diversified brand in our industry.<br />

We believe this strong competitive<br />

position is largely founded on the<br />

global appeal of the GROHE brand.<br />

Wherever our products are – in a hotel<br />

in Hong Kong, the Olympic Stadium<br />

in Beijing, a home in North America<br />

or a public building in Germany – our<br />

customers and consumers see the<br />

same brand, differentiated through<br />

a unique combination of quality,<br />

technology and design.<br />

In the bathroom and kitchen<br />

renovation market, which accounts<br />

for approximately 70% of our business,<br />

people are spending more on their<br />

bathrooms and kitchens and need<br />

more reassurance that the brands<br />

they choose are reliable, will last a<br />

long time and will work with the latest<br />

trends in interior design. They require<br />

assurance of value sustainability to<br />

ensure they earn a return on their<br />

investment. Our brand delivers that<br />

assurance. GROHE products are<br />

frequently mentioned by developers<br />

and designers as justification for high<br />

quality, durability and good design.<br />

One Global Brand<br />

Our global brand strategy not only<br />

provides orientation and clarity to<br />

professionals and end-users, but<br />

also provides economies of scale.<br />

Our single brand allows us to<br />

focus our investment on reinforcing<br />

relationships with our key<br />

stakeholders: installers, designers,<br />

specifiers, trade customers and<br />

end-users.<br />

›<br />

›<br />

›<br />

›<br />

As a result, we enjoy high customer<br />

loyalty, forging strong business<br />

relationships with wholesalers,<br />

showroom owners, installers,<br />

designers, planners and architects.<br />

Their professional endorsement is<br />

a powerful marketing platform and<br />

we systematically build it into our<br />

communications. The strength of<br />

our global market-leading brand<br />

permits us to position ourselves<br />

as the premium lifestyle brand in<br />

our industry and communicate<br />

this through our premium pricing.<br />

The single global brand has other<br />

benefits including:<br />

enhancing customer acceptance<br />

of new products<br />

increased cross-selling for designers,<br />

specifiers, installers and wholesalers<br />

increasing our share amongst<br />

consolidating wholesalers, which<br />

stock fewer global brands.<br />

facilitating expansion into new<br />

geographic markets.

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Fit for the future 15<br />

“Some places better stay<br />

cold forever.”<br />

Dr Dieter Piepenburg,<br />

Institute for Polar Ecology,<br />

University Kiel, Germany<br />

Above<br />

Advertisement which forms part of a<br />

global campaign promoting the brand<br />

Our products are used<br />

in hotels, apartments<br />

and buildings, cruise liners,<br />

spas, airports, arenas<br />

and hospitals<br />

85%<br />

85% of consumers prefer<br />

a GROHE shower to their<br />

previous brand. Source:<br />

a study by University<br />

of Göttingen and<br />

The Consumer View<br />

Customer Preference<br />

Professional and consumer research<br />

conducted around the world confirms<br />

GROHE is one of the most preferred<br />

brands in our industry. For example, in<br />

the US professionals who have fitted<br />

GROHE recommend GROHE above all<br />

other brands. We have also conducted<br />

end-user trials for our products. For<br />

example, research conducted by the<br />

University of Göttingen and the<br />

research agency, The Consumer View,<br />

who tested RainShower, Movario<br />

and Relexa with over 400 families,<br />

revealed that 85% preferred these<br />

showers to their previous showers.<br />

Further endorsement comes from<br />

trade bodies who perform<br />

independent tests on our products<br />

against competitors, including our<br />

thermostats and flushing systems.<br />

In both cases our products emerged<br />

as clear winners.<br />

Additional endorsement also derives<br />

from the prestigious international<br />

locations where our products have<br />

been selected. The Grand Hyatt Hotel<br />

in Dubai, the Kunsthaus in Graz, the<br />

ZhongGuanCun Financial Center in<br />

Beijing, the Estadio da Luz in Lisbon<br />

and the Norwegian Jewel cruise ship<br />

are just a few of the premium projects<br />

that help to leverage our brand credibility.<br />

Brand Benefits<br />

The GROHE brand strategy aims<br />

to satisfy a broad and diverse set<br />

of needs from our target groups of<br />

installers, specifiers, designers and<br />

architects, trade customers and<br />

end-users through a comprehensive<br />

value proposition of a premium<br />

performance lifestyle brand.<br />

Our brand essence is based on GROHE<br />

being more than just a product, but<br />

an experience. The GROHE brand<br />

articulates ‘performance you can feel’.<br />

We are global water technology<br />

experts, delivering a product<br />

performance that gives the end-user<br />

the most rewarding experience through<br />

product appeal, product handling<br />

and water impact, delivered through<br />

superior quality, technology and design.<br />

These three factors – quality,<br />

technology and design – are the root<br />

of the functional benefits of the<br />

GROHE brand.<br />

They are the reason GROHE is unique,<br />

special and better in the sanitary<br />

fittings market. We are differentiated<br />

through our quality because our<br />

products are the best-built in the<br />

market, offering peerless levels<br />

of durability and reliability that won’t<br />

let the end-user down.<br />

Our commitment to design goes<br />

beyond ornamentation and superficial<br />

aesthetic appeal. For us, beautiful<br />

design means products that are easy<br />

to use and answer real human needs.<br />

When we design we design in front<br />

and behind the wall to ensure our<br />

products are fast, easy and safe<br />

to install. Each of our new flushing<br />

systems is 20% faster to install<br />

than leading competitors’ products.<br />

Moments of Truth<br />

Our six Moments of Truth are<br />

examples of how proprietary GROHE<br />

technology delivers tangible benefits<br />

for the end-user and illustrate how<br />

GROHE products are demonstrably<br />

better than the competition. We<br />

integrate Moments of Truth into<br />

our lifestyle-orientated marketing<br />

campaigns, which are building<br />

GROHE’s premium positioning in the<br />

marketplace. Over the last 12 months,<br />

we have invested in marketing to<br />

continue our strategy of building more<br />

value, and economies of scale, into<br />

our globally potent brand.<br />

For the future, we will seek to build<br />

an increasingly emotional bond with<br />

consumers. While we will continue<br />

to lead the field with our technological<br />

innovations, we will always highlight<br />

the advantages these have for<br />

improving people’s experience, and<br />

the quality of their lives.

16 Fit for the future<br />

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Our commitment to the<br />

environment with WaterCare<br />

Water is life. Water is quality of<br />

life. As a company, water inspires<br />

everything we do and sustains<br />

our business.<br />

And yet water scarcity is one<br />

of the most pressing problems<br />

facing the planet.<br />

GROHE WaterCare<br />

Today, some 700 million people around<br />

the world are short of water. Although<br />

two-thirds of the Earth is covered with<br />

water, only 2% of this can be used for<br />

drinking. As our population increases<br />

and climate change accelerates,<br />

experts predict that if nothing is done<br />

to protect this most precious natural<br />

element, the number of people<br />

suffering from water scarcity could<br />

rise to more than three billion by 2025.<br />

As a leading player in the sanitary<br />

fittings industry, GROHE has a vital<br />

role in sharing the responsibility<br />

for protecting this most precious<br />

resource. Around two-thirds of water<br />

consumption in private households<br />

is accounted for in bathrooms with a<br />

WC or urinal. And as much as a third<br />

of water consumption is flushed down<br />

the toilet. Washbasins and showers<br />

account for another third of household<br />

water consumption, but people<br />

routinely run water in their bathrooms<br />

when it is not needed at all, sending<br />

more wasted water down the drain.<br />

GROHE has long been committed<br />

to the ecological and economical use<br />

of natural resources, the protection<br />

of the environment and the active<br />

management of water resources.<br />

This commitment takes centre stage in<br />

all of our activities and is encapsulated<br />

in the GROHE WaterCare promise.<br />

Through this, we ensure that all of our<br />

products are designed to use the least<br />

amount of water possible.<br />

1 Our dual flush technology, allows users<br />

to select between a small or larger flush<br />

and is designed to use 50% less water<br />

than conventional flushing systems;<br />

2 Our GROHE TurboStat ® technology<br />

protects water and the environment by<br />

reaching the desired temperature 40%<br />

faster and using 20% less energy*;<br />

3 Our GROHE DreamSpray ® shower –<br />

the technology that lies at the heart<br />

of all our showers – requires up to<br />

30% less water to deliver a perfect<br />

shower*. And GROHE SilkMove ®<br />

also helps to save water by ensuring<br />

ultra-precise control of water flow<br />

and temperature.<br />

* compared to equivalent products from<br />

leading competitors

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Fit for the future 17<br />

“In some parts of the world<br />

water is more expensive than oil.”<br />

Best Quality, Technology<br />

and Design<br />

A key facet of our philosophy and<br />

competitive strength in the market<br />

is for our products to distinguish<br />

themselves through the best quality,<br />

technology and design. Our ability<br />

to win acceptance for products that<br />

combine great style and ease of use<br />

with responsible water consumption<br />

is an important part of this. At the same<br />

time, the unparalleled service lives of<br />

our products, achieved through their<br />

outstanding build quality, means they<br />

need to be replaced considerably less<br />

often than competitors’ products.<br />

Over time, this reduces waste and<br />

the use of raw materials. So, by<br />

buying a GROHE product, customers<br />

are assured they can enjoy their<br />

experience of water while acting in<br />

an environmentally responsible way.<br />

Ultimately, our aim is to combine<br />

lifestyle and enjoyment with intelligent<br />

technology that saves water and energy.<br />

Thanks to our in-house design team,<br />

we are able to gain deep insights into<br />

the latest consumer demands and<br />

market trends so we can see that<br />

consumers share our desire to sustain<br />

water through the enhanced design<br />

of bathroom and kitchen fittings.<br />

Demand for water-saving devices<br />

in the home is stronger than ever,<br />

as better-informed and educated<br />

consumers expect companies like<br />

ours to use their knowledge to<br />

benefit the environment.<br />

Our designers are rising to the<br />

challenge with enthusiasm and<br />

inspiration. Our adoption of wireless<br />

digital technology in the bathroom<br />

is a perfect example of how our<br />

out-of-the-box thinking is meeting<br />

heightened expectations for premium<br />

lifestyle and environmentally friendly<br />

products. With digital temperature<br />

presets, we can help save water by<br />

allowing people to find their perfect<br />

water temperature faster.<br />

Features like these will become<br />

ever more important on all our<br />

products, and, as industry leader,<br />

we will continue to push the<br />

boundaries of balancing superb<br />

performance, economy<br />

and ecology.<br />

GROHE is happy to take up<br />

the challenge and is proud of<br />

its responsibility.<br />

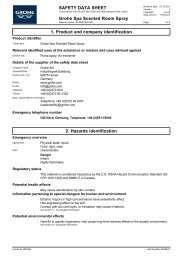

GROHE WaterCare<br />

Five Commitments<br />

1 Climate<br />

We aim to make all our operations<br />

carbon neutral in the next five years.<br />

We’ll maximise our use of renewable<br />

energy and using off-setting as a<br />

last resort.<br />

2 Waste<br />

We will continue to reduce all waste<br />

from our operations and our packaging.<br />

We will recycle an increasing<br />

percentage of our waste and set up<br />

a programme to retrieve and dispose<br />

old products responsibly.<br />

3 Sustainable Raw Materials<br />

We will endeavour to source raw<br />

materials from environmentally<br />

friendly suppliers and mining.<br />

We will protect the world’s natural<br />

resources for future generations.<br />

4 Responsible Partner<br />

By being a responsible partner,<br />

we will select and work closely with<br />

suppliers, investing where necessary<br />

to minimise environmental impact.<br />

5 Health<br />

Water is good for you. We will<br />

continue to develop products<br />

to improve the delivery of pure<br />

water in the developing and<br />

developed worlds.

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

19<br />

Performance review<br />

82%<br />

We continued to grow our presence<br />

in markets around the world, with<br />

82% of our sales generated outside<br />

our home market of Germany<br />

11%<br />

Productivity increase in our factories<br />

<strong>2006</strong> was a year of record performance for<br />

GROHE, with double-digit growth in sales,<br />

operational EBITDA and cash from operations.<br />

Our increased operational momentum, together<br />

with our investment in product development,<br />

resulted in top-line sales growth of 12% to<br />

€939 million, improvement in our gross margin<br />

of 6% to €379 million and operational EBITDA<br />

growth of 12% to €171 million. We generated<br />

€133 million of cash from operations before<br />

exceptionals and financing by the end of <strong>2006</strong>.<br />

Despite a threefold increase in the cost of brass<br />

over the last two years, we have successfully<br />

controlled our margins through a strategic<br />

hedging programme, leaner management<br />

of our working capital and well-managed price<br />

increases across our product lines.<br />

Our lean mentality and relentless focus on<br />

operational discipline were the foundations<br />

of our robust performance over the last<br />

12 months, resulting in better management of<br />

procurement, manufacturing and distribution<br />

capabilities. Moreover, as the benefits of these<br />

initiatives continue to materialise, GROHE is<br />

well-positioned to continue building on its<br />

achievements in the years to come.

20 Performance review<br />

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Sales<br />

€ million<br />

05 838<br />

06 939 12%<br />

<strong>2006</strong> 2005<br />

€m % of sales €m % of sales<br />

GROHE Bathroom Fittings 384.7 41% 343.7 41%<br />

GROHE Showers & Shower Systems 302.3 32% 254.8 30%<br />

GROHE Kitchen Faucets 122.5 13% 113.2 14%<br />

GROHE Sanitary Systems 104.7 11% 93.7 11%<br />

Other GROHE products 25.0 3% 32.3 4%<br />

Total 939.2 100% 837.7 100%<br />

05 06<br />

For GROHE, <strong>2006</strong> was a year<br />

of record growth with strong<br />

performance across all regions<br />

and strategic product groups.<br />

Our increased operational<br />

momentum, together with<br />

our investment in product<br />

development, resulted in<br />

double-digit growth in sales<br />

and operational EBITDA<br />

to €939m and €171m,<br />

respectively.<br />

Sales<br />

<strong>2006</strong> was a watershed year with<br />

sales increasing 12% to €939 million<br />

compared to €838 million in 2005.<br />

By the end of <strong>2006</strong> we had completed<br />

our sales turnaround which included<br />

the recruitment of the majority of our<br />

new management team, the rollout<br />

of our professional sales management<br />

process, and the launches of new<br />

products in thermostats, faucets,<br />

showers and sanitary systems. In July<br />

<strong>2006</strong> we successfully raised our prices<br />

by 5% to compensate for the tripling<br />

in the price of raw materials, particularly<br />

for zinc and copper, the building blocks<br />

of brass. Despite this price rise, sales<br />

grew 14% in the second half of <strong>2006</strong><br />

compared to the second half of 2005,<br />

with growth coming from all regions<br />

and categories. We believe this<br />

performance provides strong top-line<br />

momentum heading into 2007.<br />

We continued to grow our presence<br />

in markets around the world, with<br />

82% of our sales generated outside<br />

our home market of Germany. Other<br />

European (excluding Germany) and<br />

Middle East/Asian markets, which<br />

grew 14%, and 19%, respectively,<br />

were followed by strong performances<br />

in the Americas (7%) and Germany<br />

(6%). We grew our relative market<br />

share by approximately 10% across<br />

all our regions.<br />

All our strategic product groups<br />

performed strongly in <strong>2006</strong>. The<br />

GROHE Bathroom and Special<br />

Fittings division, our largest product<br />

group, generated sales of €385<br />

million, or 41% of our total sales, an<br />

increase of 12% on last year driven<br />

by the relaunch of our Eurolines range.<br />

Showers and Shower Systems<br />

generated sales of €302 million, or<br />

32% of our total sales, a 19% increase<br />

on 2005, driven by the relaunch of our<br />

Grohtherm thermostatic ranges, the<br />

launch of our Relexa product and<br />

Rainshower range and the introduction<br />

of the Digital Shower Controller in<br />

the UK. Our Kitchen Faucets division<br />

generated sales of €123 million,<br />

or 13% of our total sales, an 8%<br />

increase on 2005, driven by the<br />

relaunch of Ladylux in the US and<br />

the introduction of the K4 and<br />

Essence product lines. GROHE<br />

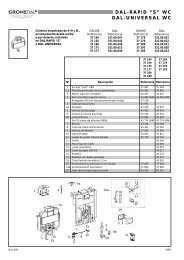

Sanitary Systems generated sales<br />

of €105 million, or 11% of our total<br />

sales, a 12% increase on 2005,<br />

driven by the launch of Rapid SL.<br />

Other GROHE products accounted<br />

for €25 million, or 3% of our<br />

total sales.

GROHE <strong>Annual</strong> <strong>Review</strong> <strong>2006</strong><br />

Performance review 21<br />

Fit for the Future, introduced in 2004,<br />

focuses on improving our operational<br />

performance through adopting lean<br />

processes and mentality.<br />

Fit for the Future:<br />

Our Lean Mentality Mission<br />

Fit for the Future, introduced in 2004,<br />

focuses on improving our operational<br />

performance through organic sales<br />

growth, an accelerated rate of<br />

product innovation and significant<br />

cost reductions of €150 million<br />

throughout the organisation by 2008.<br />

These savings exclude the effects<br />

of inflation, cost increases for brass<br />

and other raw materials, transition<br />

and restructuring costs, increased<br />