The Inside Story - Pon / Cat

The Inside Story - Pon / Cat

The Inside Story - Pon / Cat

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

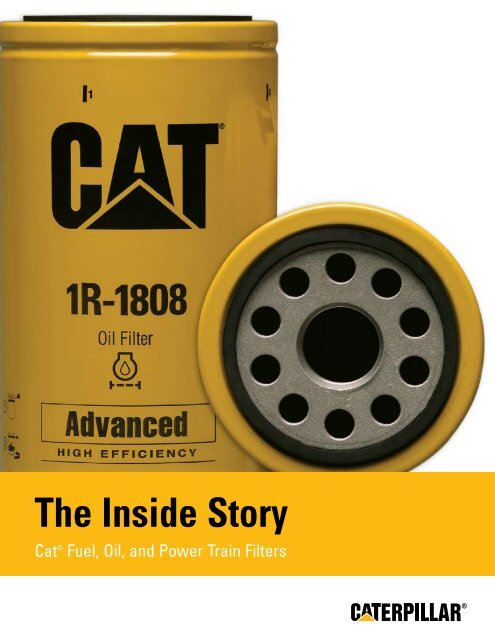

<strong>The</strong> <strong>Inside</strong> <strong>Story</strong><br />

<strong>Cat</strong> ® Fuel, Oil, and Power Train Filters

Visibly Better<br />

C a t ® F u e l , O i l , a n d<br />

P o w e r T r a i n F i l t e r s<br />

<strong>Cat</strong> ® Filters are simply made better.<br />

See for yourself. With <strong>Cat</strong> Filters, the differences are visible. <strong>Cat</strong><br />

Filters are manufactured to meet the most demanding engineering<br />

specs for filters—those specified by <strong>Cat</strong>erpillar. Our goal—to see<br />

that <strong>Cat</strong> Engine, fuel and power train component systems are<br />

protected as well on the day before an oil change as they are the<br />

day after.<br />

<strong>Cat</strong> Filters offer quality features that other filters don't.<br />

• Acrylic beads to prevent pleat bunching.<br />

• Spiral roving for greater pleat stability.<br />

• A nylon center tube and aluminum base plate to prevent metal<br />

contamination.<br />

• Molded end caps to prevent leaks.<br />

Another quality feature is the heavy gauge can that protects every<br />

<strong>Cat</strong> Filter. <strong>The</strong> one-piece design means greater burst pressures, better<br />

performance during cold starts and leaks are virtually eliminated.

Only <strong>Cat</strong> ® Filters have acrylic beads to<br />

prevent pleat bunching, a common problem<br />

experienced by virtually all other filters.<br />

When pleats bunch, the available filter area<br />

drops significantly. As a result, a filter can go<br />

into bypass and allow contaminants into your<br />

engine or other component systems. Thus<br />

other brands of filters may need to be<br />

replaced before reaching recommended<br />

change intervals.<br />

But with <strong>Cat</strong> Filters you can see the<br />

difference. Because of acrylic beads,<br />

<strong>Cat</strong> Filters pleat spacing is rigidly maintained<br />

to maximize the surface area throughout the<br />

life of the filter. Maximum surface area<br />

means maximum filter dirt-holding capacity.<br />

<strong>Cat</strong> Filters can be relied upon for the entire<br />

recommended change period without<br />

jeopardizing component life. This can<br />

mean fewer oil changes per year,<br />

decreased downtime and<br />

overall operating costs.<br />

Pleat spacing on <strong>Cat</strong> Filters is rigidly maintained by acrylic beads<br />

to provide maximum filter surface for better engine<br />

and component system protection and longer life than<br />

other filters.<br />

Acrylic Beads<br />

C a t ® F u e l , O i l , a n d P o w e r T r a i n F i l t e r s

Spiral Roving<br />

C a t ® F u e l , O i l , a n d P o w e r T r a i n F i l t e r s<br />

<strong>Cat</strong> ® Filters feature a unique fiberglass spiral roving to insure<br />

that pleats don't flex, putting an end to pleat movement.<br />

With other brands of filters, pleats are able to move<br />

or “flex.” This can release contaminants into the oil,<br />

fuel, or hydraulic fluid and cause premature wear.<br />

<strong>Cat</strong> Filters trap and hold contaminants.<br />

<strong>The</strong> spiral roving on <strong>Cat</strong> Filters means more effective filtration.<br />

With no “pleat movement” contaminants stay locked in the filter<br />

and out of your engine, drive train, and hydraulic systems.<br />

Every day a machine or engine is started, cold fluid flows<br />

into the filters. Without the pleat stability provided<br />

by spiral roving, many previously trapped<br />

contaminants break loose. <strong>The</strong>se particles<br />

re-enter the system, causing additional<br />

wear, and must be captured again.<br />

Fiberglass spiral roving of <strong>Cat</strong> ® Filters keeps pleats stable and in place, allowing for better filtration.<br />

In fuel filters, particles breaking loose are not recaptured and cause abrasive injector wear.<br />

This graph illustrates the benefit of spiral roving.<br />

250<br />

45% Increase in Particles Not Trapped<br />

Particles<br />

200<br />

150<br />

100<br />

50<br />

0<br />

123<br />

<strong>Cat</strong> Filter with Spiral<br />

Roving & Beads<br />

45%<br />

179<br />

<strong>Cat</strong> Filter without<br />

Spiral Roving

Unlike other filters, <strong>Cat</strong> ® Filters have a nylon center tube which<br />

means there is no chance of metal contamination. <strong>The</strong> nonmetallic<br />

center tubes are 30% stronger than metal tubes.<br />

Molded Endcaps<br />

C a t ® F u e l , O i l , a n d P o w e r T r a i n F i l t e r s<br />

Only <strong>Cat</strong> Filters are made with non-metallic<br />

center tubes to better protect your engine<br />

and other component systems.<br />

By inserting filter pleats into the liquid urethane as the end caps are being formed, a<br />

virtually impenetrable bond is formed to protect your system from contaminants.<br />

Conventional filters have metal center tubes,<br />

which can leave metal contaminants from<br />

the manufacturing process inside the filter.<br />

<strong>The</strong>se metal fragments can lead to scored<br />

bearings and cause damage to other critical<br />

system components.<br />

<strong>Cat</strong> Filter center tubes are clearly better<br />

because they use fiberglass-reinforced<br />

nylon instead of metal, so there is no chance<br />

of metal contamination. <strong>The</strong>se center tubes<br />

are cleaner and protect components, instead<br />

of possibly causing damage. Plus, <strong>Cat</strong> nonmetallic<br />

center tubes are 30% stronger than<br />

typical metal tubes to help prevent collapse<br />

during pressure spikes and cold oil start-ups.<br />

<strong>Cat</strong> ® Filters virtually eliminate<br />

contaminants from entering<br />

the engine, drive train and<br />

hydraulic systems with one-piece,<br />

molded polyurethane end caps.<br />

On other filters, end caps<br />

are metal and are glued directly to<br />

the filter pleats. This can cause gaps<br />

between the metal and pleats that<br />

can allow contaminants to leak<br />

between the filter media and the end cap.<br />

Center Tube<br />

C a t ® F u e l , O i l , a n d P o w e r T r a i n F i l t e r s<br />

<strong>Cat</strong> Filters' structural integrity is better<br />

because filter pleats are actually inserted<br />

into the liquid urethane as the end caps are<br />

being formed. As the polyurethane hardens<br />

an impenetrable bond is formed between the<br />

pleats and end caps. <strong>The</strong> possibility of gaps is<br />

eliminated, keeping contaminants in the filter and<br />

out of your system. <strong>Cat</strong> Filters also feature a one-piece,<br />

aluminum base plate to further protect components from<br />

leaks and ferrous metal contamination.

Out of Sight<br />

Contamination Control<br />

I s N o t O u t O f M i n d<br />

C a t ® F u e l , O i l , a n d P o w e r T r a i n F i l t e r s<br />

Sources of Fuel Contamination<br />

In the fuel<br />

A reliable fuel supplier is your best<br />

defense against source contamination.<br />

Demand periodic sampling and testing<br />

to ensure the consistent quality you<br />

need for top performance.<br />

Dirty fuel is your engine's worst enemy. Silently, quietly, this unseen<br />

villain can rob your engine of power, accelerate wear of sensitive<br />

fuel system components and reduce fuel efficiency. Keeping your<br />

fuel and fuel system clean should be a top priority. With the higher<br />

injection pressures and closer tolerances of today's diesel engines,<br />

clean fuel delivers maximum performance, fuel efficiency,<br />

productivity, and service life.<br />

During operation<br />

In dusty environments, airborne<br />

contaminants can be drawn into<br />

your fuel tank through the vent tube.<br />

Likewise, a vent in the fuel tank cap<br />

can ingest dust if it is not properly<br />

sealed. Contaminants can also develop<br />

during storage, or they can enter the<br />

system through improper fuel transfer.<br />

During Service<br />

Any time your fuel system is open,<br />

whether it is to change filters, make<br />

repairs or for refueling, contaminants<br />

can enter the system.<br />

Advanced efficiency means more protection<br />

<strong>Cat</strong> ® Advanced Efficiency Fuel Filters are specially designed for<br />

today's higher injector pressures and precision components,<br />

using a super-fine filtration media to remove more than 98 percent<br />

of particles 4 microns and larger. By comparison, standard <strong>Cat</strong> Fuel<br />

Filters have a minimum particle size of 15 microns. Advanced<br />

Efficiency Fuel Filters result in maximum performance, longer<br />

component life, fewer repairs and lower engine operating costs.<br />

<strong>The</strong> most measurable and controllable contaminants are<br />

particulates. <strong>The</strong>y can vary greatly in size, hardness and abrasion.<br />

<strong>The</strong> comparison illustrated below demonstrates the very tight<br />

clearances in your fuel system and the size of particles.<br />

As you can see, even particles that you can't see<br />

(smaller than 80 microns) can wear away at your<br />

fuel injectors and reduce performance.<br />

One critical element in any fuel<br />

contamination control program<br />

is <strong>Cat</strong> ® Advanced Efficiency Fuel<br />

Filters. <strong>The</strong>y're specially designed<br />

for today's diesels, using a<br />

super-fine cellulose/synthetic<br />

blend media for maximum filtration.<br />

Fuel system components are more<br />

sensitive than ever to fuel contaminants,<br />

but you can maintain performance and<br />

extend component life by carefully<br />

managing your fuel-related<br />

operations and procedures.<br />

Human Hair Standard Filtration Damages Fuel Systems Advanced Efficiency Filtration<br />

(80 microns) (15 microns) (5-10 microns) (4 microns)

Not all filters are equal. While other filters may be lower priced,<br />

it's important to know they provide significantly less protection.<br />

And with today's sophisticated engine and other component<br />

systems, that's a risk that just doesn't make sense to take.<br />

Only <strong>Cat</strong> ® Filters have these quality design features:<br />

• One-piece molded end caps prevent leaks<br />

• Acrylic beads prevent pleat bunching<br />

• Spiral roving keeps pleats from “moving”<br />

• Nonmetallic center tubes to protect your engine<br />

Because <strong>Cat</strong> Filters are made better, they provide consistent<br />

performance to protect your engine, drive train, and hydraulic<br />

systems. While other filter brands may fit, <strong>Cat</strong> Filters offer the<br />

superior quality and protection you need to maximize your<br />

engine and other component system’s life.<br />

Get the <strong>Inside</strong> <strong>Story</strong>.<br />

LEDQ6225-04<br />

www.cat.com<br />

© 2008 <strong>Cat</strong>erpillar | All Rights Reserved | Printed in USA<br />

CAT, CATERPILLAR, their respective logos, “<strong>Cat</strong>erpillar Yellow” and the POWER EDGE trade dress, as well as<br />

corporate and product identity used herein, are trademarks of <strong>Cat</strong>erpillar and may not be used without permission.