GE Consumer & Industrial - G E Power Controls

GE Consumer & Industrial - G E Power Controls

GE Consumer & Industrial - G E Power Controls

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6.1.1 General visual inspection<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Check out for damages or cracks of the frame, the<br />

adapter or the arc chute.<br />

Check out the black marks on the countersunk screws.<br />

These marks shall be aligned together. If any screw is<br />

loosening, shall be replaced with new one, using Loctite<br />

222. Afterwards, mark the screw with black line to sign<br />

its position in nest.<br />

Check out for missing screws or caps.<br />

Check out for damaged labels. Clean and repair.<br />

Check out for corrosion. In case of significant corrosion,<br />

please contact <strong>GE</strong> representative for assistance.<br />

Check out for distinct manifestations of flame or smoke<br />

at the frame. Especially in lower area of the breaker.<br />

Please document and contact <strong>GE</strong> representative for<br />

assistance.<br />

Clean the breaker of dirt and dust. Remove all dirt with a<br />

dry cloth. No particularly high signs of abrasion (rough<br />

chips) should be visible anywhere.<br />

Clean and degrease the copper terminals.<br />

6.1.2 General functional inspection<br />

<br />

Pay attention to the warnings, Section 1!<br />

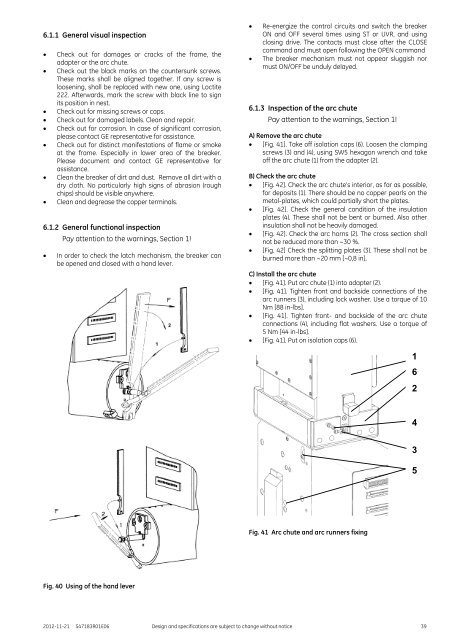

In order to check the latch mechanism, the breaker can<br />

be opened and closed with a hand lever.<br />

<br />

<br />

Re-energize the control circuits and switch the breaker<br />

ON and OFF several times using ST or UVR, and using<br />

closing drive. The contacts must close after the CLOSE<br />

command and must open following the OPEN command<br />

The breaker mechanism must not appear sluggish nor<br />

must ON/OFF be unduly delayed.<br />

6.1.3 Inspection of the arc chute<br />

Pay attention to the warnings, Section 1!<br />

A) Remove the arc chute<br />

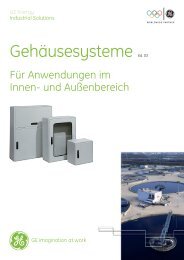

[Fig. 41]. Take off isolation caps (6). Loosen the clamping<br />

screws (3) and (4), using SW5 hexagon wrench and take<br />

off the arc chute (1) from the adapter (2).<br />

B) Check the arc chute<br />

[Fig. 42]. Check the arc chute’s interior, as far as possible,<br />

for deposits (1). There should be no copper pearls on the<br />

metal-plates, which could partially short the plates.<br />

[Fig. 42]. Check the general condition of the insulation<br />

plates (4). These shall not be bent or burned. Also other<br />

insulation shall not be heavily damaged.<br />

[Fig. 42]. Check the arc horns (2). The cross section shall<br />

not be reduced more than ~30 %.<br />

[Fig. 42] Check the splitting plates (3). These shall not be<br />

burned more than ~20 mm [~0,8 in].<br />

C) Install the arc chute<br />

[Fig. 41]. Put arc chute (1) into adapter (2).<br />

[Fig. 41]. Tighten front and backside connections of the<br />

arc runners (3), including lock washer. Use a torque of 10<br />

Nm [88 in-lbs].<br />

[Fig. 41]. Tighten front- and backside of the arc chute<br />

connections (4), including flat washers. Use a torque of<br />

5 Nm [44 in-lbs].<br />

[Fig. 41]. Put on isolation caps (6).<br />

1<br />

6<br />

2<br />

4<br />

3<br />

5<br />

Fig. 41 Arc chute and arc runners fixing<br />

Fig. 40 Using of the hand lever<br />

2012-11-21 S47183R01E06 Design and specifications are subject to change without notice 39