FISHEYE ELIMINATOR - Globalsafetynet.com

FISHEYE ELIMINATOR - Globalsafetynet.com

FISHEYE ELIMINATOR - Globalsafetynet.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECHNICAL DATA SHEET<br />

Page 1 of 2<br />

June 2004<br />

<strong>FISHEYE</strong> <strong>ELIMINATOR</strong><br />

DESCRIPTION:<br />

Special additive to be used in Lesonal car refinishes topcoats in case of silicone<br />

contamination.<br />

PRODUCT:<br />

BASIC RAW<br />

MATERIALS:<br />

APPLICATION:<br />

SUITABILITY:<br />

NOTE:<br />

MIXING RATIO:<br />

1.<br />

Lesonal Fisheye Eliminator<br />

Special solvents and anti-silicone agent.<br />

Lesonal Fisheye Eliminator may be used in:<br />

—Any Lesonal Clearcoat<br />

Do not use Fisheye Eliminator in Basecoat SB, Primers, Primer Fillers or Sealers.<br />

Depending on the degree of contamination, add 1/2 to 2 measuring caps full to<br />

1 liter of Ready to Spray Product.<br />

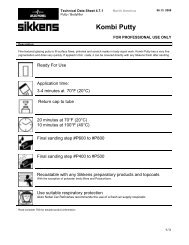

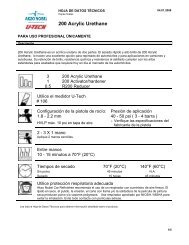

Addition of Lesonal Fisheye Eliminator in conjunction with Universal Clear.<br />

Contains acrylic resins and<br />

other ingredients. When mixed,<br />

the ready to spray paint also<br />

contains isocyanates.<br />

4.<br />

1 liter (1000 ml): ½ to 2 caps<br />

–Universal Clear<br />

Ready to Spray<br />

–Lesonal Fisheye Eliminator<br />

2.<br />

3:1:1<br />

Lesonal Universal Clear<br />

Lesonal Clear Hardener<br />

Lesonal Clear Slow<br />

Activator<br />

5.<br />

Stir thoroughly<br />

Use the Lesonal measuring<br />

Stick # 7.<br />

Apply topcoat in thinner<br />

layers<br />

3.<br />

6.

TECHNICAL DATA SHEET<br />

Page 2 of 2<br />

June 2004<br />

<strong>FISHEYE</strong> <strong>ELIMINATOR</strong><br />

STOCK KEEPING:<br />

COLOR:<br />

CONTAINER<br />

SIZE:<br />

SHELF LIFE:<br />

SAFETY ASPECTS:<br />

NOTICE:<br />

Clear<br />

One liter<br />

Two years if stored unopened at room temperature.<br />

Do not handle until the Material Safety Data Sheets have been read and<br />

understood. Regulations require that all employees be trained on Material Safety<br />

Data Sheets for all chemicals with which they <strong>com</strong>e in contact. The manufacturer<br />

re<strong>com</strong>mends the use of protective equipment when mixing and spraying this<br />

material. Protect skin with gloves and spray suit, wear safety glasses or goggles<br />

when mixing, and wear a full hood fresh air-fed respirator while spraying.