Autocoat LV Epoxy Chassis Black - Globalsafetynet.com

Autocoat LV Epoxy Chassis Black - Globalsafetynet.com

Autocoat LV Epoxy Chassis Black - Globalsafetynet.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Data Sheet<br />

Primers<br />

FOR PROFESSIONAL USE ONLY<br />

Description<br />

03.04.2009<br />

<strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong><br />

<strong>Black</strong><br />

A two-<strong>com</strong>ponent high solids epoxy chassis primer. <strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong> <strong>Black</strong> has superior corrosion protection in a high<br />

gloss finish. <strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong> <strong>Black</strong> is designed for chassis applications or other <strong>com</strong>ponents located out of direct<br />

sunlight or where epoxy chalking is not a concern. The ready to spray VOC is 3.6 lbs/gal.<br />

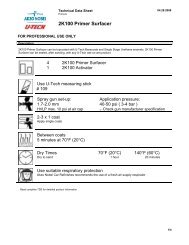

2 <strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong> <strong>Black</strong><br />

1 <strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> CIP Hardener<br />

Mix thoroughly<br />

Use Sikkens measuring stick #2<br />

Spray gun set-up (RP Pressure):<br />

Fluid delivery:<br />

0.8 – 1.1 mm 12 – 16 oz/min<br />

36 – 44psi Check gun manufacturer specification<br />

2 x 1 coat<br />

Apply 2 – 3 single flowing coats. Allow proper flash time between coats.<br />

Between coats<br />

Final Flash<br />

15 minutes at 70°F (21°C) 15 minutes at 70°F (21°C)<br />

70°F (21°C) 140°F (60°C)<br />

Dry to Sand 8 hours 1 hour<br />

Use suitable respiratory protection<br />

Akzo Nobel Car Refinishes re<strong>com</strong>mends the use of a fresh air supply respirator<br />

Read <strong>com</strong>plete TDS for detailed product information<br />

1/4

Technical Data Sheet<br />

Primers<br />

FOR PROFESSIONAL USE ONLY<br />

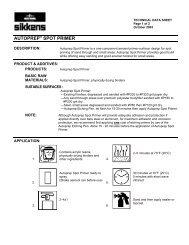

Spray gun set-up / application pressure<br />

Application process<br />

03.04.2009<br />

<strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong><br />

<strong>Black</strong><br />

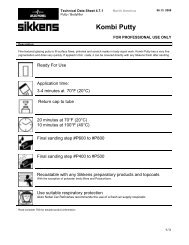

RP – Pressure Feed 0.8 – 1.1mm 36 – 44psi 12 – 16 oz/min<br />

HVLP – Pressure Feed 1.0 – 1.2mm Max 10psi 10 – 14 oz/min<br />

HVLP – Gravity Feed 1.5 – 1.7mm Max 10psi<br />

HVLP – Siphon Feed 1.8 – 2.2mm Max 10psi<br />

Pressure Feed 1.0 – 1.4mm 50 – 60psi 12 – 16 oz/min<br />

Gravity Feed 1.3 – 1.5mm 50 – 60psi<br />

Siphon Feed 1.4 – 1.7mm 50 – 60psi<br />

Electrostatic 1.2 – 1.7mm 60 – 70psi 12 – 14 oz/min<br />

Airless Spray 0.011 – 0.015in 1500 – 3000psi<br />

Air Assisted Airless 0.011 – 0.015in 700 – 900psi<br />

Apply two (2) medium wet coats with proper flash time between coats<br />

Dry Film Thickness<br />

Flash Times<br />

2.0 – 2.5 mils<br />

15 minutes at 70°F (21°C) between coats<br />

15 minutes at 70°F (21°C) final flash before curing<br />

Dry Times<br />

Object Temp Drying Time<br />

Dust Free<br />

90 min<br />

70°F (21°C)<br />

Tack Free<br />

6 hrs<br />

Dry to handle<br />

24 hrs<br />

Dust Free<br />

1 hr<br />

100°F (38°C)<br />

Tack Free<br />

2 hrs<br />

Dry to handle<br />

2 ½ hrs<br />

Dust Free<br />

45 min<br />

140°F (60°C)<br />

Tack Free<br />

45 min<br />

Dry to handle<br />

1 hr<br />

<strong>Autocoat</strong> <strong>LV</strong> EP <strong>Chassis</strong> <strong>Black</strong> may experience slight loss of gloss when baked at 140°F (60°C)<br />

3/4

Technical Data Sheet<br />

Primers<br />

FOR PROFESSIONAL USE ONLY<br />

Recoatability<br />

Cleaning of equipment<br />

VOC<br />

Product Storage and Shelf Life<br />

03.04.2009<br />

<strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong><br />

<strong>Black</strong><br />

<strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong> <strong>Black</strong> may be top coated with <strong>Autocoat</strong> <strong>LV</strong> after 60 minutes at 70°F (21°C).<br />

It is re<strong>com</strong>mended to air dry <strong>Autocoat</strong> <strong>LV</strong> when applied over <strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong> <strong>Black</strong>. Baking<br />

<strong>Autocoat</strong> <strong>LV</strong> over <strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong> <strong>Black</strong> can result in die back problems.<br />

The maximum recoat time without sanding is 72 hours at 70°F (21°C). Periods longer than 72 hours<br />

require sanding prior to top coating.<br />

Clean equipment with Sikkens Cleaning Solvent<br />

<strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong> <strong>Black</strong> 3.6 lb/gal 430 g/l<br />

VOC is ready to spray at a mix ratio of 2:1, less exempt. Method 24.<br />

Store products unopened and used products with closed lids. Store products between 70°F-95°F (21°C-<br />

35°C). Optimal storage temperature is 77°F (25°C). Avoid extreme temperature fluctuation when<br />

storing.<br />

<strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> <strong>Chassis</strong> <strong>Black</strong><br />

<strong>Autocoat</strong> <strong>LV</strong> <strong>Epoxy</strong> CIP Hardener<br />

1 year<br />

1 year<br />

FOR PROFESSIONAL USE ONLY<br />

IMPORTANT NOTE: The information in this data sheet is not intended to be exhaustive and is based on the present state of our<br />

knowledge and on current laws: any person using the product for any purpose other than that specifically re<strong>com</strong>mended in the<br />

technical data sheet without first obtaining written confirmation from us as to the suitability of the product for the intended purpose<br />

does so at his own risk. It is always the responsibility of the user to take all necessary steps to fulfill the demands set out in the local<br />

rules and legislation. Always read the Material Data Sheet and the Technical Data Sheet for this product if available. All advice we<br />

give or any statement made about the product by us (whether in this data sheet or otherwise) is correct to the best of our<br />

knowledge but we have no control over the quality or the condition of the substrate or the many factors affecting the use and<br />

application of the product. Therefore, unless we specifically agree in writing otherwise, we do not accept any liability whatsoever for<br />

the performance of the product or for any loss or damage arising out of the use of the product. All products supplied and technical<br />

advices given are subject to our standard terms and conditions of sale. You should request a copy of this document and review it<br />

carefully. The information contained in this data sheet is subject to modification from time to time in the light of experience and our<br />

policy of continuous development. It is the user's responsibility to verify that this data sheet is current prior to using the product.<br />

Coating brand names mentioned in this data sheet are trademarks of or are licensed to Akzo Nobel.<br />

Head Office<br />

Akzo Nobel Car Refinishes Inc. 5555 Spalding Drive Norcross, GA 30092, USA. www.sikkenscr.<strong>com</strong><br />

4/4