Technical Paper by J.H. Greenwood - IGS - International ...

Technical Paper by J.H. Greenwood - IGS - International ...

Technical Paper by J.H. Greenwood - IGS - International ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DISCUSSION AND CLOSURE D Designing to Residual Strength Instead of Stress-Rupture<br />

T R = 1 − T S t ∕ 10<br />

(7)<br />

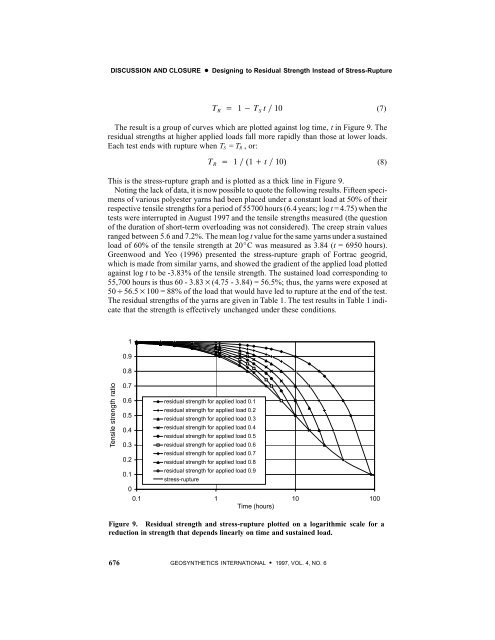

The result is a group of curves which are plotted against log time, t in Figure 9. The<br />

residual strengths at higher applied loads fall more rapidly than those at lower loads.<br />

Each test ends with rupture when T S =T R ,or:<br />

T R = 1 ∕ (1 + t ∕ 10)<br />

(8)<br />

This is the stress-rupture graph and is plotted as a thick line in Figure 9.<br />

Noting the lack of data, it is now possible to quote the following results. Fifteen specimens<br />

of various polyester yarns had been placed under a constant load at 50% of their<br />

respective tensile strengths for a period of 55700 hours (6.4 years; log t = 4.75) when the<br />

tests were interrupted in August 1997 and the tensile strengths measured (the question<br />

of the duration of short-term overloading was not considered). The creep strain values<br />

ranged between 5.6 and 7.2%. The mean log t value for the same yarns under a sustained<br />

load of 60% of the tensile strength at 20_C was measured as 3.84 (t = 6950 hours).<br />

<strong>Greenwood</strong> and Yeo (1996) presented the stress-rupture graph of Fortrac geogrid,<br />

which is made from similar yarns, and showed the gradient of the applied load plotted<br />

against log t to be -3.83% of the tensile strength. The sustained load corresponding to<br />

55,700 hours is thus 60 - 3.83×(4.75 - 3.84) = 56.5%; thus, the yarns were exposed at<br />

50÷56.5×100 = 88% of the load that would have led to rupture at the end of the test.<br />

The residual strengths of the yarns are given in Table 1. The test results in Table 1 indicate<br />

that the strength is effectively unchanged under these conditions.<br />

1<br />

0.9<br />

0.8<br />

Percent Tensile tensile strength strength ratio<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

residual strength for applied load 0.1<br />

residual strength for applied load 0.2<br />

residual strength for applied load 0.3<br />

residual strength for applied load 0.4<br />

residual strength for applied load 0.5<br />

residual strength for applied load 0.6<br />

residual strength for applied load 0.7<br />

residual strength for applied load 0.8<br />

residual strength for applied load 0.9<br />

stress-rupture<br />

0.1 1 10 100<br />

Time (hours)<br />

Figure 9. Residual strength and stress-rupture plotted on a logarithmic scale for a<br />

reduction in strength that depends linearly on time and sustained load.<br />

676 GEOSYNTHETICS INTERNATIONAL S 1997, VOL. 4, NO. 6