From low to high viscosity products, from small ... - Gea-tds.com

From low to high viscosity products, from small ... - Gea-tds.com

From low to high viscosity products, from small ... - Gea-tds.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

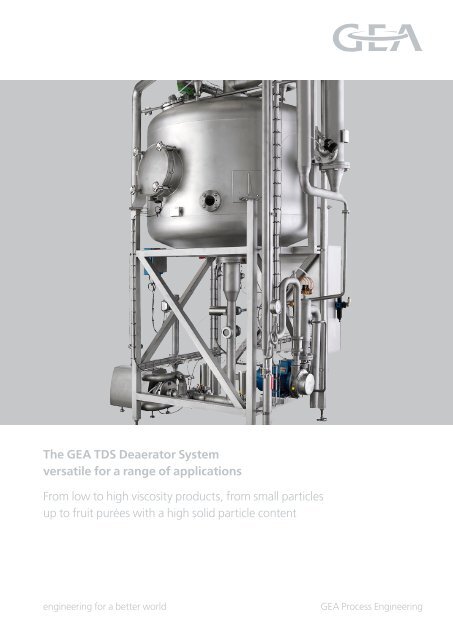

The GEA TDS Deaera<strong>to</strong>r System<br />

versatile for a range of applications<br />

<strong>From</strong> <strong>low</strong> <strong>to</strong> <strong>high</strong> <strong>viscosity</strong> <strong>products</strong>, <strong>from</strong> <strong>small</strong> particles<br />

up <strong>to</strong> fruit purées with a <strong>high</strong> solid particle content<br />

engineering for a better world<br />

GEA Process Engineering

Dearation <strong>to</strong> perfection<br />

For process plants for various applications, GEA TDS provides deaera<strong>to</strong>r<br />

systems which are tailored exactly <strong>to</strong> requirements – an essential building<br />

block for achieving the best product quality.<br />

The reduction of gas during the thermal<br />

heating process is the prerequisite for<br />

obtaining a long-lasting production<br />

cycle. The effective reduction of oxygen<br />

in the solution plays a decisive role for<br />

the quality of the product. A GEA TDS<br />

deaera<strong>to</strong>r system effectively prevents<br />

oxidation and foam formation. Ideal<br />

results are achieved by reducing unwanted<br />

flavouring and odorant substances. The<br />

<strong>com</strong>bined and integrated aroma recovery<br />

process minimizes aroma loss during<br />

deaeration.<br />

The deaera<strong>to</strong>r system effectively frees reconstituted solutions<br />

or <strong>products</strong> mixed with powdery substances <strong>from</strong> air brought<br />

in during the mixing process. Fluid aroma substances can be<br />

removed and condensed in an external cooler and returned <strong>to</strong><br />

the product f<strong>low</strong>. The deaera<strong>to</strong>r system, including the external<br />

cooler, can be fully integrated in<strong>to</strong> the au<strong>to</strong>matic thermal<br />

process, for instance in<strong>to</strong> a UHT plant. CIP cleaning of the<br />

deaera<strong>to</strong>r system is also performed au<strong>to</strong>matically.<br />

Gentle <strong>to</strong> the product: a mushroomshaped<br />

product distribu<strong>to</strong>r for <strong>products</strong><br />

containing solid particles<br />

Viscous liquids with chunky particles are<br />

gently deaerated without vacuum support<br />

in a special buffer tank, the thermaldynamic<br />

layer s<strong>to</strong>rage tank.<br />

The product enters the tank <strong>from</strong> the bot<strong>to</strong>m and is applied<br />

evenly and uniformly <strong>to</strong> the previous product surface in very<br />

thin layers by a mushroom-shaped product distribu<strong>to</strong>r. The<br />

layers of product are vertically stable, i.e. they do not mix with<br />

each other, so that the product that is filled in first also leaves<br />

the deaera<strong>to</strong>r first. To ensure that the product f<strong>low</strong>s gently and<br />

smoothly in<strong>to</strong> the tank, the product distribu<strong>to</strong>r is flexibly mounted<br />

on the product supply pipe, so that the static height can be varied.<br />

V<br />

GOA<br />

W<br />

W<br />

IW<br />

IW<br />

LIC<br />

IW<br />

PIC<br />

LSL<br />

A<br />

CIS<br />

Pr<br />

Pr<br />

Productpump<br />

PR<br />

TIC<br />

W<br />

V<br />

W<br />

Schematic process f<strong>low</strong> diagram<br />

for <strong>products</strong> with a <strong>high</strong>er<br />

content of solid particles/pieces

Product distribu<strong>to</strong>r, <strong>high</strong>er position<br />

Cooling coil for foam reduction<br />

Product distribu<strong>to</strong>r, <strong>low</strong>er position<br />

Advantage: adjustable cascade valve for the product inlet<br />

A special, adjustable cascade valve for the product inlet provides<br />

a very effective product surface in the deaeration vessel. The<br />

valve thus helps <strong>to</strong> achieve an optimal deaeration result.<br />

V<br />

Pr<br />

Pr<br />

PI<br />

LIC<br />

TIS<br />

W<br />

W<br />

CIS<br />

LSL<br />

W<br />

Pr<br />

W<br />

V<br />

Schematic process f<strong>low</strong> diagram for<br />

fruit juices with a <strong>high</strong>er fibre content<br />

or milk / milk-like <strong>products</strong><br />

02<br />

03

We live our values.<br />

Excellence • Passion • Integrity • Responsibility • GEA-versity<br />

GEA Group is a global engineering <strong>com</strong>pany with multi-billion euro sales and operations in more than<br />

50 countries. Founded in 1881, the <strong>com</strong>pany is one of the largest providers of innovative equipment and<br />

process technology. GEA Group is listed in the STOXX® Europe 600 Index.<br />

GEA Process Engineering<br />

GEA TDS GmbH<br />

Voss-Strasse 11/13, 31157 Sarstedt, Germany<br />

Phone +49 5066 990-0<br />

Am Industriepark 2–10, 21514 Büchen, Germany<br />

Phone +49 4155 49-0<br />

Kruppstrasse 3, 48683 Ahaus, Germany<br />

Phone +49 2561 8602-0<br />

gea<strong>tds</strong>@gea.<strong>com</strong>, www.gea.<strong>com</strong><br />

422e • 01/13 • inform-werbeagentur.de