Market leader in China opts for technology from ... - Gea-tds.com

Market leader in China opts for technology from ... - Gea-tds.com

Market leader in China opts for technology from ... - Gea-tds.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Tuchenhagen<br />

Dairy Systems<br />

EUROPEAN DAIRY MAGAZINE<br />

Dairy & Fluid Foods Technology<br />

K 10189<br />

September<br />

5<br />

September<br />

Septembre<br />

2006<br />

<strong>Market</strong> <strong>leader</strong> <strong>in</strong> Ch<strong>in</strong>a<br />

<strong>opts</strong> <strong>for</strong> <strong>technology</strong><br />

<strong>from</strong> Germany<br />

Tuchenhagen Dairy Systems builds<br />

a new dairy <strong>in</strong> Inner Mongolia<br />

Yili's new showcase facility <strong>in</strong> Hohot

Milk silos at the showcase facility <strong>in</strong> Hohhot<br />

Yili has four CIP plants <strong>in</strong> the new facility<br />

The Ch<strong>in</strong>ese dairy <strong>com</strong>pany Inner Mongolia Yili Industrial Co. Ltd., the<br />

market <strong>leader</strong> <strong>in</strong> Ch<strong>in</strong>a, has started operations at a new, ultra-modern<br />

production facility <strong>in</strong> Hohhot. The entire milk process<strong>in</strong>g room equipment,<br />

<strong>in</strong>clud<strong>in</strong>g automation and clean<strong>in</strong>g systems, was supplied and <strong>in</strong>stalled<br />

by Tuchenhagen Dairy Systems (TDS) <strong>in</strong> cooperation with GEA Process<br />

Eng<strong>in</strong>eer<strong>in</strong>g Ch<strong>in</strong>a (GPCN). GEA was also responsible <strong>for</strong> project management,<br />

process plann<strong>in</strong>g and eng<strong>in</strong>eer<strong>in</strong>g.<br />

Accord<strong>in</strong>g to Christiane Schetzschen,<br />

responsible <strong>for</strong> the Ch<strong>in</strong>ese<br />

market at TDS, the order was<br />

awarded <strong>in</strong> October 2004 after a<br />

tough negotiation marathon, which started<br />

<strong>in</strong> autumn 2003. A GEA team spent a<br />

couple of weeks <strong>in</strong> Ch<strong>in</strong>a to<br />

clarify the details with Yili<br />

because the project was<br />

def<strong>in</strong>itely ambitious: Yili was<br />

striv<strong>in</strong>g to set up a showcase<br />

production facility that is<br />

unrivalled <strong>in</strong> the whole of<br />

Ch<strong>in</strong>a. Christiane Schetzschen<br />

said, “The GEA-Group, with its<br />

<strong>in</strong>dividual <strong>com</strong>panies – TDS, Westfalia<br />

Separator, GEA Ecoflex, Niro Soavi, GPCN<br />

and GEA Wiegand – successfully outrivalled<br />

other <strong>in</strong>ternationally active plant eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>com</strong>panies because tailor-made<br />

solutions were offered at a fair price, and<br />

TDS and GPCN can draw on valuable<br />

experience <strong>from</strong> build<strong>in</strong>g large-scale dairies<br />

both <strong>in</strong> Ch<strong>in</strong>a and other countries<br />

worldwide.”<br />

The facility, one of the largest green-field<br />

dairy facilities <strong>in</strong> Ch<strong>in</strong>a <strong>for</strong> the production of<br />

dr<strong>in</strong>k<strong>in</strong>g milk, was built on a total area of<br />

290,000 m 2 . This first construction stage<br />

has the ability to process 1 million litres of<br />

The Yili logo wants to convey<br />

fresh and natural like the<br />

local pastures<br />

raw milk per day. Yili is <strong>in</strong> the centre of<br />

Ch<strong>in</strong>a’s most important dairy region Inner<br />

Mongolia (28 per cent of the entire milk<br />

production). It acquires raw material of the<br />

best available quality, i. e. with a bacterial<br />

count of less than 500,000 germs/ml, <strong>from</strong><br />

its own farms and local<br />

producers. The factoryowned<br />

milk collect<strong>in</strong>g<br />

trucks are unloaded at<br />

twelve milk reception po<strong>in</strong>ts<br />

<strong>in</strong> six bays and<br />

the milk is<br />

pumped <strong>in</strong>to two<br />

underground buffer tanks. It’s<br />

then heated by a GEA Ecoflex<br />

plate heat exchanger with a flow<br />

rate of 60,000 l/h, currently the<br />

largest milk pasteuriser <strong>in</strong> Ch<strong>in</strong>a.<br />

A milk evaporator to <strong>in</strong>crease the<br />

dry matter content, a suitably<br />

matched separator with Prote<strong>in</strong><br />

Plus System, an automatic<br />

standardisation system, and a<br />

homogeniser <strong>com</strong>plete the milk<br />

pre-process<strong>in</strong>g equipment. The<br />

next stages <strong>in</strong>clude <strong>com</strong>plex<br />

mix<strong>in</strong>g processes <strong>for</strong> dry and<br />

liquid additives be<strong>for</strong>e the<br />

product reaches the fill<strong>in</strong>g l<strong>in</strong>es<br />

via UHT plants (the <strong>for</strong>mer are not supplied<br />

by GEA).<br />

The fully automated factory has 1,100<br />

pneumatic valves: about 500 of the<br />

Tuchenhagen VARIVENT type and around<br />

the same number of pneumatic butterfly<br />

valves produced <strong>in</strong> Shanghai by GPCN (GEA<br />

uses these butterfly valves exclusively on<br />

the Ch<strong>in</strong>ese market). In addition there are<br />

600 manually-operated butterfly valves, 40<br />

control valves, 95 pumps and 38 heat<br />

exchangers <strong>for</strong> the four CIP plants and the<br />

production areas. The facility is controlled<br />

by two S7-417 systems.<br />

For the first time, Yili ordered an<br />

<strong>in</strong>tegrated MES system <strong>in</strong> addition to the<br />

automation of the production systems <strong>for</strong><br />

this new dairy. Apart <strong>from</strong> delivery and<br />

implementation of the system, TDS was<br />

also <strong>in</strong> charge of coord<strong>in</strong>at<strong>in</strong>g data<br />

<strong>com</strong>munication with the co-suppliers. The<br />

plant provides the follow<strong>in</strong>g functionality:<br />

Some people <strong>in</strong> Inner Mongolia still live <strong>in</strong> yurts of this type<br />

2

IMAGE_DAIRY_90x270_4C_E.qxd 25.08.2006 9:56 Uhr Seite 1<br />

Work<strong>in</strong>g<br />

together.<br />

Common<br />

understand<strong>in</strong>g leads<br />

to optimal solutions.<br />

Tuchenhagen’s philosophy<br />

is listen<strong>in</strong>g, understand<strong>in</strong>g<br />

and work<strong>in</strong>g<br />

together. We exchange<br />

know-how, which often<br />

The spacious pastures of Inner Mongolia are predest<strong>in</strong>ed <strong>for</strong> milk<br />

production<br />

– Recipe management and job control<br />

Powder meter<strong>in</strong>g processes are recorded by means of<br />

barcode scanners – this ensures that the recipe is followed<br />

and that the product can be traced back to the powder<br />

supplier.<br />

– Tanker truck management and logistics<br />

Trucks are registered by transponder cards at different<br />

stations on the factory premises (gateman, outside clean<strong>in</strong>g,<br />

weigh<strong>in</strong>g po<strong>in</strong>t, milk reception, etc.) and guided through the<br />

system. By <strong>in</strong>tegrat<strong>in</strong>g the laboratory systems, the trucks can<br />

be assigned to the unload<strong>in</strong>g bays <strong>in</strong> accordance with the raw<br />

milk quality.<br />

YILI<br />

The dairy <strong>com</strong>pany Inner Mongolia Yili Industrial Co. Ltd.,<br />

based <strong>in</strong> Hohhot, has experienced a strong expansion <strong>in</strong> the<br />

past few years: while 200 tonnes of milk products a day were<br />

produced <strong>in</strong> 1997, current production amounts to more than<br />

7 000 tonnes. The <strong>com</strong>pany’s success is based on ultra-modern<br />

process<strong>in</strong>g and packag<strong>in</strong>g <strong>technology</strong> and strict quality<br />

assurance. With a market share of approximately 20 per cent<br />

of the milk market, Yili is currently the <strong>leader</strong> on the national<br />

market; the advertis<strong>in</strong>g message is “fresh and natural like the<br />

pastures”.<br />

The group operates 24 market milk factories alone and takes<br />

<strong>in</strong> milk <strong>from</strong> the three core regions <strong>in</strong> Inner Mongolia, the<br />

metropolitan area of Beij<strong>in</strong>g and the north-east of the country.<br />

39 production factories, which apart <strong>from</strong> market milk also<br />

produce ice cream, milk powder and sour milk products,<br />

belong to the Yili group. Yili is one of the 500 lead<strong>in</strong>g<br />

<strong>com</strong>panies <strong>in</strong> Ch<strong>in</strong>a, and <strong>in</strong> mid 2005 they also took the lead <strong>in</strong><br />

their sector when they outclassed their <strong>com</strong>petitors Mengniu<br />

and Shanghai Bright Dairy, with a sales volume of more than<br />

g 1.2 billion. All <strong>in</strong> all, Yili boasts annual sales of about g 1.5<br />

billion; their 2004:2005 growth rate stood at 39.38 per cent.<br />

The <strong>com</strong>pany has also been export<strong>in</strong>g UHT products and other<br />

products to neighbour<strong>in</strong>g markets.<br />

A <strong>com</strong>pany of GEA Group<br />

Tuchenhagen Dairy Systems GmbH<br />

Am Industriepark 2–10<br />

21514 Büchen, Germany<br />

Phone: +49-(0) 41 55 / 49 22 00<br />

Fax: +49-(0) 41 55 / 49 27 24<br />

<strong>in</strong>fo-<strong>tds</strong>@tuchenhagen.de<br />

www.tuchenhagen.de<br />

leads to new discoveries<br />

and new challenges.<br />

As a result of this, we<br />

create new <strong>technology</strong>, fulfill<strong>in</strong>g<br />

future demands.<br />

Tuchenhagen will<br />

always be work<strong>in</strong>g<br />

closely with you so<br />

that we can f<strong>in</strong>d<br />

solutions together.<br />

3

The milk is processed by a GEA Ecoflex pasteuriser with a flow rate of<br />

60,000 l/h; the photo also shows the GEA Wiegand evaporator<br />

Detail of the pasteuriser; the milk processed has a bacterial count of less<br />

than 500,000 germs/ml, i. e. high-quality measured by local standards<br />

– Laboratory management<br />

OTAS Laboratory was used to establish<br />

an <strong>in</strong>tegrated laboratory management<br />

system. TDS paid special attention to<br />

ease of use and high efficiency <strong>in</strong> the<br />

day-to-day runn<strong>in</strong>g of the laboratory.<br />

This was achieved by <strong>in</strong>tegrat<strong>in</strong>g<br />

barcode scanners and pr<strong>in</strong>ters, as<br />

well as onl<strong>in</strong>e connection of analysis<br />

equipment.<br />

– Batch track<strong>in</strong>g<br />

Batch track<strong>in</strong>g is achieved us<strong>in</strong>g the<br />

graphical user <strong>in</strong>terface of OTAS Track &<br />

Trace. UHT systems, fill<strong>in</strong>g l<strong>in</strong>es and the<br />

fully automated warehouse <strong>from</strong> cosuppliers<br />

were <strong>in</strong>tegrated <strong>in</strong>to the batch<br />

track<strong>in</strong>g system.<br />

– The entire MES system allows fast onl<strong>in</strong>e<br />

English/Ch<strong>in</strong>ese language switch<strong>in</strong>g.<br />

The operators were tra<strong>in</strong>ed <strong>in</strong> four<br />

other GEA-built Yili facilities dur<strong>in</strong>g 2000 to<br />

2003, so that they were already familiar<br />

with the control PC, OTAS and the<br />

production systems. After pre-selection of<br />

source and dest<strong>in</strong>ation tanks or recipes the<br />

programmes run automatically.<br />

The new facility, which adds another<br />

UHT milk production and an ice cream<br />

production plant to the region, ma<strong>in</strong>ly<br />

supplies UHT products. UHT milk amounts<br />

to approximately 50 per cent of the<br />

production output, with the other 50 per<br />

cent be<strong>in</strong>g divided between flavoured<br />

UHT dr<strong>in</strong>ks or UHT dr<strong>in</strong>ks conta<strong>in</strong><strong>in</strong>g lactic<br />

or citric acid. The products are stored <strong>for</strong><br />

distribution <strong>in</strong> a modern, fully automatic<br />

high-bay warehouse with 20,000 pallet<br />

locations. The f<strong>in</strong>al products are distributed<br />

<strong>in</strong> the region and <strong>in</strong> the whole of Ch<strong>in</strong>a.<br />

In<strong>for</strong>mation about the fill<strong>in</strong>g <strong>technology</strong><br />

<strong>in</strong>stalled <strong>in</strong> the new dairy can be found <strong>in</strong><br />

another article of SIG Combibloc <strong>in</strong> this<br />

issue.<br />

Thanks to GEA’s successful management<br />

the project went smoothly so that the<br />

facility was <strong>com</strong>pleted on schedule and set<br />

<strong>in</strong>to operation <strong>in</strong> time <strong>for</strong> the important 5th<br />

Ch<strong>in</strong>a Dairy Product Tech Exhibition <strong>in</strong><br />

Hohhot on 27th August 2005.<br />

A UTHORS:<br />

– Christiane Schetzschen<br />

(schetzschen.christiane@tuchenhagen.de),<br />

GEA Tuchenhagen Dairy Systems<br />

– Roland Sossna, European Dairy Magaz<strong>in</strong>e<br />

4<br />

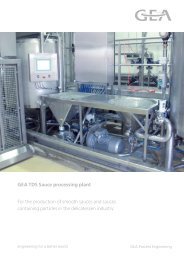

Detail of an OTAS milk process<strong>in</strong>g screen at Yili