RED HERRING PROSPECTUS Dated August 24 ... - Globus Spirits

RED HERRING PROSPECTUS Dated August 24 ... - Globus Spirits RED HERRING PROSPECTUS Dated August 24 ... - Globus Spirits

The Spent Wash generated from distillation is highly polluted in nature, as it is acidic in content. It adversely affects the flora & fauna of the region. In view of the above, for effective control of pollution, Effluent Treatment Plant (ETP) is required: The treatment plant comprises as under: (a) (b) (c) Pre treatment: The Company has 2 Nos. of Mechanical Decanters, Model NX- 408, Make- Alfa Laval, Capacity 10 M3 each to separate the dry grain from the spent wash which is saleable in the market and thin slops (liquid) goes to Primary Treatment Plant. Primary treatment plant: The thin slops are treated in closed tank with the help of Methane forming bacteria. The organic matter is degraded by Methane forming bacteria in to Biogas, which is highly inflammable as it contains 60-65% CH4 content, used as fuel in the Boiler. Secondary treatment plant: To bring the above effluent to desired norms of pollution control Board, further treatment plant is required i.e. Secondary treatment plant based on Activated Sludge process and followed by extended aeration. The effluent from primary treatment plant is feed in to this plant. This plant comprises following different units: 1. Aeration Tanks 2. Clarifier 3. Extended Aeration tank 4. Clarifier 5. Sludge drying beds The secondary treatment is based on Aeration. The Aerators are provided to the tank with the result that the Aerobic bacteria degrade the organic matter. (d) Disposal of treated effluent: At present we are following ferti-irrigation system as per norms prescribed by the Pollution Control Boards and the Ministry of Environment and Forest. However, we propose to put up a Multi Effect Evaporation Plant to achieve avail zero pollution. The Pollution load, as of on date, is as under: Water: Before Treatment: S.S. : 3,200 Kg./Day B.O.D. : 18,000 Kg./Day C.O.D. : 40,000 Kg./Day After Primary Treatments: S.S. : 900 Kg./Day B.O.D. : 1,600 Kg./Day C.O.D. : 3,600 Kg./Day After the installation of the Multi Effect Evaporation system, the resultant pollution load shall be Zero, due to non-discharge. b. Samalkha Facility: The Spent Wash generated from distillation is highly polluted in nature, as it is acidic in content. It adversely affects the flora & fauna of the region. In view of the above, for effective control of pollution, Effluent Treatment Plant (ETP) is required: The treatment plant comprises as under: 95

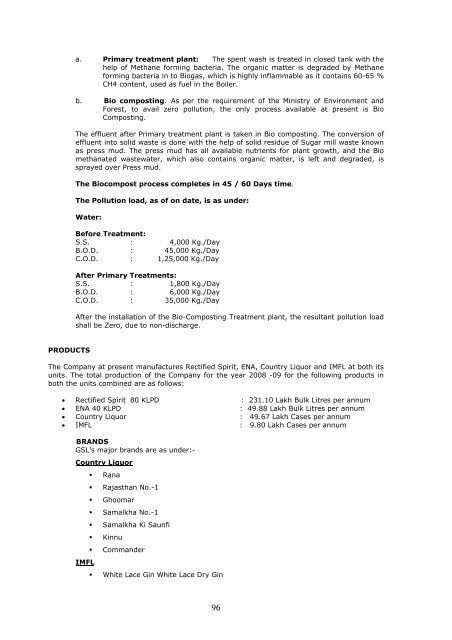

a. Primary treatment plant: The spent wash is treated in closed tank with the help of Methane forming bacteria. The organic matter is degraded by Methane forming bacteria in to Biogas, which is highly inflammable as it contains 60-65 % CH4 content, used as fuel in the Boiler. b. Bio composting: As per the requirement of the Ministry of Environment and Forest, to avail zero pollution, the only process available at present is Bio Composting. The effluent after Primary treatment plant is taken in Bio composting. The conversion of effluent into solid waste is done with the help of solid residue of Sugar mill waste known as press mud. The press mud has all available nutrients for plant growth, and the Bio methanated wastewater, which also contains organic matter, is left and degraded, is sprayed over Press mud. The Biocompost process completes in 45 / 60 Days time. The Pollution load, as of on date, is as under: Water: Before Treatment: S.S. : 4,000 Kg./Day B.O.D. : 45,000 Kg./Day C.O.D. : 1,25,000 Kg./Day After Primary Treatments: S.S. : 1,800 Kg./Day B.O.D. : 6,000 Kg./Day C.O.D. : 35,000 Kg./Day After the installation of the Bio-Composting Treatment plant, the resultant pollution load shall be Zero, due to non-discharge. PRODUCTS The Company at present manufactures Rectified Spirit, ENA, Country Liquor and IMFL at both its units. The total production of the Company for the year 2008 -09 for the following products in both the units combined are as follows: • Rectified Spirit 80 KLPD : 231.10 Lakh Bulk Litres per annum • ENA 40 KLPD : 49.88 Lakh Bulk Litres per annum • Country Liquor : 49.67 Lakh Cases per annum • IMFL : 9.80 Lakh Cases per annum BRANDS GSL’s major brands are as under:- Country Liquor • Rana • Rajasthan No.-1 • Ghoomar • Samalkha No.-1 • Samalkha Ki Saunfi • Kinnu • Commander IMFL • White Lace Gin White Lace Dry Gin 96

- Page 71 and 72: Alcobrew has vide its letter dated

- Page 73 and 74: K GENERAL CORPORATE PURPOSES: The l

- Page 75 and 76: FUNDS DEPLOYED As per the certifica

- Page 77 and 78: Terms of Payment Margin Amount empl

- Page 79 and 80: BASIS FOR ISSUE PRICE The Issue Pri

- Page 81 and 82: Note: The average return on net wor

- Page 83 and 84: STATEMENT OF TAX BENEFITS TAX BENEF

- Page 85 and 86: According to section 10(38) of the

- Page 87 and 88: As per the provisions of Section 11

- Page 89 and 90: Tax. However, the aforesaid income

- Page 91 and 92: SECTION IV: ABOUT THE ISSUER COMPAN

- Page 93 and 94: In India alcohol is largely produce

- Page 95 and 96: Government Policy & Regulations The

- Page 97 and 98: • Scotch rose by 7.0%. Scotch bra

- Page 99 and 100: substantial market share to India s

- Page 101 and 102: As the Company is increasing its In

- Page 103 and 104: Higher level of instrumentation has

- Page 105 and 106: II. ORDERS ALREADY PLACED: Sl. No 1

- Page 107 and 108: Engineering, Plot No. 65, Bhagwati

- Page 109 and 110: 2 nd Stage (Bio-composting) The was

- Page 111 and 112: converts the slurry into a hydrated

- Page 114 and 115: FLOW CHART OF FINISHING GOODS Recti

- Page 116 and 117: The availability of grain particula

- Page 118 and 119: Domestic - 10 KL Per Day TOTAL - 14

- Page 120 and 121: Power Generation Present Requiremen

- Page 124 and 125: • White Lace Duet Gin GR 8 Times

- Page 126 and 127: Indian IMFL Industry has undergone

- Page 128 and 129: Certificate dated 23 rd January 200

- Page 130 and 131: 6. Manufacturing Agreement Parties:

- Page 132 and 133: its distinct identity in the Countr

- Page 134 and 135: PROPERTY A. Properties owned by the

- Page 136 and 137: Date of Agreement: 25.3.1995 vide D

- Page 138 and 139: Date of Agreement: 12.1.1995 vide D

- Page 140 and 141: 27. M/s Globus Agronics Limited Dat

- Page 142 and 143: Parties Sub-Lessor Associated Disti

- Page 144 and 145: Class 33 (Thirty Three) Applicant G

- Page 146 and 147: Sr. No Mark Registration Number Cla

- Page 148 and 149: BRIEF HISTORY AND OTHER CORPORATE M

- Page 150 and 151: 22.08.1995 • Change in Authorised

- Page 152 and 153: DIN: 00769308 01.08.2009) Term: 3 y

- Page 154 and 155: Limited in 1983 and later promoted

- Page 156 and 157: Industrial Engineer where he was re

- Page 158 and 159: If at any time the director ceases

- Page 160 and 161: CORPORATE GOVERNANCE CORPORATE GOVE

- Page 162 and 163: 1. To scrutinize the Share transfer

- Page 164 and 165: Further, the Directors are also int

- Page 166 and 167: Chart 1: BEHROR UNIT, RAJASTHAN 139

- Page 168 and 169: 141

- Page 170 and 171: joined Radico Khaitan Limited in 19

a. Primary treatment plant: The spent wash is treated in closed tank with the<br />

help of Methane forming bacteria. The organic matter is degraded by Methane<br />

forming bacteria in to Biogas, which is highly inflammable as it contains 60-65 %<br />

CH4 content, used as fuel in the Boiler.<br />

b. Bio composting: As per the requirement of the Ministry of Environment and<br />

Forest, to avail zero pollution, the only process available at present is Bio<br />

Composting.<br />

The effluent after Primary treatment plant is taken in Bio composting. The conversion of<br />

effluent into solid waste is done with the help of solid residue of Sugar mill waste known<br />

as press mud. The press mud has all available nutrients for plant growth, and the Bio<br />

methanated wastewater, which also contains organic matter, is left and degraded, is<br />

sprayed over Press mud.<br />

The Biocompost process completes in 45 / 60 Days time.<br />

The Pollution load, as of on date, is as under:<br />

Water:<br />

Before Treatment:<br />

S.S. : 4,000 Kg./Day<br />

B.O.D. : 45,000 Kg./Day<br />

C.O.D. : 1,25,000 Kg./Day<br />

After Primary Treatments:<br />

S.S. : 1,800 Kg./Day<br />

B.O.D. : 6,000 Kg./Day<br />

C.O.D. : 35,000 Kg./Day<br />

After the installation of the Bio-Composting Treatment plant, the resultant pollution load<br />

shall be Zero, due to non-discharge.<br />

PRODUCTS<br />

The Company at present manufactures Rectified Spirit, ENA, Country Liquor and IMFL at both its<br />

units. The total production of the Company for the year 2008 -09 for the following products in<br />

both the units combined are as follows:<br />

• Rectified Spirit 80 KLPD : 231.10 Lakh Bulk Litres per annum<br />

• ENA 40 KLPD : 49.88 Lakh Bulk Litres per annum<br />

• Country Liquor : 49.67 Lakh Cases per annum<br />

• IMFL : 9.80 Lakh Cases per annum<br />

BRANDS<br />

GSL’s major brands are as under:-<br />

Country Liquor<br />

• Rana<br />

• Rajasthan No.-1<br />

• Ghoomar<br />

• Samalkha No.-1<br />

• Samalkha Ki Saunfi<br />

• Kinnu<br />

• Commander<br />

IMFL<br />

• White Lace Gin White Lace Dry Gin<br />

96