- Page 1 and 2:

RED HERRING PROSPECTUS Please read

- Page 3 and 4:

TABLE OF CONTENTS SECTION TITLE PAG

- Page 5 and 6:

Chatrath & Co., Chartered Accountan

- Page 7 and 8:

Margin Amount Memorandum of Associa

- Page 9 and 10:

Company/Industry Related Terms/Tech

- Page 11 and 12:

NRE Account Non Resident External A

- Page 13 and 14:

• Company’s ability to successf

- Page 15 and 16:

The Company constantly endeavours t

- Page 17 and 18:

The Company has reported a net nega

- Page 19 and 20:

the Excise and liquor sourcing poli

- Page 21 and 22:

Writ Petitions related to notificat

- Page 23 and 24:

Northern India Alcohol Sales Pvt. L

- Page 25 and 26:

8. Dependence on agri products Mana

- Page 27 and 28:

l. In addition to the BRLMs, the Co

- Page 29 and 30:

enforced prohibition in 1996, but h

- Page 31 and 32:

THE ISSUE Equity Shares offered: Fr

- Page 33 and 34:

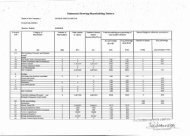

Particulars As on 31.03.2005 31.03.

- Page 35 and 36:

Particulars For the Year/Period End

- Page 37 and 38:

BOARD OF DIRECTORS Name of the Dire

- Page 39 and 40:

Jawahar Vyapar Bhawan, 14th Floor 1

- Page 41 and 42:

STATEMENT OF INTER SE ALLOCATION OF

- Page 43 and 44:

The grading is however, constrained

- Page 45 and 46:

Industry Outlook & Prospects The do

- Page 47 and 48:

on a proportionate basis. For furth

- Page 49 and 50:

CAPITAL STRUCTURE OF THE COMPANY Sh

- Page 51 and 52:

others # 17.4.1995 $ 2,11,640 10 47

- Page 53 and 54:

1.11.1994 Acquisition 18,75,000 10

- Page 55 and 56:

Category Code Category of Sharehold

- Page 57 and 58:

8. Mr. Ashok Kumar 33 0.0003 9. Mr.

- Page 59 and 60: OBJECTS OF THE ISSUE The Company pr

- Page 61 and 62: In case of variations in the actual

- Page 63 and 64: 1. Plant and Machinery for 35 KLPD

- Page 65 and 66: Taxes & Duties 127.00 Total 918.00

- Page 67 and 68: Franchise Fees - - - 4.00 Bond Fees

- Page 69 and 70: Mass Media options: • Hoardings 3

- Page 71 and 72: Alcobrew has vide its letter dated

- Page 73 and 74: K GENERAL CORPORATE PURPOSES: The l

- Page 75 and 76: FUNDS DEPLOYED As per the certifica

- Page 77 and 78: Terms of Payment Margin Amount empl

- Page 79 and 80: BASIS FOR ISSUE PRICE The Issue Pri

- Page 81 and 82: Note: The average return on net wor

- Page 83 and 84: STATEMENT OF TAX BENEFITS TAX BENEF

- Page 85 and 86: According to section 10(38) of the

- Page 87 and 88: As per the provisions of Section 11

- Page 89 and 90: Tax. However, the aforesaid income

- Page 91 and 92: SECTION IV: ABOUT THE ISSUER COMPAN

- Page 93 and 94: In India alcohol is largely produce

- Page 95 and 96: Government Policy & Regulations The

- Page 97 and 98: • Scotch rose by 7.0%. Scotch bra

- Page 99 and 100: substantial market share to India s

- Page 101 and 102: As the Company is increasing its In

- Page 103 and 104: Higher level of instrumentation has

- Page 105 and 106: II. ORDERS ALREADY PLACED: Sl. No 1

- Page 107 and 108: Engineering, Plot No. 65, Bhagwati

- Page 109: 2 nd Stage (Bio-composting) The was

- Page 114 and 115: FLOW CHART OF FINISHING GOODS Recti

- Page 116 and 117: The availability of grain particula

- Page 118 and 119: Domestic - 10 KL Per Day TOTAL - 14

- Page 120 and 121: Power Generation Present Requiremen

- Page 122 and 123: The Spent Wash generated from disti

- Page 124 and 125: • White Lace Duet Gin GR 8 Times

- Page 126 and 127: Indian IMFL Industry has undergone

- Page 128 and 129: Certificate dated 23 rd January 200

- Page 130 and 131: 6. Manufacturing Agreement Parties:

- Page 132 and 133: its distinct identity in the Countr

- Page 134 and 135: PROPERTY A. Properties owned by the

- Page 136 and 137: Date of Agreement: 25.3.1995 vide D

- Page 138 and 139: Date of Agreement: 12.1.1995 vide D

- Page 140 and 141: 27. M/s Globus Agronics Limited Dat

- Page 142 and 143: Parties Sub-Lessor Associated Disti

- Page 144 and 145: Class 33 (Thirty Three) Applicant G

- Page 146 and 147: Sr. No Mark Registration Number Cla

- Page 148 and 149: BRIEF HISTORY AND OTHER CORPORATE M

- Page 150 and 151: 22.08.1995 • Change in Authorised

- Page 152 and 153: DIN: 00769308 01.08.2009) Term: 3 y

- Page 154 and 155: Limited in 1983 and later promoted

- Page 156 and 157: Industrial Engineer where he was re

- Page 158 and 159: If at any time the director ceases

- Page 160 and 161:

CORPORATE GOVERNANCE CORPORATE GOVE

- Page 162 and 163:

1. To scrutinize the Share transfer

- Page 164 and 165:

Further, the Directors are also int

- Page 166 and 167:

Chart 1: BEHROR UNIT, RAJASTHAN 139

- Page 168 and 169:

141

- Page 170 and 171:

joined Radico Khaitan Limited in 19

- Page 172 and 173:

PROMOTERS Mr. Ajay Kumar Swarup and

- Page 174 and 175:

Sl. No. Name of Shareholder No. of

- Page 176 and 177:

Related Party Transactions For deta

- Page 178 and 179:

estatements and regroupings as cons

- Page 180 and 181:

ANNEXURE-II STATEMENT OF PROFIT & L

- Page 182 and 183:

At each balance sheet an assessment

- Page 184 and 185:

Particulars Key Management Personal

- Page 186 and 187:

Particulars Associates Key Manageme

- Page 188 and 189:

ENA BL 44.93 1477.37 14.06 1080.81

- Page 190 and 191:

AS ON PARTICULARS 31-Mar-05 31-Mar-

- Page 192 and 193:

guaranteed by Sh. Madhav K. Swarup

- Page 194 and 195:

ANNEXURE-XI STATEMENT OF CURRENT LI

- Page 196 and 197:

Note: ** Information pertaining to

- Page 198 and 199:

EXISTING BORROWING FACILITIES The C

- Page 200 and 201:

Prepayment Charges: 2% of the Prepa

- Page 202 and 203:

losses and deferred expenditure not

- Page 204 and 205:

There are no defaults in meeting an

- Page 206 and 207:

3. Networth means aggregate of valu

- Page 208 and 209:

SHAREHOLDING Sl. No. Name of Shareh

- Page 210 and 211:

horticulture and agriculture in all

- Page 212 and 213:

There are no defaults in meeting an

- Page 214 and 215:

Ajay Swarup) together hold 100% sha

- Page 216 and 217:

3. Networth means aggregate of valu

- Page 218 and 219:

MANAGEMENT’S DISCUSSION AND ANALY

- Page 220 and 221:

Interest & Finance Charge 40.29 53.

- Page 222 and 223:

Interest and Finance Expenses The i

- Page 224 and 225:

Similarly, for consumers like fuel

- Page 226 and 227:

(b). Recovery Suits 1. Globus Agron

- Page 228 and 229:

SB. Civil Writ Petition No. 3454 of

- Page 230 and 231:

ecovery of the amount of cess payab

- Page 232 and 233:

New-Delhi. which on account of any

- Page 234 and 235:

(Prevention & Control of Pollution)

- Page 236 and 237:

Whisky (Own Brand) and Country Liqu

- Page 238 and 239:

Transformer and 11 KV Line Validity

- Page 240 and 241:

Valid until cancelled. Government o

- Page 242 and 243:

4 - Distributable profits have been

- Page 244 and 245:

The filing of the Red Herring Prosp

- Page 246 and 247:

person consequent to or in connecti

- Page 248 and 249:

Others The total fees payable to th

- Page 250 and 251:

The auditors of the Company are app

- Page 252 and 253:

• Right to receive surplus on liq

- Page 254 and 255:

Application by Eligible NRIs/FIIs r

- Page 256 and 257:

Market Lot Share Who can apply ** E

- Page 258 and 259:

ISSUE PROCEDURE Principal Terms And

- Page 260 and 261:

one Bid in the ASBA Bid cum Applica

- Page 262 and 263:

exchange in India only in favour of

- Page 264 and 265:

Bidders are advised to ensure that

- Page 266 and 267:

2. In accordance with the SEBI guid

- Page 268 and 269:

The Bidders may note that the Escro

- Page 270 and 271:

) The book gets built up at various

- Page 272 and 273:

Filing of the Red Herring Prospectu

- Page 274 and 275:

c. Do not Bid on another Bid-cum-Ap

- Page 276 and 277:

The Company in its absolute discret

- Page 278 and 279:

In case of Bids made by Insurance C

- Page 280 and 281:

c) In case of Resident QIB Bidders:

- Page 282 and 283:

application received and a photo ma

- Page 284 and 285:

Herring Prospectus and as per the i

- Page 286 and 287:

have submitted Bids at or above the

- Page 288 and 289:

EQUITY SHARES IN DEMATERIALIZED FOR

- Page 290 and 291:

the disclosed manner and/ or demat

- Page 292 and 293:

The Company will provide adequate f

- Page 294 and 295:

Our Company, in consultation with t

- Page 296 and 297:

• The BRLMs shall ensure that ade

- Page 298 and 299:

eceived the ASBA in a physical or e

- Page 300 and 301:

ank account and not to the Bankers

- Page 302 and 303:

In case of ASBA Bids made pursuant

- Page 304 and 305:

SECTION IX MAIN PROVISIONS OF THE A

- Page 306 and 307:

CAPITAL AND INCREASE AND REDUCTION

- Page 308 and 309:

to accept the shares offered, the B

- Page 310 and 311:

in lieu thereof, to the satisfactio

- Page 312 and 313:

30. A call may be revoked or postpo

- Page 314 and 315:

46. The Board may, at anytime befor

- Page 316 and 317:

The Board may, at any time, give no

- Page 318 and 319:

10. The Register and Index of benef

- Page 320 and 321:

that in the case of an Annual Gener

- Page 322 and 323:

committee or other legal guardian;

- Page 324 and 325:

DIRECTORS (8) The book containing t

- Page 326 and 327:

notwithstanding fixed by the Articl

- Page 328 and 329:

(a) a director in such company, and

- Page 330 and 331:

the Board may by resolution vest in

- Page 332 and 333:

(a) (b) the names of the Directors

- Page 334 and 335:

mortgage may contain a power of sal

- Page 336 and 337:

(b) The Company shall also be at, l

- Page 338 and 339:

174. For the purpose of giving effe

- Page 340 and 341:

Register of Members, shall have bee

- Page 342 and 343:

Documents for Inspection i) Memoran

- Page 344:

DECLARATION All the relevant provis