Improving Global Quality of Life

Improving Global Quality of Life

Improving Global Quality of Life

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

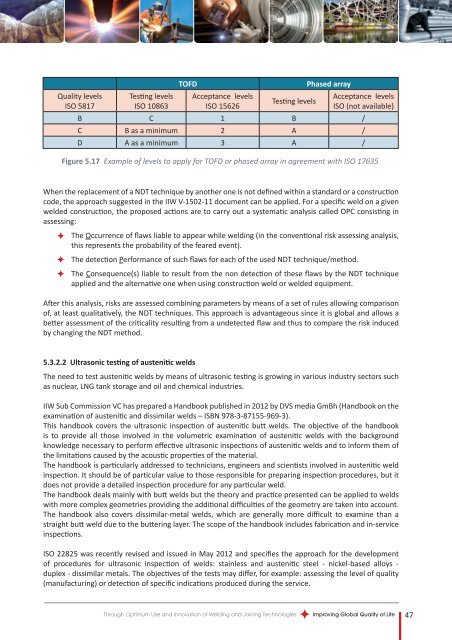

TOFD<br />

Phased array<br />

Testing levels Acceptance levels<br />

ISO 10863<br />

ISO 15626<br />

Testing levels<br />

B C 1 B /<br />

C B as a minimum 2 A /<br />

D A as a minimum 3 A /<br />

<strong>Quality</strong> levels<br />

ISO 5817<br />

Acceptance levels<br />

ISO (not available)<br />

Figure 5.17 Example <strong>of</strong> levels to apply for TOFD or phased array in agreement with ISO 17635<br />

When the replacement <strong>of</strong> a NDT technique by another one is not defined within a standard or a construction<br />

code, the approach suggested in the IIW V-1502-11 document can be applied. For a specific weld on a given<br />

welded construction, the proposed actions are to carry out a systematic analysis called OPC consisting in<br />

assessing:<br />

The Occurrence <strong>of</strong> flaws liable to appear while welding (in the conventional risk assessing analysis,<br />

this represents the probability <strong>of</strong> the feared event).<br />

The detection Performance <strong>of</strong> such flaws for each <strong>of</strong> the used NDT technique/method.<br />

The Consequence(s) liable to result from the non detection <strong>of</strong> these flaws by the NDT technique<br />

applied and the alternative one when using construction weld or welded equipment.<br />

After this analysis, risks are assessed combining parameters by means <strong>of</strong> a set <strong>of</strong> rules allowing comparison<br />

<strong>of</strong>, at least qualitatively, the NDT techniques. This approach is advantageous since it is global and allows a<br />

better assessment <strong>of</strong> the criticality resulting from a undetected flaw and thus to compare the risk induced<br />

by changing the NDT method.<br />

5.3.2.2 Ultrasonic testing <strong>of</strong> austenitic welds<br />

The need to test austenitic welds by means <strong>of</strong> ultrasonic testing is growing in various industry sectors such<br />

as nuclear, LNG tank storage and oil and chemical industries.<br />

IIW Sub Commission VC has prepared a Handbook published in 2012 by DVS media GmBh (Handbook on the<br />

examination <strong>of</strong> austenitic and dissimilar welds – ISBN 978-3-87155-969-3).<br />

This handbook covers the ultrasonic inspection <strong>of</strong> austenitic butt welds. The objective <strong>of</strong> the handbook<br />

is to provide all those involved in the volumetric examination <strong>of</strong> austenitic welds with the background<br />

knowledge necessary to perform effective ultrasonic inspections <strong>of</strong> austenitic welds and to inform them <strong>of</strong><br />

the limitations caused by the acoustic properties <strong>of</strong> the material.<br />

The handbook is particularly addressed to technicians, engineers and scientists involved in austenitic weld<br />

inspection. It should be <strong>of</strong> particular value to those responsible for preparing inspection procedures, but it<br />

does not provide a detailed inspection procedure for any particular weld.<br />

The handbook deals mainly with butt welds but the theory and practice presented can be applied to welds<br />

with more complex geometries providing the additional difficulties <strong>of</strong> the geometry are taken into account.<br />

The handbook also covers dissimilar-metal welds, which are generally more difficult to examine than a<br />

straight butt weld due to the buttering layer. The scope <strong>of</strong> the handbook includes fabrication and in-service<br />

inspections.<br />

ISO 22825 was recently revised and issued in May 2012 and specifies the approach for the development<br />

<strong>of</strong> procedures for ultrasonic inspection <strong>of</strong> welds: stainless and austenitic steel - nickel-based alloys -<br />

duplex - dissimilar metals. The objectives <strong>of</strong> the tests may differ, for example: assessing the level <strong>of</strong> quality<br />

(manufacturing) or detection <strong>of</strong> specific indications produced during the service.<br />

Through Optimum Use and Innovation <strong>of</strong> Welding and Joining Technologies<br />

<strong>Improving</strong> <strong>Global</strong> <strong>Quality</strong> <strong>of</strong> <strong>Life</strong><br />

47