Improving Global Quality of Life

Improving Global Quality of Life

Improving Global Quality of Life

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Finally, testing <strong>of</strong> welds will be extended to all periods <strong>of</strong> the life-cycle <strong>of</strong> the welded structures. In addition<br />

to the fabrication and service phase, they will also significantly contribute to life-cycle extension (repair)<br />

procedure <strong>of</strong> the critical components.<br />

4.2 High energy density welding processes and material response<br />

High energy density (HED) welding simply refers to Laser Beam Welding (LBW) and Electron Beam Welding<br />

(EBW) processes. The benefits <strong>of</strong>fered by HED fusion welding are narrow, deep weld penetration, high<br />

welding speeds, low heat input (and hence low distortion and heat affect) and precision. EBW is somewhat<br />

mature and has various well-accepted applications including packaging (e.g. pressure sensors) and aerospace<br />

components. There have been attempts to broaden application to high production (e.g. automotive)<br />

manufacturing, but incompatibility <strong>of</strong> vacuum systems with the demands <strong>of</strong> large scale production have<br />

prevented these applications. In contrast, LBW has benefited from continual development <strong>of</strong> new laser<br />

sources with new capabilities and is somewhat more compatible with the demands <strong>of</strong> high production and<br />

large component manufacturing, so it enjoys a broader range <strong>of</strong> applications.<br />

Nonetheless, challenges <strong>of</strong> high equipment cost, lack <strong>of</strong> system portability, laser safety, lack <strong>of</strong> robustness to<br />

manufacturing environments (particularly, the need for cleanliness <strong>of</strong> optical surfaces) continue to hamper<br />

LBW applications. Smaller, more efficient laser sources or central laser generators with fibre distribution<br />

system would help with LBW portability. Practical, robust cost-competitive out-<strong>of</strong>-vacuum capability would<br />

promote EBW applications. Eliminating root defects in partial penetration LBW would assist its application,<br />

and laser systems with multiprocess capability (i.e. cut, drill, weld, machine interchangeably on the same<br />

system) would be more economical. The general need for <strong>of</strong>f-line process planning for virtual manufacturing<br />

are the same as for other joining processes, but the models and needs for HED processes are unique.<br />

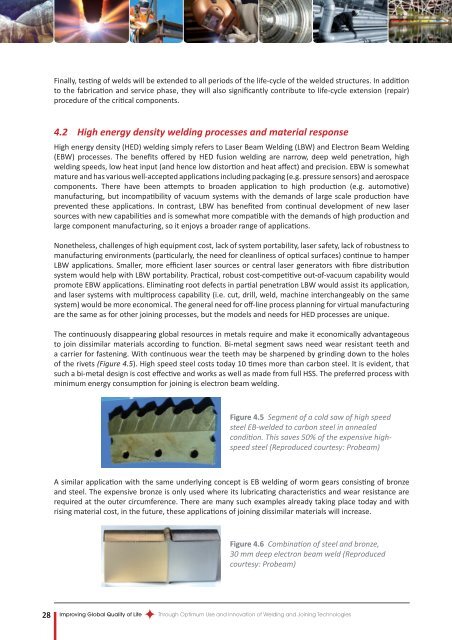

The continuously disappearing global resources in metals require and make it economically advantageous<br />

to join dissimilar materials according to function. Bi-metal segment saws need wear resistant teeth and<br />

a carrier for fastening. With continuous wear the teeth may be sharpened by grinding down to the holes<br />

<strong>of</strong> the rivets (Figure 4.5). High speed steel costs today 10 times more than carbon steel. It is evident, that<br />

such a bi-metal design is cost effective and works as well as made from full HSS. The preferred process with<br />

minimum energy consumption for joining is electron beam welding.<br />

Figure 4.5 Segment <strong>of</strong> a cold saw <strong>of</strong> high speed<br />

steel EB-welded to carbon steel in annealed<br />

condition. This saves 50% <strong>of</strong> the expensive highspeed<br />

steel (Reproduced courtesy: Probeam)<br />

A similar application with the same underlying concept is EB welding <strong>of</strong> worm gears consisting <strong>of</strong> bronze<br />

and steel. The expensive bronze is only used where its lubricating characteristics and wear resistance are<br />

required at the outer circumference. There are many such examples already taking place today and with<br />

rising material cost, in the future, these applications <strong>of</strong> joining dissimilar materials will increase.<br />

Figure 4.6 Combination <strong>of</strong> steel and bronze,<br />

30 mm deep electron beam weld (Reproduced<br />

courtesy: Probeam)<br />

28 <strong>Improving</strong> <strong>Global</strong> <strong>Quality</strong> <strong>of</strong> <strong>Life</strong> Through Optimum Use and Innovation <strong>of</strong> Welding and Joining Technologies