IEA Solar Heating and Cooling Programm - NachhaltigWirtschaften.at

IEA Solar Heating and Cooling Programm - NachhaltigWirtschaften.at IEA Solar Heating and Cooling Programm - NachhaltigWirtschaften.at

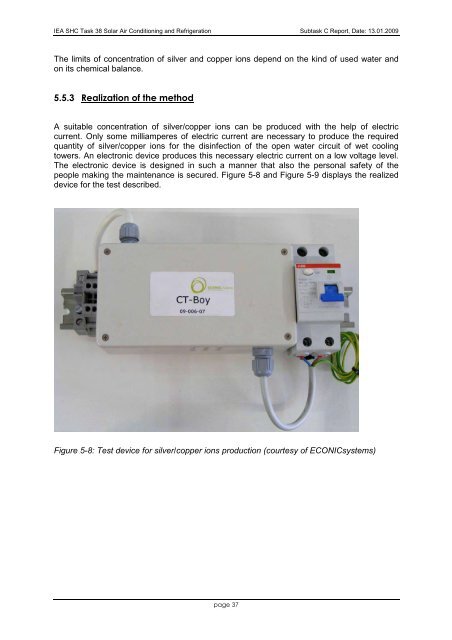

IEA SHC Task 38 Solar Air Conditioning and Refrigeration Subtask C Report, Date: 13.01.2009 The limits of concentration of silver and copper ions depend on the kind of used water and on its chemical balance. 5.5.3 Realization of the method A suitable concentration of silver/copper ions can be produced with the help of electric current. Only some milliamperes of electric current are necessary to produce the required quantity of silver/copper ions for the disinfection of the open water circuit of wet cooling towers. An electronic device produces this necessary electric current on a low voltage level. The electronic device is designed in such a manner that also the personal safety of the people making the maintenance is secured. Figure 5-8 and Figure 5-9 displays the realized device for the test described. Figure 5-8: Test device for silver/copper ions production (courtesy of ECONICsystems) page 37

IEA SHC Task 38 Solar Air Conditioning and Refrigeration Subtask C Report, Date: 13.01.2009 Figure 5-9: Silver/copper electrodes for cooling tower basin (courtesy of ECONICsystems) The silver/copper electrodes are also available for integration in the cooling water pipe system. In summary it can be said, that the first results are promising to the development of a suitable disinfection method for small scale wet cooling towers. However, further research on the disinfection method and tests in real heat rejection applications are necessary to verify the effectiveness of the disinfection method in long term tests and for different chemical composition of the cooling water. This shall be carried out in near future. 5.6 Cost comparison After analysis and description of the two physical water treatments for a hygienic operation of small wet cooling towers, it is also worth to compare the estimated cost of the proposed measures. In the table below the investment and operation cost are listed over an operation period of 15 years. Table 5-2 Annual cost of hygienic measures for a small cooling tower (30 kW) over a operation time of 15 years Investment Operational cost Maintenance & replacement Euro Euro/a Euro/a page 38 Remarks UV-C disinfection 450 1) to 1000 2) 90 65 Cleaning, lamp Silver/copper disinfection ions Note 1) : Equipment according to Figure 5-5 Note 2) : Equipment according to Figure 5-6 100 to 300 0,5 27,5 Inspection The numbers in the Table 5-2 are calculated for a small wet cooling tower with cooling capacity of 30 kW under the following conditions:

- Page 558 and 559: IEA SHC Task 38 Solar Air Condition

- Page 560 and 561: IEA SHC Task 38 Solar Air Condition

- Page 562 and 563: IEA SHC Task 38 Solar Air Condition

- Page 564 and 565: IEA SHC Task 38 Solar Air Condition

- Page 566 and 567: IEA SHC Task 38 Solar Air Condition

- Page 568 and 569: IEA SHC Task 38 Solar Air Condition

- Page 570 and 571: IEA SHC Task 38 Solar Air Condition

- Page 572 and 573: Task 38 Solar Air-Conditioning and

- Page 574 and 575: IEA SHC Task 38 Solar Air Condition

- Page 576 and 577: IEA SHC Task 38 Solar Air Condition

- Page 578 and 579: IEA SHC Task 38 Solar Air Condition

- Page 580 and 581: IEA SHC Task 38 Solar Air Condition

- Page 582 and 583: IEA SHC Task 38 Solar Air Condition

- Page 584 and 585: IEA SHC Task 38 Solar Air Condition

- Page 586 and 587: IEA SHC Task 38 Solar Air Condition

- Page 588 and 589: IEA SHC Task 38 Solar Air Condition

- Page 590 and 591: IEA SHC Task 38 Solar Air Condition

- Page 592 and 593: IEA SHC Task 38 Solar Air Condition

- Page 594 and 595: IEA SHC Task 38 Solar Air Condition

- Page 596 and 597: IEA SHC Task 38 Solar Air Condition

- Page 598 and 599: IEA SHC Task 38 Solar Air Condition

- Page 600 and 601: IEA SHC Task 38 Solar Air Condition

- Page 602 and 603: IEA SHC Task 38 Solar Air Condition

- Page 604 and 605: IEA SHC Task 38 Solar Air Condition

- Page 606 and 607: IEA SHC Task 38 Solar Air Condition

- Page 610 and 611: IEA SHC Task 38 Solar Air Condition

- Page 612 and 613: IEA SHC Task 38 Solar Air Condition

- Page 614 and 615: Grundprinzip Solare Wärme thermisc

- Page 616 and 617: Hintergrund Operating Agent: Hans-M

- Page 618 and 619: - Leistungsvergleich von verfügbar

- Page 620 and 621: Subtask A: Pre-engineered systems f

- Page 622 and 623: Abb. 3: Das Bürogebäude in St. Sc

- Page 624 and 625: Beispiele realisierter großer Syst

- Page 626 and 627: a) b) c) Abb. 9: Installation eines

- Page 628 and 629: Subtask C: Modelling and fundamenta

- Page 630 and 631: Liste der Systeme im Monitoring von

- Page 632 and 633: Liste der Systeme im Monitoring von

- Page 634 and 635: Marletta, L., Evola, G. and Sicurel

- Page 636 and 637: Ellehauge & Kildemoes Vestergade 48

- Page 638: Tekniker Centro Tecnológico Teknik

<strong>IEA</strong> SHC Task 38 <strong>Solar</strong> Air Conditioning <strong>and</strong> Refriger<strong>at</strong>ion Subtask C Report, D<strong>at</strong>e: 13.01.2009<br />

The limits of concentr<strong>at</strong>ion of silver <strong>and</strong> copper ions depend on the kind of used w<strong>at</strong>er <strong>and</strong><br />

on its chemical balance.<br />

5.5.3 Realiz<strong>at</strong>ion of the method<br />

A suitable concentr<strong>at</strong>ion of silver/copper ions can be produced with the help of electric<br />

current. Only some milliamperes of electric current are necessary to produce the required<br />

quantity of silver/copper ions for the disinfection of the open w<strong>at</strong>er circuit of wet cooling<br />

towers. An electronic device produces this necessary electric current on a low voltage level.<br />

The electronic device is designed in such a manner th<strong>at</strong> also the personal safety of the<br />

people making the maintenance is secured. Figure 5-8 <strong>and</strong> Figure 5-9 displays the realized<br />

device for the test described.<br />

Figure 5-8: Test device for silver/copper ions production (courtesy of ECONICsystems)<br />

page 37