IEA Solar Heating and Cooling Programm - NachhaltigWirtschaften.at

IEA Solar Heating and Cooling Programm - NachhaltigWirtschaften.at IEA Solar Heating and Cooling Programm - NachhaltigWirtschaften.at

IEA SHC Task 38 Solar Air Conditioning and Refrigeration Subtask C1 Report, 31 October 2010 Table 2: Process data in case of dry heat rejection for four locations (single stage, continuous operation, evaporation at 0°C, NH3/H2O) Location Outside air temp. Low process temp. High process temp. Condensation pressure Heating medium temp. WF concentration °C °C °C bar °C % Naples 30 40 98 16,0 105/95 47/41 Athen 33 43 112 18,0 117/109 43/37 Johannesburg 28 38 96 15,5 101/93 48/42 Abu Dhabi 41 51 118 22 123/115 40/34 2.5 Relevant references – Ammonia/Water Systems In particular, references [2] and [3] give the reader the answers to the key questions of absorption refrigeration technology. [1] Mouchot, Augustin, La chaleur Solaire et ses Applications Industrielles, (German translation 1987, published in Olynthus Verlag, 1987) [2] Niebergall, W., Sorptionskältemaschinen, Handbuch der Kältetechnik, Bd 7, Springer Verlag, 1959. [3] Bogard, M., Ammonia Absorption Refrigeration in Industrial Processes, Gulf Publishing Company, Book Division, Housten, Paris, London, Tokyo [4] Grosman, G., Bourne, J.R., Ben-Dror, J., Kimichi, Y., Vardi, I., Design improvements in LiBr absorption chillers for solar applications, Transactions ASME, Journal of Solar Energy Engineering, 103 56-61 (1981) [5] Podesser, E., Solare Kühlung, Dissertation an der Technischen Universität Graz, Fakultät für Maschinenbau, Institut für Wärmetechnik (Prof. P. V. Gilli), 1984. [6] Podesser, E., Enzinger, P., Gossar, H., Monschein, W., Taferner, I., Proceedings of the XVII International Congress of refrigeration, Vienna 1987. 2.6 Description of the technology – Water/Lithium Bromide Systems Robert Ghirlando (University of Malta) The principle of operation of absorption cycles has already been described in detailed in the preceding sections. Hence this section will limit itself to pointing out some important differences between the two working fluid pairs, i.e. ammonia/water and water/lithium bromide. The most common combinations of refrigerant and absorbent are ammonia/water and water/lithium bromide. Since in the water/lithium combination, the refrigerant is water, the condensing temperature cannot go below 0 0 C; in fact the minimum temperature that can be reached is 3 0 C. This is a problem in refrigeration, but not in air-conditioning. On the other hand, in the ammonia/water pair, the refrigerant is ammonia which can condense at temperatures below zero and can therefore be used in refrigeration applications. Water has a high latent heat and its use as a refrigerant in H 2 O/LiBr systems is an advantage. It is important to point out that in the H 2 O/LiBr system, for the water to evaporate at the very low temperatures required to produce the desired cooling effect, it needs to be at a very low pressure. At 4 0 C, for example, water vapour pressure is only 0.8kPa, i.e. 8millibar. On the other hand, ammonia-water systems operate above atmospheric pressure. Also LiBr tends to crystallize, and methods have been devised to prevent this from happening. These page 15

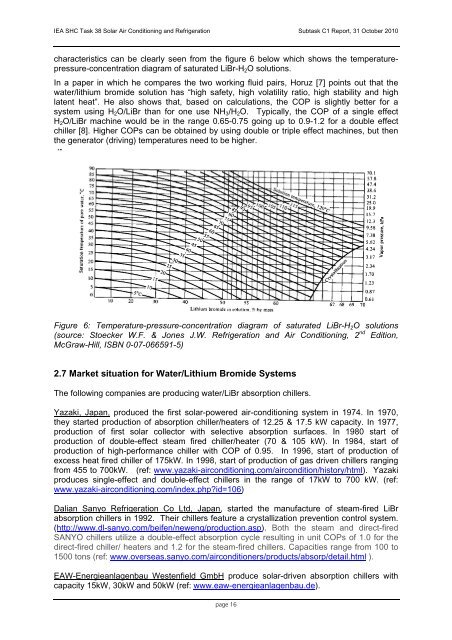

IEA SHC Task 38 Solar Air Conditioning and Refrigeration Subtask C1 Report, 31 October 2010 characteristics can be clearly seen from the figure 6 below which shows the temperaturepressure-concentration diagram of saturated LiBr-H 2 O solutions. In a paper in which he compares the two working fluid pairs, Horuz [7] points out that the water/lithium bromide solution has “high safety, high volatility ratio, high stability and high latent heat”. He also shows that, based on calculations, the COP is slightly better for a system using H 2 O/LiBr than for one use NH 3 /H 2 O. Typically, the COP of a single effect H 2 O/LiBr machine would be in the range 0.65-0.75 going up to 0.9-1.2 for a double effect chiller [8]. Higher COPs can be obtained by using double or triple effect machines, but then the generator (driving) temperatures need to be higher. Figure 6: Temperature-pressure-concentration diagram of saturated LiBr-H 2 O solutions (source: Stoecker W.F. & Jones J.W. Refrigeration and Air Conditioning, 2 nd Edition, McGraw-Hill, ISBN 0-07-066591-5) 2.7 Market situation for Water/Lithium Bromide Systems The following companies are producing water/LiBr absorption chillers. Yazaki, Japan, produced the first solar-powered air-conditioning system in 1974. In 1970, they started production of absorption chiller/heaters of 12.25 & 17.5 kW capacity. In 1977, production of first solar collector with selective absorption surfaces. In 1980 start of production of double-effect steam fired chiller/heater (70 & 105 kW). In 1984, start of production of high-performance chiller with COP of 0.95. In 1996, start of production of excess heat fired chiller of 175kW. In 1998, start of production of gas driven chillers ranging from 455 to 700kW. (ref: www.yazaki-airconditioning.com/aircondition/history/html). Yazaki produces single-effect and double-effect chillers in the range of 17kW to 700 kW. (ref: www.yazaki-airconditioning.com/index.php?id=106) Dalian Sanyo Refrigeration Co Ltd, Japan, started the manufacture of steam-fired LiBr absorption chillers in 1992. Their chillers feature a crystallization prevention control system. (http://www.dl-sanyo.com/beifen/neweng/production.asp). Both the steam and direct-fired SANYO chillers utilize a double-effect absorption cycle resulting in unit COPs of 1.0 for the direct-fired chiller/ heaters and 1.2 for the steam-fired chillers. Capacities range from 100 to 1500 tons (ref: www.overseas.sanyo.com/airconditioners/products/absorp/detail.html ). EAW-Energieanlagenbau Westenfield GmbH produce solar-driven absorption chillers with capacity 15kW, 30kW and 50kW (ref: www.eaw-energieanlagenbau.de). page 16

- Page 364 and 365: Fragebogen an Besitzer solare Kühl

- Page 366 and 367: Fragebogen an Besitzer solare Kühl

- Page 368 and 369: Fragebogen an Besitzer solare Kühl

- Page 370 and 371: Cuestionario para propietarios de i

- Page 372 and 373: Cuestionario para propietarios de i

- Page 374 and 375: Cuestionario para propietarios de i

- Page 376 and 377: Cuestionario para propietarios de i

- Page 378 and 379: Questions to Package Solution Provi

- Page 380 and 381: 9. Maintenance o What type of maint

- Page 382 and 383: IEA SHC Task 38 Solar Air Condition

- Page 384 and 385: IEA SHC Task 38 Solar Air Condition

- Page 386 and 387: IEA SHC Task 38 Solar Air Condition

- Page 388 and 389: IEA SHC Task 38 Solar Air Condition

- Page 390 and 391: IEA SHC Task 38 Solar Air Condition

- Page 392 and 393: IEA SHC Task 38 Solar Air Condition

- Page 394 and 395: IEA SHC Task 38 Solar Air Condition

- Page 396 and 397: IEA SHC Task 38 Solar Air Condition

- Page 398 and 399: IEA SHC Task 38 Solar Air Condition

- Page 400 and 401: IEA SHC Task 38 Solar Air Condition

- Page 402 and 403: IEA SHC Task 38 Solar Air Condition

- Page 404 and 405: IEA SHC Task 38 Solar Air Condition

- Page 406 and 407: IEA SHC Task 38 Solar Air Condition

- Page 408 and 409: IEA SHC Task 38 Solar Air Condition

- Page 410 and 411: IEA SHC Task 38 Solar Air Condition

- Page 412 and 413: IEA SHC Task 38 Solar Air Condition

- Page 416 and 417: IEA SHC Task 38 Solar Air Condition

- Page 418 and 419: IEA SHC Task 38 Solar Air Condition

- Page 420 and 421: IEA SHC Task 38 Solar Air Condition

- Page 422 and 423: IEA SHC Task 38 Solar Air Condition

- Page 424 and 425: IEA SHC Task 38 Solar Air Condition

- Page 426 and 427: IEA SHC Task 38 Solar Air Condition

- Page 428 and 429: IEA SHC Task 38 Solar Air Condition

- Page 430 and 431: IEA SHC Task 38 Solar Air Condition

- Page 432 and 433: IEA SHC Task 38 Solar Air Condition

- Page 434 and 435: IEA SHC Task 38 Solar Air Condition

- Page 436 and 437: IEA SHC Task 38 Solar Air Condition

- Page 438 and 439: IEA SHC Task 38 Solar Air Condition

- Page 440 and 441: IEA SHC Task 38 Solar Air Condition

- Page 442 and 443: IEA SHC Task 38 Solar Air Condition

- Page 444 and 445: IEA SHC Task 38 Solar Air Condition

- Page 446 and 447: IEA SHC Task 38 Solar Air Condition

- Page 448 and 449: IEA SHC Task 38 Solar Air Condition

- Page 450 and 451: IEA SHC Task 38 Solar Air Condition

- Page 452 and 453: IEA SHC Task 38 Solar Air Condition

- Page 454 and 455: IEA SHC Task 38 Solar Air Condition

- Page 456 and 457: IEA SHC Task 38 Solar Air Condition

- Page 458 and 459: IEA SHC Task 38 Solar Air Condition

- Page 460 and 461: IEA SHC Task 38 Solar Air Condition

- Page 462 and 463: IEA SHC Task 38 Solar Air Condition

<strong>IEA</strong> SHC Task 38 <strong>Solar</strong> Air Conditioning <strong>and</strong> Refriger<strong>at</strong>ion Subtask C1 Report, 31 October 2010<br />

characteristics can be clearly seen from the figure 6 below which shows the temper<strong>at</strong>urepressure-concentr<strong>at</strong>ion<br />

diagram of s<strong>at</strong>ur<strong>at</strong>ed LiBr-H 2 O solutions.<br />

In a paper in which he compares the two working fluid pairs, Horuz [7] points out th<strong>at</strong> the<br />

w<strong>at</strong>er/lithium bromide solution has “high safety, high vol<strong>at</strong>ility r<strong>at</strong>io, high stability <strong>and</strong> high<br />

l<strong>at</strong>ent he<strong>at</strong>”. He also shows th<strong>at</strong>, based on calcul<strong>at</strong>ions, the COP is slightly better for a<br />

system using H 2 O/LiBr than for one use NH 3 /H 2 O. Typically, the COP of a single effect<br />

H 2 O/LiBr machine would be in the range 0.65-0.75 going up to 0.9-1.2 for a double effect<br />

chiller [8]. Higher COPs can be obtained by using double or triple effect machines, but then<br />

the gener<strong>at</strong>or (driving) temper<strong>at</strong>ures need to be higher.<br />

Figure 6: Temper<strong>at</strong>ure-pressure-concentr<strong>at</strong>ion diagram of s<strong>at</strong>ur<strong>at</strong>ed LiBr-H 2 O solutions<br />

(source: Stoecker W.F. & Jones J.W. Refriger<strong>at</strong>ion <strong>and</strong> Air Conditioning, 2 nd Edition,<br />

McGraw-Hill, ISBN 0-07-066591-5)<br />

2.7 Market situ<strong>at</strong>ion for W<strong>at</strong>er/Lithium Bromide Systems<br />

The following companies are producing w<strong>at</strong>er/LiBr absorption chillers.<br />

Yazaki, Japan, produced the first solar-powered air-conditioning system in 1974. In 1970,<br />

they started production of absorption chiller/he<strong>at</strong>ers of 12.25 & 17.5 kW capacity. In 1977,<br />

production of first solar collector with selective absorption surfaces. In 1980 start of<br />

production of double-effect steam fired chiller/he<strong>at</strong>er (70 & 105 kW). In 1984, start of<br />

production of high-performance chiller with COP of 0.95. In 1996, start of production of<br />

excess he<strong>at</strong> fired chiller of 175kW. In 1998, start of production of gas driven chillers ranging<br />

from 455 to 700kW. (ref: www.yazaki-airconditioning.com/aircondition/history/html). Yazaki<br />

produces single-effect <strong>and</strong> double-effect chillers in the range of 17kW to 700 kW. (ref:<br />

www.yazaki-airconditioning.com/index.php?id=106)<br />

Dalian Sanyo Refriger<strong>at</strong>ion Co Ltd, Japan, started the manufacture of steam-fired LiBr<br />

absorption chillers in 1992. Their chillers fe<strong>at</strong>ure a crystalliz<strong>at</strong>ion prevention control system.<br />

(http://www.dl-sanyo.com/beifen/neweng/production.asp). Both the steam <strong>and</strong> direct-fired<br />

SANYO chillers utilize a double-effect absorption cycle resulting in unit COPs of 1.0 for the<br />

direct-fired chiller/ he<strong>at</strong>ers <strong>and</strong> 1.2 for the steam-fired chillers. Capacities range from 100 to<br />

1500 tons (ref: www.overseas.sanyo.com/airconditioners/products/absorp/detail.html ).<br />

EAW-Energieanlagenbau Westenfield GmbH produce solar-driven absorption chillers with<br />

capacity 15kW, 30kW <strong>and</strong> 50kW (ref: www.eaw-energieanlagenbau.de).<br />

page 16