- Page 1 and 2:

City of Light: The Story of Fiber O

- Page 3 and 4:

THE SLOAN TECHNOLOGY SERIES Dark Su

- Page 5 and 6:

3 Oxford New York Auckland Bangkok

- Page 7 and 8:

THE SLOAN TECHNOLOGY SERIES Technol

- Page 9 and 10:

viii PREFACE TO THE PAPERBACK EDITI

- Page 11 and 12:

x PREFACE bright and beautiful idea

- Page 13 and 14:

xii CONTENTS 13 A Demonstration for

- Page 15 and 16:

This page intentionally left blank

- Page 17 and 18:

4 CITY OF LIGHT reach across the wo

- Page 19 and 20:

6 CITY OF LIGHT Laser Focus. It was

- Page 21 and 22:

8 CITY OF LIGHT speech—300 to 300

- Page 23 and 24:

10 CITY OF LIGHT patients’ throat

- Page 25 and 26: 2 Guiding Light and Luminous Founta

- Page 27 and 28: 14 CITY OF LIGHT Figure 2-1: Collad

- Page 29 and 30: 16 CITY OF LIGHT Special Effects fo

- Page 31 and 32: 18 CITY OF LIGHT the British exhibi

- Page 33 and 34: Figure 2-3: A mirror aimed light fr

- Page 35 and 36: Figure 2-4: William Wheeler’s lig

- Page 37 and 38: 24 CITY OF LIGHT Total Internal Ref

- Page 39 and 40: 26 CITY OF LIGHT into glass bend in

- Page 41 and 42: 3 Fibers of Glass I do not believe,

- Page 43 and 44: 30 CITY OF LIGHT sington district o

- Page 45 and 46: 32 CITY OF LIGHT made: ‘‘All th

- Page 47 and 48: 4 The Quest for Remote Viewing Tele

- Page 49 and 50: 36 CITY OF LIGHT An Array of Light

- Page 51 and 52: 38 CITY OF LIGHT He never got that

- Page 53 and 54: 40 CITY OF LIGHT reading to a dista

- Page 55 and 56: 42 CITY OF LIGHT Lamm decided a bun

- Page 57 and 58: 44 CITY OF LIGHT He hurried to the

- Page 59 and 60: 5 A Critical Insight The Birth of t

- Page 61 and 62: 48 CITY OF LIGHT Figure 5-1: Total

- Page 63 and 64: 50 CITY OF LIGHT Corning Glass Work

- Page 65 and 66: 52 CITY OF LIGHT in 1925. He was a

- Page 67 and 68: 54 CITY OF LIGHT in single fibers.

- Page 69 and 70: 56 CITY OF LIGHT little known outsi

- Page 71 and 72: 58 CITY OF LIGHT Hopkins knew he ne

- Page 73 and 74: A good 6 99 Percent Perspiration Th

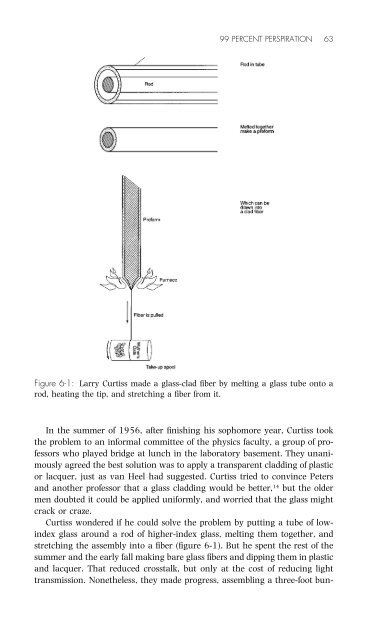

- Page 75: 62 CITY OF LIGHT school building eq

- Page 79 and 80: 66 CITY OF LIGHT some weeks later,

- Page 81 and 82: 68 CITY OF LIGHT A Problem with Ima

- Page 83 and 84: 70 CITY OF LIGHT ble—among other

- Page 85 and 86: 72 CITY OF LIGHT bundles into facep

- Page 87 and 88: 74 CITY OF LIGHT Some applications

- Page 89 and 90: A t 7 A Vision of the Future Commun

- Page 91 and 92: 78 CITY OF LIGHT phone, and asking

- Page 93 and 94: 80 CITY OF LIGHT Figure 7-1: Modula

- Page 95 and 96: 82 CITY OF LIGHT Figure 7-2: Alexan

- Page 97 and 98: 84 CITY OF LIGHT Newfoundland, whil

- Page 99 and 100: 86 CITY OF LIGHT long distance. The

- Page 101 and 102: 88 CITY OF LIGHT ways to modulate a

- Page 103 and 104: 90 CITY OF LIGHT Fibers as Dielectr

- Page 105 and 106: 8 The Laser Stimulates the Emission

- Page 107 and 108: 94 CITY OF LIGHT Maiman used ruby b

- Page 109 and 110: 96 CITY OF LIGHT Waveguides for Lig

- Page 111 and 112: 98 CITY OF LIGHT the potential of c

- Page 113 and 114: 100 CITY OF LIGHT profits. Nor were

- Page 115 and 116: 102 CITY OF LIGHT could not carry i

- Page 117 and 118: 104 CITY OF LIGHT costs, particular

- Page 119 and 120: 106 CITY OF LIGHT that was promisin

- Page 121 and 122: 108 CITY OF LIGHT date the fiber gu

- Page 123 and 124: 110 CITY OF LIGHT combination of wo

- Page 125 and 126: 112 CITY OF LIGHT lindrical claddin

- Page 127 and 128:

114 CITY OF LIGHT that fiber-optic

- Page 129 and 130:

116 CITY OF LIGHT Table 9-1 What De

- Page 131 and 132:

118 CITY OF LIGHT devices making bu

- Page 133 and 134:

120 CITY OF LIGHT Military Support

- Page 135 and 136:

122 CITY OF LIGHT A Budgetary Windf

- Page 137 and 138:

124 CITY OF LIGHT It’s a big chal

- Page 139 and 140:

126 CITY OF LIGHT it made eminent s

- Page 141 and 142:

128 CITY OF LIGHT Japanese companie

- Page 143 and 144:

130 CITY OF LIGHT reviewed optical

- Page 145 and 146:

132 CITY OF LIGHT silica stared him

- Page 147 and 148:

134 CITY OF LIGHT Fused silica was

- Page 149 and 150:

136 CITY OF LIGHT University of Wat

- Page 151 and 152:

138 CITY OF LIGHT pulling about 160

- Page 153 and 154:

140 CITY OF LIGHT worry about compe

- Page 155 and 156:

142 CITY OF LIGHT The few other fib

- Page 157 and 158:

144 CITY OF LIGHT Maurer also lost

- Page 159 and 160:

146 CITY OF LIGHT these nice low lo

- Page 161 and 162:

148 CITY OF LIGHT transistor electr

- Page 163 and 164:

150 CITY OF LIGHT Figure 12-1: The

- Page 165 and 166:

152 CITY OF LIGHT much that the las

- Page 167 and 168:

154 CITY OF LIGHT Figure 12-2: The

- Page 169 and 170:

156 CITY OF LIGHT Nick Holonyak, Jr

- Page 171 and 172:

158 CITY OF LIGHT Downs and Ups at

- Page 173 and 174:

13 A Demonstration for the Queen (1

- Page 175 and 176:

162 CITY OF LIGHT Marsh saw the pro

- Page 177 and 178:

164 CITY OF LIGHT A pair of wires c

- Page 179 and 180:

166 CITY OF LIGHT proposed, Bell co

- Page 181 and 182:

168 CITY OF LIGHT link switching ce

- Page 183 and 184:

170 CITY OF LIGHT meetings—until

- Page 185 and 186:

172 CITY OF LIGHT variation, althou

- Page 187 and 188:

174 CITY OF LIGHT bels. 93 All syst

- Page 189 and 190:

14 Three Generations in Five Years

- Page 191 and 192:

178 CITY OF LIGHT modest increase i

- Page 193 and 194:

180 CITY OF LIGHT The Rise of Irvin

- Page 195 and 196:

182 CITY OF LIGHT British Field Tri

- Page 197 and 198:

184 CITY OF LIGHT On March 27 Horig

- Page 199 and 200:

186 CITY OF LIGHT millions of bits

- Page 201 and 202:

188 CITY OF LIGHT Opening the 1.3-m

- Page 203 and 204:

190 CITY OF LIGHT pack of beer. The

- Page 205 and 206:

192 CITY OF LIGHT The Chinese also

- Page 207 and 208:

194 CITY OF LIGHT but the infusion

- Page 209 and 210:

196 CITY OF LIGHT In January 1980,

- Page 211 and 212:

198 CITY OF LIGHT contracts for sin

- Page 213 and 214:

200 CITY OF LIGHT munications was a

- Page 215 and 216:

202 CITY OF LIGHT elements. A call

- Page 217 and 218:

204 CITY OF LIGHT between them, and

- Page 219 and 220:

206 CITY OF LIGHT 1978, when they b

- Page 221 and 222:

208 CITY OF LIGHT of fiber together

- Page 223 and 224:

210 CITY OF LIGHT bles, and the Fre

- Page 225 and 226:

212 CITY OF LIGHT reaching the wate

- Page 227 and 228:

214 CITY OF LIGHT microwave counter

- Page 229 and 230:

16 The Last Mile An Elusive Vision

- Page 231 and 232:

218 CITY OF LIGHT rebuilding to pro

- Page 233 and 234:

220 CITY OF LIGHT transmission dist

- Page 235 and 236:

222 CITY OF LIGHT puter that showed

- Page 237 and 238:

224 CITY OF LIGHT Aftermaths of Ear

- Page 239 and 240:

226 CITY OF LIGHT Although fibers w

- Page 241 and 242:

228 CITY OF LIGHT it was time for h

- Page 243 and 244:

230 CITY OF LIGHT was selling fiber

- Page 245 and 246:

232 CITY OF LIGHT part of Lucent Te

- Page 247 and 248:

234 CITY OF LIGHT miles. Racks of e

- Page 249 and 250:

236 CITY OF LIGHT Today’s Technol

- Page 251 and 252:

238 CITY OF LIGHT on the overhead c

- Page 253 and 254:

240 CITY OF LIGHT innovators were c

- Page 255 and 256:

242 CITY OF LIGHT The erbium amplif

- Page 257 and 258:

244 CITY OF LIGHT sent signals at f

- Page 259 and 260:

246 CITY OF LIGHT the same type of

- Page 261 and 262:

248 CITY OF LIGHT ments. Nor could

- Page 263 and 264:

250 CITY OF LIGHT passed 10,000 for

- Page 265 and 266:

252 CITY OF LIGHT space. Anyone who

- Page 267 and 268:

254 CITY OF LIGHT they didn’t nee

- Page 269 and 270:

256 CITY OF LIGHT Like the fiber bu

- Page 271 and 272:

258 CITY OF LIGHT Bergano, Neal: Be

- Page 273 and 274:

260 CITY OF LIGHT Holonyak, Nick, J

- Page 275 and 276:

262 CITY OF LIGHT Norton, Frederick

- Page 277 and 278:

264 CITY OF LIGHT proposal for fibe

- Page 279 and 280:

266 CITY OF LIGHT 1887: Charles Ver

- Page 281 and 282:

268 CITY OF LIGHT 1956: First trans

- Page 283 and 284:

270 CITY OF LIGHT abandon thin-film

- Page 285 and 286:

272 CITY OF LIGHT 1971-1972: Focus

- Page 287 and 288:

274 CITY OF LIGHT September 1978: F

- Page 289 and 290:

276 CITY OF LIGHT February 1993: Mo

- Page 291 and 292:

This page intentionally left blank

- Page 293 and 294:

280 NOTES TO PAGES 13-17 6. Daniel

- Page 295 and 296:

282 NOTES TO PAGES 23-27 37. It was

- Page 297 and 298:

284 NOTES TO PAGES 35-39 4. H. C. S

- Page 299 and 300:

286 NOTES TO PAGES 44-50 of Munich

- Page 301 and 302:

288 NOTES TO PAGES 54-59 47. Lee Du

- Page 303 and 304:

290 NOTES TO PAGES 65-70 18. Court

- Page 305 and 306:

292 NOTES TO PAGES 74-80 way taken

- Page 307 and 308:

294 NOTES TO PAGES 88-91 35. Antoni

- Page 309 and 310:

296 NOTES TO PAGES 95-99 on Lasers

- Page 311 and 312:

298 NOTES TO PAGES 103-110 Chapter

- Page 313 and 314:

300 NOTES TO PAGES 119-123 that pro

- Page 315 and 316:

302 NOTES TO PAGES 129-140 59. See

- Page 317 and 318:

304 NOTES TO PAGES 147-151 of atten

- Page 319 and 320:

306 NOTES TO PAGES 155-159 1970); p

- Page 321 and 322:

308 NOTES TO PAGES 163-166 broadcas

- Page 323 and 324:

310 NOTES TO PAGES 168-171 51. Reev

- Page 325 and 326:

312 NOTES TO PAGES 174-178 95. A. G

- Page 327 and 328:

314 NOTES TO PAGES 183-186 37. Keck

- Page 329 and 330:

316 NOTES TO PAGES 192-197 76. Inte

- Page 331 and 332:

318 NOTES TO PAGES 202-208 3. Arthu

- Page 333 and 334:

320 NOTES TO PAGES 213-220 54. Davi

- Page 335 and 336:

322 NOTES TO PAGES 223-229 Sandbank

- Page 337 and 338:

324 NOTES TO PAGES 236-242 29. Tom

- Page 339 and 340:

326 NOTES TO PAGES 246-253 31. Kazu

- Page 341 and 342:

This page intentionally left blank

- Page 343 and 344:

330 INDEX Barlow, Harold 86, 110, 1

- Page 345 and 346:

332 INDEX Endoscopes 41-44, 51, 57-

- Page 347 and 348:

334 INDEX Index of refraction 24-26

- Page 349 and 350:

336 INDEX Møller Hansen, Holger 50

- Page 351 and 352:

338 INDEX Rocky Point Laboratory (R

- Page 353:

340 INDEX ULE glass 133-134 Ulexite