Lions Gate Biogas Application - FortisBC

Lions Gate Biogas Application - FortisBC

Lions Gate Biogas Application - FortisBC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

April 14, 2009<br />

British Columbia Utilities Commission<br />

6 th Floor, 900 Howe Street<br />

Vancouver, BC<br />

V6Z 2N3<br />

Attention:<br />

Ms. Erica M. Hamilton, Commission Secretary<br />

Dear Ms. Hamilton:<br />

Tom A. Loski<br />

Chief Regulatory Officer<br />

16705 Fraser Highway<br />

Surrey, B.C. V4N 0E8<br />

Tel: (604) 592-7464<br />

Cell: (604) 250-2722<br />

Fax: (604) 576-7074<br />

Email: tom.loski@terasengas.com<br />

www.terasengas.com<br />

Regulatory Affairs Correspondence<br />

Email: regulatory.affairs@terasengas.com<br />

Re: Terasen Gas Inc. - <strong>Lions</strong> <strong>Gate</strong> Waste Water Treatment Plant <strong>Biogas</strong> Upgrade<br />

Pilot Project <strong>Application</strong><br />

Terasen Gas Inc. (“Terasen Gas”, “TGI” or the “Company”) submits this application (the<br />

“<strong>Application</strong>”) to the British Columbia Utilities Commission (the “Commission”) for approval of<br />

its biogas upgrading demonstration project (the “Project”) at Metro Vancouver’s <strong>Lions</strong> <strong>Gate</strong><br />

Waste Water Treatment Plant (“<strong>Lions</strong> <strong>Gate</strong> WWTP”). Terasen Gas seeks the following<br />

approvals in respect of the Project:<br />

1. A Certificate of Public Convenience and Necessity (“CPCN”) pursuant to Sections 45<br />

and 46 of the Utilities Commission Act ("UCA") to construct and operate the biogas<br />

upgrading facilities at the <strong>Lions</strong> <strong>Gate</strong> WWTP, and to add to rate base the net capital<br />

cost incurred by TGI of approximately $1.33 million (representing $1.7 million direct<br />

project cost, less a $0.366 million contribution from the Province’s Innovative Clean<br />

Energy Fund (“ICE Fund”).<br />

2. Approval pursuant to Section 71 of the UCA of an energy supply agreement with<br />

Greater Vancouver Sewerage & Drainage District (“Metro Vancouver”) for biogas<br />

from the <strong>Lions</strong> <strong>Gate</strong> WWTP in the form included as Appendix 1 to this <strong>Application</strong>,<br />

whereby the raw biogas is acquired by the Company at no charge.<br />

3. Approval pursuant to Sections 59-61 of the UCA to charge the costs (and volumes) of<br />

service for the Project (including the return on rate base, depreciation expense,<br />

operating and maintenance expenses, property taxes and income taxes) to the<br />

Company’s Midstream Cost Reconciliation Account ("MCRA") and recover these<br />

costs from customers through the Midstream Cost Recovery Charge. Since the raw<br />

biogas is being acquired from Metro Vancouver at no charge, the costs of service for<br />

the Project are those associated with the biogas upgrading facilities to be owned and<br />

operated by Terasen Gas.

April 14, 2009<br />

British Columbia Utilities Commission<br />

TGI <strong>Lions</strong> <strong>Gate</strong> WWTP <strong>Biogas</strong> Upgrade Pilot Project <strong>Application</strong><br />

Page 2<br />

The Project represents a significant first step in the development of biogas upgrading as a<br />

new source of renewable energy in British Columbia. As the major natural gas utility in British<br />

Columbia we are uniquely positioned to invest in the Project and promote biogas upgrading<br />

in BC. The Project will permit the upgrading of biogas that would otherwise be flared to<br />

pipeline grade biomethane, and injecting it into our distribution system. The injected<br />

biomethane is expected to displace the quantity of natural gas required to serve<br />

approximately 130 households, and thus reduce greenhouse gases (“GHGs”) by<br />

approximately 645 tonnes annually. As such, the Project is consistent with the 2007 BC<br />

Energy Plan, the province’s Bioenergy Strategy and the "government’s energy objectives" as<br />

set out in the UCA. Further, the government has demonstrated its support of the Project<br />

through the awarding of ICE Funding in July 2008. The Project was one of fifteen proposals<br />

chosen from the sixty applicants for ICE funding under the program’s first call. The Ministry<br />

of Agriculture & Lands have also indicated their support of biogas projects so that lessons<br />

learned from projects such as <strong>Lions</strong> <strong>Gate</strong> can be applied to the agriculture sector to reduce<br />

GHG emissions from agricultural practices.<br />

As indicated in Terasen Gas' recently approved Resource Plan, we see biomethane as a<br />

potential source of supply to meet our customers' evolving needs. We anticipate that the<br />

demonstration Project will yield significant knowledge and experience that can be applied to<br />

future biogas upgrading projects. While the cost of the biomethane yielded by the Project is<br />

greater on a per GJ basis than the current cost of gas acquired by TGI for our customers, the<br />

impact on customer rates is negligible due to the small scale of the Project, and the cost is<br />

more than outweighed by the benefit of having a practical application of biogas upgrading in<br />

service. The technical and environmental risks associated with the Project are considered to<br />

be minimal, and the Squamish Nation has indicated they are generally supportive of the<br />

Project.<br />

Pursuant to Section 71(5) of the Utilities Commission Act and Section 6.0 of the Rules for<br />

Natural Gas Energy Supply Contacts we respectfully request that the Commission exercise<br />

its discretion and hold confidential the information contained in Appendix 2 of this <strong>Application</strong><br />

since it is an energy supply agreement that is not intended for public disclosure. We wish to<br />

maintain the normal practice of filing energy supply agreements on a confidential basis even<br />

though the project involved in this case is a small demonstration project. Future biogas<br />

projects may involve either public or private interests and it may be harmful to the future<br />

development of biogas markets if the commercial agreements must be publicly disclosed in<br />

some cases.<br />

We propose a written hearing process for this <strong>Application</strong>, and believe that the process steps<br />

below will permit proper consideration of the <strong>Application</strong>. In addition, we are prepared to<br />

hold a workshop to explain the <strong>Application</strong> and answer the questions of workshop<br />

participants if the Commission considers that to be of value in supporting an efficient<br />

regulatory review process. We suggest a date of May 7, 2009 for the workshop if one is to be<br />

held. We believe the proposed timetable for review of the <strong>Application</strong> is suitable given the<br />

strong government support of the Project and the minimal impact of this relatively small<br />

demonstration project on customers’ rates. The proposed Regulatory Timetable follows:

April 14, 2009<br />

British Columbia Utilities Commission<br />

TGI <strong>Lions</strong> <strong>Gate</strong> WWTP <strong>Biogas</strong> Upgrade Pilot Project <strong>Application</strong><br />

Page 3<br />

Action: Proposed date:<br />

Commission Procedural Order April 24<br />

Intervenor Registration May 1<br />

Commission Information Request May 11<br />

Intervenor Information Request May 15<br />

TGI Response to Intervenor IR and Commission IR May 29<br />

Intervenor Submissions June 12<br />

TGI Submissions and Reply June 23<br />

The regulatory process outlined above contemplates a Commission decision in July 2009.<br />

A copy of the <strong>Application</strong> has been forwarded directly to the Squamish Nation and we are<br />

following up with the Squamish Nation by telephone.<br />

If you have any questions related to this <strong>Application</strong>, please do not hesitate to contact Dave<br />

Perttula at (604) 592-7470.<br />

Yours very truly,<br />

TERASEN GAS INC.<br />

Original signed:<br />

Tom A. Loski<br />

Attachments<br />

cc : Squamish Nation - Attention: Chief Gibby Jacob<br />

Metro Vancouver - Attention: Martin Clarke<br />

TGI 2008 Annual Review and 2008 Resource Plan Intervenors<br />

Ministry of Energy, Mines and Petroleum Resources<br />

Ministry of Agriculture and Lands

TERASEN GAS INC.<br />

<strong>Lions</strong> <strong>Gate</strong><br />

Waste Water Treatment Plant<br />

<strong>Biogas</strong> Upgrade Pilot Project<br />

<strong>Application</strong><br />

April 14, 2009

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

Table of Contents<br />

Section 1 Introduction and Overview ................................................................................... 1<br />

Section 2 Regulatory and Policy Context ............................................................................. 4<br />

Section 3 Project Description and Costs .............................................................................. 5<br />

Section 4 Project Justification .............................................................................................. 8<br />

Section 5 Project Risks and Steps to Mitigate Risks ............................................................ 9<br />

Section 6 The <strong>Lions</strong> <strong>Gate</strong> WWTP Biomethane Project Agreement .................................... 12<br />

Section 7 Proposed Regulatory and Financial Treatment .................................................. 13<br />

Section 8 Other Permits and Approvals ............................................................................. 16<br />

Section 9 Consultation ....................................................................................................... 17<br />

Section 10 Conclusion ......................................................................................................... 17<br />

Appendix 1 Draft BCUC Orders<br />

List of Appendices<br />

Appendix 2 Terasen Gas / Metro Vancouver Energy Supply Agreement (filed confidentially<br />

under separate cover)<br />

Appendix 3 Technical Appendix<br />

Appendix 4 Capital Cost Detail<br />

Appendix 5 Financial Model<br />

Page i

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

1.0 Introduction and Overview<br />

The Project represents a significant first step in the development of biogas upgrading as a new<br />

source of renewable energy in British Columbia. As the major natural gas utility in British<br />

Columbia Terasen Gas is uniquely positioned to invest in the Project and promote biogas<br />

upgrading in BC. The Project will use innovative technology to upgrade biogas that would<br />

otherwise be flared to pipeline grade biomethane, 1<br />

and the upgraded biomethane will be<br />

injected into the Company’s distribution system. The injected biomethane is expected to<br />

displace the quantity of natural gas required to serve approximately 130 households, and thus<br />

reduce greenhouse gases (“GHGs”) by approximately 645 tonnes annually. As such, the<br />

Project is consistent with the 2007 BC Energy Policy, the province’s Bioenergy Strategy and the<br />

"government’s energy objectives" as set out in the UCA. The Government has demonstrated its<br />

support of the Project through the awarding of ICE Funding in July 2008. The Project was one<br />

of fifteen proposals chosen from the sixty applicants for ICE funding under the program’s first<br />

call. The Ministry of Agriculture and Lands have also indicated their support of biogas projects<br />

so that lessons learned from projects such as <strong>Lions</strong> <strong>Gate</strong> can be applied to the agriculture<br />

sector to reduce GHG emissions from agricultural practices.<br />

As indicated in Terasen Gas' recently approved Resource Plan, we see biomethane as a<br />

potential source of renewable supply to meet our customers' evolving needs. We anticipate that<br />

the demonstration Project will yield significant knowledge and experience that can be applied to<br />

future projects. While the cost of the biomethane yielded by the Project is greater on a per GJ<br />

basis than the current cost of natural gas acquired by TGI for our customers, the impact on<br />

customer rates is negligible and is more than outweighed by the benefit of having a practical<br />

application of biogas upgrading in service. The technical and environmental risks associated<br />

with the Project are considered to be minimal, and we have obtained local First Nations’ support<br />

of the Project through consultation with First Nations.<br />

1.1 Applicant<br />

1.1.1 Name, Address, and Nature of Business<br />

TGI is a company incorporated under the laws of the Province of British Columbia and is a<br />

wholly-owned subsidiary of Terasen Inc., which in turn is a wholly-owned subsidiary of Fortis Inc.<br />

TGI maintains an office and place of business at 16705 Fraser Highway, Surrey, British<br />

Columbia, V4N 0E8.<br />

TGI is the largest natural gas distribution utility in British Columbia, providing sales and<br />

transportation services to residential, commercial, and industrial customers in more than 100<br />

communities throughout British Columbia, with approximately 840,000 customers served on the<br />

mainland including the Inland, Columbia, and Lower Mainland service areas. TGI’s distribution<br />

network delivers gas to more than eighty percent of the natural gas customers in British<br />

Columbia.<br />

1 Throughout the <strong>Application</strong> the term “biomethane” will be used to refer to the gas stream after the upgrading<br />

process and the term “biogas” will be used to refer to the raw gas stream prior to the upgrading process.<br />

Page 1

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

1.1.2 Financial Capability of Applicant<br />

TGI is regulated by the Commission. TGI is capable of financing the Project either directly or<br />

through its parent, Terasen Inc. TGI has credit ratings for senior unsecured debentures from<br />

Dominion Bond Rating Service and Moody’s Investors Service of A and A3 respectively.<br />

Terasen Inc. has credit ratings for senior unsecured debentures from Dominion Bond Rating<br />

Service and Moody’s Investors Service of BBB (High) and Baa2 respectively.<br />

1.1.3 Technical Capability of Applicant<br />

TGI has designed and constructed a system of integrated high, intermediate and low pressure<br />

pipelines and operates more than 38,000 kilometres of natural gas transmission and natural gas<br />

distribution mains and service lines in British Columbia. This transmission and distribution<br />

infrastructure serves approximately 840,000 customers on the mainland. We have the technical<br />

capability, qualified staff and extensive experience in gas flow measurement and gas quality<br />

testing. In addition we have experience operating and maintaining a gas purification system at<br />

our Tilbury LNG facility.<br />

1.1.4 Name, Title, and Address of Company Contact<br />

Tom A. Loski.<br />

Chief Regulatory Officer<br />

Terasen Gas Inc.<br />

16705 Fraser Highway<br />

Surrey, B.C., V4N 0E8<br />

Phone: (604) 592-7464<br />

Facsimile: (604) 576-7074<br />

E-mail: tom.loski@terasengas.com<br />

Regulatory Matters: regulatory.affairs@terasengas.com<br />

1.1.5 Name, Title, and Address of Legal Counsel<br />

Matthew Ghikas<br />

Fasken Martineau DuMoulin LLP<br />

21st Floor, 1075 West Georgia Street<br />

Vancouver, B.C. V6E 3G2<br />

Phone: (604) 631-3191<br />

Facsimile: (604) 632-3191<br />

E-mail: mghikas@fasken.com<br />

1.2 Organization of <strong>Application</strong><br />

This <strong>Application</strong> is organized as follows:<br />

Page 2

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

Section 2 Regulatory and Policy Context<br />

Section 3 Project Description and Costs<br />

Section 4 Project Justification<br />

Section 5 Project Risks and Steps to Mitigate Risks<br />

Section 6 The <strong>Lions</strong> <strong>Gate</strong> WWTP Biomethane Project Agreement<br />

Section 7 Proposed Regulatory and Financial Treatment<br />

Section 8 Other Permits and Approvals<br />

Section 9 Consultation<br />

Section 10 Conclusion<br />

1.3 Approvals Sought<br />

Terasen Gas Inc. (“Terasen Gas”, “TGI” or the “Company”) submits this application<br />

(“<strong>Application</strong>”) to the British Columbia Utilities Commission (the “Commission”) for approval of<br />

its biogas upgrading demonstration project (the “Project”) at Metro Vancouver’s <strong>Lions</strong> <strong>Gate</strong><br />

Waste Water Treatment Plant (“<strong>Lions</strong> <strong>Gate</strong> WWTP”). Terasen Gas seeks the following<br />

approvals in respect of the Project:<br />

1. A Certificate of Public Convenience and Necessity (“CPCN”) pursuant to Sections 45<br />

and 46 of the Utilities Commission Act ("UCA") to construct and operate the biogas<br />

upgrading facilities at the <strong>Lions</strong> <strong>Gate</strong> WWTP, and to add to rate base the net capital cost<br />

incurred by TGI of approximately $1.33 million (representing $1.7 million direct project<br />

cost, less a $0.366 million contribution from the Province’s Innovative Clean Energy<br />

Fund (“ICE Fund”).<br />

2. Approval pursuant to Section 71 of the UCA of an energy supply contract with Greater<br />

Vancouver Sewerage & Drainage District (“Metro Vancouver”) for biogas from the <strong>Lions</strong><br />

<strong>Gate</strong> WWTP in the form included as Appendix 2 to this <strong>Application</strong>, whereby the raw<br />

biogas is acquired by the Company at no charge.<br />

3. Approval pursuant to Section 59-61 of the UCA to charge the costs (and volumes) of<br />

service for the Project (including the return on rate base, depreciation expense,<br />

operating and maintenance expenses, property taxes and income taxes) to the<br />

Company’s Midstream Cost Reconciliation Account ("MCRA") and recover these costs<br />

from customers through the Midstream Cost Recovery Charge. Since the raw biogas is<br />

being acquired from Metro Vancouver at no charge, the costs of service for the Project<br />

are those associated with the biogas upgrading facilities, net of ICE Funding, to be<br />

owned and operated by Terasen Gas.<br />

In Appendix 1 we have included draft Commission orders pertaining to this <strong>Application</strong>. The first<br />

is a draft procedural order setting out the proposed regulatory process and timetable. The<br />

second is a draft order for approval of the <strong>Application</strong> as filed.<br />

Page 3

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

2.0 Regulatory and Policy Context<br />

<strong>Biogas</strong> upgrading, as recognized in TGI's latest Resource Plan, represents a potential future<br />

source of renewable supply. Leadership and funding by Terasen Gas is necessary to meet<br />

changing customer needs and expectations. As a public gas utility, Terasen Gas is in a key<br />

position to promote the development of biogas upgrading in support of the Province’s energy<br />

objectives. This Section discusses the regulatory and policy context for this <strong>Application</strong>.<br />

2.1 Regulatory Context<br />

<strong>Biogas</strong> upgrading, including the Project, was identified in TGI’s 2008 Resource Plan as potential<br />

new supply resources for the Company to assist in meeting the goals of the 2007 BC Energy<br />

Plan and the legislated "government's energy objectives”. We stated our intention to pursue<br />

biogas developments in Item 7 of the Action Plan. 2<br />

The Commission accepted the 2008<br />

Resource Plan on December 15, 2008 by Order No. G-194-08. The Commission's acceptance<br />

was unqualified with respect to Action Plan Item 7.<br />

The Project is a small-scale demonstration project. We are in the process of developing<br />

business models and evaluation approaches for future, larger scale, biogas upgrading projects.<br />

We are exploring alternative regulatory and financial treatment models. We anticipate<br />

discussing the next stages of biogas development in our revenue requirement application<br />

expected to be filed in June 2009.<br />

In applying for this CPCN, we recognize that the net capital cost incurred by TGI for the Project<br />

of approximately $1.33 million ($1.7 million total Project cost, less $0.366 million of ICE funding)<br />

is well below the $5 million threshold for CPCN applications established in TGI’s current<br />

Performance Based Rate (“PBR”) Settlement. 3<br />

However, the PBR Settlement contemplated<br />

that in certain circumstances CPCN applications could be filed for smaller projects and the<br />

capital cost associated with CPCN projects is additive to the formula-driven capital under the<br />

PBR Settlement. It is appropriate to seek a CPCN for the Project since it involves new<br />

alternative energy technology and is the first project of this type in British Columbia.<br />

2.2 Policy Context<br />

The policy context supports the development of this Project. As discussed below, biogas<br />

upgrading and the Project align with "government’s energy objectives" of reducing GHGs and<br />

encouraging public utilities to use new technologies that promote the use of renewable<br />

resources. The Project is also consistent with the development of alternative energy sources<br />

and the development of bioenergy projects as outlined in the 2007 BC Energy Plan and the BC<br />

Bioenergy Strategy.<br />

Sections 46 and 71 of the UCA require the Commission to consider "government’s energy<br />

objectives" in the approval of CPCN applications (Section 46 (3.1)) and energy supply contracts<br />

2 In particular, see Section 7.2.2 and Chapter 9. TGI also reiterated its intentions in paragraphs 5 and 12 of the<br />

Company’s final argument dated October 7, 2008.<br />

3 Settlement approved by BCUC Order No. G-51-03<br />

Page 4

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

(Section 71 (2.5)). The definition of “government’s energy objectives” in section 1 of the UCA<br />

includes:<br />

(a) to encourage public utilities to reduce greenhouse gas emissions;<br />

…<br />

(e) to encourage public utilities to use innovative energy technologies<br />

(i) that facilitate electricity self-sufficiency or the fulfillment of their long-term transmission<br />

requirements, or<br />

(ii) that support energy conservation or efficiency or the use of clean or renewable<br />

sources of energy;<br />

The Project and the associated energy supply contract with Metro Vancouver promote the<br />

reduction of GHGs by displacing load that would otherwise be served by traditional natural gas<br />

and reduce GHG emissions accordingly. Moreover, the Project makes use of innovative energy<br />

technologies and renewable sources of energy. It will showcase British Columbia technology<br />

and innovation in QuestAir’s advanced gas purification system. 4<br />

The BC Government’s support for biogas project development is highlighted in 2008 BC<br />

Bioenergy Strategy. The Bioenergy Strategy states that “Government and its partners will<br />

collaborate to develop B.C. bioenergy projects utilizing energy from wood waste, agriculture,<br />

5<br />

renewable fuels and municipal waste” . The Project will provide the Province, Terasen Gas and<br />

Metro Vancouver with the knowledge and experience to develop larger commercially viable<br />

projects in the future.<br />

3.0 Project Description and Project Costs<br />

This section of the <strong>Application</strong> provides a Project description and identifies the Project costs.<br />

3.1 Project Description<br />

The Project involves the installation of a small, skid-mounted plant within the <strong>Lions</strong> <strong>Gate</strong> WWTP<br />

to recover pipeline-grade biomethane from the raw biogas, and inject the product biomethane<br />

into the local distribution pressure gas line serving the <strong>Lions</strong> <strong>Gate</strong> WWTP that is owned and<br />

operated by Terasen Gas. Based on operating data from the <strong>Lions</strong> <strong>Gate</strong> WWTP provided by<br />

Metro Vancouver, the facility produces approximately 180 cubic meters per hour (m3/h) of<br />

biogas. The wastewater treatment plant uses roughly 100 m3/h for its own heating purposes.<br />

On average, 80 cubic meters per hour (m3/h) of excess raw biogas is produced from the<br />

digestion of municipal waste at the <strong>Lions</strong> <strong>Gate</strong> WWTP. This biogas is burned in a flare operated<br />

at the <strong>Lions</strong> <strong>Gate</strong> WWTP. Upgrading the excess raw biogas will yield approximately 13 TJ<br />

annually of biomethane, enough energy to supply 130 homes.<br />

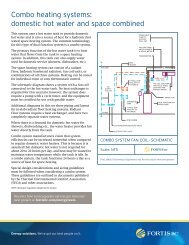

A schematic diagram of the biogas upgrading process, which uses QuestAir’s advanced gas<br />

purification systems, is found in Figure 1 below. The first component in the process - an<br />

anaerobic digester - is already in operation at the <strong>Lions</strong> <strong>Gate</strong> WWTP and is owned by Metro<br />

4 Further information about the technology is found in the Technical Appendix.<br />

5 BC Bioenergy Strategy – Growing our Natural Energy Advantage, 2008, p.8.<br />

Page 5

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

Vancouver. The existing flare is also part of Metro Vancouver’s waste water treatment process<br />

and ownership will remain with Metro Vancouver.<br />

Terasen Gas will own the equipment and related infrastructure for the biogas upgrading process<br />

which comprises all the remaining components in Figure 1 (Items B, C, D and E). This includes<br />

the pre-treatment, compression, QuestAir Pressure Swing Adsorption (“PSA”), metering and<br />

interconnection equipment. These facilities will all be skid mounted and located on the property<br />

of the <strong>Lions</strong> <strong>Gate</strong> WWTP. The location of the upgrading and interconnection facilities within the<br />

fence of the <strong>Lions</strong> <strong>Gate</strong> WWTP site means that issues of permitting and consultation are<br />

minimized and can be dealt with in conjunction with Metro Vancouver’s own projects on the site.<br />

Locating the upgrading facilities inside the WWTP property means that environmental studies<br />

are not required.<br />

The Project is expected to be operational by October 2009.<br />

Figure 1: Schematic of <strong>Biogas</strong> Upgrading Process<br />

(A)<br />

Anaerobic<br />

Digester<br />

3.2 Project Costs<br />

(B)<br />

Pre-treatment<br />

(C)<br />

Compressor<br />

QuestAir<br />

M-3200 PSA<br />

Waste Gas<br />

Flare<br />

Interconnection<br />

Facilities<br />

96+% CH4<br />

Product to Pipeline<br />

The overall Project cost, before accounting for the Province’s $366,000 contribution through the<br />

ICE Fund, is approximately $1.7 million. The capital cost estimates for the upgrading facilities<br />

are summarized in Table 1<br />

(D)<br />

(F)<br />

(E)<br />

Page 6

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

Table 1- Capital Cost Summary<br />

Item Feb. 2009 Estimate<br />

Design $ 170,000<br />

Plant Equipment & Fabrication (PE&F)<br />

Feed compressor and exhaust blower<br />

H2S removal system<br />

QuestAir PSA<br />

Piping and Instrumentation<br />

H2S monitoring<br />

PE&F Total 820,000<br />

Subtotal $ 990,000<br />

Support for Facility Engineering, Construction & Installation 35,000<br />

Commissioning, Start-up and Testing 165,000<br />

Metering, regulating and odorizing skid (Terasen Gas) 80,000<br />

Site facilities 118,000<br />

Geotechnical and foundations 54,300<br />

Metro Vancouver costs 145,700<br />

Total (before PST) $ 1,588,000<br />

PST 111,160<br />

Total Capital Cost $ 1,699,160<br />

A more detailed breakdown of the Plant Equipment and Fabrication portion of the capital costs<br />

is found in Appendix 4.<br />

The low energy yield of the Project means that the costs per GJ of biomethane produced at the<br />

facility will exceed the forecasted cost of natural gas supply. To help improve the economics of<br />

the Project, we applied to the BC government for funding from the ICE Fund. The ICE Fund<br />

was developed by the BC Government to support the GHG reduction goals identified in the<br />

2007 BC Energy Plan. According to the Program Information and <strong>Application</strong> Guidelines:<br />

The mandate of the ICE Fund is to accelerate the development of new<br />

energy technologies that have the potential to solve real, everyday energy<br />

and environmental issues and create significant socio-economic benefits for<br />

all British Columbians 6<br />

.<br />

In July 2008, we were awarded $366,000 from the ICE Fund to help fund the development of<br />

British Columbia’s first biogas upgrading project. Our success in the ICE Funding process is a<br />

6 INNOVATIVE CLEAN ENERGY FUND Program Information & <strong>Application</strong> Guidelines, p.3.<br />

Page 7

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

strong indication of the Government’s support of the Project. Only 15 of 60 projects applying to<br />

the ICE Fund’s first call process were successful.<br />

TGI’s net investment (after ICE funding) is approximately $1.33 million ($1.7 million less $0.366<br />

million).<br />

4.0 Project Justification<br />

The Project justification has three elements. The primary benefit anticipated from the Project is<br />

that our experience with a low volume demonstration project will help us understand the<br />

technical requirements of pursuing biogas as a potential future source of renewable supply on a<br />

larger scale. The Project is an ideal size from a pilot/demonstration perspective. Second, the<br />

Project will also reduce GHG emissions. Third, the success of the Project will potentially lead to<br />

opportunities to work with Metro Vancouver and others on new projects. The anticipated<br />

technical "lessons learned", GHG benefits, and potential opportunities are each discussed<br />

below.<br />

4.1. Improved Technical Understanding of <strong>Biogas</strong> Upgrading<br />

The biogas upgrading plant at the <strong>Lions</strong> <strong>Gate</strong> WWTP will be operated as a demonstration/test<br />

facility. The primary purpose of this demonstration Project will be to validate the technical<br />

feasibility of upgrading biogas from a wastewater treatment plant to pipeline grade, and for all<br />

parties involved including Terasen Gas to gain familiarity with the injection of biomethane into a<br />

gas distribution system.<br />

The Project is expected to yield a number of technical "lessons learned", including:<br />

1. Validation of the performance of the raw biogas pre-treatment system for removal of<br />

contaminants (siloxanes, C2+ hydrocarbons, H2S) from the raw biogas feed. Performance<br />

characteristics to be measured include:<br />

• Contaminant removal efficiency<br />

• Consumption/deactivation rating of consumable adsorption media<br />

• Operating costs related to replacement of consumable media.<br />

2. Validation of the performance the PSA system for upgrading biogas from the digestion of<br />

municipal wastewater to meet Terasen Gas pipeline grade specifications. Key performance<br />

characteristics to be measured include:<br />

• Overall PSA separation efficiency / methane losses<br />

• Performance to meet and/or exceed Terasen Gas’ gas quality specifications<br />

• Removal efficiency of residual contaminants in pre-treated biogas.<br />

3. Overall integration of the biogas upgrading plant into the biogas handling system of the<br />

<strong>Lions</strong> <strong>Gate</strong> WWTP. Performance characteristics to be validated include:<br />

• System control and capability to handle variations in feed gas composition and flow rate<br />

• Integration with the existing flare system at <strong>Lions</strong> <strong>Gate</strong> WWTP to combust the exhaust<br />

gas from the PSA system.<br />

Page 8

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

4. Production levels and output:<br />

• Frequency of outages over a period of time<br />

• Confirm the degree to which, if any, raw biogas production levels exceed the design<br />

upgrading capacity.<br />

The lessons learned at the <strong>Lions</strong> <strong>Gate</strong> WWTP will be used to improve the processes in the<br />

development of other biogas upgrading projects in the municipal waste and agriculture sectors.<br />

The development of biomethane recovery projects will reduce GHGs by displacing natural gas<br />

with clean biomethane. Lessons learned from the Project will also assist in understanding the<br />

cost parameters of biogas projects and what might be expected in terms of economies of scale<br />

from larger projects. Terasen Gas is in a key position to provide leadership and funding to<br />

advance these types of projects with the hope that biogas developments will be able, in the<br />

longer term, to deliver sustainable environmental benefits at a reasonable cost.<br />

4.2 GHG Reduction<br />

A second benefit from the Project is a reduction in GHG emissions. The Project will result in a<br />

reduction in GHG emissions because renewable biomethane created from the upgrading of raw<br />

biogas for will be substituted for 12,900 gigajoules of traditional natural gas. The expected<br />

annual GHG emission reduction associated from the <strong>Lions</strong> <strong>Gate</strong> project is 645 tonnes of CO2e<br />

per year.<br />

The calculation for annual CO2 reduction is as follows:<br />

Gigajoules of Natural Gas displaced 12,900 Gigajoules<br />

Tonnes of CO2e per gigajoule 0.050<br />

Tonnes of CO2e reduced 645<br />

4.3 Opportunities for Future Projects<br />

As indicated in Section 2 above, TGI’s approved 2008 Resource Plan identified biogas<br />

upgrading as a potential new supply resource to help meet our customers’ evolving<br />

expectations and also meet “government's energy objectives”. The success of the Project will<br />

give rise to further opportunities to work with Metro Vancouver, and others, to upgrade the raw<br />

biogas at other wastewater treatment plants. It is estimated that Metro Vancouver could<br />

upgrade a total of 740,000 GJ of biomethane annually which would provide a reduction of<br />

approximately 37,000 tonnes of CO2e per year. A further 2.5 million GJ of biomethane annually<br />

from agricultural waste has been identified for possible upgrading in the Fraser Valley which<br />

could reduce GHG emissions in the region by approximately 125,000 tonnes per year.<br />

5.0 Project Risks and Steps to Mitigate Risks<br />

In this Section, we discuss the Project risks and steps taken to manage those risks. TGI has<br />

managed cost risks through contractual arrangements, and has actively engaged the Squamish<br />

Nation. From an operational perspective, we believe that the Project poses little risk to the<br />

system, and the steps taken to minimize operational risks are also described below.<br />

Page 9

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

5.1 Cost Risk<br />

The Project cost accounts for the recent decrease in the Canadian dollar relative to the U.S.<br />

dollar. The Project cost has increased from $1.1 million (at the time the ICE funding application<br />

was submitted) to $1.7 million, primarily as a result of the Canadian / U.S. exchange rate<br />

influences. 7<br />

The fixed price contract with QuestAir for the upgrading equipment has alleviated<br />

further concerns about exchange rate impacts on the project capital cost.<br />

The Project may be eligible for a provincial sales tax exemption on portions of the upgrading<br />

facilities. Accordingly, we are preparing an application for a PST exemption and will reduce the<br />

Project costs to the extent that the application is successful. Other project cost risks are not<br />

expected to be material.<br />

5.2 First Nations and Land Tenure<br />

TGI has participated with Metro Vancouver in consultation with the Squamish Nation to secure<br />

its support for the Project.<br />

The upgrading facilities will be located on a portion of land known as the "Cut-off Lands". The<br />

Cut-off Lands are the subject of an agreement among the Province of British Columbia, Canada<br />

and the Squamish Indian Band dated December 5, 1983 to transfer the use and the benefit of<br />

the Cut-off Lands to the Squamish Indian Band. The Cut-off Land Agreement requires Canada<br />

to enter into a lease agreement with Metro Vancouver in respect of Metro Vancouver waste<br />

water treatment plant. The Province of British Columbia by Order in Council No. 387 dated<br />

March 6, 1984 has ordered that the administration, control and benefit of the Cut-off Lands be<br />

transferred to Canada; however, Canada has not yet accepted the transfer of the Cut-off<br />

Lands. Metro Vancouver, the Province of BC, the Squamish Nation and Canada are negotiating<br />

the terms of a lease of the portion of the Cut-off Lands occupied by Metro Vancouver's <strong>Lions</strong><br />

<strong>Gate</strong> WWTP. This lease is not yet finalized.<br />

Metro Vancouver has provided the Squamish Nation of notice of its intention to enter into an<br />

agreement with Terasen Gas to locate the Project facilities on the grounds of the <strong>Lions</strong> <strong>Gate</strong><br />

WWTP. Terasen Gas in turn has provided written notification to the Squamish Nation regarding<br />

the facility. Terasen Gas and Metro Vancouver met with the Squamish Nation on March 4, 2009<br />

to discuss the Project. The Squamish Nation was supportive of the Project.<br />

5.3 Operational and System Risk<br />

The Project poses minimal operational and system risk.<br />

7 Other contributors to the $600,000 cost increase between the ICE Funding application and this<br />

<strong>Application</strong> are the Metro Vancouver costs and provincial sales tax (both identified in Table 1 above)<br />

which were not included in the ICE funding application.<br />

Page 10

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

First, from a system capacity perspective there are no issues related to the Project since the<br />

biomethane volumes are very small compared to the capacity of the receiving distribution<br />

system in West Vancouver.<br />

Second, we have assessed considerations associated with system integrity. Unlike natural gas,<br />

biomethane does not contain ethane or propane which are used in the chemical detection of the<br />

presence of natural gas. A review of routine leak survey records in the area of the <strong>Lions</strong> <strong>Gate</strong><br />

WWTP confirmed no leaks in the system and no readings for swamp gas which is often<br />

mistaken by the public as natural gas. The biomethane will be odorized through a bypass prior<br />

to injection into the distribution system. Terasen Gas will build and operate the odorant injection<br />

equipment as part of the interconnection facilities.<br />

Terasen Gas will maintain the odorant equipment, meter and regulator. During the start-up<br />

phase of the Project, we will retain QuestAir to maintain the upgrading equipment. The facility<br />

will be monitored by our Gas Control department. Terasen Gas and Metro Vancouver staff will<br />

be trained to operate the equipment. We will also include procedures in our Emergency<br />

Response Plan.<br />

Third, with respect to gas quality, the biomethane will meet the specifications of the West Coast<br />

Energy Inc. tariff, which is the standard on which Terasen Gas receives gas into its transmission<br />

and distribution system. In addition, bacteria will be removed from the raw biogas in the<br />

upgrading process.<br />

During the months following start-up, we will frequently monitor the gas quality received from the<br />

<strong>Lions</strong> <strong>Gate</strong> WWTP, at the outlet of the upgrading plant and at points along the distribution<br />

system within the area. The monitoring is intended to confirm the assumptions used for this<br />

Project as well as providing data to allow for quality control and operational adjustments.<br />

Fourth, with respect to system risk, in the unlikely event that the biomethane was to negatively<br />

affect the quality of gas being consumed in customers’ appliances the overall impact would be<br />

manageable. Low volumes of biomethane will be produced and injected into the distribution<br />

infrastructure. System analysis of the surrounding distribution network indicates that the<br />

maximum number of customers that could be burning the biomethane is approximately 120.<br />

While it is not anticipated that the biomethane will result in customers noticing any difference in<br />

the operation of their appliances or any adverse impacts, one of the key objectives of the pilot is<br />

to prove this out so that future larger scale projects can move forward with confidence.<br />

5.4 Supply Risk<br />

We have managed supply risk through the Biomethane Project Agreement with Metro<br />

Vancouver, discussed in the next section of this <strong>Application</strong>.<br />

Metro Vancouver’s longer term plans for the <strong>Lions</strong> <strong>Gate</strong> WWTP are uncertain at this time. It is a<br />

relatively small facility that may be closed and/or replaced within the 10 to 20 year timeframe. If<br />

changes to Metro Vancouver’s plans resulted in early closure of the <strong>Lions</strong> <strong>Gate</strong> WWTP the<br />

potential impact on viability of the biogas upgrading project is not large and can be mitigated.<br />

The Terasen Gas-owned upgrading facilities are being depreciated over the 15-year contract life<br />

and so the assets are likely to be substantially depreciated by the time such plan changes would<br />

Page 11

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

occur. Further, the upgrading facilities will be skid mounted and it will likely be possible to<br />

redeploy these assets at another biogas upgrading project site.<br />

6.0 The <strong>Lions</strong> <strong>Gate</strong> WWTP Biomethane Project Agreement<br />

TGI is seeking approval pursuant to Section 71 of the UCA of the <strong>Lions</strong> <strong>Gate</strong> WWTP<br />

Biomethane Project Agreement, which is an energy supply contract with Metro Vancouver for<br />

biogas from the <strong>Lions</strong> <strong>Gate</strong> WWTP. The Agreement is found in Appendix 2 of the <strong>Application</strong>.<br />

The Agreement reflects the cooperative working arrangement developed between TGI and<br />

Metro Vancouver and is reasonable and appropriate for allowing the Project to be developed as<br />

a biogas demonstration project. The Agreement is consistent with “government’s energy<br />

objectives” for the reasons described in Section 2 of this <strong>Application</strong>.<br />

The following are highlights of the components of the Agreement.<br />

1. The Agreement sets out that the biogas in excess of Metro Vancouver’s own needs of<br />

approximately 58% of the <strong>Lions</strong> <strong>Gate</strong> WWTP biogas production at the will be made<br />

available to Terasen Gas for upgrading to biomethane.<br />

2. The term of the agreement is for fifteen years from the Effective Date (unless early<br />

termination occurs according to provisions in the agreement.)<br />

3. The Agreement sets out the roles and responsibilities of Metro Vancouver and Terasen<br />

Gas. Metro Vancouver agrees to maintain the <strong>Lions</strong> <strong>Gate</strong> WWTP in a manner that<br />

maintains the quantity and quality of excess biogas and that it will not install new<br />

equipment intended to increase the consumption of biogas at the plant.<br />

4. Terasen Gas is responsible for the costs related to designing, building, operating and<br />

maintaining the biogas upgrading facilities within certain portions of the <strong>Lions</strong> <strong>Gate</strong><br />

WWTP site defined as the “Project Area”.<br />

5. Various terms deal with reports, information and plans that must be provided by one<br />

party to the other and approvals that must be obtained before proceeding with the plans.<br />

6. Various terms set out the conditions of access to the <strong>Lions</strong> <strong>Gate</strong> WWTP by Terasen<br />

agents, employees, contractors and subcontractors and that permission must be<br />

obtained before bringing guests or visitors to the plant.<br />

7. The Agreement sets out that Metro Vancouver will provide the biogas to Terasen Gas at<br />

no charge unless Net Revenues, as defined in the Agreement, are greater than zero.<br />

There is not a significant likelihood that Net Revenues will be greater than zero before<br />

the upgrading facilities are fully depreciated. If circumstances occur where Net<br />

Revenues are greater then zero then Net Revenues will be shared. 8<br />

The fact that, under the Agreement, the raw biogas is being provided to TGI without charge<br />

(other than in the unlikely circumstances outlined in point 7 above) gives the Project a solid<br />

foundation and makes it an ideal candidate as a biogas demonstration project. The Agreement<br />

8<br />

The Agreement describes the sharing arrangement in greater detail. The Agreement has been filed separately on a<br />

confidential basis.<br />

Page 12

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

reflects the desire of both TGI and Metro Vancouver for the Project to succeed and produce the<br />

anticipated technical lessons learned and GHG benefits outlined in Section 4.0 of this<br />

<strong>Application</strong>. Both parties are interested in understanding the potential for future biogas projects.<br />

We have every expectation that the parties to the Agreement will continue to work<br />

collaboratively to ensure the success of the Project.<br />

7.0 Regulatory and Financial Treatment of Project Costs and Biomethane<br />

Volumes<br />

We are proposing to track separately the costs of biomethane development and procurement,<br />

as part of the purpose of the Project is to understand the associated costs. We are seeking<br />

approval pursuant to Section 60 of the UCA to charge the costs of service (and volumes) for the<br />

Project to the Company’s Midstream Cost Reconciliation Account (MCRA) and recover these<br />

costs from customers through the Midstream Cost Recovery Charge. It is efficient to use<br />

existing regulatory and financial constructs for this low volume demonstration Project. The<br />

proposed regulatory and financial treatment appropriately recognizes the Project as a new<br />

supply source into TGI's system. We are considering other alternative financial and regulatory<br />

treatment for future projects, but the proposed approach is most suitable in the circumstances.<br />

7.1 Tracking of Costs<br />

The Company’s investment in biogas upgrading equipment at the <strong>Lions</strong> <strong>Gate</strong> WWTP will be<br />

tracked in separate asset accounts. Further, operating and maintenance costs and any other<br />

costs pertaining to the acquisition and upgrading of biogas to suitable quality for injection into<br />

the Terasen Gas system will be recorded in separate accounts. The separate tracking of<br />

biomethane costs will enable an overall calculation of the cost of service and average unit cost<br />

of biomethane, as discussed in section 7.2.<br />

Since the raw biogas is being acquired from Metro Vancouver at no charge, the costs of service<br />

for the Project are those associated with the biogas upgrading facilities to be owned and<br />

operated by Terasen Gas. The components of the overall biomethane costs will be as follows:<br />

o Terasen Gas capital costs of biogas upgrading equipment to be recorded in the<br />

appropriate Products Extraction Plant accounts (Accounts 420 - 429 in the BCUC<br />

Uniform System of Accounts for Gas Utilities).`<br />

o Operating & maintenance costs, depreciation expense and any property taxes related to<br />

biogas upgrading and connecting facilities will be recorded in appropriate accounts<br />

corresponding to the asset accounts.<br />

o <strong>Biogas</strong> and biomethane purchase costs will be recorded in separate commodity<br />

accounts. The Agreement with Metro Vancouver (attached as Appendix 2) does not<br />

include any payments being made by Terasen Gas for the raw biogas for the first<br />

number of years. After the upgrading facilities have been fully depreciated there is the<br />

possibility that some payments will be made for to Metro Vancouver under the benefits<br />

sharing provisions of the Agreement. Future contracts in respect of other bioenergy<br />

developments will potentially include costs associated with either raw biogas or<br />

upgraded biomethane purchases.<br />

Page 13

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

7.2 Determination of Cost of Service<br />

All of the separately-tracked costs for biogas upgrading at <strong>Lions</strong> <strong>Gate</strong> WWTP will be used to<br />

determine an overall cost of service for the Project. The elements of the cost of service, which<br />

will be recalculated annually, are described below:<br />

o Return on the biogas rate base will be determined in the normal fashion using the<br />

approved Terasen Gas capital structure, debt rates and return on equity. Any future<br />

approved changes to TGI’s capital structure and return on equity will be reflected in the<br />

return on rate base of the <strong>Lions</strong> <strong>Gate</strong> assets.<br />

o Depreciation expense for the Terasen-owned upgrading facilities at <strong>Lions</strong> <strong>Gate</strong> WWTP<br />

will be based on a 6.67% depreciation rate. The 6.67% depreciation rate has been<br />

adopted to reflect the term of the contract with Metro Vancouver. The depreciation rate is<br />

also consistent with the expected service life of the upgrading equipment which is in the<br />

range of 15 to 20 years. If the <strong>Lions</strong> <strong>Gate</strong> WWTP ceases to operate or the<br />

demonstration Project is discontinued for any reason there is a reasonable likelihood<br />

that the assets will have useful life remaining and can be redeployed at another biogas<br />

upgrading site.<br />

o Income taxes will be determined in the same fashion as with other TGI revenue<br />

requirement / cost of service filings. The effects of depreciation expense and capital cost<br />

allowance on the income tax calculation will be based on the specific depreciation rates<br />

and capital cost allowance classes for the Terasen-owned biogas upgrading facilities.<br />

o Operating and maintenance expenses for the <strong>Lions</strong> <strong>Gate</strong> upgrading facilities are<br />

estimated to be about $40,000 annually. These are for electrical power, measurement<br />

and monitoring of the biogas flows and quality, replacement of consumable media,<br />

telecommunications costs, equipment maintenance and general maintenance around<br />

the facilities. Property taxes for the biogas upgrading facilities are not expected to be<br />

material but will be included in the biomethane cost of service to the extent that any<br />

incremental property taxes are incurred.<br />

o If and when there are purchase costs for raw biogas or upgraded biomethane these<br />

costs (and volumes) will also be included in the overall cost of service for biomethane.<br />

o The upgraded biomethane volumes injected into the Terasen Gas system from the <strong>Lions</strong><br />

<strong>Gate</strong> WWTP will be exempt from the BC Carbon Tax. Any benefit of the carbon tax<br />

exemption will be netted against the overall cost of service of the upgraded biomethane.<br />

A financial model of the Project incorporating all the above elements is attached to this<br />

application as Appendix 5 9<br />

. The forecast average cost of the product biomethane based on the<br />

assumptions employed is $13.64 / GJ over the life of the project. While the biomethane supply<br />

from the Project is more costly than natural gas in current market conditions the annual volumes<br />

9 Appendix 5 provides an analysis of the Project on both a cost of service basis and a cash flow basis. The cash flow<br />

analysis is provided to comply with the directive in the BCUC Decision on the Fraser River Crossing Upgrade<br />

Project (Order C-2-09 and Decision dated March 12, 2009, page 49). Since the Project is being advanced as a<br />

demonstration project and not as a competitive energy supply option the results of the analysis under either basis are<br />

presented primarily for information purposes.<br />

Page 14

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

from the Project are small, representing only about 1/100th of one percent of the Company’s<br />

core market sales volumes, so the impact on customers will not be significant. We also note that<br />

there have been periods of volatility and high prices in natural gas markets in the past in which<br />

gas prices have exceeded the expected average cost of biomethane from the Project. We<br />

believe the benefits of proceeding with the Project, in terms of gaining knowledge and<br />

experience with biogas upgrading, and setting the stage for future biomethane developments<br />

and advancement of "government’s energy objectives", more than outweigh the incremental<br />

costs associated with the Project.<br />

7.3 Proposed Financial Treatment and Recovery of Costs through MCRA<br />

As an initial approach to dealing with the biomethane costs from the <strong>Lions</strong> <strong>Gate</strong> facility as<br />

commodity costs, Terasen Gas proposes to transfer the overall biomethane costs of service and<br />

volumes into the MCRA on a monthly basis. There are two key reasons why the proposed<br />

financial treatment and the use of the MCRA are appropriate at this time.<br />

First, the biomethane from the Project will be a new commodity source and it is appropriate at<br />

this early stage of biogas supply and market development to use an existing commodity<br />

mechanism to recover the costs from customers. We considered the potential to develop new<br />

regulatory and financial structures for this Project, including mechanisms that would allow for<br />

the segregation of biogas-related costs and permit the biomethane to be sold as a “green”<br />

offering at a premium versus the regular rates. This may prove to be a viable option in the<br />

future, but it is premature to implement such structures without the benefit of the anticipated<br />

“lessons learned” from the Project. Given the Project will be Terasen’s sole source of<br />

biomethane the lack of supply diversity will make it difficult to manage a “green” offering. A<br />

“green” offering will be more appropriate at such time as we understand the supply profile and<br />

have multiple sources of biomethane to manage supply and demand for the “green” offering. .<br />

Second, the Project costs and volumes associated with the Project are analogous to costs and<br />

volumes already captured through commodity-related accounts such as the MCRA. The costs<br />

of service of the upgrading facilities are integral components of the biomethane commodity<br />

costs. Raw biogas is not of acceptable quality to take into the Company’s distribution system.<br />

The upgrading facilities in a biomethane project perform the same function of removing<br />

contaminants from the raw biogas as a natural gas processing plant does for the raw natural<br />

gas stream. The costs of biogas upgrading are therefore a supply cost component of the<br />

biomethane just as natural gas processing costs are part of the supply costs of natural gas.<br />

We have considered whether it would be appropriate to include the biomethane costs in the<br />

Commodity Cost Reconciliation Account (CCRA) rather than the MCRA but concluded that the<br />

MCRA is more appropriate. In addition to the reasons outlined above, the biomethane from the<br />

<strong>Lions</strong> <strong>Gate</strong> does not comply with the CCRA requirements to deliver the commodity in certain<br />

proportions at natural gas market hubs. Unlike CCRA supply contracts, the biomethane supply<br />

from the Project cannot be characterized as firm baseload supply; the frequency of outages and<br />

variability in flows of raw biogas from the Project are still unknown.<br />

Biomethane is exempt from the BC Carbon Tax. 10<br />

Since the costs of biomethane from the <strong>Lions</strong><br />

<strong>Gate</strong> WWTP will be recovered from customers through the MCRA and Midstream Charge it is<br />

10 The Carbon Tax Act contains the following definition of “fuel” for the purposes of determining the carbon tax:<br />

Page 15

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

appropriate that the savings from avoided carbon taxes also be passed through in the same<br />

fashion.<br />

7.4 Next Steps in <strong>Biogas</strong> Development and New Regulatory Structures<br />

We are currently in the process of developing an overall strategy and plan with respect to<br />

biomethane programs and we expect to bring forward the next phases of our biomethane<br />

strategy development in our revenue requirement application to be filed later in 2009. We<br />

recently received nine (9) expressions of interest in its <strong>Biogas</strong> Request for Expressions of<br />

Interest (“RFEOI”) process. Evaluation and development of these expressions of interest will<br />

continue to occur over the coming months but the results of that evaluation will inform<br />

expectations about the future development of biomethane supplies in BC.<br />

A related element of our assessment of biogas opportunities will be the potential to develop new<br />

regulatory and financial structures tailored to biogas supply. This analysis will include<br />

mechanisms that would allow for the segregation of biogas-related costs and permit the biogas<br />

to be sold as a “green” offering at a premium versus the regular rates.<br />

8.0 Other Permits and Approvals<br />

We have made an assessment of other permits and approvals that will be required for the<br />

Project and do not anticipate that these will pose a hindrance to the Project proceeding. These<br />

are as follows.<br />

The Project is regulated from a technical perspective by the Oil and Gas Commission (“OGC”)<br />

which follows the CSA Z662 code. The OGC determines in its approval whether environmental<br />

or archaeological reviews are required. Since the Project is located on the existing site of the<br />

<strong>Lions</strong> <strong>Gate</strong> WWTP and there are no archaeological sites on that land these reviews are not<br />

expected to be required. Based on our experience in working with the OGC and the particular<br />

circumstances of the Project we expect that OGC approval will be obtained in a timely fashion in<br />

the normal course of business.<br />

A Building Permit must be obtained from the City of West Vancouver. The City of West<br />

Vancouver handles building code compliance on its own behalf and on behalf of the Squamish<br />

Nation where Squamish Nation interests are involved. Given the Squamish Nation support for<br />

the Project (discussed in Sections 5.2 and 9) we believe that obtaining the building permit<br />

should be a straightforward matter.<br />

Since the lands occupied by the <strong>Lions</strong> <strong>Gate</strong> WWTP are adjacent to the shoreline of Burrard Inlet<br />

we are presently confirming whether notification or information must be provided to bodies with<br />

jurisdiction over the local marine environment such as Port Metro Vancouver or the Department<br />

"fuel" means a substance set out in column 2 of the Table in Schedule 1 but does not include<br />

(a) ethanol or methanol produced from biomass,<br />

(b) biodiesel and other biofuels, and<br />

(c) methane produced by waste in a landfill;<br />

Page 16

TERASEN GAS INC<br />

LIONS GATE WASTE WATER TREATMENT PLANT BIOGAS UPGRADE PILOT PROJECT APPLICATION<br />

of Fisheries and Oceans Given the Project’s offset from the marine foreshore environment, it<br />

is not anticipated that any review of the Project required by these bodies will be onerous.<br />

Once the Project is constructed and ready to begin operating, a pressure vessel operating<br />

permit must be obtained from the BC Safety Authority. This is a normal course permit that<br />

Terasen Gas obtains regularly in carrying out its operations. We do not expect any impediments<br />

in obtaining this permit.<br />

9.0 Consultation<br />

TGI has worked cooperatively with Metro Vancouver, the operator of the facility, as is evidenced<br />

by the Agreement. The Province has indicated its support through providing funding for the<br />

Project.<br />

Consultation with the Squamish Nation has taken place in a manner, and to an extent that<br />

appropriately recognizes the Squamish Nation's ongoing interest in the Project lands but also<br />

the limited potential for the Project to adversely affect the nearby Reserve or any asserted<br />

aboriginal rights and title beyond the Reserve lands. The Project is located on previously<br />

disturbed land entirely within the existing <strong>Lions</strong> <strong>Gate</strong> WWTP. The <strong>Lions</strong> <strong>Gate</strong> WWTP is<br />

physically removed from surrounding residences or businesses. The Project facilities are<br />

mounted on a skid. As such, the Project is unlikely to have any physical impact on the<br />

surrounding areas, or the land itself. The Project will reduce the need for flaring of raw biogas.<br />

Metro Vancouver has provided the Squamish Nation of notice of its intention to enter into an<br />

agreement with Terasen Gas to locate the Project facilities on the grounds of the <strong>Lions</strong> <strong>Gate</strong><br />

WWTP. Terasen Gas in turn has provided written notification to the Squamish Nation regarding<br />

the facility. Terasen Gas and Metro Vancouver met with the Squamish Nation on March 4, 2009<br />

to discuss the Project. The Squamish Nation was supportive of the Project.<br />

We will continue to work to address any issues raised by the Squamish Nation.<br />

10.0 Conclusion<br />

The Project represents a significant first step in the development of biogas as a new source of<br />

renewable energy to meet our customers’ changing expectations and “government’s energy<br />

objectives”. TGI, as the major natural gas utility in British Columbia and the local natural gas<br />

distribution provider in the vicinity of the <strong>Lions</strong> <strong>Gate</strong> WWTP, is uniquely positioned to invest in<br />

the Project and promote the development of biogas upgrading in BC. The Project, and the<br />

associated Agreement, is consistent with the 2007 BC Energy Policy, the province’s Bioenergy<br />

Strategy and "government’s energy objectives" as set out in the Act. The proposed financial and<br />

regulatory treatment is appropriate in the circumstances of this Project.<br />

Terasen Gas respectfully requests that the Commission grant the orders as sought in this<br />

<strong>Application</strong>.<br />

Page 17

Appendix 1<br />

DRAFT ORDERS

SIXTH FLOOR, 900 HOWE STREET, BOX 250<br />

VANCOUVER, B.C. V6Z 2N3 CANADA<br />

web site: http://www.bcuc.com<br />

IN THE MATTER OF<br />

the Utilities Commission Act, R.S.B.C. 1996, Chapter 473<br />

and<br />

Order No. G-XX-0X<br />

Page 1 of 4<br />

TELEPHONE: (604) 660-4700<br />

BC TOLL FREE: 1-800-663-1385<br />

FACSIMILE: (604) 660-1102<br />

An <strong>Application</strong> by Terasen Gas Inc.<br />

for a Certificate of Public and Convenience and Necessity<br />

for the <strong>Lions</strong> <strong>Gate</strong> Waste Water Treatment Plant <strong>Biogas</strong> Upgrading Demonstration Project<br />

and<br />

for approval of an Energy Supply Contract for <strong>Biogas</strong> from the <strong>Lions</strong> <strong>Gate</strong> Waste Water Treatment Plant<br />

BEFORE:<br />

WHEREAS:<br />

(Date)<br />

A. On April 9, 2009, Terasen Gas applied, pursuant to sections 45 and 46 of the Utilities Commission Act<br />

(the “Act”), for a Certificate of Public Convenience and Necessity (“CPCN”) (the “<strong>Application</strong>”) to construct<br />

and operate the biogas upgrading facilities at Metro Vancouver’s <strong>Lions</strong> <strong>Gate</strong> Waste Water Treatment Plant<br />

(“<strong>Lions</strong> <strong>Gate</strong> WWTP”) as a demonstration Project (the “Project”); and<br />

B. The Project, involves the installation at the <strong>Lions</strong> <strong>Gate</strong> WWTP of a small, skid-mounted plant to recover<br />

pipeline-grade biomethane from the raw biogas produced by <strong>Lions</strong> <strong>Gate</strong> WWTP and inject the pipelinegrade<br />

biomethane into TGI’s local distribution pressure gas line serving the <strong>Lions</strong> <strong>Gate</strong> WWTP; and<br />

C. The Government of British Columbia has demonstrated its support of the Project through the awarding<br />

Innovative Clean Energy funding of $ 366,000 in July 2008. The Ministry of Agriculture and Lands has also<br />

indicated support of biogas projects so that lessons learned from projects such as the <strong>Lions</strong> <strong>Gate</strong> project can<br />

be applied to the agriculture sector to reduce GHG emissions from agricultural practices.<br />

D. The Project has a direct capital cost of approximately $1.7 million (offset by funding from the Province in the<br />

amount of approximately $366,000); and

SIXTH FLOOR, 900 HOWE STREET, BOX 250<br />

VANCOUVER, B.C. V6Z 2N3 CANADA<br />

web site: http://www.bcuc.com<br />

Order No. G-XX-0X<br />

Page 2 of 4<br />

TELEPHONE: (604) 660-4700<br />

BC TOLL FREE: 1-800-663-1385<br />

FACSIMILE: (604) 660-1102<br />

E. TGI also applies pursuant to section 71 of the Act for approval of an energy supply contract with Greater<br />

Vancouver Sewerage and Drainage District ("Metro Vancouver") for raw biogas from the <strong>Lions</strong> <strong>Gate</strong> WWTP<br />

in the form included as Appendix 1 to the <strong>Application</strong>; and<br />

F. TGI seeks approval pursuant to sections 59-61 of the Act to charge the costs (and volumes) of service for the<br />

Project (including the return on rate base, depreciation expense, operating and maintenance expenses,<br />

property taxes and income taxes) to the Midstream Cost Reconciliation Account and recover these costs<br />

from customers through the Midstream Cost Recover Charge; and<br />

G. TGI states that the Project is a significant first step in the development of a new source of renewable energy<br />

to meet evolving customer expectations and is consistent with the 2007 BC Energy Policy, the Province’s<br />

Bioenergy Strategy and the “government’s energy objectives” as set out in the Act; and<br />

H. TGI states that while the cost of the biomethane yielded by the Project is greater on a per GJ basis than the<br />

current cost of gas acquired by TGI for its customers, the impact on rates will be negligible and will be<br />

outweighed by the significant learning benefits of having a practical application of biogas upgrading in<br />

service; and<br />

I. TGI states that appropriate consultation in respect of the Project has been undertaken with the Squamish<br />

Nation; and<br />

J. TGI has advised that notice of this <strong>Application</strong> has been provided to participants in TGI's 2008 Annual Review<br />

and intervenors in TGI's most recent Resource Plan; and<br />

K. TGI considers that a written hearing process is appropriate for the review of the <strong>Application</strong> and proposes a<br />

regulatory timetable; and<br />

L. The Commission considers that establishing a Regulatory Timetable for the registration of Intervenors and<br />

for the review of the <strong>Application</strong> is necessary and in the public interest.; and<br />

M. The Commission has reviewed the <strong>Application</strong> and considers that a written public hearing process is<br />

required.<br />

NOW THEREFORE the Commission orders as follows:<br />

1. The <strong>Application</strong> will be examined by a written public hearing process in accordance with the<br />

Regulatory Timetable attached as Appendix A.

SIXTH FLOOR, 900 HOWE STREET, BOX 250<br />

VANCOUVER, B.C. V6Z 2N3 CANADA<br />

web site: http://www.bcuc.com<br />

Order No. G-XX-0X<br />

Page 3 of 4<br />

TELEPHONE: (604) 660-4700<br />

BC TOLL FREE: 1-800-663-1385<br />

FACSIMILE: (604) 660-1102<br />

2. The <strong>Application</strong>, together with any supporting materials, will be made available for inspection at<br />

the TGI Office, 16705 Fraser Highway, Surrey, BC, V4N 0E8 and at the British Columbia Utilities<br />

Commission, Sixth Floor, 900 Howe Street, Vancouver, B.C., V6Z 2N3 and will also be available on<br />

the TGI website.<br />

3. Intervenors or Interested Parties should register with the Commission, in writing or electronic<br />

submission, by Friday May 1, 2009. Intervenors should specifically state the nature of their interest<br />

in the <strong>Application</strong> and identify the extent of their anticipated involvement in the review process.<br />

DATED at the City of Vancouver, In the Province of British Columbia, this 24th day of April, 2009.<br />

Attachment<br />

BY ORDER

SIXTH FLOOR, 900 HOWE STREET, BOX 250<br />

VANCOUVER, B.C. V6Z 2N3 CANADA<br />

web site: http://www.bcuc.com<br />

REGULATORY AGENDA AND TIMETABLE<br />

APPENDIX A<br />

to Order No. G-XX-0X<br />

Page 4 of 4<br />

TELEPHONE: (604) 660-4700<br />

BC TOLL FREE: 1-800-663-1385<br />

FACSIMILE: (604) 660-1102<br />

An <strong>Application</strong> by Terasen Gas Inc.<br />

for a Certificate of Public and Convenience and Necessity<br />

for the <strong>Lions</strong> <strong>Gate</strong> Waste Water Treatment Plant <strong>Biogas</strong> Upgrading Demonstration Project<br />

and<br />

for approval of an Energy Supply Contract for <strong>Biogas</strong> from the <strong>Lions</strong> <strong>Gate</strong> Waste Water Treatment Plant<br />

ACTION<br />

DATES (2009)<br />

Commission Issues Procedural Order Friday, April 24<br />

Intervenor Registration Friday, May 1<br />

<strong>Application</strong> Workshop (if desired) Thursday, May 7<br />

Commission Information Request No. 1 Monday, May 11<br />

Intervenor Information Request No. 1 Friday, May 15<br />

TGI Response to Intervenor IR No. 1 and Commission IR No.1 Friday, May 29<br />

Intervenor Submissions Friday, June 12<br />

TGI Submissions and Reply Friday, June 23<br />

Anticipated Commission Decision July

SIXTH FLOOR, 900 HOWE STREET, BOX 250<br />

VANCOUVER, B.C. V6Z 2N3 CANADA<br />

web site: http://www.bcuc.com<br />

IN THE MATTER OF<br />

The Utilities Commission Act, R.S.B.C. 1996 Chapter 473<br />

and<br />

An <strong>Application</strong> by Terasen Gas Inc.<br />

for a Certificate of Public and Convenience and Necessity<br />

Order No. G-XX-0X<br />

Page 1 of 2<br />

TELEPHONE: (604) 660-4700<br />

BC TOLL FREE: 1-800-663-1385<br />

FACSIMILE: (604) 660-1102<br />

for the <strong>Lions</strong> <strong>Gate</strong> Waste Water Treatment Plant <strong>Biogas</strong> Upgrading Demonstration Project<br />

and<br />

for approval of an Energy Supply Contract for <strong>Biogas</strong> from the <strong>Lions</strong> <strong>Gate</strong> Waste Water Treatment Plant<br />

BEFORE:<br />

A. On April 14, 2009, Terasen Gas Inc. (“TGI”) applied to the British Columbia Utilities Commission (the<br />

“Commission”), pursuant to sections 45 and 46 of the Utilities Commission Act (the “Act”), for a<br />

Certificate of Public Convenience and Necessity (“CPCN”) for the <strong>Lions</strong> <strong>Gate</strong> Waste Water Treatment<br />

Plant (“<strong>Lions</strong> <strong>Gate</strong> WWTP”) <strong>Biogas</strong> Upgrading Demonstration Project (the “Project”);<br />

B. The Project, which has a direct capital cost of approximately $1.7 million (offset by funding from the<br />

Province in the amount of approximately $366,000), involves the installation at the <strong>Lions</strong> <strong>Gate</strong><br />

WWTP of a small, skid-mounted plant to recover pipeline-grade biomethane from the raw biogas<br />

produced by <strong>Lions</strong> <strong>Gate</strong> WWTP and inject the pipeline-grade biomethane into TGI’s local distribution<br />