DIRECT COMPRESSION

DIRECT COMPRESSION

DIRECT COMPRESSION

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

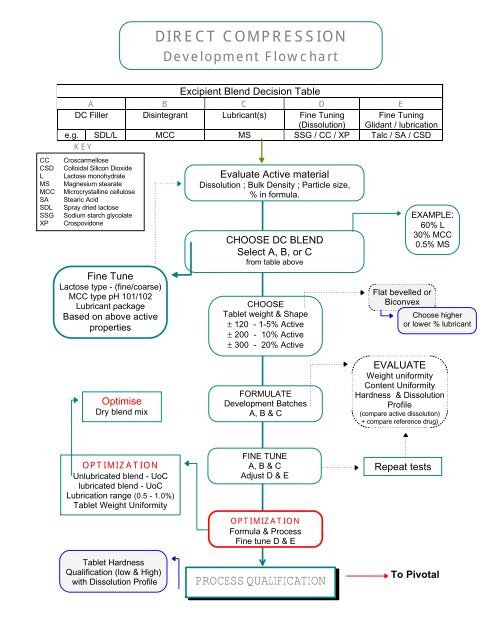

<strong>DIRECT</strong> <strong>COMPRESSION</strong><br />

Development Flowchart<br />

Excipient Blend Decision Table<br />

A B C D E<br />

DC Filler Disintegrant Lubricant(s) Fine Tuning Fine Tuning<br />

(Dissolution) Glidant / lubrication<br />

e.g.<br />

KEY<br />

SDL/L MCC MS SSG / CC / XP Talc / SA / CSD<br />

CC Croscarmellose<br />

CSD Colloidal Silicon Dioxide<br />

L Lactose monohydrate<br />

MS Magnesium stearate<br />

MCC Microcrystalline cellulose<br />

SA Stearic Acid<br />

SDL Spray dried lactose<br />

SSG Sodium starch glycolate<br />

XP Crospovidone<br />

Fine Tune<br />

Lactose type - (fine/coarse)<br />

MCC type pH 101/102<br />

Lubricant package<br />

Based on above active<br />

properties<br />

Optimise<br />

Dry blend mix<br />

OPTIMIZATION<br />

Unlubricated blend - UoC<br />

lubricated blend - UoC<br />

Lubrication range (0.5 - 1.0%)<br />

Tablet Weight Uniformity<br />

Tablet Hardness<br />

Qualification (low & High)<br />

with Dissolution Profile<br />

Evaluate Active material<br />

Dissolution ; Bulk Density ; Particle size,<br />

% in formula.<br />

CHOOSE DC BLEND<br />

Select A, B, or C<br />

from table above<br />

CHOOSE<br />

Tablet weight & Shape<br />

± 120 - 1-5% Active<br />

± 200 - 10% Active<br />

± 300 - 20% Active<br />

FORMULATE<br />

Development Batches<br />

A, B & C<br />

FINE TUNE<br />

A, B & C<br />

Adjust D & E<br />

OPTIMIZATION<br />

Formula & Process<br />

Fine tune D & E<br />

PROCESS QUALIFICATION<br />

Flat bevelled or<br />

Biconvex<br />

EXAMPLE:<br />

60% L<br />

30% MCC<br />

0.5% MS<br />

Choose higher<br />

or lower % lubricant<br />

EVALUATE<br />

Weight uniformity<br />

Content Uniformity<br />

Hardness & Dissolution<br />

Profile<br />

(compare active dissolution)<br />

+ compare reference drug)<br />

Repeat tests<br />

To Pivotal

<strong>DIRECT</strong> <strong>COMPRESSION</strong><br />

Manufacturing Flowchart [I]<br />

LACTOSE<br />

Active<br />

Material<br />

MICROCRYSTALLINE<br />

CELLULOSE<br />

SUPER<br />

DISINTEGRANTS<br />

Development<br />

Content Uniformity on<br />

unlubricated blend to<br />

establish mixing time<br />

AQUEOUS<br />

FILM COAT<br />

To printing<br />

SDL(30%) - MCC(60%)<br />

Roller mixer<br />

MIX Y-cone<br />

Mill<br />

Where necessary<br />

0.6 -0.8 mm<br />

MIX Y-cone<br />

BLEND STEP<br />

rpm + time<br />

COMPRESS<br />

FLUSH<br />

COATED DC TABLETS<br />

SUITABILITY:<br />

Glibenclamide 5 mg<br />

Selegiline 5 mg<br />

Famotidine 10/20/40 mg<br />

Bromhexine 8 mg<br />

Amitriphyline 10 mg<br />

Lubricant<br />

and Glidant<br />

SIEVE<br />

50 MESH<br />

MIX<br />

rpm + time<br />

IPQC<br />

ID<br />

Assay<br />

Content Uniformity<br />

QC<br />

Weight uniformity<br />

Thickness<br />

Hardness<br />

Disintegration<br />

RELEASE<br />

ID<br />

Assay<br />

Content Uniformity<br />

Dissolution<br />

Lubricant coats<br />

the lactose<br />

providing<br />

greater control<br />

over final<br />

blending stage

35%<br />

SUITABILITY:<br />

1. Buspirone 5/10 mg<br />

2. Tamoxifen 10/20/40 mg -<br />

<strong>DIRECT</strong> <strong>COMPRESSION</strong><br />

Manufacturing Flowchart [II]<br />

Active<br />

Material (10%)<br />

MICROCRYSTALLINE<br />

CELLULOSE (15%)<br />

SODIUM STARCH<br />

GLYCOLATE (2%)<br />

AEROSIL (0.5%)<br />

STARCH (6%)<br />

Aerosil mixed with either<br />

starch (4), lactose (1+3)<br />

or lubricant (2)<br />

During<br />

Development<br />

Content Uniformity of<br />

unlubricated blend to<br />

establish mixing time<br />

AQUEOUS<br />

FILM COAT<br />

To printing<br />

SDL(60%) - MCC(30%)<br />

Roller mixer<br />

(See Chapter 11)<br />

MIX Y-cone<br />

20 - 25 min<br />

MIX Y-cone<br />

20 - 25 min<br />

BLEND Y-cone<br />

5 min<br />

COMPRESS<br />

LACTOSE<br />

(65%)<br />

Sieve<br />

(Where necessary)<br />

0.8 mm<br />

COATED DC TABLETS<br />

[Product suitable for either Wet or Dry Granulation]<br />

Lubricant<br />

(1%)<br />

SIEVE<br />

50 MESH<br />

Lubricant coats<br />

final blend<br />

in Y-Cone<br />

directly for a<br />

short period<br />

(3-5 min)<br />

IPQC<br />

ID<br />

Assay<br />

Content Uniformity<br />

QC<br />

Weight uniformity<br />

Thickness<br />

Hardness<br />

Disintegration<br />

RELEASE<br />

ID<br />

Assay<br />

Content Uniformity<br />

Dissolution