cartridge mechanical seals series - Szelence Képviseleti Kft.

cartridge mechanical seals series - Szelence Képviseleti Kft.

cartridge mechanical seals series - Szelence Képviseleti Kft.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

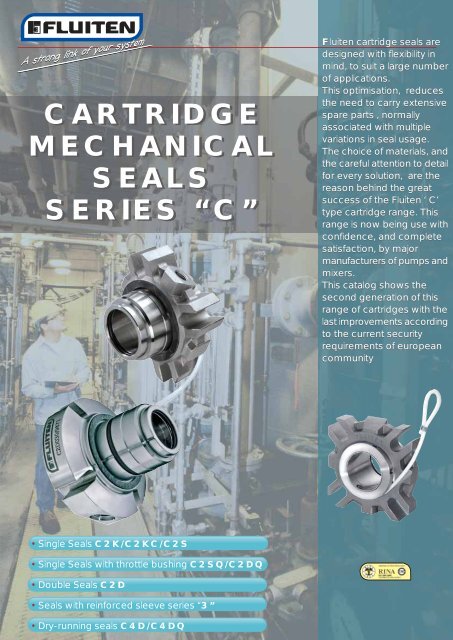

A A strong link link of of your system<br />

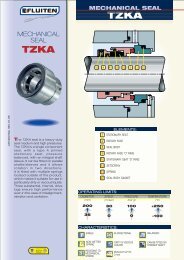

CARTRIDGE<br />

MECHANICAL<br />

SEALS<br />

SERIES “C”<br />

• Single Seals C2K/C2KC/C2S<br />

• Single Seals with throttle bushing C2SQ/C2DQ<br />

• Double Seals C2D<br />

• Seals with reinforced sleeve <strong>series</strong> “3”<br />

• Dry-running <strong>seals</strong> C4D/C4DQ<br />

Fluiten <strong>cartridge</strong> <strong>seals</strong> are<br />

designed with flexibility in<br />

mind, to suit a large number<br />

of applications.<br />

This optimisation, reduces<br />

the need to carry extensive<br />

spare parts , normally<br />

associated with multiple<br />

variations in seal usage.<br />

The choice of materials, and<br />

the careful attention to detail<br />

for every solution, are the<br />

reason behind the great<br />

success of the Fluiten ‘ C’<br />

type <strong>cartridge</strong> range. This<br />

range is now being use with<br />

confidence, and complete<br />

satisfaction, by major<br />

manufacturers of pumps and<br />

mixers.<br />

This catalog shows the<br />

second generation of this<br />

range of <strong>cartridge</strong>s with the<br />

last improvements according<br />

to the current security<br />

requirements of european<br />

community

2<br />

SINGLE SEALS<br />

CHARACTERISTICS<br />

CONNECTION FOR FLUSHING<br />

FROM PUMP DISCHARGE (PLAN 11)<br />

OR FLUSHING FROM EXTERNAL<br />

SOURCE (PLAN 32)<br />

(VERSIONS C2KC - C3KC)<br />

PATENTED DRIVE<br />

SPRING<br />

“DINAMIC” GASKETS IN FLUIGAM<br />

(PTFE ENERGIZED) FOR<br />

TOTAL COMPABILITY<br />

(O-RING ALTERNATIVE)<br />

MATERIALS:<br />

MATERIALS:<br />

STATIONARY SEAT:<br />

Graphite<br />

Silicon carbide<br />

Tungsten carbide<br />

ROTARY FACE:<br />

Silicon carbide<br />

Tungsten carbide<br />

“STATIC” GASKETS IN PTFE<br />

FOR TOTAL COMPABILITY<br />

(O-RING ALTERNATIVE)<br />

STATIONARY SEAT:<br />

Silicon carbide<br />

ROTARY FACE:<br />

AISI 316+graphite<br />

AISI 316+silicon carbide<br />

SLOTTED SEAL GLAND PLATE<br />

FOR STUFFING BOXES OF<br />

DIFFERENT SIZES<br />

AUTO-POSITIONING<br />

DEVICE - REMOVING<br />

BEFORE START-UP<br />

BALANCED SEAL<br />

WITH SOLID RINGS<br />

C2K/C2KC/C3K/C3KC<br />

GASKETS:<br />

EPDM / FKM / PTFE (Fluigam)<br />

Perfluoroelastomers (if request)<br />

SPRING:<br />

Superinox<br />

C2S/C3S (C2SQ/C3SQ with throttle bushing for quench)<br />

GASKETS:<br />

EPDM / FKM<br />

Perfluoroelastomers<br />

THROTTLE BUSHING<br />

(C2SQ-C3SQ):<br />

Bronze<br />

SLOTTED SEAL GLAND PLATE<br />

FOR STUFFING BOXES OF<br />

DIFFERENT SIZES<br />

EXTERNAL<br />

MULTI-SPRING<br />

AUTO-POSITIONING<br />

DEVICE - REMOVING<br />

BEFORE START-UP<br />

REINFORCED SLEEVE<br />

(SERIES 3)<br />

OTHER METAL PARTS:<br />

AISI 316<br />

CONNECTION FOR FLUSHING<br />

FROM PUMP DISCHARGE (PLAN 11)<br />

OR FLUSHING FROM EXTERNAL<br />

SOURCE (PLAN 32)<br />

(VERSIONS C2KC - C3KC)<br />

REINFORCED SLEEVE<br />

WITH LARGE CLEARANCE<br />

(SERIES 3)<br />

SPRINGS:<br />

AISI 316<br />

Hastelloy (if request)<br />

OTHER METAL PARTS:<br />

AISI 316<br />

Hastelloy (if request)

DUAL SEAL CAN USE EITHER<br />

A PRESSURIZED BARRIER FLUID<br />

(PLAN 53) OR AN UNPRESSURIZED<br />

BUFFER FLUID (PLAN 52)<br />

EXTERNAL<br />

MULTI-SPRINGS<br />

MATERIALS:<br />

DOUBLE SEALS<br />

CHARACTERISTICS<br />

CLEANED EXTERNAL PROFILE<br />

SUITABLE FOR SLURRIES AND<br />

HIGH VISCOSITY LIQUIDS<br />

REINFORCED SLEEVE<br />

WITH LARGE CLEARANCE<br />

UNDER SEAL RINGS (SERIES 3)<br />

STATIONARY SEAT:<br />

Graphite<br />

Silicon carbide<br />

Tungsten carbide<br />

ROTARY FACE:<br />

Silicon carbide<br />

Tungsten carbide<br />

GASKETS:<br />

EPDM / FKM<br />

Perfluoroelastomers<br />

PRODUCT SIDE<br />

C2D/C3D/C4D<br />

(C2DQ/C3DQ/C4DQ with throttle bushing for quench)<br />

BALANCED SEAL<br />

WITH SOLID FACE<br />

SPRINGS:<br />

AISI 316<br />

Hastelloy (if request)<br />

OTHER METAL PARTS:<br />

AISI 316<br />

Hastelloy (if request)<br />

CONNECTIONS FOR BARRIER<br />

FLUID (PLAN 53) OR BUFFER<br />

FLUID (PLAN 52)<br />

PATENTED DRIVE DEVICE<br />

STATIONARY SEAT:<br />

Silicon carbide<br />

ROTARY FACE:<br />

AISI 316+graphite<br />

BI-DIRECTIONAL PUMPING<br />

DEVIDE FOR EFFECTIVE<br />

FLUID CINCULATION<br />

ATMOSPHERE SIDE<br />

GASKETS:<br />

EPDM / FKM<br />

Perfluoroelastomers (if request)<br />

SLOTTED SEAL GLAND PLATE<br />

FOR STUFFING BOXES OF<br />

DIFFERENT SIZES<br />

AUTO-POSITIONING<br />

DEVICE - REMOVING<br />

BEFORE START-UP<br />

CARBON v SILICON<br />

CARBIDE AUXILIARY SEAL<br />

COOLED BARRIED FLUID<br />

THROTTLE BUSHING<br />

(C2DQ/C3DQ/C4DQ):<br />

Bronze<br />

SPRING:<br />

Superinox<br />

3

4<br />

J<br />

CHEMICAL<br />

INDUSTRY<br />

MAIN<br />

CHARACTERISTICS<br />

BI-DIRECTIONAL<br />

Can be installed on<br />

clockwise or anticlockwise<br />

rotating shafts.<br />

UNIVERSAL<br />

Geometry and materials<br />

maximize its application<br />

range.<br />

SELF-POSITIONING<br />

Auto-positioning device<br />

removing before start-up<br />

PHARMACEUTICAL<br />

FIELD<br />

INDUSTRY<br />

FOOD<br />

INDUSTRY<br />

PAPER<br />

FIELD<br />

APPLICATIONS<br />

WATER<br />

TREATMENT<br />

ATEX COMPLIANCE<br />

CENTRIFUGAL<br />

PUMPS<br />

MACHINES<br />

<br />

SIDE ENTRY BOTTOM ENTRY<br />

MIXERS MIXERS<br />

<br />

TOP ENTRY<br />

MIXERS<br />

<br />

VERTICAL<br />

PUMPS<br />

The Cartridges FLUITEN <strong>seals</strong> range are certified according the ATEX directive 94/9/CE<br />

(TÜV) which has defined the European requirements for equipment installed in critical<br />

potential explosive areas.<br />

A declaration of conformity and a specific instruction manual can be supplied on demand.<br />

This documentation complete the equipment certification required for the duty validation.<br />

For high risk applications Fluiten can provide double <strong>mechanical</strong> <strong>seals</strong> lubricated and<br />

monitored by a thermocouple which has the probe located inside the stationary rings or<br />

in contact with the barrier fluid to have direct temperature relief.<br />

GALVANIC BARRIER<br />

RANGE : 0-200 °C<br />

OUTLET: 4-20 mA<br />

LOW HEAT<br />

GENERATION<br />

PRICE<br />

Engineered to reduce<br />

production costs without<br />

compromising its quality<br />

level.<br />

NO CATASTROPHIC<br />

FAILURES<br />

The absence of a bellows<br />

guarantees that, in case<br />

of failure, there is no total<br />

fluid leakage<br />

LOW TURBULENCE<br />

HEAT GENERATIONS<br />

Its internal geometry<br />

reduces the amount of heat<br />

generated by turbulences.<br />

ROBUST CARTRIDGE<br />

The seal includes 2 robust<br />

Seal complete of flange and<br />

clutch pins resistant to<br />

shaft sleeve to guarantee<br />

vibrations, cavitations and<br />

reliable and easy installation.<br />

<strong>mechanical</strong> stress.<br />

LARGE<br />

CLEARANCE<br />

RESISTANT TO<br />

ACIDS & BASES<br />

The seal is resistant to<br />

products that are moderately<br />

chemically aggressive.<br />

SELF-CLEANING<br />

The seal eliminates by<br />

centrifugal force possible<br />

particle sedimentations.<br />

STOCK REDUCTION<br />

Ottimized material for<br />

stock reduction<br />

LOW EMISSIONS<br />

The geometry of the rings has<br />

been studied to avoid<br />

deformations and guarantee<br />

contact effectiveness<br />

THERMOCOUPLE (OPTIONAL)<br />

OXIDE MINERAL ISOLATED<br />

AISI 316 STEM<br />

ROTATING CONNECTION: 1/4" G<br />

RANGE : 0-200 °C

d4<br />

d3<br />

c<br />

b<br />

OPERATING LIMITS: (*)<br />

SEALS DIMENSIONS<br />

C2K - C2KC<br />

DIAMETER SPEED PRESSURE TEMPERATURE<br />

(mm) (m/sec) (bar)<br />

(°C)<br />

100<br />

25<br />

d1<br />

FLUI TEN<br />

C2K e C2KC with shaft<br />

diameter 50 mm<br />

CHARACTERISTICS:<br />

C2K<br />

Single <strong>cartridge</strong> seal, recommended for low duty service.<br />

PLAN 01 or PLAN 02 (see pag. 11)<br />

C2KC<br />

Single <strong>cartridge</strong> seal with connection for flushing,<br />

recommended for low duty service.<br />

PLAN 11 or PLAN 32 (see pag. 11)<br />

12<br />

0<br />

12<br />

+200<br />

–50<br />

(*) Pressure limitations depend upon a pressure-velocity relationship based<br />

on size, speed, face materials and fluid. Contact our Technical-Commercial<br />

office for technical specifics.<br />

0<br />

m<br />

l<br />

C2K<br />

b<br />

f<br />

11 8 13 9 2 35 1 10 16 7 15 12<br />

c<br />

h<br />

Seal<br />

Diam.<br />

25<br />

28<br />

30<br />

33<br />

35<br />

38<br />

40<br />

43<br />

45<br />

48<br />

50<br />

55<br />

60<br />

65<br />

70<br />

75<br />

80<br />

85<br />

90<br />

95<br />

g<br />

C2K e C2KC with shaft<br />

diameter > 50 mm<br />

m<br />

d4<br />

d1 d3 d4 b c f g g ‘ h h ‘ l l ‘ m r<br />

90<br />

d3<br />

119<br />

d1<br />

min<br />

max<br />

25 42 44 53 63 98 51.5 27 38.5 20 31.5 24,5 13 12 Rp 1/4"<br />

28 45 47 53 63 98 51,5 27 38,5 20 31,5 24,5 13 12 Rp 1/4"<br />

30 47 49 55 65 98 51,5 27 38,5 20 31,5 24,5 13 12 Rp 1/4"<br />

33 54 56 60 68 106 55 28 39.5 20 31,5 27 15.5 12 Rp 1/4"<br />

35 54 56 60 68 106 55 28 39,5 20 31,5 27 15,5 12 Rp 1/4"<br />

38 57 59 68 76 120 56 29 39,5 21 31,5 27 16.5 14 Rp 1/4"<br />

40 59 61 68 76 120 56 29 39,5 21 31,5 27 16,5 14 Rp 1/4"<br />

43 62 64 73 81 135 56 29 39,5 21 31,5 27 16,5 14 Rp 1/4"<br />

45 64 66 73 81 135 56 29 39,5 21 31,5 27 16,5 14 Rp 1/4"<br />

48 67 69 79 87 148 56 29 39,5 21 31,5 27 16,5 14 Rp 1/4"<br />

50 69 71 79 87 148 59 29.5 39,5 21.5 31,5 29.5 19.5 14 Rp 1/4"<br />

55 78 80 84 95 148 60.5 30.5 40 22 31,5 30 20.5 18 Rp 3/8"<br />

60 83 85 92 102 158 60,5 30,5 40 22 31,5 30 20,5 18 Rp 3/8"<br />

65 88 90 102 112 163 60,5 30,5 40 22 31,5 30 20,5 18 Rp 3/8"<br />

70 99 101 112 125 178 64.5 31.5 40 23 31,5 33 24.5 18 Rp 3/8"<br />

75 104 106 117 130 185 64,5 31,5 40 23 31,5 33 24,5 18 Rp 3/8"<br />

80 109 111 122 135 193 70 36 45.5 25.5 35 34 24,5 18 Rp 3/8"<br />

85 114 116 126 140 198 70 36 45,5 25,5 35 34 24,5 22 Rp 3/8"<br />

121<br />

134<br />

145<br />

95 124 126 139 150<br />

205<br />

208<br />

70<br />

70<br />

100 100 129 131 144 155 218 70<br />

Dimensions subject to modifications without notice.<br />

SEAL ELEMENTS:<br />

1 STATIONARY SEAT<br />

2 ROTARY FACE<br />

7 DRIVE COLLAR<br />

8 SHAFT SLEEVE<br />

9 ROTARY FACE GASKET<br />

10 STATIONARY SEAT GASKET<br />

l ‘<br />

C2KC<br />

11 8 13 35 9 2 1 10 16 7 15 12<br />

36<br />

36<br />

36<br />

45,5<br />

45,5<br />

45,5<br />

f<br />

h ‘<br />

25,5<br />

25,5<br />

25,5<br />

g ‘<br />

r<br />

35<br />

35<br />

35<br />

11 SHAFT SLEEVE GASKET<br />

12 SET SCREWS<br />

13 SPRING<br />

15 POSITIONING DEVICE<br />

16 FLANGE<br />

35 FLANGE GASKET<br />

34<br />

34<br />

34<br />

24,5 22<br />

24,5 22<br />

24,5 22<br />

Rp 3/8"<br />

Rp 3/8"<br />

Rp 3/8"<br />

5

6<br />

d4<br />

d3<br />

OPERATING LIMITS: (*)<br />

DIAMETER<br />

(mm)<br />

100<br />

25<br />

d1<br />

c<br />

b<br />

CHARACTERISTICS:<br />

C2S<br />

Single <strong>cartridge</strong> seal, recommended for general purpose.<br />

PLAN 11 or PLAN 32 (see pag. 11)<br />

C2SQ<br />

Single <strong>cartridge</strong> seal with throttle bushing for low pressure<br />

quench (< 1 bar), recommended for general purpose.<br />

PLAN 11/62 or PLAN 32/62 (see pag. 11)<br />

DIAMETER TEMPERATURE<br />

SPEED<br />

(m/sec)<br />

12<br />

0<br />

C2S<br />

SEALS DIMENSIONS<br />

C2S - C2SQ<br />

PRESSURE<br />

(bar)<br />

25<br />

0<br />

TEMPERATURE<br />

(°C)<br />

+250<br />

–50<br />

(*) Pressure limitations depend upon a pressure-velocity relationship based<br />

on size, speed, face materials and fluid. Contact our Technical-Commercial<br />

office for technical specifics.<br />

l<br />

f<br />

11 8 13 35 9 2 1 10 16 7 15 12<br />

FLUI TEN<br />

C2S with shaft<br />

diameter 50 mm<br />

m<br />

b<br />

r<br />

h<br />

g<br />

c<br />

m<br />

C2S with shaft<br />

diameter > 50 mm<br />

C2SQ with shaft<br />

diameter from 25 to 100 mm<br />

d4<br />

d3<br />

d1<br />

Seal d1 d3 d4 b c f f' g g' h h' l m r<br />

Diam.<br />

min max<br />

25 25 43 44 51 63 98 63,5 74,5 38,5 49,5 31,5 33,5 25 12 Rp 1/4”<br />

28 28 46 47 52 63 98 63,5 74,5 38,5 49,5 31,5 33,5 25 12 Rp 1/4”<br />

30 30 48 49 56 65 98 63,5 74,5 38,5 49,5 31,5 33,5 25 12 Rp 1/4”<br />

32 32 50 51 57 68 106 63,5 74,5 38,5 49,5 31,5 33,5 25 12 Rp 1/4”<br />

33 33 53 54 61,5 68 106 64,5 78 39,5 53 31,5 36 25 12 Rp 1/4”<br />

35 35 53 54 61,5 68 106 64,5 78 39,5 53 31,5 36 25 12 Rp 1/4”<br />

38 38 56 57 66 76 120 64,5 79 39,5 54 31,5 37 25 14 Rp 1/4”<br />

40 40 58 59 68 76 120 64,5 79 39,5 54 31,5 37 25 14 Rp 1/4”<br />

43 43 61 62 70,5 81 135 64,5 79 39,5 54 31,5 37 25 14 Rp 1/4”<br />

45 45 63 64 73 81 135 64,5 79 39,5 54 31,5 37 25 14 Rp 1/4”<br />

48 48 66 67 75 87 148 64,5 79 39,5 54 31,5 37 25 14 Rp 1/4”<br />

50 50 68 69 78 87 148 64,5 81 39,5 56 31,5 39 25 14 Rp 1/4”<br />

55 55 73 74 83 95 148 65 82,5 40 57,5 31,5 40 25 18 Rp 3/8”<br />

60 60 78 79 91 102 158 65 82,5 40 57,5 31,5 40 25 18 Rp 3/8”<br />

65 65 83 84,5 98,5 112 163 65 82,5 40 57,5 31,5 40 25 18 Rp 3/8”<br />

70 70 93 95 108 125 178 65 87,5 40 62,5 31,5 45 25 18 Rp 3/8”<br />

75 75 98 100 113 130 185 65 87,5 40 62,5 31,5 45 25 18 Rp 3/8”<br />

80 80 105 107 118 135 193 77 99 47 69 36,5 49 30 18 Rp 3/8”<br />

85 85 110 113 123 140 198 77 99 47 69 36,5 49 30 22 Rp 3/8”<br />

90 90 115 118 130 145 205 77 99 47 69 36,5 49 30 22 Rp 3/8”<br />

95 95 121 124 135 150 208 78 100 47 69 36,5 49 31 22 Rp 3/8”<br />

100 100 126 129 140 155 218 78 100 47 69 36,5 49 31 22 Rp 3/8”<br />

Dimensions subject to modifications without notice.<br />

SEAL ELEMENTS:<br />

1 STATIONARY SEAT<br />

2 ROTARY FACE<br />

7 DRIVE COLLAR<br />

8 SHAFT SLEEVE<br />

9 ROTARY FACE “O” RING<br />

10 STATIONARY SEAT “O” RING<br />

10a THROTTLE BUSHING “O” RING<br />

11 SHAFT SLEEVE “O” RING<br />

l<br />

C2SQ<br />

11 8 13 35 9 2 1 10 16 10a 42 40a 7<br />

f ’<br />

h ’<br />

12 SET SCREWS<br />

13 SPRINGS<br />

15 POSITIONING DEVICE<br />

16 FLANGE<br />

35 FLANGE GASKET<br />

40a SNAP RING<br />

42 THROTTLE BUSHING<br />

g ’<br />

r<br />

15 12

d4<br />

d3<br />

CHARACTERISTICS:<br />

SEALS DIMENSIONS<br />

C2D - C2DQ<br />

C2D<br />

Double <strong>cartridge</strong> seal, recommended for high duty service.<br />

PLAN 52 or PLAN 53 o PLAN 54 (see pag. 11)<br />

C2DQ<br />

Single <strong>cartridge</strong> seal with throttle bushing for low pressure<br />

quench (< 1 bar), recommended for high duty service.<br />

PLAN 62 (see pag. 11)<br />

OPERATING LIMITS: (*)<br />

DIAMETER<br />

(mm)<br />

DIAMETER TEMPERATURE<br />

100<br />

25<br />

d1<br />

b<br />

SPEED<br />

(m/sec)<br />

12<br />

0<br />

C2D<br />

PRESSURE<br />

(bar)<br />

25<br />

0<br />

Externar fluid pressure:<br />

- C2D (tandem): atmospheric pressure<br />

- C2D (dual): 1-2 bar over product pressure<br />

TEMPERATURE<br />

(°C)<br />

+250<br />

–50<br />

(*) Pressure limitations depend upon a pressure-velocity relationship based<br />

on size, speed, face materials and fluid. Contact our Technical-Commercial<br />

office for technical specifics.<br />

l<br />

11 8 13 9 2 1 10 4a 13a 9a 2a 1a 10a 7 15<br />

c<br />

28<br />

35<br />

26<br />

m<br />

f<br />

o<br />

h<br />

d4<br />

r<br />

g<br />

d3<br />

16<br />

d1<br />

12<br />

Seal d1 d3 d4 b c f g h l m o r<br />

Diam.<br />

min max<br />

C2DQ<br />

25 25 43 44 51 63 98 94 49,5 33,5 44,5 12 6 Rp 1/4”<br />

28 28 46 47 52 63 98 94 49,5 33,5 44,5 12 6 Rp 1/4”<br />

30 30 48 49 56 65 98 94 49,5 33,5 44,5 12 6 Rp 1/4”<br />

32 32 50 51 57 67 106 94 49,5 33,5 44,5 12 6 Rp 1/4”<br />

33 33 53 54 61,5 71 106 97,5 53 36 44,5 12 6 Rp 1/4”<br />

35 35 53 54 61,5 71 106 97,5 53 36 44,5 12 6 Rp 1/4”<br />

38 38 56 57 66 76 120 98,5 54 37 44,5 12 6 Rp 1/4”<br />

40 40 58 59 68 76 120 98,5 54 37 44,5 14 6 Rp 1/4”<br />

43 43 61 62 70,5 81 130 98,5 54 37 44,5 14 6 Rp 1/4”<br />

45 45 63 64 73 81 135 98,5 54 37 44,5 14 6 Rp 1/4”<br />

48 48 66 67 75 87 135 98,5 54 37 44,5 14 6 Rp 1/4”<br />

50 50 68 69 78 87 148 100,5 56 39 44,5 14 6 Rp 1/4”<br />

55 55 73 74 83 95 148 102 57,5 40 44,5 18 6 Rp 3/8”<br />

60 60 78 79 91 102 158 102 57,5 40 44,5 18 6 Rp 3/8”<br />

65 65 83 84,5 98,5 112 163 102 57,5 40 44,5 18 6 Rp 3/8”<br />

70 70 93 95 108 125 178 107 62,5 45 44,5 18 6 Rp 3/8”<br />

75 75 98 100 113 130 185 107 62,5 45 44,5 18 6 Rp 3/8”<br />

80 80 105 107 118 135 193 121 69 49 52 18 6 Rp 3/8”<br />

85 85 110 113 123 140 198 121 69 49 52 22 6 Rp 3/8”<br />

90 90 115 118 130 145 205 121 69 49 52 22 6 Rp 3/8”<br />

95 95 121 124 135 150 208 123 69 49 54 22 6 Rp 3/8”<br />

100 100 126 129 140 155 218 123 69 49 54 22 6 Rp 3/8”<br />

Dimensions subject to modifications without notice.<br />

SEAL ELEMENTS:<br />

1 STATIONARY SEAT 10a THROTTLE BUSHING “O” RING (C2DQ)<br />

1a STATIONARY SEAT<br />

11 SHAFT SLEEVE “O” RING<br />

2 ROTARY FACE<br />

12 SET SCREWS<br />

2a ROTARY FACE<br />

13 SPRINGS<br />

4a SEAL BODY 13a SPRING<br />

7 DRIVE COLLAR<br />

15 POSITIONING DEVICE<br />

8 SHAFT SLEEVE<br />

16 FLANGE<br />

9 ROTARY FACE “O” RING<br />

26 EXTERNAL FLANGE GASKET<br />

9a ROTARY FACE “O” RING<br />

35 FLANGE GASKET<br />

10 STATIONARY SEAT “O” RING 40a SNAP RING<br />

10a STATIONARY SEAT “O” RING (C2D)<br />

l<br />

28<br />

35<br />

26<br />

f<br />

o<br />

11 8 13 9 2 1 10 16 40a 42 10a 7 15 12<br />

h<br />

42 THROTTLE BUSHING<br />

r<br />

g<br />

7

8<br />

d4<br />

d3<br />

d1<br />

c<br />

b<br />

CHARACTERISTICS:<br />

FLUI TEN<br />

C3K e C3KC with shaft<br />

diameter 45 mm<br />

SEALS DIMENSIONS<br />

C3K - C3KC<br />

l<br />

C3K<br />

11 8 13 9 2 35 1 10 16<br />

7 15 12<br />

m<br />

f<br />

b<br />

h<br />

g<br />

c<br />

C3K e C3KC with shaft<br />

diameter > 45 mm<br />

m<br />

1 STATIONARY SEAT<br />

2 ROTARY FACE<br />

C3K<br />

Single <strong>cartridge</strong> seal, recommended for low duty service.<br />

Seal d1<br />

Diam.<br />

20 20<br />

d3<br />

42<br />

d4<br />

min max<br />

44 53<br />

b<br />

63<br />

c<br />

98<br />

f<br />

51.5<br />

g<br />

27<br />

g ‘<br />

38.5<br />

h<br />

20<br />

h ‘<br />

31.5<br />

l<br />

24,5<br />

l ‘<br />

13<br />

m<br />

12<br />

r<br />

Rp 1/4"<br />

PLAN 01 or PLAN 02 (see pag. 11)<br />

22 22 45 47 53 63 98 51,5 27 38,5 20 31,5 24,5 13 12 Rp 1/4"<br />

C3KC<br />

25 25 47 49 55 65 98 51,5 27 38,5 20 31,5 24,5 13 12 Rp 1/4"<br />

Single <strong>cartridge</strong> seal with connection for flushing,<br />

30 30 54 56 60 68 106 55 28 39.5 20 31,5 27 15.5 12 Rp 1/4"<br />

recommended for low duty service.<br />

PLAN 11 or PLAN 32 (see pag. 11)<br />

33<br />

35<br />

33<br />

35<br />

57<br />

59<br />

59<br />

61<br />

68<br />

68<br />

76<br />

76<br />

120<br />

120<br />

56<br />

56<br />

29<br />

29<br />

39,5<br />

39,5<br />

21<br />

21<br />

31,5<br />

31,5<br />

27<br />

27<br />

16,5<br />

16.5<br />

14<br />

14<br />

Rp 1/4"<br />

Rp 1/4"<br />

- Reinforced sleeve.<br />

- Important “Run-out” allowed for mixers applications.<br />

38 38 62 64 73 81 135 56 29 39,5 21 31,5 27 16,5 14 Rp 1/4"<br />

40 40 64 66 73 81 135 56 29 39,5 21 31,5 27 16,5 14 Rp 1/4"<br />

OPERATING LIMITS: (*)<br />

43<br />

45<br />

43<br />

45<br />

67<br />

69<br />

69<br />

71<br />

79<br />

79<br />

87<br />

87<br />

148<br />

148<br />

56<br />

59<br />

29<br />

29,5<br />

39,5<br />

39,5<br />

21<br />

21,5<br />

31,5<br />

31,5<br />

27<br />

29,5<br />

16,5<br />

19,5<br />

14<br />

14<br />

Rp 1/4"<br />

Rp 1/4"<br />

DIAMETER SPEED PRESSURE TEMPERATURE 48 48 78 80 84 95 148 60,5 30,5 40 22 31,5 30 20,5 18 Rp 3/8"<br />

(mm) (m/sec) (bar)<br />

(°C)<br />

50 50 78 80 84 95 148 60.5 30.5 40 22 31,5 30 20.5 18 Rp 3/8"<br />

90 12 12 +200<br />

53<br />

55<br />

53<br />

55<br />

83<br />

83<br />

85<br />

85<br />

92<br />

92<br />

102<br />

102<br />

158<br />

158<br />

60,5<br />

60,5<br />

30,5<br />

30,5<br />

40<br />

40<br />

22<br />

22<br />

31,5<br />

31,5<br />

30<br />

30<br />

20,5<br />

20,5<br />

18<br />

18<br />

Rp 3/8"<br />

Rp 3/8"<br />

58 58 88 90 102 112 163 60,5 30,5 40 22 31,5 30 20,5 18 Rp 3/8"<br />

20 0 0 –50<br />

60<br />

63<br />

60<br />

63<br />

88<br />

99<br />

90 102<br />

101 112<br />

112<br />

125<br />

163<br />

178<br />

60,5<br />

64,5<br />

30,5<br />

31.5<br />

40<br />

40<br />

22<br />

23<br />

31,5<br />

31,5<br />

30<br />

33<br />

20,5<br />

24.5<br />

18<br />

18<br />

Rp 3/8"<br />

Rp 3/8"<br />

65 65 99 101 112 125 178 64,5 31.5 40 23 31,5 33 24.5 18 Rp 3/8"<br />

(*) Pressure limitations depend upon a pressure-velocity relationship based<br />

68 68 104 106 117 130 185 64,5 31,5 40 23 31,5 33 24,5 18 Rp 3/8"<br />

on size, speed, face materials and fluid. Contact our Technical-Commercial<br />

office for technical specifics.<br />

70<br />

75<br />

70<br />

75<br />

109<br />

114<br />

111 122<br />

116 126<br />

135<br />

140<br />

193<br />

198<br />

70<br />

70<br />

36<br />

36<br />

45.5 25.5<br />

45,5 25,5<br />

35<br />

35<br />

34<br />

34<br />

24,5<br />

24,5<br />

18<br />

22<br />

Rp 3/8"<br />

Rp 3/8"<br />

80 80 119 121 134 145 205 70 36 45,5 25,5 35 34 24,5 22 Rp 3/8"<br />

85 85 124 126 139 150 208 70 36 45,5 25,5 35 34 24,5 22 Rp 3/8"<br />

90 90 129 131 144 155 218 70 36 45,5 25,5 35 34 24,5 22 Rp 3/8"<br />

d4<br />

d3<br />

Dimensions subject to modifications without notice.<br />

SEAL ELEMENTS:<br />

d1<br />

7 DRIVE COLLAR<br />

8 SHAFT SLEEVE<br />

9 ROTARY FACE GASKET<br />

10 STATIONARY SEAT GASKET<br />

l ‘<br />

C3KC<br />

f<br />

h ‘<br />

11 SHAFT SLEEVE GASKET<br />

12 SET SCREWS<br />

13 SPRING<br />

15 POSITIONING DEVICE<br />

16 FLANGE<br />

35 FLANGE GASKET<br />

11 8 13 35 9 2 1 10 16 7 15 12<br />

g ‘<br />

r

d4<br />

d3<br />

c<br />

b<br />

CHARACTERISTICS:<br />

C3S<br />

Single <strong>cartridge</strong> seal, for general purpose.<br />

PLAN 11 or PLAN 32 (see pag. 11)<br />

OPERATING LIMITS: (*)<br />

90<br />

20<br />

d1<br />

FLUI TEN<br />

C3S with shaft<br />

diameter 45 mm<br />

SEALS DIMENSIONS<br />

C3S - C3SQ<br />

C3SQ<br />

Single <strong>cartridge</strong> seal with throttle bushing for low pressure<br />

quench (< 1 bar), recommended for general purpose.<br />

PLAN 11/62 or PLAN 32/62 (see pag. 11)<br />

- Reinforced sleeve.<br />

- Important “Run-out” allowed for mixers applications.<br />

DIAMETER SPEED PRESSURE<br />

TEMPERATURE<br />

(mm) (m/sec) (bar)<br />

(°C)<br />

12<br />

0<br />

C3S<br />

25<br />

0<br />

+250<br />

–50<br />

(*) Pressure limitations depend upon a pressure-velocity relationship based<br />

on size, speed, face materials and fluid. Contact our Technical-Commercial<br />

office for technical specifics.<br />

l<br />

m<br />

b<br />

f<br />

11 8 13 35 9 2 1 10 16 7 15 12<br />

c<br />

h<br />

g<br />

C3S with shaft<br />

diameter > 45 mm<br />

C3SQ with shaft<br />

diameter from 20 to 90 mm<br />

r<br />

m<br />

d4<br />

d3<br />

d1<br />

SEAL ELEMENTS:<br />

1 STATIONARY SEAT<br />

2 ROTARY FACE<br />

7 DRIVE COLLAR<br />

8 SHAFT SLEEVE<br />

9 ROTARY FACE “O” RING<br />

10 STATIONARY SEAT “O” RING<br />

10a THROTTLE BUSHING “O” RING<br />

11 SHAFT SLEEVE “O” RING<br />

l<br />

C3SQ<br />

11 8 13 9 35 2 1 10 16 10a 42 40a 7<br />

f ‘<br />

h ‘<br />

g ‘<br />

r<br />

12 SET SCREWS<br />

13 SPRINGS<br />

15 POSITIONING DEVICE<br />

16 FLANGE<br />

35 FLANGE GASKET<br />

40a SNAP RING<br />

42 THROTTLE BUSHING<br />

15 12<br />

Shaft d1<br />

Diam.<br />

d3 d4<br />

min max<br />

b c f f' g g' h h' l m r<br />

20 20 43 44 51 63 98 63,5 74,5 38,5 49,5 31,5 33,5 25 12 Rp 1/4”<br />

22 22 46 47 52 63 98 63,5 74,5 38,5 49,5 31,5 33,5 25 12 Rp 1/4”<br />

25 25 48 49 56 65 98 63,5 74,5 38,5 49,5 31,5 33,5 25 12 Rp 1/4”<br />

28 28 50 51 57 68 106 63,5 74,5 38,5 49,5 31,5 33,5 25 12 Rp 1/4”<br />

30 30 53 54 61,5 68 106 64,5 78 39,5 53 31,5 36 25 12 Rp 1/4”<br />

32 32 56 57 66 76 120 64,5 79 39,5 54 31,5 37 25 12 Rp 1/4”<br />

33 33 56 57 66 76 120 64,5 79 39,5 54 31,5 37 25 14 Rp 1/4”<br />

35 35 58 59 68 76 120 64,5 79 39,5 54 31,5 37 25 14 Rp 1/4”<br />

38 38 61 62 70,5 81 135 64,5 79 39,5 54 31,5 37 25 14 Rp 1/4”<br />

40 40 63 64 73 81 135 64,5 79 39,5 54 31,5 37 25 14 Rp 1/4”<br />

43 43 66 67 75 87 148 64,5 79 39,5 54 31,5 37 25 14 Rp 1/4”<br />

45 45 68 69 78 87 148 64,5 81 39,5 56 31,5 39 25 14 Rp 1/4”<br />

48 48 73 74 83 95 148 65 82,5 40 57,5 31,5 40 25 18 Rp 3/8”<br />

50 50 73 74 83 95 148 65 82,5 40 57,5 31,5 40 25 18 Rp 3/8”<br />

53 53 78 79 91 102 158 65 82,5 40 57,5 31,5 40 25 18 Rp 3/8”<br />

55 55 78 79 91 102 158 65 82,5 40 57,5 31,5 40 25 18 Rp 3/8”<br />

58 58 83 84,5 98,5 112 163 65 82,5 40 57,5 31,5 40 25 18 Rp 3/8”<br />

60 60 83 84,5 98,5 112 163 65 82,5 40 57,5 31,5 40 25 18 Rp 3/8”<br />

63 63 93 95 108 125 178 65 87,5 40 62,5 31,5 45 25 18 Rp 3/8”<br />

65 65 93 95 108 125 178 65 87,5 40 62,5 31,5 45 25 18 Rp 3/8”<br />

68 68 98 100 113 130 185 65 87,5 40 62,5 31,5 45 25 18 Rp 3/8”<br />

70 70 105 107 118 135 193 77 99 47 69 36,5 49 30 18 Rp 3/8”<br />

75 75 110 113 123 140 198 77 99 47 69 36,5 49 30 22 Rp 3/8”<br />

80 80 115 118 130 145 205 77 99 47 69 36,5 49 30 22 Rp 3/8”<br />

85 85 121 124 135 150 208 78 100 47 69 36,5 49 31 22 Rp 3/8”<br />

90 90 126 129 140 155 218 78 100 47 69 36,5 49 31 22 Rp 3/8”<br />

Dimensions subject to modifications without notice.<br />

9

10<br />

d4<br />

d3<br />

d1<br />

SEALS DIMENSIONS<br />

C3D - C3DQ - C4D - C4DQ<br />

C3D<br />

C4D<br />

CHARACTERISTICS:<br />

l<br />

28<br />

35<br />

26<br />

f<br />

o<br />

11 8 13 9 2 1 10 4a 13a 9a 2a 1a 10a 7 15<br />

b<br />

c<br />

m<br />

h<br />

g<br />

r<br />

d4<br />

16<br />

d3<br />

12<br />

C3DQ<br />

C4DQ<br />

Seal<br />

Diam.<br />

C3D<br />

Double <strong>cartridge</strong> seal, recommended for high duty service. 20<br />

d1<br />

20<br />

d3<br />

43<br />

d4<br />

min max<br />

44 51<br />

b<br />

63<br />

c<br />

98<br />

f<br />

94<br />

g<br />

49,5<br />

h<br />

33,5<br />

l<br />

44,5<br />

m<br />

12<br />

o<br />

6<br />

r<br />

Rp 1/4”<br />

PLAN 52 or PLAN 53 o PLAN 54 (see pag. 11)<br />

22 22 46 47 52 63 98 94 49,5 33,5 44,5 12 6 Rp 1/4”<br />

C3DQ<br />

Single <strong>cartridge</strong> seal with throttle bushing for low pressure<br />

quench (< 1 bar), recommended for high duty service.<br />

25<br />

28<br />

25<br />

28<br />

48<br />

50<br />

49<br />

51<br />

56<br />

57<br />

65<br />

67<br />

98<br />

106<br />

94<br />

94<br />

49,5<br />

49,5<br />

33,5<br />

33,5<br />

44,5<br />

44,5<br />

12<br />

12<br />

6<br />

6<br />

Rp 1/4”<br />

Rp 1/4”<br />

PLAN 62 (see pag. 11)<br />

30 30 53 54 61,5 71 106 97,5 53 36 44,5 12 6 Rp 1/4”<br />

C4D<br />

32 32 56 57 66 76 120 98,5 54 37 44,5 12 6 Rp 1/4”<br />

Duoble <strong>cartridge</strong> dry-running seal.<br />

Nitrogen PLAN 54 or PLAN 02/61 with connections<br />

33 33 56 57 66 76 120 98,5 54 37 44,5 12 6 Rp 1/4”<br />

purchaser’s use. (see pag. 11)<br />

35 35 58 59 68 76 120 98,5 54 37 44,5 14 6 Rp 1/4”<br />

C4DQ<br />

38 38 61 62 70,5 81 130 98,5 54 37 44,5 14 6 Rp 1/4”<br />

Single <strong>cartridge</strong> dry-running seal.<br />

PLAN 02 or PLAN 02/62 with throttle bushing (see pag. 11)<br />

40 40 63 64 73 81 135 98,5 54 37 44,5 14 6 Rp 1/4”<br />

- Reinforced sleeve.<br />

- Important “Run-out” allowed for mixers applications.<br />

43<br />

45<br />

43<br />

45<br />

66<br />

68<br />

67<br />

69<br />

75<br />

78<br />

87<br />

87<br />

135<br />

148<br />

98,5<br />

100,5<br />

54<br />

56<br />

37<br />

39<br />

44,5<br />

44,5<br />

14<br />

14<br />

6<br />

6<br />

Rp 1/4”<br />

Rp 1/4”<br />

OPERATING LIMITS: (*)<br />

48 48 73 74 83 95 148 102 57,5 40 44,5 18 6 Rp 3/8”<br />

50 50 73 74 83 95 148 102 57,5 40 44,5 18 6 Rp 3/8”<br />

DIAMETER SPEED PRESSURE TEMPERATURE 53 53 78 79 91 102 158 102 57,5 40 44,5 18 6 Rp 3/8”<br />

(mm) (m/sec) (bar)<br />

(°C) 55 55 78 79 91 102 158 102 57,5 40 44,5 18 6 Rp 3/8”<br />

90 12<br />

(0,3 m/s for<br />

C4D/C4DQ)<br />

25<br />

(3 bar for<br />

C4D/C4DQ)<br />

+250<br />

(150 °C for<br />

C4D/C4DQ)<br />

58<br />

60<br />

58<br />

60<br />

83<br />

83<br />

84,5<br />

84,5<br />

98,5<br />

98,5<br />

112<br />

112<br />

163<br />

163<br />

102<br />

102<br />

57,5<br />

57,5<br />

40<br />

40<br />

44,5<br />

44,5<br />

18<br />

18<br />

6<br />

6<br />

Rp 3/8”<br />

Rp 3/8”<br />

63 63 93 95 108 125 178 107 62,5 45 44,5 18 6 Rp 3/8”<br />

20 0 0 –50<br />

65<br />

68<br />

65<br />

68<br />

93<br />

98<br />

95<br />

100<br />

108<br />

113<br />

125<br />

130<br />

178<br />

185<br />

107<br />

107<br />

62,5<br />

62,5<br />

45<br />

45<br />

44,5<br />

44,5<br />

18<br />

18<br />

6<br />

6<br />

Rp 3/8”<br />

Rp 3/8”<br />

70 70 105 107 118 135 193 121 69 49 52 18 6 Rp 3/8”<br />

75 75 110 113 123 140 198 121 69 49 52 22 6 Rp 3/8”<br />

Externar fluid pressure:<br />

- C3D (tandem): atmospheric pressure<br />

80 80 115 118 130 145 205 121 69 49 52 22 6 Rp 3/8”<br />

- C3D (dual): 1-2 bar over product pressure<br />

85 85 121 124 135 150 208 123 69 49 54 22 6 Rp 3/8”<br />

(*) Pressure limitations depend upon a pressure-velocity relationship based 90 90 126 129 140 155 218 123 69 49 54 22 6 Rp 3/8”<br />

on size, speed, face materials and fluid. Contact our Technical-Commercial<br />

office for technical specifics.<br />

Dimensions subject to modifications without notice.<br />

d1<br />

SEAL ELEMENTS:<br />

1 STATIONARY SEAT 10a THROTTLE BUSHING “O” RING (C3DQ)<br />

1a STATIONARY SEAT<br />

11 SHAFT SLEEVE “O” RING<br />

2 ROTARY FACE<br />

12 SET SCREWS<br />

2a ROTARY FACE<br />

13 SPRINGS<br />

4a SEAL BODY 13a SPRING<br />

7 DRIVE COLLAR<br />

15 POSITIONING DEVICE<br />

8 SHAFT SLEEVE<br />

16 FLANGE<br />

9 ROTARY FACE “O” RING<br />

26 EXTERNAL FLANGE GASKET<br />

9a ROTARY FACE “O” RING<br />

35 FLANGE GASKET<br />

10 STATIONARY SEAT “O” RING 40a SNAP RING<br />

10a STATIONARY SEAT “O” RING (C3D)<br />

l<br />

28<br />

35<br />

26<br />

f<br />

o<br />

42 THROTTLE BUSHING<br />

11 8 13 9 2 1 10 16 40a 42 10a 7 15 12<br />

h<br />

g<br />

r

API PLANS<br />

APPLICABLE<br />

FOR ORIZONTAL CENTRIFUGAL PUMPS:<br />

PLAN 02<br />

Dead-ended seal chamber<br />

with no circulation of flushed fluid.<br />

C2DQ - C3DQ<br />

With PLAN 62<br />

Optional<br />

Plugged connections<br />

for possible future<br />

circulating fluid.<br />

PLAN 52<br />

Vent<br />

Normally<br />

open<br />

Reservoir<br />

Un-pressurized external<br />

fluid reservoir with forced circulation;<br />

(typically used with tandem seal<br />

arrangement)<br />

C2D - C3D<br />

PLAN 01<br />

Internal recirculation from<br />

pump discharge to seal.<br />

C2K - C3K<br />

Optional<br />

PLAN 53<br />

Pressurized external fluid<br />

reservoir with forced circulation;<br />

(typically used with double seal<br />

arrangement)<br />

C2D - C3D<br />

External<br />

pressure inlet<br />

Reservoir<br />

FOR TOP ENTRY MIXERS:<br />

Plugged connections<br />

for possible future<br />

circulating fluid.<br />

PLAN 02<br />

Dead-ended seal chamber<br />

with no circulation of flushed fluid.<br />

C4D - C4DQ<br />

With PLAN 62<br />

PLAN 62<br />

External fluid quench (steam,<br />

gas, water, etc.) typically used<br />

whit throttle bushing or auxiliary<br />

sealing device.<br />

C3DQ - C4DQ<br />

PLAN 52<br />

Un-pressurized external<br />

fluid reservoir with forced circulation;<br />

(typically used with tandem seal<br />

arrangement)<br />

API PLAN LEGEND<br />

Pressure indicator<br />

Temperature indicator<br />

Pressure switch<br />

For not present specific applications contact our Technical-Commercial office<br />

C3D<br />

Vent<br />

Normally<br />

open<br />

Normally<br />

open<br />

Reservoir<br />

Circulation pump<br />

Low pressure alarm<br />

High level alarm<br />

Low level alarm<br />

High flow alarm<br />

PLAN 11<br />

Recirculation from pump<br />

case through orifice to seal.<br />

C2KC - C3KC<br />

C2S - C3S<br />

PLAN 54<br />

Circulation of clean fluid from<br />

external system; (typically<br />

used with double seal<br />

arrangement)<br />

C2D - C3D<br />

External<br />

pressure inlet<br />

PLAN 53<br />

Pressurized external fluid<br />

reservoir with forced circulation;<br />

(typically used with double seal<br />

arrangement)<br />

C3D<br />

Normally<br />

open<br />

Reservoir<br />

Circulation pump<br />

Flushing inlet/<br />

pressurization<br />

Flushing outlet/<br />

pressurization<br />

Barrier gas inlet<br />

Barrier gas outlet<br />

By vendor<br />

By<br />

purch.<br />

PLAN 32<br />

Injection to seal from external<br />

source of clean fluid.<br />

C2KC - C3KC<br />

C2S - C3S<br />

PLAN 62<br />

External fluid quench (steam,<br />

gas, water, etc.) typically used<br />

whit throttle bushing or auxiliary<br />

sealing device.<br />

C2SQ - C3SQ<br />

C2DQ - C3DQ<br />

Optional<br />

GBI GBO<br />

PLAN 74<br />

Pressurized gas barrier regulated<br />

from control panel; (typically used<br />

with dry-running double seal<br />

arrangement)<br />

C4D<br />

Strainer<br />

Flow-regulation valve<br />

Block valve<br />

Check valve<br />

Orifice<br />

11

CAT029 ENG – Rev. 05 / 10<br />

SERVICE<br />

SOLUTIONS<br />

The Fluiten service department, independent from the<br />

production process, offer a fast, flexible and high quality<br />

assistance for any necessity.<br />

During the repair process are also considered up grading<br />

evaluation to make the <strong>seals</strong> compliant to the recent<br />

environmental rules and using the present superior material<br />

technology.<br />

High experienced technicians operates according the quality<br />

manual which define the level of repair to the initial<br />

manufacturing tolerances and performances.<br />

Customer and After sales service for assistance and technical support tel. +39 02 339403.1<br />

or contact us by info@fluiten.it or www.fluiten.it<br />

Distributed by:<br />

A A strong link link of of your system<br />

FLUITEN ITALIA SpA<br />

20016 Pero (Milano) Italy • Via L. Da Vinci, 14 • Telefono +39 02. 339403.1 Fax +39 02. 3538641<br />

www.fluiten.it E-mail: info@fluiten.it