cross section crash boxes

cross section crash boxes

cross section crash boxes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

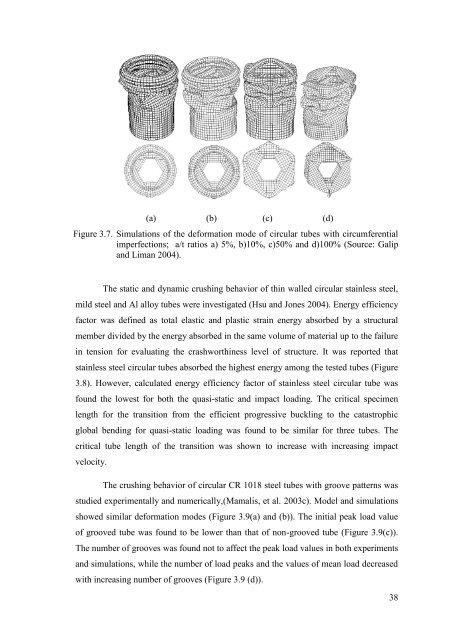

(a) (b) (c) (d)<br />

Figure 3.7. Simulations of the deformation mode of circular tubes with circumferential<br />

imperfections; a/t ratios a) 5%, b)10%, c)50% and d)100% (Source: Galip<br />

and Liman 2004).<br />

The static and dynamic crushing behavior of thin walled circular stainless steel,<br />

mild steel and Al alloy tubes were investigated (Hsu and Jones 2004). Energy efficiency<br />

factor was defined as total elastic and plastic strain energy absorbed by a structural<br />

member divided by the energy absorbed in the same volume of material up to the failure<br />

in tension for evaluating the <strong>crash</strong>worthiness level of structure. It was reported that<br />

stainless steel circular tubes absorbed the highest energy among the tested tubes (Figure<br />

3.8). However, calculated energy efficiency factor of stainless steel circular tube was<br />

found the lowest for both the quasi-static and impact loading. The critical specimen<br />

length for the transition from the efficient progressive buckling to the catastrophic<br />

global bending for quasi-static loading was found to be similar for three tubes. The<br />

critical tube length of the transition was shown to increase with increasing impact<br />

velocity.<br />

The crushing behavior of circular CR 1018 steel tubes with groove patterns was<br />

studied experimentally and numerically,(Mamalis, et al. 2003c). Model and simulations<br />

showed similar deformation modes (Figure 3.9(a) and (b)). The initial peak load value<br />

of grooved tube was found to be lower than that of non-grooved tube (Figure 3.9(c)).<br />

The number of grooves was found not to affect the peak load values in both experiments<br />

and simulations, while the number of load peaks and the values of mean load decreased<br />

with increasing number of grooves (Figure 3.9 (d)).<br />

38