Construction Program Management and Inspection Guide

Construction Program Management and Inspection Guide

Construction Program Management and Inspection Guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SAMPLE<br />

▼ Once the cause of the failing test results is determined, appropriate corrective action<br />

will be taken (e.g. Add moisture, Regrade <strong>and</strong> compact. The failing Earthwork<br />

material will be reworked <strong>and</strong> three additional r<strong>and</strong>om QC tests will be performed<br />

for the Sublot. The results of the 3 additional r<strong>and</strong>om QC tests will be evaluated in<br />

accordance with the steps above until all 3 additional test results are within the<br />

Engineering Limits <strong>and</strong> the overall Percent Within Limits (PWL) for the Sublot<br />

equals or exceeds 85%.<br />

▼ Earthwork material that cannot be reworked to achieve the specified in-place density<br />

<strong>and</strong> in-place moisture content will be disposed of Off-Site.<br />

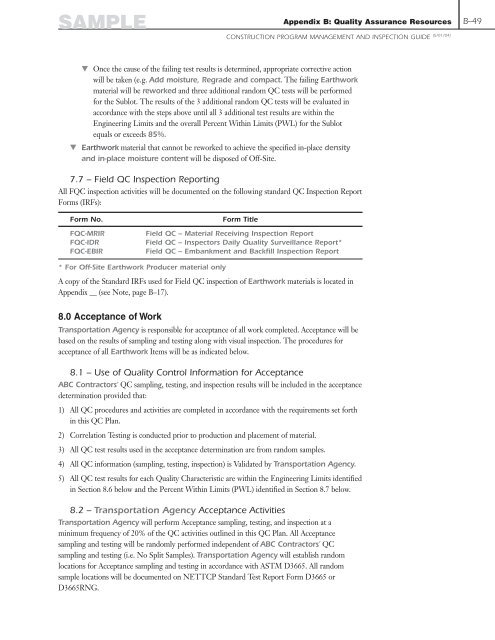

7.7 – Field QC <strong>Inspection</strong> Reporting<br />

All FQC inspection activities will be documented on the following st<strong>and</strong>ard QC <strong>Inspection</strong> Report<br />

Forms (IRFs):<br />

Form No. Form Title<br />

FQC-MRIR Field QC – Material Receiving <strong>Inspection</strong> Report<br />

FQC-IDR Field QC – Inspectors Daily Quality Surveillance Report*<br />

FQC-EBIR Field QC – Embankment <strong>and</strong> Backfill <strong>Inspection</strong> Report<br />

* For Off-Site Earthwork Producer material only<br />

A copy of the St<strong>and</strong>ard IRFs used for Field QC inspection of Earthwork materials is located in<br />

Appendix __ (see Note, page B–17).<br />

8.0 Acceptance of Work<br />

Transportation Agency is responsible for acceptance of all work completed. Acceptance will be<br />

based on the results of sampling <strong>and</strong> testing along with visual inspection. The procedures for<br />

acceptance of all Earthwork Items will be as indicated below.<br />

8.1 – Use of Quality Control Information for Acceptance<br />

ABC Contractors’ QC sampling, testing, <strong>and</strong> inspection results will be included in the acceptance<br />

determination provided that:<br />

1) All QC procedures <strong>and</strong> activities are completed in accordance with the requirements set forth<br />

in this QC Plan.<br />

2) Correlation Testing is conducted prior to production <strong>and</strong> placement of material.<br />

3) All QC test results used in the acceptance determination are from r<strong>and</strong>om samples.<br />

4) All QC information (sampling, testing, inspection) is Validated by Transportation Agency.<br />

5) All QC test results for each Quality Characteristic are within the Engineering Limits identified<br />

in Section 8.6 below <strong>and</strong> the Percent Within Limits (PWL) identified in Section 8.7 below.<br />

8.2 – Transportation Agency Acceptance Activities<br />

Transportation Agency will perform Acceptance sampling, testing, <strong>and</strong> inspection at a<br />

minimum frequency of 20% of the QC activities outlined in this QC Plan. All Acceptance<br />

sampling <strong>and</strong> testing will be r<strong>and</strong>omly performed independent of ABC Contractors’ QC<br />

sampling <strong>and</strong> testing (i.e. No Split Samples). Transportation Agency will establish r<strong>and</strong>om<br />

locations for Acceptance sampling <strong>and</strong> testing in accordance with ASTM D3665. All r<strong>and</strong>om<br />

sample locations will be documented on NETTCP St<strong>and</strong>ard Test Report Form D3665 or<br />

D3665RNG.<br />

Appendix B: Quality Assurance Resources<br />

CONSTRUCTION PROGRAM MANAGEMENT AND INSPECTION GUIDE (5/01/04)<br />

B–49