Construction Program Management and Inspection Guide

Construction Program Management and Inspection Guide

Construction Program Management and Inspection Guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

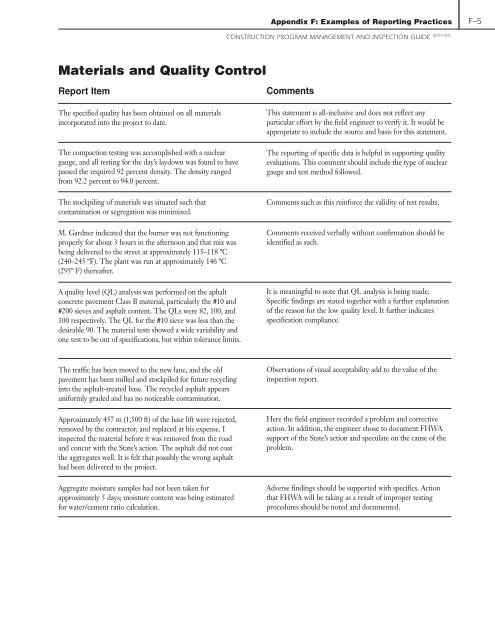

Materials <strong>and</strong> Quality Control<br />

Report Item<br />

The specified quality has been obtained on all materials<br />

incorporated into the project to date.<br />

The compaction testing was accomplished with a nuclear<br />

gauge, <strong>and</strong> all testing for the day’s laydown was found to have<br />

passed the required 92 percent density. The density ranged<br />

from 92.2 percent to 94.0 percent.<br />

The stockpiling of materials was situated such that<br />

contamination or segregation was minimized.<br />

M. Gardner indicated that the burner was not functioning<br />

properly for about 3 hours in the afternoon <strong>and</strong> that mix was<br />

being delivered to the street at approximately 115–118 ºC<br />

(240–245 ºF). The plant was run at approximately 146 ºC<br />

(295º F) thereafter.<br />

A quality level (QL) analysis was performed on the aphalt<br />

concrete pavement Class B material, particularly the #10 <strong>and</strong><br />

#200 sieves <strong>and</strong> asphalt content. The QLs were 82, 100, <strong>and</strong><br />

100 respectively. The QL for the #10 sieve was less than the<br />

desirable 90. The material tests showed a wide variability <strong>and</strong><br />

one test to be out of specifications, but within tolerance limits.<br />

The traffic has been moved to the new lane, <strong>and</strong> the old<br />

pavement has been milled <strong>and</strong> stockpiled for future recycling<br />

into the asphalt-treated base. The recycled asphalt appears<br />

uniformly graded <strong>and</strong> has no noticeable contamination.<br />

Approximately 457 m (1,500 ft) of the base lift were rejected,<br />

removed by the contractor, <strong>and</strong> replaced at his expense. I<br />

inspected the material before it was removed from the road<br />

<strong>and</strong> concur with the State’s action. The asphalt did not coat<br />

the aggregates well. It is felt that possibly the wrong asphalt<br />

had been delivered to the project.<br />

Aggregate moisture samples had not been taken for<br />

approximately 5 days; moisture content was being estimated<br />

for water/cement ratio calculation.<br />

Appendix F: Examples of Reporting Practices<br />

CONSTRUCTION PROGRAM MANAGEMENT AND INSPECTION GUIDE (5/01/04)<br />

Comments<br />

This statement is all-inclusive <strong>and</strong> does not reflect any<br />

particular effort by the field engineer to verify it. It would be<br />

appropriate to include the source <strong>and</strong> basis for this statement.<br />

The reporting of specific data is helpful in supporting quality<br />

evaluations. This comment should include the type of nuclear<br />

gauge <strong>and</strong> test method followed.<br />

Comments such as this reinforce the validity of test results.<br />

Comments received verbally without confirmation should be<br />

identified as such.<br />

It is meaningful to note that QL analysis is being made.<br />

Specific findings are stated together with a further explanation<br />

of the reason for the low quality level. It further indicates<br />

specification compliance.<br />

Observations of visual acceptability add to the value of the<br />

inspection report.<br />

Here the field engineer recorded a problem <strong>and</strong> corrective<br />

action. In addition, the engineer chose to document FHWA<br />

support of the State’s action <strong>and</strong> speculate on the cause of the<br />

problem.<br />

Adverse findings should be supported with specifics. Action<br />

that FHWA will be taking as a result of improper testing<br />

procedures should be noted <strong>and</strong> documented.<br />

F–5