Comparison of Disintegration Methods at a Full-scale ... - BVSDE

Comparison of Disintegration Methods at a Full-scale ... - BVSDE

Comparison of Disintegration Methods at a Full-scale ... - BVSDE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Comparison</strong> <strong>of</strong> <strong>Disintegr<strong>at</strong>ion</strong> <strong>Methods</strong> <strong>at</strong> a <strong>Full</strong>-<strong>scale</strong> Anaerobic<br />

Digestion Plant<br />

Anke Winter, Johannes A. Müller<br />

Institute <strong>of</strong> Sanitary and Environmental Engineering, Technical University <strong>of</strong> Braunschweig<br />

Pockelsstraße 2a, D-38106 Braunschweig, Germany<br />

(E-mail: a.winter@tu-bs.de, jo.mueller@tu-bs.de )<br />

Abstract<br />

Various half-<strong>scale</strong> and lab-<strong>scale</strong> investig<strong>at</strong>ions have already shown th<strong>at</strong> the disintegr<strong>at</strong>ion <strong>of</strong> excess sludge is a<br />

possible pre-tre<strong>at</strong>ment to optimise anaerobic digestion. To verify these results, different methods <strong>of</strong> disintegr<strong>at</strong>ion<br />

were investig<strong>at</strong>ed <strong>at</strong> a full-<strong>scale</strong> plant. Two stirred ball mills, a plant for oxid<strong>at</strong>ion with ozone, a lys<strong>at</strong>e centrifuge and<br />

an ultrasonic homogeniser were applied.<br />

A positive influence <strong>of</strong> disintegr<strong>at</strong>ion on the anaerobic biodegradability could be established with all aggreg<strong>at</strong>es. The<br />

enhancement <strong>of</strong> the degree <strong>of</strong> degrad<strong>at</strong>ion varied between 7.4 to 26 %. Beside this, labor<strong>at</strong>ory investig<strong>at</strong>ions proved<br />

th<strong>at</strong> disintegr<strong>at</strong>ion increases the polymer demand and leads to a lower solid content after dew<strong>at</strong>ering. Higher ammonia<br />

concentr<strong>at</strong>ions in the process w<strong>at</strong>er after dew<strong>at</strong>ering corrobor<strong>at</strong>ed the results <strong>of</strong> the anaerobic degrad<strong>at</strong>ion.<br />

Capital costs for the aggreg<strong>at</strong>es, costs for energy, manpower and maintenance can be covered, if specific costs for<br />

disposal are high. If the development <strong>of</strong> sludge tre<strong>at</strong>ment costs in future and the current discussion about sludge<br />

disposal are taken into account, sewage sludge disintegr<strong>at</strong>ion can be a suitable technique to minimise costs on waste<br />

w<strong>at</strong>er tre<strong>at</strong>ment plants.<br />

Keywords<br />

<strong>Disintegr<strong>at</strong>ion</strong>, economic efficiency, full-<strong>scale</strong> investig<strong>at</strong>ions, improvement <strong>of</strong> stabilis<strong>at</strong>ion, lys<strong>at</strong>e centrifugal<br />

technique, ozone tre<strong>at</strong>ment, stirred ball mills, ultrasonic homogeniser<br />

INTRODUCTION<br />

Costs for disposal and energy make up the main part <strong>of</strong> costs <strong>at</strong> waste w<strong>at</strong>er tre<strong>at</strong>ment plants. This<br />

research project focuses on the minimis<strong>at</strong>ion <strong>of</strong> the disposal costs by reducing the amount <strong>of</strong> sludge.<br />

Also a minimis<strong>at</strong>ion <strong>of</strong> the energy costs by increasing the biogas production and by optimising<br />

biogas utilis<strong>at</strong>ion is intended. These aims will be achieved by a disintegr<strong>at</strong>ion <strong>of</strong> the sludge.<br />

Sewage sludge disintegr<strong>at</strong>ion is a stressing <strong>of</strong> sewage sludge by external forces using<br />

mechanical, thermal, chemical or biological methods. With low energy input this tre<strong>at</strong>ment changes<br />

the floc structure. A higher energy input needed for the disruption <strong>of</strong> the cell wall results in a<br />

solubilis<strong>at</strong>ion <strong>of</strong> the organic m<strong>at</strong>ter in the sludge. Due to th<strong>at</strong>, disintegr<strong>at</strong>ion enables an acceler<strong>at</strong>ed<br />

and an enhanced degrad<strong>at</strong>ion <strong>of</strong> organic m<strong>at</strong>ter. Extensive research work in half-<strong>scale</strong> and lab-<strong>scale</strong><br />

plants has already shown th<strong>at</strong> disintegr<strong>at</strong>ion is a suitable method to make organic m<strong>at</strong>erial from<br />

excess sludge available for the degrad<strong>at</strong>ion in an anaerobic process. An increase in the degree <strong>of</strong><br />

degrad<strong>at</strong>ion <strong>of</strong> 10 to 30 % can be <strong>at</strong>tained. Another effect is a change in dew<strong>at</strong>erability (ATV,<br />

2001). In most cases a higher polymer demand for an optimal dew<strong>at</strong>ering could be observed. The<br />

increased degree <strong>of</strong> degrad<strong>at</strong>ion also effects the process w<strong>at</strong>er after dew<strong>at</strong>ering, which shows a high<br />

concentr<strong>at</strong>ion <strong>of</strong> ammonia-nitrogen.<br />

In order to verify the above mentioned results full-<strong>scale</strong> investig<strong>at</strong>ions are necessary. This paper<br />

will show results <strong>of</strong> investig<strong>at</strong>ions <strong>at</strong> a municipal WWTP loc<strong>at</strong>ed in Schermbeck (Lippeverband,<br />

Germany) comparing different disintegr<strong>at</strong>ion aggreg<strong>at</strong>es and methods. The applic<strong>at</strong>ion <strong>of</strong> two<br />

different stirred ball mills (disk mill system, annular chamber mill system), a chemical<br />

disintegr<strong>at</strong>ion by partial oxid<strong>at</strong>ion with ozone, a lys<strong>at</strong>e centrifuge and an ultrasonic homogeniser<br />

were investig<strong>at</strong>ed.<br />

572

METHODS AND MATERIAL<br />

<strong>Disintegr<strong>at</strong>ion</strong> <strong>at</strong> Schermbeck WWTP<br />

Schermbeck WWTP is an activ<strong>at</strong>ed sludge plant with a capacity <strong>of</strong> 17,000 PE. The waste w<strong>at</strong>er<br />

tre<strong>at</strong>ment consists <strong>of</strong> primary settling followed by biological nitrogen and phosphorous removal.<br />

The excess sludge is thickened in a gravity thickener to 25 g/l suspended solids (vol<strong>at</strong>ile suspended<br />

solids: 17 g/l) before being digested together with the primary sludge in two mesophilic digesters<br />

with a retention time <strong>of</strong> 17-18 days. Daily flow <strong>of</strong> excess sludge varies from 12 to 30 m 3 /d. Flow <strong>of</strong><br />

primary sludge is about 6 to 10 m 3 /d with an average concentr<strong>at</strong>ion <strong>of</strong> suspended solids <strong>of</strong> 27 g/l<br />

(vol<strong>at</strong>ile suspended solids: 20 g/l). <strong>Disintegr<strong>at</strong>ion</strong> <strong>of</strong> excess sludge takes place in the influent <strong>of</strong> one<br />

digester. Up to now, there have not been enough long-term experiences about the disintegr<strong>at</strong>ion <strong>of</strong><br />

sewage sludge. Due to th<strong>at</strong> fact, the disintegr<strong>at</strong>ion aggreg<strong>at</strong>es with the exception <strong>of</strong> the ultrasonic<br />

homogeniser only worked for five days a week. To ensure a continuous effluent from the gravity<br />

thickener as well as a continuous influent in the digester, two storage tanks were installed in front<br />

<strong>of</strong> and behind the disintegr<strong>at</strong>ion aggreg<strong>at</strong>e.<br />

<strong>Methods</strong> <strong>of</strong> Sludge <strong>Disintegr<strong>at</strong>ion</strong><br />

Stirred Ball Mills consists <strong>of</strong> a cylindrical grinding chamber which is almost completely filled with<br />

grinding beads. A rotor forces the beads into a rot<strong>at</strong>ional movement. The micro-organisms are<br />

disintegr<strong>at</strong>ed between the beads by shear and pressure forces. For a continuous oper<strong>at</strong>ion the beads<br />

are held back by centrifugal forces and an additional sieve. This kind <strong>of</strong> mill is called disk mill<br />

system and was investig<strong>at</strong>ed in Schermbeck (Type LME 50 K, Netzsch Feinmahltechnik GmbH).<br />

The motor r<strong>at</strong>ing was 37 kW. Circumferential speed <strong>of</strong> the rotor was set <strong>at</strong> 15 m/sec. The grinding<br />

chamber kept a volume <strong>of</strong> 52.8 l. About 85 % <strong>of</strong> the grinding chamber were filled with grinding<br />

beads, which were <strong>of</strong> a different m<strong>at</strong>erial and diameter (SAZ-balls/600-800 µm and zirkonsand/150-250<br />

µm).<br />

For the annular chamber mill the grinding chamber is made up <strong>of</strong> two double cylinders.<br />

Separ<strong>at</strong>ion <strong>of</strong> the grinding beads is achieved by centrifugal forces alone. A stirred ball mill from the<br />

company Draiswerke (Type Cosmo 25), also investig<strong>at</strong>ed in Schermbeck, makes use <strong>of</strong> this method.<br />

The motor r<strong>at</strong>ing was 30 kW. The grinding chamber was smaller and kept a volume <strong>of</strong> about 8.5 l.<br />

Circumferential speed <strong>of</strong> the rotor was set <strong>at</strong> 22 m/sec.<br />

Chemical <strong>Disintegr<strong>at</strong>ion</strong> with Ozone: Due to ozone tre<strong>at</strong>ment cell walls <strong>of</strong> micro-organisms are<br />

disintegr<strong>at</strong>ed and inner cell products can be released. In addition ozone reacts with organic<br />

compounds th<strong>at</strong> are less biodegradable, oxidising them to smaller compounds which are bioavailable.<br />

In Schermbeck a plant for ozone tre<strong>at</strong>ment was made available from the company<br />

Wedeco. It consisted <strong>of</strong> a storage tank for oxygen, an ozone gener<strong>at</strong>or (maximum power r<strong>at</strong>ing<br />

7.5 kW), and a reaction tank <strong>of</strong> 6 m 3 volume. A maximum ozone load <strong>of</strong> 1 kg O3/h could be<br />

gener<strong>at</strong>ed. Ozone was inserted by an injector in the reaction tank bypass.<br />

The Lys<strong>at</strong>e-Centrifugal-Technique uses a thickening centrifuge equipped with a disintegr<strong>at</strong>ion<br />

device loc<strong>at</strong>ed <strong>at</strong> the discharge <strong>of</strong> the thickened sludge. Tools on the rotor and the st<strong>at</strong>or stress the<br />

sludge by shear-forces. Additional energy needed for the disintegr<strong>at</strong>ion is low. But this results in a<br />

very low degree <strong>of</strong> disintegr<strong>at</strong>ion. A lys<strong>at</strong>e centrifuge from the company Hiller (Type<br />

DECATHICK DT31-422) was investig<strong>at</strong>ed for four months. Motor r<strong>at</strong>ing was 15 kW. The number<br />

<strong>of</strong> revolutions <strong>of</strong> the drum was 8500 per minute with a maximum flow <strong>of</strong> 10 m 3 /h. During the<br />

research project only the effect <strong>of</strong> disintegr<strong>at</strong>ion and not the effect <strong>of</strong> thickening sludge were to be<br />

investig<strong>at</strong>ed. For this reason the thickened sludge was diluted again with centr<strong>at</strong>e w<strong>at</strong>er. This was<br />

the only possibility for comparing the two digesters with similar hydraulic retention times.<br />

Ultrasonic Homogenisers consist <strong>of</strong> three major components. A gener<strong>at</strong>or supplies a highfrequent<br />

voltage. A ceramic-crystal <strong>of</strong> piezo-electrical m<strong>at</strong>erial transforms electrical into<br />

mechanical impulses, which are transmitted by a sonotrode into the fluid. Cavit<strong>at</strong>ion bubbles are<br />

cre<strong>at</strong>ed by altern<strong>at</strong>ing overpressure and underpressure (Müller, 2000). The following implosion <strong>of</strong><br />

the gas and vapour-filled bubbles leads to high mechanical shear-forces which are apt to<br />

573

disintegr<strong>at</strong>e bacterial cell m<strong>at</strong>erial (Neis et al., 1999). During this research project an ultrasonic<br />

homogeniser from the company Sonotronic was applied. It consisted <strong>of</strong> five sonotrodes (frequency<br />

25 kHz) with a total power r<strong>at</strong>ing <strong>of</strong> 5 kW. Volume <strong>of</strong> the loop-reactor was about 30 l. Only a<br />

partial flow <strong>of</strong> the excess sludge was tre<strong>at</strong>ed by ultrasound. It was assumed in earlier investig<strong>at</strong>ions<br />

(Friedrich, 2000) th<strong>at</strong> even with a low energy input an activ<strong>at</strong>ion <strong>of</strong> the bacteria could be achieved.<br />

These results were to be verified during this research project.<br />

Programme <strong>of</strong> Investig<strong>at</strong>ion<br />

At first pre-investig<strong>at</strong>ions were carried out to find optimal oper<strong>at</strong>ing conditions for the stirred ball<br />

mills. Different parameters were varied such as sludge flow (450 – 1300 l/h), concentr<strong>at</strong>ion <strong>of</strong><br />

suspended solids (5 – 25 g/l SS) and bead diameter (150-250 µm, 600-800µm). The plant for ozone<br />

tre<strong>at</strong>ment initially ran in b<strong>at</strong>ch oper<strong>at</strong>ion with an increasing ozone dose up to 0.06 g O3/g SS. The<br />

sludge flow <strong>of</strong> the lys<strong>at</strong>e centrifuge varied between 2.4 and 4.3 m 3 /h when the centrifuge was in<br />

continuous oper<strong>at</strong>ion. Investig<strong>at</strong>ing the ultrasonic homogeniser, sludge flow was varied between 50<br />

and 450 l/h. The results <strong>of</strong> the disintegr<strong>at</strong>ion were quantified by the degree <strong>of</strong> disintegr<strong>at</strong>ion. This<br />

parameter is determined by the r<strong>at</strong>e <strong>of</strong> oxygen demand (DDO) and the COD release (DDCOD). Both<br />

methods are described elsewhere. (Müller, 2000).<br />

After finishing pre-investig<strong>at</strong>ions each aggreg<strong>at</strong>e ran for 2-4 months. To quantify the influence<br />

<strong>of</strong> disintegr<strong>at</strong>ion on anaerobic digestion the specific gas production rel<strong>at</strong>ed to the input <strong>of</strong> organic<br />

m<strong>at</strong>ter and the degree <strong>of</strong> degrad<strong>at</strong>ion <strong>of</strong> the organic m<strong>at</strong>ter were determined. For th<strong>at</strong> reason the<br />

concentr<strong>at</strong>ion <strong>of</strong> vol<strong>at</strong>ile suspended solids VSS was analysed daily in the influent and effluent <strong>of</strong><br />

both digesters. The influent flow <strong>of</strong> raw sludge was recorded as well as the flow <strong>of</strong> biogas.<br />

<strong>Disintegr<strong>at</strong>ion</strong> <strong>of</strong> sewage sludge has a strong influence on conditioning and dew<strong>at</strong>ering<br />

characteristics even after digestion (Kopp and Dichtl, 1998). To characterise this effect, the specific<br />

resistance to filtr<strong>at</strong>ion, the capillary suction time and the polymer demand for an optimum<br />

dew<strong>at</strong>ering were estim<strong>at</strong>ed in lab-<strong>scale</strong> investig<strong>at</strong>ions. Furthermore a prediction <strong>of</strong> full-<strong>scale</strong><br />

dew<strong>at</strong>ering results by thermo-gravimetric determin<strong>at</strong>ion <strong>of</strong> the w<strong>at</strong>er distribution <strong>of</strong> sludge was<br />

possible. The applied method is described elsewhere (Kopp and Dichtl, 2001). In addition the<br />

sludge was dew<strong>at</strong>ered in a pilot filter press. To quantify the pollution level <strong>of</strong> process w<strong>at</strong>er after<br />

dew<strong>at</strong>ering, concentr<strong>at</strong>ions <strong>of</strong> COD and ammonia-nitrogen were analysed.<br />

Results and Discussion<br />

Energy consumption<br />

During the oper<strong>at</strong>ion <strong>of</strong> both stirred ball mills, the degree <strong>of</strong> disintegr<strong>at</strong>ion was estim<strong>at</strong>ed by<br />

measuring the oxygen demand DDO. When applying chemical oxid<strong>at</strong>ion with ozone and lys<strong>at</strong>e<br />

centrifugal technique, calcul<strong>at</strong>ion <strong>of</strong> the degree <strong>of</strong> disintegr<strong>at</strong>ion by measuring the COD (DDCOD)<br />

was the only possible method. Using ozone would have inhibited the bacteria and would have<br />

overlayed the disintegr<strong>at</strong>ion and inactiv<strong>at</strong>ion <strong>of</strong> the bacteria. In case <strong>of</strong> applying lys<strong>at</strong>e centrifuge,<br />

very low and <strong>of</strong>ten neg<strong>at</strong>ive values were determined when measuring the DDO. This could be an<br />

indic<strong>at</strong>ion for an activ<strong>at</strong>ion <strong>of</strong> the bacteria.<br />

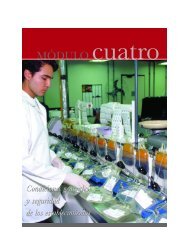

The different disintegr<strong>at</strong>ion methods can be compared using the degree <strong>of</strong> disintegr<strong>at</strong>ion in<br />

rel<strong>at</strong>ion to the specific energy which is shown in the figure below. The specific energy is defined as<br />

the energy input rel<strong>at</strong>ed to the tre<strong>at</strong>ed solid mass.<br />

574

degree <strong>of</strong> disintegr<strong>at</strong>ion DD COD [%]<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

(DD cod) oxid<strong>at</strong>ion with ozone, including energy for oxygene<br />

(DD cod) ultrasonic homogeniser<br />

(DD cod) lys<strong>at</strong>e centrifuge<br />

(DD o) disk mill sytem, bead diameter: 600-800 µm<br />

(DD o) disk mill system, bead diameter: 150-250 µm<br />

(DD o) annular chamber mill system<br />

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0<br />

specific energy [kWh/kg TS]<br />

Figure 1 <strong>Comparison</strong> <strong>of</strong> different disintegr<strong>at</strong>ion methods by energy consumption<br />

The annular chamber mill reaches a medium degree <strong>of</strong> disintegr<strong>at</strong>ion <strong>at</strong> a rel<strong>at</strong>ively low energy<br />

demand. The disk mill uses a higher energy input, due to th<strong>at</strong>, a higher degree <strong>of</strong> disintegr<strong>at</strong>ion can<br />

be achieved. Using grinding beads with smaller diameters improves efficiency. With chemical<br />

oxid<strong>at</strong>ion a high degree <strong>of</strong> disintegr<strong>at</strong>ion can be achieved, but additional energy for the production<br />

<strong>of</strong> pure oxygen, necessary for gener<strong>at</strong>ing the ozone, is needed. This has already been considered in<br />

the figure above. Energy input <strong>of</strong> an ultrasonic homogeniser is less effective than the other<br />

aggreg<strong>at</strong>es. With lys<strong>at</strong>e centrifugal technique an average degree <strong>of</strong> disintegr<strong>at</strong>ion <strong>of</strong> 10 % DDCOD<br />

could be achieved. During long-term investig<strong>at</strong>ions with the stirred ball mills an average degree <strong>of</strong><br />

disintegr<strong>at</strong>ion <strong>of</strong> about 25 % DDO (annular chamber mill) and 60 % DDO (disk mill) was obtained.<br />

Tre<strong>at</strong>ment with ozone resulted in 30 % DDCOD mean value. Mean value 17 % DDCOD was achieved<br />

with the ultrasonic homogeniser.<br />

Oper<strong>at</strong>ional behaviour<br />

Clogging by coarse or fibrous particles was not a problem for any <strong>of</strong> the aggreg<strong>at</strong>es. A mechanical<br />

pre-tre<strong>at</strong>ment was not necessary. No abnormal wear <strong>at</strong> the aggreg<strong>at</strong>es was observed. Only a high<br />

loss <strong>of</strong> grinding beads because <strong>of</strong> wear (disk mill) and the sudden shutdown <strong>of</strong> the mill (annular<br />

chamber mill) occurred. The ozone plant was more difficult to handle because <strong>of</strong> foaming problems<br />

and had several breakdowns. The ultrasonic homogeniser had <strong>at</strong> first problems with he<strong>at</strong>. The<br />

sludge flow was not high enough for cooling the sonotrodes. This resulted in several break downs<br />

<strong>of</strong> the sonotrodes. Since an extern cooling system was installed no further problems occurred.<br />

Anaerobic tre<strong>at</strong>ment<br />

When applying the different disintegr<strong>at</strong>ion aggreg<strong>at</strong>es, an increase <strong>of</strong> the anaerobic biodegradability<br />

could be observed in all cases. This effect varied depending on the degree <strong>of</strong> disintegr<strong>at</strong>ion. The<br />

following table shows the degree <strong>of</strong> degrad<strong>at</strong>ion <strong>of</strong> both digesters, one fed with disintegr<strong>at</strong>ed excess<br />

sludge and one fed with untre<strong>at</strong>ed sludge.<br />

An evident increase <strong>of</strong> the degree <strong>of</strong> degrad<strong>at</strong>ion could be achieved using a stirred ball mill and<br />

chemical disintegr<strong>at</strong>ion with ozone. A lesser effect was observed with lys<strong>at</strong>e centrifuge and<br />

100<br />

75<br />

50<br />

25<br />

0<br />

degree <strong>of</strong> disintegr<strong>at</strong>ion DD O [%]<br />

575

ultrasonic homogenizer. Both aggreg<strong>at</strong>es achieved a lower degree <strong>of</strong> disintegr<strong>at</strong>ion and hence a low<br />

increase in the degree <strong>of</strong> degrad<strong>at</strong>ion.<br />

Table 1 Influence <strong>of</strong> disintegr<strong>at</strong>ion on the degree <strong>of</strong> degrad<strong>at</strong>ion<br />

disintegr<strong>at</strong>ion aggreg<strong>at</strong>e /<br />

method<br />

stirred ball mill<br />

(total flow disintegr<strong>at</strong>ion)<br />

chemical disintegr<strong>at</strong>ion with<br />

ozone<br />

(total flow disintegr<strong>at</strong>ion)<br />

lys<strong>at</strong>e centrifugal technique<br />

(total flow disintegr<strong>at</strong>ion)<br />

ultrasonic homogeniser<br />

(partial flow disintegr<strong>at</strong>ion)<br />

degree <strong>of</strong><br />

degrad<strong>at</strong>ion<br />

with untre<strong>at</strong>ed<br />

sludge<br />

[%]<br />

degree <strong>of</strong> degrad<strong>at</strong>ion<br />

with disintegr<strong>at</strong>ed<br />

sludge<br />

[%]<br />

rel<strong>at</strong>ive<br />

increase<br />

[%]<br />

44.0 55.8 26<br />

46.6 55.5 19<br />

44.0 47.9 8.8<br />

48.8 52.4 7.4<br />

Dew<strong>at</strong>ering and conditioning<br />

As a consequence <strong>of</strong> disintegr<strong>at</strong>ion the fraction <strong>of</strong> small particles increases. Due to th<strong>at</strong>, capillary<br />

suction time and specific resistance to filtr<strong>at</strong>ion deterior<strong>at</strong>e. Parameters, such as the polymer<br />

demand and the solid content in the sludge cake after dew<strong>at</strong>ering, which directly influence costs for<br />

dew<strong>at</strong>ering and disposal, are <strong>of</strong> a gre<strong>at</strong>er interest.<br />

Table 2 Influence <strong>of</strong> disintegr<strong>at</strong>ion on the polymer demand and the solid content after dew<strong>at</strong>ering<br />

disintegr<strong>at</strong>ion aggreg<strong>at</strong>e /<br />

method<br />

stirred ball mill<br />

(total flow disintegr<strong>at</strong>ion)<br />

chemical disintegr<strong>at</strong>ion with<br />

ozone<br />

(total flow disintegr<strong>at</strong>ion)<br />

lys<strong>at</strong>e centrifugal technique<br />

(total flow disintegr<strong>at</strong>ion)<br />

ultrasonic homogeniser<br />

(partial flow disintegr<strong>at</strong>ion)<br />

rel<strong>at</strong>ive change<br />

<strong>of</strong> polymer demand<br />

[%]<br />

change <strong>of</strong> dew<strong>at</strong>ering result [% TS]<br />

thermogravimetric<br />

measurement<br />

pilot chamber<br />

filter press<br />

+7.4 +0.2 -2.9<br />

+31 -1.4 -2.7<br />

+5.2 -0.7 -2.3<br />

+8.7 +0.6 -0.7<br />

Table 2 shows th<strong>at</strong> the polymer demand increased slightly due to disintegr<strong>at</strong>ion. Only disintegr<strong>at</strong>ion<br />

with ozone leads to an evident increase <strong>of</strong> polymer demand <strong>of</strong> about 31 %. With thermo-gravimetric<br />

measurements hardly any difference in the full dew<strong>at</strong>ering results was predicted, while dew<strong>at</strong>ering<br />

with a pilot chamber filter press resulted in a lower solid content in the sludge cake. Only<br />

disintegr<strong>at</strong>ion with the ultrasonic homogeniser did not influence the dew<strong>at</strong>ering result.<br />

576

The pollution level <strong>of</strong> process w<strong>at</strong>er after dew<strong>at</strong>ering corrobor<strong>at</strong>ed the results <strong>of</strong> the anaerobic<br />

degrad<strong>at</strong>ion. TKN in the process w<strong>at</strong>er consisted mainly <strong>of</strong> ammonia-nitrogen, which is, among<br />

other substances, a product <strong>of</strong> protein degrad<strong>at</strong>ion. Because <strong>of</strong> disintegr<strong>at</strong>ion the concentr<strong>at</strong>ion <strong>of</strong><br />

ammonia-nitrogen increased, corresponding to the improved degrad<strong>at</strong>ion <strong>of</strong> organic m<strong>at</strong>ter. During<br />

the period <strong>of</strong> investig<strong>at</strong>ion, ammonia concentr<strong>at</strong>ion increased by about 10 % (stirred ball mill),<br />

17 % (oxid<strong>at</strong>ion with ozone), 10 % (lys<strong>at</strong>e centrifuge) and 5 % (ultrasonic homogeniser).<br />

Furthermore COD increased about 2 % (ultrasonic homogeniser), 5 % (lys<strong>at</strong>e centrifuge), 17 %<br />

(stirred ball mill) and 52 % (oxid<strong>at</strong>ion with ozone) due to the solubilis<strong>at</strong>ion by disintegr<strong>at</strong>ion and<br />

only partial degrad<strong>at</strong>ion in the digester.<br />

Economic efficiency<br />

Costs for disintegr<strong>at</strong>ion were estim<strong>at</strong>ed for a model wastew<strong>at</strong>er tre<strong>at</strong>ment plant <strong>of</strong> 100.000 PE. On<br />

one hand capital costs for the aggreg<strong>at</strong>es including storage tanks, pumps, measurement and control<br />

systems have to be covered as well as energy costs for disintegr<strong>at</strong>ion. This makes up the main part<br />

<strong>of</strong> costs, furthermore costs for manpower, maintenance. Costs for the higher polymer demand and<br />

cost for additional aer<strong>at</strong>ion resulted from the higher pollution level <strong>of</strong> sludge process w<strong>at</strong>er are<br />

negligible.<br />

On the other hand pr<strong>of</strong>it <strong>of</strong> thermal and electrical energy is possible due to the higher gas<br />

production resulting from disintegr<strong>at</strong>ion. But the main part <strong>of</strong> pr<strong>of</strong>it is made by minimising<br />

disposal costs because <strong>of</strong> a decreased amount <strong>of</strong> sludge resulting from the higher degree <strong>of</strong><br />

degrad<strong>at</strong>ion. Costs for disposal include transport and dew<strong>at</strong>ering. Figure 2 shows the different<br />

annual costs as well as the pr<strong>of</strong>it due to disintegr<strong>at</strong>ion.<br />

annual costs and pr<strong>of</strong>it from disintegr<strong>at</strong>ion [€/a]<br />

250,000<br />

200,000<br />

150,000<br />

100,000<br />

50,000<br />

0<br />

-50,000<br />

-100,000<br />

-150,000<br />

-200,000<br />

-250,000<br />

-300,000<br />

stirred ball mill oxid<strong>at</strong>ion with ozone lys<strong>at</strong>e centrifuge<br />

38,420<br />

38,836<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

102,048<br />

<br />

<br />

-83,087<br />

<br />

<br />

-99,090<br />

<br />

<br />

-36,327<br />

<br />

<br />

<br />

29,363<br />

29,681<br />

77,991<br />

<br />

<br />

<br />

-44,505<br />

<br />

<br />

-77,722<br />

<br />

<br />

<br />

<br />

<br />

-112,311<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

12,665 11,771<br />

12,802 11,899<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

ultrasonic<br />

homogeniser<br />

total flow disintegr<strong>at</strong>ion total flow disintegr<strong>at</strong>ion total flow disintegr<strong>at</strong>ion partial flow disintegr<strong>at</strong>ion<br />

pr<strong>of</strong>it from electric energy<br />

pr<strong>of</strong>it from thermal energy<br />

minimis<strong>at</strong>ion <strong>of</strong> disposal costs<br />

capital costs<br />

<br />

33,541 31,266<br />

energy for<br />

disintegr<strong>at</strong>ion<br />

oxygen<br />

maintenance<br />

manpower<br />

polymere<br />

energy for aer<strong>at</strong>ion<br />

<br />

<br />

<br />

-60,968<br />

-29,572<br />

<br />

<br />

<br />

-28,000<br />

<br />

<br />

<br />

<br />

<br />

Figure 2 <strong>Comparison</strong> <strong>of</strong> costs and pr<strong>of</strong>it due to disintegr<strong>at</strong>ion with specific disposal costs about 400 Euro<br />

per Mg digested sludge<br />

577

Annual costs for disintegr<strong>at</strong>ion are high, especially for the stirred ball mill and oxid<strong>at</strong>ion with<br />

ozone. In case <strong>of</strong> applying chemical oxid<strong>at</strong>ion with ozone, additional costs for the oxygen necessary<br />

for gener<strong>at</strong>ing the ozone had to be taken into account. When only a partial flow <strong>of</strong> the excess sludge<br />

is disintegr<strong>at</strong>ed, costs decrease . This is evident for the applic<strong>at</strong>ion <strong>of</strong> the ultrasonic homogeniser. In<br />

case <strong>of</strong> the applic<strong>at</strong>ion <strong>of</strong> a lys<strong>at</strong>e centrifuge, capital costs are low when a conventional centrifuge is<br />

already installed. Due to this, costs result only from upgrading with the lys<strong>at</strong>e equipment.<br />

Additional energy resulting from the use <strong>of</strong> the lys<strong>at</strong>e equipment depends on the dimension <strong>of</strong> the<br />

centrifuge and makes up <strong>at</strong> maximum 30 % <strong>of</strong> the energy needed for the oper<strong>at</strong>ion <strong>of</strong> a conventional<br />

centrifuge.<br />

Most pr<strong>of</strong>it can be achieved applying a stirred ball mill and oxid<strong>at</strong>ion with ozone. In dependence<br />

<strong>of</strong> the enhancement <strong>of</strong> the anaerobic biodegradability pr<strong>of</strong>it becomes lower when applying an<br />

ultrasonic homogeniser or a lys<strong>at</strong>e centrifuge. When calcul<strong>at</strong>ing the pr<strong>of</strong>it from disintegr<strong>at</strong>ion, it has<br />

to be taken into account th<strong>at</strong> pr<strong>of</strong>it made from the minimis<strong>at</strong>ion <strong>of</strong> disposal costs is influenced by<br />

the specific costs for disposal depending on the way <strong>of</strong> disposal. In this case specific costs <strong>of</strong> about<br />

400 Euro per Mg dry mass <strong>of</strong> digested sludge were calcul<strong>at</strong>ed. Under this circumstances pr<strong>of</strong>it is<br />

lower than costs for the stirred ball mill, oxid<strong>at</strong>ion with ozone and ultrasonic homogenisers. A<br />

break-even-point can be achieved if specific costs for disposal are about 625 Euro (stirred ball mill),<br />

1,087 Euro (oxid<strong>at</strong>ion with ozone) or 1,350 Euro per Mg dry mass <strong>of</strong> digested sludge.<br />

The economic efficiency <strong>of</strong> a disintegr<strong>at</strong>ion prior to anaerobic digestion is mainly influenced by<br />

three factors:<br />

• The achieved improvement <strong>of</strong> the anaerobic degrad<strong>at</strong>ion, because this determines the additional<br />

gas production and the reduction <strong>of</strong> the amount <strong>of</strong> sludge to be disposed <strong>of</strong><br />

• The specific disposal costs <strong>of</strong> the sludge, because they determine most <strong>of</strong> the cost savings<br />

• The size <strong>of</strong> the WWTP, because the specific capital costs for the disintegr<strong>at</strong>ion devices are<br />

reduced with increasing size <strong>of</strong> the WWTP.<br />

By varying these factors, it is possible to calcul<strong>at</strong>e the break-even-point for individual<br />

circumstances. In Figure 4 such a calcul<strong>at</strong>ion based on the results obtained in this research work is<br />

shown. A vol<strong>at</strong>ile solids reduction <strong>of</strong> 45 % was assumed for the conventional anaerobic process and<br />

an energy consumption <strong>of</strong> 0.5 kWh/kg TS needed for disintegr<strong>at</strong>ion. Because the capital costs for<br />

all disintegr<strong>at</strong>ion methods are in the same order <strong>of</strong> magnitude Figure 3 is independent <strong>of</strong> the method<br />

th<strong>at</strong> is used.<br />

Vol<strong>at</strong>ile Solids Reduction [%]<br />

75<br />

70<br />

65<br />

60<br />

55<br />

50<br />

1000<br />

45<br />

0<br />

0 25 50 75 100 125 150 175 200<br />

750<br />

600<br />

Specific disposal costs<br />

[Euro / Mg TS]<br />

450<br />

300<br />

200<br />

150<br />

Size <strong>of</strong> Wastew<strong>at</strong>er Tre<strong>at</strong>ment Plant [1000 * m 3 /d]<br />

Figure 3 Break even point for the applic<strong>at</strong>ion <strong>of</strong> disintegr<strong>at</strong>ion prior to anaerobic digestion<br />

100<br />

66<br />

55<br />

44<br />

33<br />

22<br />

11<br />

Increase in Vol<strong>at</strong>ile Solids Reduction [%]<br />

578

Using these curves, the cost efficiency can be estim<strong>at</strong>ed. If for example a WWTP with an influent<br />

flow <strong>of</strong> 50,000 m³/d and specific disposal costs <strong>of</strong> 300 Euro/Mg can achieve an increase in the<br />

vol<strong>at</strong>ile solids reduction <strong>of</strong> more than 30 % (from 45 to more than 58.5 %), the install<strong>at</strong>ion <strong>of</strong> a<br />

disintegr<strong>at</strong>ion device on the plant will save costs.<br />

In this investig<strong>at</strong>ion the best results were obtained using the stirred ball mill (see Figure 2),<br />

although cost efficiency was not achieved on the basis <strong>of</strong> the model WWTP <strong>of</strong> 100,000 PE (20,000<br />

m³/d). With an increase in vol<strong>at</strong>ile solids reduction <strong>of</strong> 26 % and specific disposal costs <strong>of</strong> 400<br />

Euro/Mg TS it can be derived from Figure 3 th<strong>at</strong> cost efficiency can be reached for WWTP <strong>of</strong> more<br />

than 50,000 m³/d tre<strong>at</strong>ment capacity.<br />

Conclusions<br />

<strong>Disintegr<strong>at</strong>ion</strong> <strong>of</strong> excess sludge is a possible pre-tre<strong>at</strong>ment to optimise anaerobic digestion. This has<br />

been shown already in various half-<strong>scale</strong> and lab-<strong>scale</strong> investig<strong>at</strong>ions. To valid<strong>at</strong>e these results two<br />

stirred ball mills, oxid<strong>at</strong>ion with ozone, a lys<strong>at</strong>e centrifuge and an ultrasonic homogeniser were<br />

investig<strong>at</strong>ed <strong>at</strong> a full-<strong>scale</strong> plant in Schermbeck.<br />

In continuous oper<strong>at</strong>ion a constant quality <strong>of</strong> disintegr<strong>at</strong>ed sludge could be produced with all<br />

aggreg<strong>at</strong>es. A positive influence <strong>of</strong> disintegr<strong>at</strong>ion on the anaerobic biodegradability could be<br />

established. The enhancement <strong>of</strong> the degree <strong>of</strong> degrad<strong>at</strong>ion varied between 7.4 % and 26 %.<br />

Labor<strong>at</strong>ory investig<strong>at</strong>ions valid<strong>at</strong>ed th<strong>at</strong> disintegr<strong>at</strong>ion increases the polymer demand and leads to a<br />

lower solid content after dew<strong>at</strong>ering. Higher ammonia concentr<strong>at</strong>ions in the process w<strong>at</strong>er after<br />

dew<strong>at</strong>ering corrobor<strong>at</strong>ed the results <strong>of</strong> the anaerobic degrad<strong>at</strong>ion.<br />

A balance <strong>of</strong> costs and pr<strong>of</strong>it from disintegr<strong>at</strong>ion was estim<strong>at</strong>ed. The main part <strong>of</strong> pr<strong>of</strong>it is made<br />

up from the minimis<strong>at</strong>ion <strong>of</strong> disposal costs because <strong>of</strong> a decreased amount <strong>of</strong> sludge resulting from<br />

the higher degree <strong>of</strong> degrad<strong>at</strong>ion. The economic efficiency <strong>of</strong> a disintegr<strong>at</strong>ion is mainly influenced<br />

by the achieved improvement <strong>of</strong> the anaerobic degrad<strong>at</strong>ion, the specific disposal costs <strong>of</strong> the sludge<br />

and the size <strong>of</strong> the WWTP. If the development <strong>of</strong> costs and the current discussion about sludge<br />

disposal is taken into account, sewage sludge disintegr<strong>at</strong>ion can be a suitable technique for<br />

minimising costs <strong>at</strong> waste w<strong>at</strong>er tre<strong>at</strong>ment plants.<br />

Acknowledgements<br />

The research project is a cooper<strong>at</strong>ion project funded by the BMBF (Ministry for Research and<br />

Educ<strong>at</strong>ion) within the four cooper<strong>at</strong>ion partners Emschergenossenschaft/Lipperverband, Institute <strong>of</strong><br />

Sanitary and Environmental Engineering from the Technical University <strong>of</strong> Braunschweig, the<br />

Emschergesellschaft für Wassertechnik and the company Aw<strong>at</strong>ech. We would also like to thank the<br />

companies Netzsch Feinmahltechnik, Draiswerke, Wedeco, Hiller and Sonotronic for making their<br />

aggreg<strong>at</strong>es and manpower available.<br />

References<br />

ATV Arbeitsgruppe 3.1.6 (2000). Verfahren und Anwendungsgebiete der mechanischen Klärschlammdesintegr<strong>at</strong>ion,<br />

Teil 1 des Arbeitsberichts, Korrespondenz Abwasser 4/2000, pp. 571-576<br />

ATV Arbeitsgruppe 3.1.6 (2001). Verfahrensvergleich und Ergebnisse der mechanischen Klärschlammdesintegr<strong>at</strong>ion,<br />

Teil 2 des Arbeitsberichts, Korrespondenz Abwasser 3/2001, pp. 393-400<br />

Friedrich, H. (2000). Schlamm im Schall – voll desintegriert, Umweltmagazin Nov./Dez. 2000, pp. 57-58<br />

Kopp J. and Dichtl N. (1998). Influence <strong>of</strong> Surface Charge and Exopolysaccharids on the Conditioning Characteristics<br />

<strong>of</strong> Sewage Sludge. In: Chemical W<strong>at</strong>er and Wastew<strong>at</strong>er Tre<strong>at</strong>ment. Hahn H., H<strong>of</strong>fmann E. and H. ∅degaard (ed),<br />

Springer-Verlag, Berlin Heidelberg, New York, pp. 285-296<br />

Kopp J. and Dichtl. N. (2001). Influence <strong>of</strong> the free w<strong>at</strong>er content on the dew<strong>at</strong>erability <strong>of</strong> sewage sludge. In: Sludge<br />

Management Entering the 3 rd Millennium – Industrial, Combined, W<strong>at</strong>er and Wastew<strong>at</strong>er Residues, Taipei Taiwan, pp.<br />

270-275<br />

Müller J. (2000). Sludge management for the 21 st century: <strong>Disintegr<strong>at</strong>ion</strong> as a key-step in sewage sludge tre<strong>at</strong>ment. W<strong>at</strong>.<br />

Sci. Techn., 41(8), pp. 123-130<br />

Neis U., Nickel K. and Thiem A. (1999). Enhancement <strong>of</strong> anaerobic sludge digestion by Ultrasonic <strong>Disintegr<strong>at</strong>ion</strong>. In:<br />

Disposal and Utilis<strong>at</strong>ion <strong>of</strong> Sewage sludge - Tre<strong>at</strong>ment <strong>Methods</strong> and Applic<strong>at</strong>ion Modalities, Athen, pp.129-136<br />

579