THE FLYING LADY - Rolls-Royce Owners' Club

THE FLYING LADY - Rolls-Royce Owners' Club

THE FLYING LADY - Rolls-Royce Owners' Club

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

291<br />

<strong>THE</strong> <strong>FLYING</strong> <strong>LADY</strong><br />

No. 57-4<br />

AUGUST, 1957<br />

JOHN W. MCFARLANE, Editor<br />

Huntington Hills, Wisner Road, Rochester 9. New York, U.S.A.<br />

JOIIN R. UTZ, Associate Editor<br />

140 Avon Road. Rochester 10, New York. U.S.A.<br />

MISS MARY WINKELJOHN, Circulation Manager<br />

Standard Printing Co., Celina. Ohio, U.S.A.<br />

<strong>THE</strong> PERIODICAL OF <strong>THE</strong> ROLLS-ROYCE OWNERS' CLUB, INC.<br />

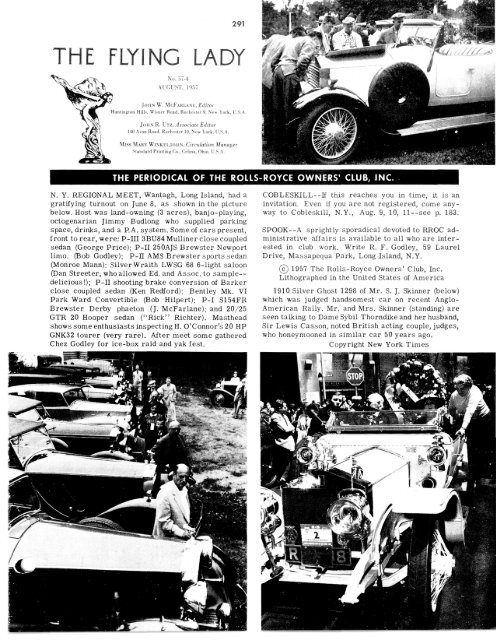

N. Y. REGIONAL MEET, Wantagh, Long Island, had a<br />

gratifying turnout on June 8, as shown in the picture<br />

below. Host was land-owning (3 acres), banjo-playing,<br />

octogenarian Jimmy Budlong who supplied parking<br />

space, drinks, and a P.A. system. Some of cars present,<br />

front to rear, were: P-III 3BU84 Mulliner close coupled<br />

sedan (George Price); P-II 250AJS Brewster Newport<br />

limo. (Bob Godley); P-II AMS Brewster sports sedan<br />

(Monroe Mann); Silver Wraith LWSG 68 6-light saloon<br />

(Dan Streeter, who allowed Ed. and Assoc. to sample-delicious!);<br />

P-II shooting brake conversion of Barker<br />

close coupled sedan (Ken Redford); Bentley Mk. VI<br />

Park Ward Convertible (Bob Hilpert); P-I S154FR<br />

Brewster Derby phaeton (J. McFarlane); and 20/25<br />

GTR 20 Hooper sedan ("Rick" Richter). Masthead<br />

shows some enthusiasts inspecting H. O'Connor's 20 HP<br />

GNK32 tourer (very rare). After meet some gathered<br />

Chez Godley for ice-box raid and yak fest.<br />

COBLESKILL--H this reaches you in time, it is an<br />

invitation. Even if you are not registered, come anyway<br />

to Cobleskill, N.Y., Aug. 9, 10, ll--see p. 183.<br />

SPOOK--A sprightly sporadical devoted to RROC administrative<br />

affairs is available to all who are interested<br />

in club work. Write R. F. Godley, 59 Laurel<br />

Drive, Massapequa Park, Long Island, N.Y.<br />

1957 The <strong>Rolls</strong>-<strong>Royce</strong> <strong>Owners'</strong> <strong>Club</strong>, Inc.<br />

Lithographed in the United States of America<br />

1910 Silver Ghost 1298 of Mr. S. J. Skinner (below)<br />

which was judged handsomest car on recent Anglo-<br />

American Rally. Mr. and Mrs. Skinner (standing) are<br />

seen talking to Dame Sybil Thorndike and her husband,<br />

Sir Lewis Casson, noted British acting couple, judges,<br />

who honeymooned in similar car 50 years ago.<br />

Copyright New York Times

292<br />

MEXICO BY PHANTOM II<br />

by Fred Kelly<br />

Probably the severest service, other than racing<br />

competition, that a passenger auto can undergo is pulling<br />

a heavy house trailer in hot weather over rough,<br />

twisty, mountainous roads. The drag of the trailer<br />

forces the engine to operate under constant load for<br />

long periods; the gears must be used to pull up steep<br />

hills; brakes receive the severest service on the downgrade;<br />

and the weight of the trailer on the rear of the<br />

car overloads tires and wheel bearings as well as<br />

stressing springs to their maximum.<br />

This is the kind of ordeal through which I put my<br />

1930 Phantom II early this year when I towed a 5000pound<br />

house trailer from Scarsdale, N.Y., to Mexico<br />

City, lived in it with my family for three months, then<br />

made the return trip with trailer as far as Hot Springs,<br />

Arkansas and soloed home for a total distance travelled<br />

of 9850 miles.<br />

The P-II is GN151, a right hand drive model which<br />

had 38,000 miles on the speedometer at the start of<br />

the trip. When I acquired the car as a chassis in 1954,<br />

I completely disassembled the engine, thoroughly<br />

cleaned all parts, renewed the top compression ring<br />

of each piston, replaced the slipper flywheel linings<br />

and Hardy flexible coupling, ground the valves, and<br />

added a by-pass Purolator oil filter to the engine oiling<br />

system. Subsequent to the trip a water-heated type<br />

of intake manifold riser was put in place of the exhaust<br />

heated variety which usually scales up and cracks after<br />

a few months' service. A rather odd-appearing body<br />

for the chassis was assembled from surplus Brewster<br />

body sections discovered on the premises of Sam<br />

Adelman.<br />

The car was fitted with 21-inch wheels, ideal for<br />

clearing the obstructions found on Mexican roads, and<br />

five almost new Dunlop tires and reinforced tubes. A<br />

massive trailer hitch was constructed on the rear of<br />

the chassis but no overload springs, ride leveling de-<br />

vices or other trailer hauling accessories were added<br />

except connections for lights and electric brakes. The<br />

ball of the hitch is 45 inches behind the rear axle of<br />

the car.<br />

The trailer is a 22-foot 1948 Travelo having one<br />

axle and electric brakes with an unladen weight of<br />

4200 pounds and an estimated laden weight of 4900<br />

pounds. The trailer is 80 inches wide and stands almost<br />

100 inches off the ground. Obviously the vehicle has<br />

sufficient frontal area to offer considerable wind resistance.<br />

It is not the ideal trailer for long, fast trips.<br />

Top speed of car and trailer on a good level road<br />

was about 65 mph but gas consumption was prohibitive<br />

at such a speed. Most of our level travel was at 45 mph<br />

at which speed we obtained a gas mileage of 7.8 mpg.<br />

In the 3100 miles of roundabout travel from Scarsdale<br />

to Mexico City, most of it in cold weather, we used<br />

six quarts of No. 30 high detergent oil--an almost<br />

miraculous lack of oil consumption for a car operating<br />

under heavy load. Oil pressure never dropped below<br />

22.5 psi even when engine was operating close to the<br />

boiling point. Running at high speed (over 60 mph) on<br />

the return trip from Hot Springs to Scarsdale, a distance<br />

of 1398 miles, without trailer our oil consumption<br />

was a quart for every 280 miles and we made 10.2<br />

miles per gallon of low test gasoline.<br />

Before leaving the United States to cross the border<br />

at Laredo, Texas, we detected an engine "miss" which<br />

was found to be caused by a no-clearance No. 6 exhaust<br />

valve. All valves were readjusted as they had very<br />

little clearance although a liberal setting of .003 inch<br />

had been made before the start of the trip. This condition<br />

recalled to mind the warning I had received<br />

previously that P-I and P-II valves have a tendency to<br />

"tulip" or stretch under hard, hot driving conditions<br />

thus reducing the rocker arm clearance. With readjustment,<br />

however, mine seemed to work satisfactorily<br />

so we set off for the 760-mile trip from the<br />

border to the Mexican capital.<br />

The Pan American Highway has 114 miles of the<br />

twistiest, steepest mountain road of any paved Mexican<br />

highway (a new road has just been opened from Monterey<br />

to Mexico City which by-passes the mountains).<br />

What an opportunity for the mighty <strong>Rolls</strong> to show its<br />

stuff. From a point only 300 feet above sea level, we<br />

climbed to 6500 feet altitude in one 25-mile stretch.<br />

Of course, with the trailer on behind, the <strong>Rolls</strong> could<br />

not make this ascent in high gear—even in third speed<br />

it would reach the boiling point and we would have to<br />

drop to second to obtain enough rpm for water circulation.<br />

(Drivers of American cars pulling trailers in<br />

hot mountainous country employ an evaporative cooling<br />

system in which water in a separate tank is sprayed<br />

slowly over the front of the radiator to obtain sufficient<br />

cooling.) But the <strong>Rolls</strong> handled the load masterfully.<br />

The great weight of the car prevented the swaying and<br />

jerking which characterizes a heavy trailer haul with<br />

the conventional car. Unfortunately, the engine again<br />

developed a miss near the end of the ascent and I knew

As everywhere, Mexican boys admire P-II plumbing.<br />

that the exhaust valve which had been holding open had<br />

been burned and would need regrinding. As we gained<br />

altitude, the carburetor mixture lever was moved<br />

toward the lean position and at 8000 feet, the best combustion<br />

was obtained with the lever to the extreme left.<br />

Paked in a beautiful trailer camp in Mexico City,<br />

it as not an onerous chore to regrind valves and be<br />

ready for many adverturesome side trips without the<br />

trailer. (Incidentally, in Mexico City trailer parking<br />

is $1.25 a day which includes all utilities, food in the<br />

native market is about one quarter of the cost at home,<br />

and low test gas for the <strong>Rolls</strong> costs 16 cents a gallon.<br />

And the sun shines every day.) No car could be more<br />

ideally suited for rough going than the P-II. The high<br />

clearance allowed us to explore roads off the beaten<br />

path that only trucks might traverse. Without the<br />

trailer, the P-II could master any climb without overheating<br />

and the use of gears for long descents was a<br />

Godsend which the owners of automatic transmission<br />

cars could not fully experience.<br />

Valve grinding compound (walled, that is!).<br />

Headed home, we again crossed the Mexican border<br />

at Laredo and filled up with low test American gasoline.<br />

It was a hot day in April and we had not gone 10 miles<br />

before the <strong>Rolls</strong> came to a stop with a violent case of<br />

vapor lock. The Mexican gas which has much less<br />

volatility than its American counterpart had never<br />

caused vapor lock under the most torrid operating<br />

conditions. What to do? Suddenly I recalled the benefits<br />

of evaporative cooling in low humidity climates. I took<br />

a pan of water from the trailer, stuck one end of a bath<br />

towel in the water and wrapped the remainder of the<br />

towel around the end of the vacuum tank that protrudes<br />

through the firewall into the driver's compartment.<br />

The evaporative cooling produced by the water soaked<br />

towel cured my vapor lock and we continued on our way.<br />

No story of taking a trailer to Mexico behind a P-II<br />

can be completely meaningful without some reference<br />

to the experiences of other less fortunate motorists<br />

•who pulled their trailers with conventional passenger<br />

cars. Those who employed Chevy, Dodge, GMC, or<br />

P-II resident in Mexican trailer camp.<br />

International 1/2 or 3/4-tontrucks made out reasonably<br />

well but those driving late model passenger cars were<br />

in a pitiful state. Hydramatic transmission bands<br />

burned out on the long mountain grades; hydraulic<br />

automatic transmissions broke their seals and lost<br />

their oil from overheating; 10 to 1 compression ratio<br />

engines knocked themselves to pieces on heavy climbs<br />

using low octane gas. Rear axles and rear wheel bearings<br />

broke from the extra load of the trailers and all<br />

late model cars left mufflers and other under-chassis<br />

parts along the highways where they could not clear<br />

obstructions.<br />

Sturdy trailer hitch mounting.<br />

Only serious shortcoming of GN151 was insufficient<br />

power at high altitude. This engine has only a 4.75 to<br />

1 compression ratio and it becomes very sluggish and<br />

lazy at altitudes over 5000 feet with a heavy trailer<br />

load. I would like to take the same trip with one of the<br />

last model P-II's which had a higher compression ratio<br />

and other refinements. As a matter of fact, to pull a<br />

heavy trailer properly in mountainous regions, an<br />

engine with upward of 200 hp is needed. The new<br />

American cars turn out the horsepower when the engines<br />

buzz at 3000 rpm but the carriage is quite hopeless<br />

for trailer work. The <strong>Rolls</strong> has everything but a<br />

few horses--maybe a little supercharging and higher<br />

compression will still make these 27-year-old marvels<br />

superior to anything offered today.<br />

Mexican version of a hot doggery.<br />

293

PHANTOM II PILOT JET STICKING<br />

Difficult starting is sometimes caused by the starting<br />

carburetter piston sticking, particularly if the car<br />

hasn't been used for a few days. The piston moves part<br />

of the way, so the carburetter makes the proper hissing<br />

noise, but not far enough to admit sufficient fuel. Cure:<br />

If dressed in overalls, remove starting carburetter<br />

and clean out. If dressed in a suit, push a small screwdriver<br />

through one of the holes in the starting carburetter<br />

and push the piston down, then remove screwdriver<br />

and start engine. W. R. Matthews, England<br />

CHROME PLATING<br />

All U.S. built cars starting with S151FR had chrome<br />

plated trim. Some earlier ones which were returned<br />

to the factory for reconditioning, were also chrome<br />

trimmed. Probably all the P-I's 'up dated' with Hall<br />

(bowl shaped) headlamps were so treated. Some Ghosts<br />

may have been refinished in chrome. It therefore seems<br />

authentic to use chrome on some of these cars, at least<br />

the factory would have done so.<br />

Chroming has its problems. The worst is finding a<br />

really good plater. Steel, even brass, should first be<br />

copper, then nickel plated for best chrome plating.<br />

While later P-I's had a removable radiator shell,<br />

earlier cars had none. Therefore the radiator has to<br />

be disassembled for plating, at about $100 - $150.<br />

While we have not heard of it being done, it might be<br />

possible to mask the front and rear of the radiator core<br />

with asphalt, then plate, then dissolve the asphalt.<br />

In plating a radiator shell, idiots will hang it on a<br />

plater's hook--result, a 'burned' pitted area, very<br />

obvious. Be very emphatic about avoiding this.<br />

Another problem is how to remove a hood--er,<br />

bonnet--hinge, plate, and replace it in a workmanlike<br />

manner. Has anyone done this?<br />

Consider carefully before plating wheels. They<br />

must be completely disassembled (spokes may be<br />

294<br />

20 H.P. 1928 GFN39 Hooper drophead with Dr. Eric<br />

Budden, former owner and Capt. C. K. Wildman, in England.<br />

This chassis type is reputed quietest ever made.<br />

GHOST THROTTLE AIR LEAK--MORE (see p. 289)<br />

It is possible to materially reduce, or even completely<br />

prevent over-run backfiring by richening the<br />

slow-running jet slightly, and driving the car with the<br />

governor lever well up, so that the engine idles at<br />

5-600 RPM. It can, of course, be shut down when car<br />

is stationary. This cuts down the inlet manifold vacuum,<br />

and the engine therefore draws a mixture of proper<br />

strength which it can fire, instead of an excessively<br />

weak mixture. This is, of course, only a palliative; the<br />

boring and new piston as previously recommended is<br />

the only real cure. It is also essential for avoidance<br />

of this trouble that both ignitions are correctly adjusted<br />

and 100% efficient, and that there are no leaks<br />

in the exhaust. In this connection, cut-outs can sometimes<br />

be troublesome; many British Ghosts have had<br />

the cut-out sealed off by R-R, for example, Bob Ley's<br />

33CE, once mine. W. R. Matthews, England<br />

rusted into nipples) and prepared. Unless the plater<br />

has special electrodes, plating will not "throw" into<br />

hollow areas on the rim.<br />

Preparing any part for plating means disassembly,<br />

and making the part almost as smooth as you expect<br />

the plating to be. Nicks and corrosion pits will be still<br />

there. Use a file, emery paper, etc. Don't send in<br />

rusty nuts or bolts, it is a waste of time. The plater's<br />

solutions will clean off the rust but not replace it with<br />

chrome nor make the surface smooth.<br />

Good nuts and bolts, with snug-fitting threads will<br />

be too tight when plated. The plating does add thickness.<br />

Either chase the threads beforehand to allow for the<br />

extra metal, or chase them after plating so they will<br />

fit. This requires taps and dies for Whitworth threads.<br />

Plating the lady mascot is quite a ticklish job. A<br />

ham-fisted buffer may easily buff the features right off.<br />

A plater familiar with silver tableware may do better.<br />

Unless the plater positions a special electrode down<br />

between the wings, no chrome goes there. Mr. Don<br />

Clairmonte, creator of excellent mascot replicas (p.64),<br />

recommends as a plater of mascots the Clermont Electroplating<br />

Works, 480 Clermont Ave., Brooklyn, N. Y.<br />

Before committing any work to a plater, get some<br />

references to his work. The best references will be<br />

from another R-R owner who has had similar parts<br />

done. When you take parts to a plater, give him a detailed<br />

list and keep a duplicate. Good luck! J. W. McF.<br />

Space left over, dammit.<br />

CAN ANYONE MAKE <strong>THE</strong>SE?<br />

This is the soft rubber bushing<br />

for the bumper supports on<br />

late U.S. Ghost and early P-I.<br />

Most owners of these cars<br />

need four each. Editor has an<br />

unused sample.<br />

Mascots from Frederic C. Palmer

R R BRAKES - U.S. HUBS<br />

by A.W. Soutter<br />

The instructions for removing hubs and drums by<br />

V. C. Allen, p. 246-7-8 apply to Springfield built R.H.<br />

drive Silver Ghosts which are fitted with Dunlop wheels.<br />

These are all chassis of the CE, NE, AG, LG, MG, JG,<br />

UG, and SG series, and chassis 4TG thru 36TG. All<br />

other Springfield built Silver Ghosts and P-I's were<br />

fitted with American wire wheels and hub caps having<br />

integral locking plates as shown in the attached sketch<br />

of the rear hub and drum.<br />

Comparison of this sketch with Fig. 4, p. 247, will<br />

reveal that the essential difference between British<br />

and American cars, which influences removal of the<br />

hub, is that removal of the American hub cap directly<br />

exposes the inner oil retaining cap, whereas the removal<br />

of an additional locking ring and sliding barrel<br />

is required on the British car. Sequence of removal<br />

of components is as follows:<br />

1. Hub cap, using wheel wrench supplied in kit.<br />

2. Spring locking ring which secures inner oil retaining<br />

cap to inner hub, using screwdriver.<br />

3. Inner oil retaining cap, using socket wrench<br />

supplied in kit. (No. F6955 on p. 174, 1½" socket will<br />

fit.) (R.H. thread on L.H. wheel, L.H. thread on R.H.<br />

wheel.)<br />

4. Cotter pin and castellated nut on rear axle shaft,<br />

using socket wrench supplied in kit. (Same wrench.)<br />

(R.H. thread on L.H. wheel, L.H. thread on R.H. wheel.)<br />

or cotter pin and castellated nut on front axle pivot,<br />

using socket wrench supplied in kit. (F6955) (R.H.<br />

thread on R.H. wheel, L.H. thread on L.H. wheel.)<br />

5. Front hub and drum including bearings will now<br />

slide off axle pivot.<br />

Rear hub requires further operations as follows:<br />

6. Rear axle driving dog, using any available bolt<br />

screwed loosely into tapped hole for withdrawing tool.<br />

7. Rear axle tube locking plate, using 2BA socket<br />

wrench to remove three hex nuts.<br />

8. Rear axle tube locking nuts, using special pin<br />

spanner supplied in tool kit. (G2899 on p. 174.) (R.H.<br />

thread on R.H. wheel, L.H. thread on L.H. wheel.)<br />

9. The rear hub and drums, including bearings will<br />

now slide off axle tube, use babbit hammer on inner<br />

face of brake drum.<br />

If Fig. 2, p. 246 were revised to show the hub cap<br />

and inner oil retaining cap pictured in the rear hub<br />

sketch above, the result would be a very close repre-<br />

Mr. and Mrs. Wm. R. O'Connor of Conn, with their<br />

P-I Ascot tourer S-178FR restored by H. C. Wire-<br />

295<br />

Fig. 1<br />

Fig. 2<br />

sentation of the front hub and drum assumbly fitted to<br />

all American P-I's. There is one further difference,<br />

however, and this is of the utmost importance in selecting<br />

replacement hub caps. All Americanfront brake<br />

axles, whether originally fitted to P-I's or to Silver<br />

Ghost front brake conversion jobs, have hub caps with<br />

locking plates which engage slots on the ends of the<br />

inner hubs as shown in Fig. 2. These may be identified<br />

by the overall length of 2.800 and the shoulder length<br />

of 3/8".<br />

The earlier type of hub caps, as shown in Fig. 1,<br />

have locking plates which engage internal serrations<br />

in the inner hubs. These may be identified by the overall<br />

length of 2 1/2" and shoulder length of 1/8".<br />

The important consideration is that while it is not<br />

possible to fit the earlier type hub cap to the later type<br />

hub, it is possible to fit the later type hub cap to the<br />

earlier type hub in such a manner as to thoroughly<br />

tighten the wheel and, yet, not lock it.<br />

Persons willing to shed wheels may disregard this<br />

warning.<br />

The later type hub cap was used on the rear hubs<br />

of all American P-I's of the RP, FP, KP, FR, KR, LR,<br />

MR, and PR series, 288RM, 301 thru 303FM, 310FM,<br />

311FM, 313FM, 314FM, 316FM, and 318 thru 399FM.<br />

Unique right drive Springfield P-I converted from<br />

LHD for movie. Note '34 Pontiac louvres. (D. Wynne)

296<br />

COOLING SYSTEM TROUBLES - PART III<br />

Acid Cleaning of Cylinder Blocks and Heads<br />

bv V.C. Allen<br />

The acid cleaning solution is commercial hydrochloric<br />

acid (32%) used without dilution. It is available<br />

from chemical supply houses.<br />

Hydrochloric acid can be very dangerous for inexperienced<br />

handlers. It can burn the skin, is very corrosive<br />

and is a deadly poison. Use rubber gloves.<br />

This treatment assumes the block or head is removed<br />

from the car. Leaks, especially in water tubes,<br />

may result as the removed scale may be sealing holes.<br />

Retubing will be described later.<br />

Important Note: The following instructions are<br />

applicable in general to all pre-war <strong>Rolls</strong>-<strong>Royce</strong> cars,<br />

i.e., Silver Ghost, 20 H.P., 20/25 H.P., 25/30 H.P.,<br />

25/30 H.P. "Wraith," Bentley as noted, British and<br />

U.S. Phantom I (with cast iron cylinder head), but do<br />

not apply to aluminium cylinder blocks or heads.<br />

PHANTOM I. An aluminium head was introduced<br />

commencing at British chassis No. 1-CL and onwards,<br />

i.e., at F2B series to end of H2 series. The cylinder<br />

blocks being of cast iron can be treated with acid but<br />

not the cylinder head. U.S. series FR, KR, LR, MR,<br />

and PR have aluminium heads.<br />

PHANTOM II. All Phantom II cylinder heads are of<br />

aluminium. The cylinder blocks are of cast iron and<br />

can therefore be treated with acid.<br />

WATER JACKET COVERS (ALL CARS). In all cases<br />

the water jacket covers, whether they are of cast iron<br />

or aluminium, must be removed from the side of the<br />

cylinder block prior to pouring in the acid through the<br />

water jacket apertures.<br />

It will be observed from the above that acid must<br />

not be used to clean the interior of an aluminium cylinder<br />

head (or a strong alkaline solution such as soda)<br />

because this would be dangerous to the operator and<br />

would cause extensive damage to the cylinder head.<br />

INTERNAL CLEANING OF P-I, P-II, AND P-III.<br />

With the cylinder heads removed from the engine, remove<br />

the front and rear end covers and direct a jet<br />

of air under high pressure alternatively through the<br />

front and rear end cover apertures to loosen as far as<br />

possible the corrosion product. Next, direct a jet of<br />

cold water into the cylinder head in a similar manner<br />

to thoroughly flush it out.<br />

Refit the front and rear end covers.<br />

INTERNAL CLEANING OF A PHANTOM III BLOCK<br />

If a P-III engine is due for a complete overhaul and<br />

where a rebore is necessary, we (The London Repair<br />

Depot) remove the wet cylinder liners and the water<br />

and oil sealing rings and hand scrape all the walls of<br />

the block to remove the corrosion product. A jet of air<br />

under high pressure is then directed around the walls<br />

after which the block is thoroughly flushed out with<br />

cold water under pressure before the liners and new<br />

oil and water sealing rings are fitted. It should be noted<br />

that this work should only be undertaken by a main<br />

<strong>Rolls</strong>-<strong>Royce</strong> Repair Depot having the special tools for<br />

removing and refitting the liners, etc.<br />

It is not possible to remove the corrosion product<br />

from a Phantom III cylinder block in any other way.<br />

The following is the only effective way of removing<br />

all scale accumulation especially when a car has been<br />

in service a number of years and covered a large mileage<br />

and where the scale has solidified. Scaling-upwill,<br />

of course, cause overheating of the cooling system and<br />

severe localised overheating of the cylinder head.<br />

A. IRON CYLINDER HEAD<br />

I. To Remove Scale:<br />

(i) Remove the valves and valve springs.<br />

(ii) Remove from the side of the head the two gland<br />

nuts together with the rubber packing glands and the<br />

gland seatings and seal off the two water passage holes<br />

by tapping in two suitably shaped (taper) wooden plugs.<br />

Also seal off with a plug the orifice of the thermometer<br />

union.<br />

(iii) Remove the front end cover, turn it upside down<br />

and refit complete with joint washer.<br />

Note: On Bentley M series chassis (B-2-MR to B-<br />

203-MX) a combined front end cover and thermostat<br />

casing is fitted in which case it should be removed and<br />

the aperture in the head blanked off by means of a suitable<br />

plate and joint washer.<br />

(iv) Coat the whole of the head with a thick layer of<br />

heavy grease to prevent acid contact.<br />

(v) Place the cylinder head on a level plane in a tank<br />

or container with the gasket joint face uppermost and<br />

Bentley 1948 Mk VI sedan by James Young and 1920 Silver Ghost 106FW Pall Mall tourer owned by C. S. Hoyt, Mass.

297<br />

pour slowly (to prevent frothing as far as possible) the<br />

acid through the orifice of the front end cover; (if an<br />

M series Bentley chassis see note below) continue to<br />

pour until it is seen, upon looking at the water passage<br />

holes, that the acid has risen almost to the level<br />

of the gasket joint face. The action of the acid will of<br />

course cause a certain amount of frothing and when<br />

this has subsided top up as necessary with acid to restore<br />

the level. Leave the head in this condition for<br />

not less than 16 hours but after it has been standing<br />

from 3 to 4 hours check the level of the acid and top<br />

up if necessary.<br />

Note: If an M series Bentley chassis pour in the<br />

acid very slowly (with the aid of a small funnel) through<br />

either the front or rear dowel locating hole on the<br />

gasket joint face of the head. These dowel holes have<br />

a diameter of .4375" and are situated near the front<br />

and rear end of the joint face.<br />

(vi) Next, turn the head on its side and allow the<br />

acid and residue to drain off. Restore the head to the<br />

previous level position. Remove the wooden plugs.<br />

(vii) Pour through the orifice of the front end cover<br />

(or through one of the two dowel pin holes) a strong<br />

solution of hot water and caustic soda (1/2 lb. soda to<br />

2 gallons of water) to neutralise remaining traces of<br />

acid. Repeat this operation until the solution has a<br />

clear colour. Next, allow a stream of cold tap water<br />

to pass through the head in a similar manner for a<br />

few minutes.<br />

(viii) Refit the three wooden plugs and with a hose<br />

again allow water to pass through the head and if the<br />

acid has fully disintegrated the scale a good flow of<br />

water should escape past all the water passage holes.<br />

II. Water (Air) Testing of Head:<br />

(i) Remove the front end cover (or blanking plate)<br />

and apply a thin coating of jointing compound to the<br />

joint face of the cover and the corresponding face of<br />

the head and using a new joint washer refit the cover<br />

in its normal position.<br />

(ii) Remove the rear end cover and fit a new joint<br />

washer in a similar manner. After removal of the<br />

cover a visual inspection can be made to assess the<br />

inner cleanliness of the head.<br />

(iii) Plug up with suitable shaped (taper) wooden<br />

plugs all the water passage holes on the gasket joint<br />

face and also seal off the outlet of the front end cover<br />

with a piece of hose, wooden plug and hose clamps.<br />

(iv) Make a suitable threaded air connection adaptor<br />

for screwing on to the thermometer union on the cylinder<br />

head. There are two different types of thermometer<br />

unions having threads as below (for Bentley and<br />

small <strong>Rolls</strong>):<br />

a. .375" GAS x 19 T.P.I. (R.H.). The external dia.<br />

of the thread is .648".<br />

b. .875" dia. x 20 T.P.I. (R.H.).<br />

Connect an air pressure line to the adaptor and lower<br />

and submerge the cylinder head in a tank of water<br />

having a temperature of 80°-85°C. Apply an air pressure<br />

of 12 lbs sq/ins and note if there are any air<br />

leakages and cure as necessary.<br />

(v) Remove the wooden plugs and the grease.<br />

(vi) Fit a new rubber packing gland (Part No. EB.654)<br />

to each of the two gland nuts.<br />

Controls of 20H.P. shown on masthead. Instrument<br />

at left measures gradient.<br />

B. IRON CYLINDER BLOCK<br />

I. To Remove Scale:<br />

(i) Remove all water jacket covers from the side of<br />

the block.<br />

(ii) Plug up with suitably shaped (taper) wooden<br />

plugs all water passage holes at the top of the block.<br />

(iii) To prevent the acid from accidentally contacting<br />

any of the machined surfaces of the block such<br />

as the cylinder bores and the gasket joint face and so<br />

causing "acid etch" they should all be painted with a<br />

double coat of "temporary rust preventative" (such<br />

as is used on machined parts prior to storage or dispatch)<br />

and when dry and as a further protection a thick<br />

coat of heavy grease should be applied.<br />

(iv) Lay the block level on its side with the water<br />

jacket apertures facing upwards. Slowly (to prevent<br />

frothing), pour about an equal amount of acid through<br />

each of the jacket apertures (to equally distribute it)<br />

until the level of the acid just covers the cylinder walls.<br />

Leave the block in this condition for not less than 16<br />

hours but after it has been standing from 3 to 4 hours<br />

check the level of the acid and top up if necessary to<br />

restore the level.<br />

(v) After the block has stood for 16 hours remove<br />

the lower row of wooden plugs and allow the acid and<br />

residue to run out into a container.<br />

(vi) Pour through the water jacket apertures a<br />

strong solution of hot water and caustic soda (1/2 lb<br />

soda to 2 gal. of water) to neutralise remaining traces<br />

of acid. Repeat this operation until the solution has a<br />

clear colour. Remove remaining wooden plugs. Next,<br />

allow a stream of cold tap water to pass through the<br />

block in a similar manner for a few minutes.<br />

(vii) With a hose again allow water to pass through<br />

the block and if the acid has fully disintegrated the silt<br />

a good flow of water should escape past all the water<br />

passage holes.<br />

(viii) Apply a thin coating of jointing compound to<br />

the faces of the water jacket covers and the corresponding<br />

faces of the block and using new joint washers<br />

refit the covers.<br />

II. Water (Air) Testing of Block:<br />

(i) Refit the wooden plugs.<br />

(ii) Make a suitable air connection adaptor for fitting<br />

to the orifice of the water pump elbow on the block and<br />

connect an air pressure line to it and lower and submerge<br />

the block in a tank of water having a temperature<br />

of 80°-85° C. Apply an air pressure of 12 lbs<br />

sq/ins and note if there are any air leakages and cure<br />

as necessary.<br />

(iii) Remove the wooden plugs.

298<br />

PHANTOM III, 3 BT 151, Hooper Sedanca DeVille. Genuine 6,700 miles, mint inside and out, chauffeurmaintained.<br />

Sanderson and Holmes Limited (Leicester), Bentley House, London Road, Leicester, England.<br />

ROLLS-ROYCE BAZAAR<br />

RR's and Bentleys from England. Reputable English<br />

source known to RROC will look for specific models<br />

and body types at English prices. All models 1919 to<br />

1957. No pre-1919 cars. Inquiries to R. H. Goldberg,<br />

16 Clare Terrace, Crestwood, Tuckahoe 7, N.Y.<br />

ROLLS-ROYCE Silver Ghost - 1911. Engine like new<br />

after complete overhaul. Have limousine and touring<br />

car bodies. Completely intact, wooden wheels. Only<br />

need paint job. Will accept investment of $4000. Dr.<br />

S. L. Scher, 1100 Park Avenue, New York, N.Y.<br />

SILVER GHOST 1926 Drophead Coupe. Authentic restoration<br />

partially completed. Running condition. Good<br />

investment at $925.00. William D. Small, 3458 Shenandoah<br />

Ave., St. Louis, Mo. PR1-4449.<br />

PHANTOM II Continental 29TA, 1934 Thrupp & Maberly<br />

sports saloon. Pictures on pages 111 and 177. $3500.<br />

L. Ross Sine, 12111 Nandell Lane, Los Altos, Calif.<br />

PHANTOM I (Br.) 70LF Limousine. Mechanically very<br />

good, body very good, paint fair to good. Original<br />

mascot, instruments, wheel discs, roof ventilator,<br />

occasional seats. $750 f.o.b. England, but will deliver<br />

in N.Y. State. Barrie Gillings, Edgehill, London Rd.,<br />

Harrow on the Hill, Middlesex, England.<br />

BENTLEY, Mk VI Std. steel saloon. Engine overhauled,<br />

new brakes, new paint, new leather in front seat. $3950.<br />

W.A.Anderson, Jr., 9891 Santa Monica Blvd., Beverly<br />

Hills, Cal.<br />

PHANTOM III Town Car; unique Inskip body, maroon<br />

lacquer; interior mint; engine completely rebuilt, all<br />

bills available. Owner's handbook, RR maintenance<br />

data, some tools and spares with the car. Photo, details,<br />

to interested purchasers. Price firm $1950.00.<br />

Lt. Col. John Macken, 25 Davis Ave., Warwick, Va.<br />

PHANTOM III, 3DL116, convertible with automatic top<br />

by Hooper. 2-door, 5-passenger, completely redone<br />

from bumper to bumper. I have $5000 invested. Price<br />

$5000. SILVER DAWN, 1954 Park Ward convertible.<br />

2-door, 5-passenger. 8000 miles, white with red leather<br />

like new. Automatic gear box and top. Cost $18,000.<br />

Price $9000. Dr. S. L. Scher, 1100 Park Ave., N.Y., N.Y.<br />

PHANTOM I (Br.) 1929 7-seater Barker limousine.<br />

First-class mechanical condition, running daily, good<br />

tires. Full specification and photos available. Accept<br />

$1,950, includes delivery any part of U.S.A. D. A.<br />

Russell, 321 South Sunset Place, Monrovia, California.<br />

WANTED<br />

INFORMATION. Am fully aware of availability of new<br />

Dunlops, but wish to know where I can have my 7.00 x<br />

21 tires recapped in my vicinity. Henwar Rodakiewicz,<br />

400 East 50th St., New York 22, N.Y.<br />

P-II Convertible coupe, in good condition. Harold H.<br />

Walther, RR 1, Cedar Falls, Iowa.<br />

P-II Croydon convertible or other <strong>Rolls</strong> with similar<br />

coachwork. Good condition. <strong>Royce</strong> J. Noble, 21 Woodland<br />

Road, Maiden 48, Massachusetts.<br />

SILVER GHOST, 4-speed gear box, open coachwork.<br />

All pictures will be returned. Wm. Schreiber, 12857<br />

Maple Ave., Blue Island, III.<br />

BENTLEY Standard Steel Saloon, '47 to '51. Prefer<br />

low-mileage, sunshine-roof model. Description, price,<br />

and photo to William D. Small, 3458 Shenandoah Ave.,<br />

St. Louis, Mo.<br />

PARTS AND SERVICE<br />

INFORMATION as to source of English maker of spring<br />

gaiters. Inquire Wm. Schreiber, 12857 Maple Ave.,<br />

Blue Island, III. who is satisfied customer.<br />

FOUR tires 650-19; in excellent condition, heavy tread.<br />

$100.00 shipped prepaid east of Miss. Clinton D. Keagy<br />

P. O. Box 115, New Castle, Pa.<br />

750x16 - $42.00<br />

700x17 - $47.00<br />

750x17 - $52.00<br />

NEW WHITEWALL TIRES<br />

700x18 - $56.00<br />

700x20 - $49.00<br />

650x19 - $49.00<br />

550x17 - $23.50<br />

550x18 - $21.50<br />

475x19 - $24.35<br />

450x21 - $24.15<br />

Send check or money order to Obsolete Tire Co., 159<br />

Truman Street, New Haven, Conn.<br />

FOREIGN CAR CENTER<br />

SALES * NEW CAR * SERVICE<br />

Restorers of the 1954 "<strong>Rolls</strong>-<strong>Royce</strong> Trophy" Car<br />

P. H. Shavney, Jr., Pres.<br />

Germantown Pike at Route 202, Norristown, Pa.<br />

Cable Address "ROLLS"<br />

LARGE ASSORTMENT of R-R parts for most models.<br />

S. Adelman, 635 Columbus Ave., Mt. Vernon, N.Y.<br />

Messrs Schaler and Waters<br />

Official <strong>Rolls</strong>-<strong>Royce</strong> Representatives<br />

26 West 27th Street<br />

Indianapolis Indiana<br />

Exclusively <strong>Rolls</strong>-<strong>Royce</strong> and Bentley