Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

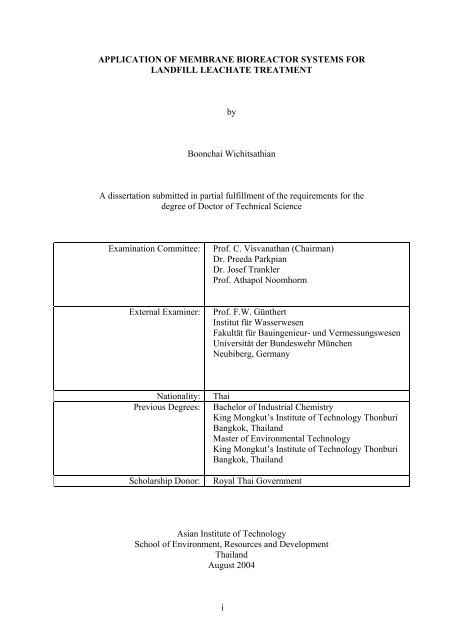

APPLICATION OF MEMBRANE BIOREACTOR SYSTEMS FOR<br />

LANDFILL LEACHATE TREATMENT<br />

i<br />

by<br />

Boonchai Wichitsa<strong>th</strong>ian<br />

A dissertation submitted in partial fulfillment <strong>of</strong> <strong>th</strong>e requirements for <strong>th</strong>e<br />

degree <strong>of</strong> Doctor <strong>of</strong> Technical Science<br />

Examination Committee: Pr<strong>of</strong>. C. Visvana<strong>th</strong>an (Chairman)<br />

Dr. Preeda Parkpian<br />

Dr. Josef Trankler<br />

Pr<strong>of</strong>. A<strong>th</strong>apol Noomhorm<br />

External Examiner: Pr<strong>of</strong>. F.W. Gün<strong>th</strong>ert<br />

Institut für Wasserwesen<br />

Fakultät für Bauingenieur- und Vermessungswesen<br />

Universität der Bundeswehr München<br />

Neubiberg, Germany<br />

Nationality: Thai<br />

Previous Degrees: B<strong>ac</strong>helor <strong>of</strong> Industrial Chemistry<br />

King Mongkut’s <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong> Thonburi<br />

Bangkok, Thailand<br />

Master <strong>of</strong> Environmental <strong>Technology</strong><br />

King Mongkut’s <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong> Thonburi<br />

Bangkok, Thailand<br />

Scholarship Donor: Royal Thai Government<br />

<strong>Asian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong><br />

School <strong>of</strong> Environment, Resources and Development<br />

Thailand<br />

August 2004

Acknowledgements<br />

I would like to deeply express my pr<strong>of</strong>ound gratitude to his advisor, Pr<strong>of</strong>. C.<br />

Visvana<strong>th</strong>an for kindly giving his stimulating ideas, valuable guidance, numerous<br />

constructive suggestions and encouragement <strong>th</strong>rough his study at AIT. The au<strong>th</strong>or also<br />

would like to <strong>th</strong>ank Dr. Preeda Parkpian, Dr. Josef Trankler, Dr. David A. Luketina, Dr.<br />

Lee Seung-Hwan, and Pr<strong>of</strong>. A<strong>th</strong>apol Noomhorm for <strong>th</strong>eir valuable comments, critical ideas<br />

and serving as members <strong>of</strong> examination committee.<br />

I am greatly indebted to Pr<strong>of</strong>. F.W. Gun<strong>th</strong>ert for kindly <strong>ac</strong>cepting to serve as<br />

External Examiner. His valuable advice, guidance and pr<strong>of</strong>essional comments are highly<br />

appreciated.<br />

I gratefully <strong>ac</strong>knowledge to Royal Thai Government for <strong>th</strong>e financial support.<br />

I am very grateful to Ms. Sindhuja Sankaran and Ms. Loshnee Nair for providing<br />

comments and helping <strong>th</strong>roughout my study at AIT.<br />

I sincerely would like to <strong>th</strong>ank all staffs and my lab colleagues in <strong>th</strong>e<br />

Environmental Engineering Program for friendship, help, and moral support, which<br />

contributed in various ways to <strong>th</strong>e completion <strong>of</strong> <strong>th</strong>is dissertation.<br />

Sincere gratitude is expressed to <strong>th</strong>e Pa<strong>th</strong>um<strong>th</strong>ani municipality and Ram-indra<br />

transfer station <strong>of</strong>fice, Thailand, for <strong>th</strong>e useful information and assistance on <strong>th</strong>e le<strong>ac</strong>hate<br />

and sample collection.<br />

Finally, I would like to express my deepest gratitude and dedicate <strong>th</strong>is research<br />

work to my parents, all family members and special friends, whose love, assisted me<br />

<strong>th</strong>rough difficult times and contributed to <strong>th</strong>e success <strong>of</strong> <strong>th</strong>is study.<br />

ii

Abstr<strong>ac</strong>t<br />

Landfill le<strong>ac</strong>hate is a complex wastewater wi<strong>th</strong> considerable variation in bo<strong>th</strong> quality<br />

and quantity. The composition and concentration <strong>of</strong> pollutants are influenced by <strong>th</strong>e types<br />

<strong>of</strong> waste deposited, hydrogeological f<strong>ac</strong>tors, and more significantly by <strong>th</strong>e age <strong>of</strong> <strong>th</strong>e<br />

landfill site. In general, le<strong>ac</strong>hate is highly contaminated wi<strong>th</strong> organic contaminants<br />

measured as chemical oxygen demand (COD) and biochemical oxygen demand (BOD),<br />

and also wi<strong>th</strong> high ammonium nitrogen concentration. Biological processes have been<br />

found ineffective for le<strong>ac</strong>hate from relatively old landfill. In le<strong>ac</strong>hate containing high<br />

concentrations <strong>of</strong> organic and nitrogen compounds such cases result in possible serious<br />

environmental problems near <strong>th</strong>e landfill site.<br />

This research was undertaken to investigate <strong>th</strong>e performance <strong>of</strong> a membrane<br />

biore<strong>ac</strong>tor (MBR) using mixed yeast culture (YMBR) and mixed b<strong>ac</strong>teria culture (BMBR)<br />

in treating raw le<strong>ac</strong>hate containing high organic and nitrogen concentrations. The<br />

inhibition effects <strong>of</strong> ammonium nitrogen and lead on yeast and b<strong>ac</strong>teria cultures were<br />

determined by measuring <strong>th</strong>e oxygen uptake rate (OUR) using <strong>th</strong>e respirometric me<strong>th</strong>od.<br />

Fur<strong>th</strong>ermore, for bo<strong>th</strong> YMBR and BMBR, treating <strong>th</strong>e stripped le<strong>ac</strong>hate, <strong>th</strong>ey were<br />

assessed <strong>th</strong>e treatment efficiency to compare <strong>th</strong>e results wi<strong>th</strong> <strong>th</strong>ose treating <strong>th</strong>e raw<br />

le<strong>ac</strong>hate.<br />

The inhibition experiment revealed <strong>th</strong>at a b<strong>ac</strong>teria culture was very sensitive to<br />

ammonium nitrogen when it was compared to a yeast culture. Also <strong>th</strong>e values <strong>of</strong> biokinetic<br />

coefficients showed <strong>th</strong>at <strong>th</strong>e specific grow<strong>th</strong> rate (µ) in b<strong>ac</strong>teria system was influenced. At<br />

ammonium concentration <strong>of</strong> 2,000 mg/L, <strong>th</strong>e response <strong>of</strong> OUR inhibition in a b<strong>ac</strong>teria<br />

system was approximately 37% whereas it was around 6% in a yeast system. Fur<strong>th</strong>ermore,<br />

bo<strong>th</strong> yeast and b<strong>ac</strong>teria cultures were also sensitive to lead.<br />

In a MBR, treating raw le<strong>ac</strong>hate, <strong>th</strong>e COD removal rate for BMBR was slightly<br />

lower <strong>th</strong>an <strong>th</strong>e YMBR for varied hydraulic retention time (HRT) at high volumetric<br />

loading rate. The average COD removal efficiency in BMBR was 62±2% while in YMBR<br />

was 65±2%. The YMBR could obtain higher COD removal rate at higher volumetric<br />

loading rate <strong>th</strong>an <strong>th</strong>e BMBR. This indicated <strong>th</strong>at <strong>th</strong>e yeast system can treat le<strong>ac</strong>hate<br />

containing high organic and nitrogen concentrations. The average TKN removal efficiency<br />

for bo<strong>th</strong> BMBR and YMBR systems was from 14-25% and 19-29%, respectively. The<br />

nitrite and nitrate concentrations (NO2 - and NO3 - ) were found to be very low.<br />

The comparative evaluation <strong>of</strong> treatment performance <strong>of</strong> MBR, treating stripped<br />

le<strong>ac</strong>hate, was examined. The COD removal <strong>of</strong> bo<strong>th</strong> BMBR and YMBR was above 70% at<br />

HRT 16 h and 24 h. As a result, <strong>th</strong>e pretreatment wi<strong>th</strong> ammonia stripping prior to BMBR<br />

showed more significant improvement in terms <strong>of</strong> COD removal when it was compared to<br />

YMBR. This could be confirmed <strong>th</strong>at <strong>th</strong>e trend <strong>of</strong> inhibition effect on b<strong>ac</strong>teria was<br />

dependent upon <strong>th</strong>e ammonium nitrogen concentration. The range <strong>of</strong> BOD concentration<br />

<strong>of</strong> effluents from bo<strong>th</strong> YMBR and BMBR, treating <strong>th</strong>e stripped le<strong>ac</strong>hate was from 30-55<br />

mg/L. This level followed <strong>th</strong>e present effluent standard. Al<strong>th</strong>ough BOD could be reduced<br />

to lower values wi<strong>th</strong> <strong>th</strong>ese me<strong>th</strong>ods, <strong>th</strong>e treated le<strong>ac</strong>hate still contained a large quantity <strong>of</strong><br />

refr<strong>ac</strong>tory organic compounds. This might be due to <strong>th</strong>e contribution <strong>of</strong> <strong>th</strong>e slowly<br />

biodegradable organics and non-biodegradable organics contained in <strong>th</strong>e le<strong>ac</strong>hate.<br />

Therefore, <strong>th</strong>ey should be fur<strong>th</strong>er treated in a post treatment for elevating <strong>th</strong>e final effluent<br />

to meet <strong>th</strong>e present effluent standard or even increasing <strong>th</strong>e biodegradable organics.<br />

iii

Under <strong>th</strong>e same operating conditions, <strong>th</strong>e YMBR could run under transmembrane<br />

pressure (TMP) 1.3-2.5 times lower <strong>th</strong>an <strong>th</strong>e BMBR wi<strong>th</strong> <strong>th</strong>e significantly reduced<br />

membrane fouling rate. This might be due to <strong>th</strong>e soluble extr<strong>ac</strong>ellular polymeric substances<br />

(soluble EPS). Hence, yeast system could enhance membrane performance and had <strong>th</strong>e<br />

potential to improve <strong>th</strong>e treatment system due to reduction <strong>of</strong> operational problems. In<br />

addition, b<strong>ac</strong>teria sludge showed a better dewatering quality compared to <strong>th</strong>at <strong>of</strong> <strong>th</strong>e yeast<br />

sludge.<br />

iv

Table <strong>of</strong> Contents<br />

Chapter Title Page<br />

Title Page i<br />

Acknowledgements ii<br />

Abstr<strong>ac</strong>t iii<br />

Table <strong>of</strong> Contents v<br />

List <strong>of</strong> Tables viii<br />

List <strong>of</strong> Figures x<br />

List <strong>of</strong> Abbreviations xii<br />

1 Introduction 1<br />

1.1 B<strong>ac</strong>kground 1<br />

1.2 Objectives <strong>of</strong> <strong>th</strong>e Study 3<br />

1.3 Scope <strong>of</strong> <strong>th</strong>e Study 4<br />

2 Literature Review 5<br />

2.1 Introduction 5<br />

2.2 Solid Waste Management Pr<strong>ac</strong>tices 6<br />

2.3 Municipal Solid Waste Landfill 7<br />

2.4 Municipal Solid Waste Landfill Le<strong>ac</strong>hate 7<br />

2.5 Le<strong>ac</strong>hate Composition and Char<strong>ac</strong>teristics 8<br />

2.6 Molecular Weight Distribution in Landfill Le<strong>ac</strong>hate 11<br />

2.7 F<strong>ac</strong>tors Affecting Le<strong>ac</strong>hate Composition 12<br />

2.7.1 Seasonal Variation 13<br />

2.7.2 Landfill Age 14<br />

2.7.3 Composition <strong>of</strong> <strong>th</strong>e Waste Dumped 16<br />

2.7.4 Geological Char<strong>ac</strong>teristic 16<br />

2.7.5 Filling Technique 16<br />

2.8 Le<strong>ac</strong>hate Treatment 17<br />

2.8.1 Biological Treatment Processes 18<br />

2.8.2 Physical Treatment 24<br />

2.8.3 Chemical Treatment 30<br />

2.8.4 Natural Le<strong>ac</strong>hate Treatment Systems 33<br />

2.8.5 Co-Treatment wi<strong>th</strong> Municipal Wastewater 35<br />

2.9 Combined Treatment F<strong>ac</strong>ility 36<br />

2.9.1 Biological Treatment and Reverse Osmosis 36<br />

2.9.2 Micr<strong>of</strong>iltration and Reverse Osmosis 37<br />

2.9.3 Denitrification-Nitrification/Ultrafiltration and Reverse Osmosis 38<br />

2.9.4 MBR-UV and Ozone-Reverse Osmosis 39<br />

2.10 Microbial Toxicity 39<br />

2.11 Membrane Biore<strong>ac</strong>tors 41<br />

2.11.1 Membrane Configuration 42<br />

2.11.2 Application <strong>of</strong> Membrane Biore<strong>ac</strong>tors 44<br />

2.11.3 Sludge Char<strong>ac</strong>teristics 45<br />

2.12 Yeasts 49<br />

2.12.1 Introduction 49<br />

2.12.2 Applications <strong>of</strong> Yeasts for Wastewater Treatment 49<br />

v

2.13 Rationale for <strong>th</strong>e Study and Proposed Treatment Sequence 52<br />

2.13.1 Le<strong>ac</strong>hate Char<strong>ac</strong>teristic 52<br />

2.13.2 Need for Ammonia Stripping 52<br />

2.13.3 Need for Membrane Biore<strong>ac</strong>tors 53<br />

3 Me<strong>th</strong>odology 54<br />

3.1 Introduction 54<br />

3.2 Le<strong>ac</strong>hate Char<strong>ac</strong>terization 54<br />

3.3 Seed Study 55<br />

3.3.1 Yeast and B<strong>ac</strong>terial Sludge 55<br />

3.3.2 Acclimatization 56<br />

3.4 Toxicity Studies 56<br />

3.4.1 Ammonia Toxicity 57<br />

3.4.2 Lead Toxicity 58<br />

3.5 Ammonia Stripping 58<br />

3.6 Membrane Biore<strong>ac</strong>tor 59<br />

3.6.1 Membrane Resistance Measurement 59<br />

3.6.2 Experimental Set-up 60<br />

3.6.3 Parametric Studies 62<br />

3.6.4 Molecular Weight Distribution 62<br />

3.6.5 Sludge Char<strong>ac</strong>terization 64<br />

3.7 Ammonia Stripping Coupled Membrane Biore<strong>ac</strong>tor 64<br />

3.8 Analytical Me<strong>th</strong>ods 65<br />

4 Results and Discussion 67<br />

4.1 Simulation <strong>of</strong> Le<strong>ac</strong>hate Char<strong>ac</strong>teristic for Treatment <strong>of</strong><br />

Middle Aged Le<strong>ac</strong>hate 67<br />

4.2 Biokinetic Studies 68<br />

4.2.1 Acclimatization <strong>of</strong> Mixed Yeast and B<strong>ac</strong>terial Sludge 68<br />

4.2.2 Kinetics <strong>of</strong> Yeast and B<strong>ac</strong>terial Grow<strong>th</strong> 72<br />

4.2.3 Toxicity Studies 75<br />

4.3 Application <strong>of</strong> Yeast and B<strong>ac</strong>teria Based Membrane Biore<strong>ac</strong>tors<br />

in Le<strong>ac</strong>hate Treatment 80<br />

4.3.1 Initial Membrane Resistance 81<br />

4.3.2 Optimization <strong>of</strong> HRT in Terms <strong>of</strong> Membrane Biore<strong>ac</strong>tor<br />

Treatment Efficiency 82<br />

4.3.3 Membrane Fouling and Membrane Resistance 89<br />

4.4 Application <strong>of</strong> Yeast and B<strong>ac</strong>teria Based Membrane Biore<strong>ac</strong>tors<br />

in Ammonia Stripped Le<strong>ac</strong>hate Treatment 91<br />

4.4.1 Ammonia Stripping Studies 91<br />

4.4.2 Membrane Resistance and Membrane Cleaning 95<br />

4.4.3 Performance <strong>of</strong> Ammonia Stripping Coupled Membrane<br />

Biore<strong>ac</strong>tor Process 97<br />

4.5 O<strong>th</strong>er Studies 106<br />

4.5.1 Biodegradability <strong>of</strong> <strong>th</strong>e Le<strong>ac</strong>hate 106<br />

4.5.2 Molecular Weight Cut-<strong>of</strong>f 110<br />

4.5.3 Sludge Properties 115<br />

4.5.4 EPS Formation 116<br />

4.5.5 Conductivity and TDS 117<br />

vi

4.5.6 Cost Analysis for Operation 117<br />

5 Conclusions and Recommendations 119<br />

5.1 Conclusions 119<br />

5.2 Recommendations for Future Work 121<br />

References 123<br />

Appendix A: Pictures <strong>of</strong> Experiments 141<br />

Appendix B: Le<strong>ac</strong>hate Char<strong>ac</strong>teristics and Experimental<br />

Data <strong>of</strong> Acclimation 145<br />

Appendix C: Experimental Data <strong>of</strong> Biokinetic Study and<br />

Toxicity Study 149<br />

Appendix D: Membrane Resistance Studies 155<br />

Appendix E: MBR wi<strong>th</strong>out Ammonia Stripping 163<br />

Appendix F: Ammonia Stripping Studies 171<br />

Appendix G: MBR wi<strong>th</strong> Ammonia Stripping 174<br />

Appendix H: O<strong>th</strong>er Studies 179<br />

vii

List <strong>of</strong> Tables<br />

Tables Title Page<br />

2.1 Le<strong>ac</strong>hate Char<strong>ac</strong>teristic in Acidogenic and Me<strong>th</strong>anogenic Phase<br />

in a Landfill 8<br />

2.2 Comparison <strong>of</strong> Le<strong>ac</strong>hate Char<strong>ac</strong>teristics <strong>of</strong> Landfills Surveyed in<br />

Asia, Europe and America 10<br />

2.3 Relation between Landfill Age, Le<strong>ac</strong>hate Char<strong>ac</strong>teristics and Treatments 11<br />

2.4 Classification <strong>of</strong> Types <strong>of</strong> Substances Using Molecular Weight Cut<strong>of</strong>f 12<br />

2.5 Variation <strong>of</strong> COD, BOD & BOD/COD wi<strong>th</strong> Increasing Landfill Ages 15<br />

2.6 Nitrogen Concentrations from Various Sources 15<br />

2.7 Nitrogen Concentration Ranges in <strong>th</strong>e Le<strong>ac</strong>hate for Landfill Stabilization 15<br />

2.8 Summary <strong>of</strong> Biokinetic Coefficient <strong>of</strong> Activated Sludge Process for<br />

Landfill Le<strong>ac</strong>hate Treatment 19<br />

2.9 Operational and Environmental Conditions for Nitrification-<br />

Denitrification Processes 23<br />

2.10 Treatment Efficiencies <strong>of</strong> Different Aerobic Biological Treatment<br />

Systems 25<br />

2.11 Treatment Efficiencies <strong>of</strong> Different Anaerobic Biological Treatment<br />

Systems 26<br />

2.12 Membrane Processes 28<br />

2.13 Removal Efficiency <strong>of</strong> Moderate to High Concentrations <strong>of</strong> Pollutants<br />

Using Nan<strong>of</strong>iltration, Ultrafiltration and Reverse Osmosis 28<br />

2.14 Typical Reverse Osmosis Plant Performance for Le<strong>ac</strong>hate Purification,<br />

Germany 30<br />

2.15 Treatment Efficiencies <strong>of</strong> Different Physico-chemical Treatment Systems 34<br />

2.16 Typical Le<strong>ac</strong>hate Composition at E<strong>ac</strong>h Stage <strong>of</strong> Le<strong>ac</strong>hate Treatment Plant 39<br />

2.17 Inhibitory Effect <strong>of</strong> Various Toxicants 41<br />

2.18 Advantages and Disadvantages <strong>of</strong> Membrane Biore<strong>ac</strong>tors 43<br />

2.19 Operating Conditions <strong>of</strong> Membrane Biore<strong>ac</strong>tor Process for Treatment<br />

<strong>of</strong> Different Kinds <strong>of</strong> Wastewater 46<br />

2.20 Operating Conditions <strong>of</strong> Yeast System Compared wi<strong>th</strong> Activated<br />

Sludge Process 51<br />

2.21 Performance <strong>of</strong> Yeast Based Treatment System in Dried Food Products<br />

and Marine Product Industry 51<br />

3.1 Composition <strong>of</strong> Simulated Le<strong>ac</strong>hate 55<br />

3.2 Operating Conditions for Yeast and B<strong>ac</strong>teria Acclimatization 56<br />

3.3 Operating Conditions for Yeast and B<strong>ac</strong>teria Mixtures in Respirometer 57<br />

3.4 Description <strong>of</strong> <strong>th</strong>e Chemical Cleaning 60<br />

3.5 Technical Parameters <strong>of</strong> <strong>th</strong>e Experimental Plant 60<br />

3.6 Experimental Operating Conditions <strong>of</strong> YMBR and BMBR Systems 62<br />

3.7 Char<strong>ac</strong>teristics <strong>of</strong> Ultrafiltration Membrane 64<br />

3.8 Parameters and Their Analytical Me<strong>th</strong>ods 66<br />

4.1 Compositions <strong>of</strong> Le<strong>ac</strong>hate Simulated from Le<strong>ac</strong>hates Obtained from<br />

Pa<strong>th</strong>um-<strong>th</strong>ani Landfill Site (PS) and Ram-Indra Transfer Station (RIS) 67<br />

4.2 Biokinetic Coefficients <strong>of</strong> Yeast and B<strong>ac</strong>teria Sludge for <strong>th</strong>e Le<strong>ac</strong>hates 74<br />

4.3 Effect <strong>of</strong> Free Ammonia Concentration on Yield Coefficient and <strong>th</strong>e<br />

Specific Grow<strong>th</strong> Rate <strong>of</strong> <strong>th</strong>e B<strong>ac</strong>terial Sludge 76<br />

viii

4.4 Effect <strong>of</strong> Free Ammonia Concentration on Yield Coefficient and <strong>th</strong>e<br />

Specific Grow<strong>th</strong> Rate <strong>of</strong> <strong>th</strong>e Yeast Sludge 77<br />

4.5 Substrate Utilization by <strong>th</strong>e Yeast and B<strong>ac</strong>terial Sludge 79<br />

4.6 COD Removal Efficiency in YMBR System at Different HRT 85<br />

4.7 COD Removal Efficiency in BMBR System at Different HRT 86<br />

4.8 TKN Removal Efficiency in YMBR System 88<br />

4.9 TKN Removal Efficiency in BMBR System 88<br />

4.10 Membrane Cleaning Frequency in <strong>th</strong>e MBR Systems 90<br />

4.11 Membrane Resistance in <strong>th</strong>e MBR Systems 90<br />

4.12 Variation in Ammonia Removal Efficiency 94<br />

4.13 Determination <strong>of</strong> Membrane Resistance <strong>of</strong> Membrane Module after<br />

Clogging in BMBR system (A = 0.42 m2; Pore Size = 0.1 µm) 96<br />

4.14 Contribution <strong>of</strong> BOD at 5, 10 and 15 Days to <strong>th</strong>e Total 20 Days BOD 108<br />

4.15 Sludge Properties in <strong>th</strong>e YMBR and BMBR Systems 115<br />

4.16 MLSS and MLVSS Concentrations in Yeast and B<strong>ac</strong>teria Re<strong>ac</strong>tors 116<br />

4.17 Bound EPS Concentration in <strong>th</strong>e YMBR and BMBR Systems 116<br />

4.18 Soluble EPS Concentration in <strong>th</strong>e YMBR and BMBR Systems 116<br />

4.19 Conductivity and TDS Concentrations in Le<strong>ac</strong>hate and Effluents 117<br />

4.20 Cost <strong>of</strong> Chemical Used for pH Adjustment 118<br />

4.21 Total Chemical Cost Requirement for E<strong>ac</strong>h Treatment System 118<br />

ix

List <strong>of</strong> Figures<br />

Figures Title Page<br />

2.1 Schematic Representation <strong>of</strong> a Typical Engineered Landfill 6<br />

2.2 Changes in Significant Parameters during Different Phases <strong>of</strong><br />

Landfill Stabilization 7<br />

2.3 Variation in Significant Pollutant Ratios wi<strong>th</strong> Increase in Age<br />

<strong>of</strong> <strong>th</strong>e Landfill 9<br />

2.4 Water Movements in <strong>th</strong>e Landfill 13<br />

2.5 Le<strong>ac</strong>hate Productions and Rainfall Variation wi<strong>th</strong> Time 14<br />

2.6 Treatment <strong>of</strong> Landfill Le<strong>ac</strong>ahte wi<strong>th</strong> Two Stage Reverse Osmosis 29<br />

2.7 Schematic Diagram <strong>of</strong> Biological Treatment and Reverse Osmosis<br />

for Le<strong>ac</strong>hate Treatment 37<br />

2.8 Schematic Diagram <strong>of</strong> Micr<strong>of</strong>iltration/Reverse Osmosis for<br />

Le<strong>ac</strong>hate Treatment 38<br />

2.9 Schematic Diagram <strong>of</strong> Denitrification-Nitrification/UF and<br />

Reverse Osmosis for Le<strong>ac</strong>hate Treatment 38<br />

2.10 Schematic Diagrams <strong>of</strong> (a) External Recirculation MBR and<br />

(b) Submerged MBR System 42<br />

3.1 Flowchart Showing Different Stages <strong>of</strong> Experimental Study 54<br />

3.2 Diagram Illustrating <strong>th</strong>e Enrichment Procedure 55<br />

3.3 Respirometer 57<br />

3.4 Experiments Conducted to Optimize Ammonia Stripping 59<br />

3.5 Schematic Diagrams <strong>of</strong> Membrane Biore<strong>ac</strong>tor wi<strong>th</strong> and wi<strong>th</strong>out<br />

Ammonia Stripping 61<br />

3.6 Me<strong>th</strong>odology for Performing Molecular Weight Cut-<strong>of</strong>f Distribution 63<br />

3.7 Flowchart Showing Ammonia Stripping Coupled MBR Process 65<br />

4.1 Variation in F/M and COD Removal Efficiency in Yeast Sludge 69<br />

4.2 Variation in F/M and COD Removal Efficiency in B<strong>ac</strong>terial Sludge 69<br />

4.3 Increase in Biomass during Acclimatization <strong>of</strong> <strong>th</strong>e B<strong>ac</strong>terial Sludge 70<br />

4.4 Increase in Biomass during Acclimatization <strong>of</strong> <strong>th</strong>e Yeast Sludge 71<br />

4.5 Predominantly Spherical and Egg-shaped Yeasts wi<strong>th</strong> Budding in<br />

<strong>th</strong>e Yeast Re<strong>ac</strong>tor (x1500) 71<br />

4.6 B<strong>ac</strong>teria Cells in <strong>th</strong>e Mixed B<strong>ac</strong>teria Sludge: a) Gram Negative and<br />

b) Gram Positive (x1500) 72<br />

4.7 Specific Grow<strong>th</strong> Rate <strong>of</strong> Mixed B<strong>ac</strong>teria Sludge wi<strong>th</strong> Increasing<br />

Substrate Concentration 72<br />

4.8 Specific Grow<strong>th</strong> Rate <strong>of</strong> Mixed Yeast Sludge wi<strong>th</strong> Increasing<br />

Substrate Concentration 72<br />

4.9 Inhibition <strong>of</strong> <strong>th</strong>e Yeast and B<strong>ac</strong>terial Culture wi<strong>th</strong> Increasing<br />

Ammonium Chloride Concentration 77<br />

4.10 Inhibitory Effect <strong>of</strong> Lead in B<strong>ac</strong>terial Sludge 79<br />

4.11 Inhibition Effect <strong>of</strong> Lead in Yeast Sludge 80<br />

4.12 Variation in Transmembrane Pressure wi<strong>th</strong> Permeate Flux (a) YMBR<br />

and (b) BMBR 81<br />

4.13 Variation in Organic Load wi<strong>th</strong> HRT 83<br />

4.14 Variation in MLSS in <strong>th</strong>e MBR Systems 83<br />

4.15 Variation in pH in <strong>th</strong>e MBR Systems 84<br />

x

4.16 COD Concentration in <strong>th</strong>e Influent and Effluent in <strong>th</strong>e BMBR and<br />

YMBR at Different HRT 84<br />

4.17 COD Removal Efficiency in <strong>th</strong>e BMBR and YMBR at Different HRT 85<br />

4.18 Variations in COD Removal Rate as a Function <strong>of</strong> F/M Ratio 86<br />

4.19 TKN Removal Efficiency in <strong>th</strong>e YMBR and BMBR wi<strong>th</strong> HRT 87<br />

4.20 Cleaning <strong>of</strong> membranes in <strong>th</strong>e YMBR and BMBR system in<br />

relation to TMP 90<br />

4.21 Variation in <strong>th</strong>e Ammonia Removal Efficiency wi<strong>th</strong> pH 93<br />

4.22 Ammonia Removal Efficiency wi<strong>th</strong> Varying Velocity Gradient and pH 93<br />

4.23 Trans-membrane Pressure Variation in MBR Process for Ammonia<br />

Stripped Le<strong>ac</strong>hate Treatment 96<br />

4.24 Variation in COD at 16 and 24 h HRT 98<br />

4.25 Variation in MLSS at 16 and 24 h HRT 98<br />

4.26 COD Removal wi<strong>th</strong> and wi<strong>th</strong>out Ammonia Stripping at 16 and 24 h HRT 99<br />

4.27 Expected and Actual Improvement in COD Removal wi<strong>th</strong> Ammonia<br />

Stripping in <strong>th</strong>e YMBR and BMBR Systems 100<br />

4.28 BOD in <strong>th</strong>e BMBR and YMBR Effluent at 16 h HRT 101<br />

4.29 BOD in <strong>th</strong>e BMBR and YMBR Effluent at 24 h HRT 101<br />

4.30 BOD Removal Efficiency in <strong>th</strong>e BMBR and YMBR Systems 102<br />

4.31 BOD/COD <strong>of</strong> <strong>th</strong>e BMBR and YMBR Effluent 102<br />

4.32 Influent and Effluent Nitrogen Content in BMBR at (a) 16 h HRT and<br />

(b) 24 h HRT 103<br />

4.33 Influent and Effluent Nitrogen Content in YMBR at (a) 16 h HRT and<br />

(b) 24 h HRT 104<br />

4.34 Overall TKN Removal in BMBR and YMBR wi<strong>th</strong> and wi<strong>th</strong>out<br />

Ammonia Stripping 105<br />

4.35 TKN Removal in MBR Process at 16 and 24 h HRT 106<br />

4.36 Change <strong>of</strong> OUR at Different Time Period for Le<strong>ac</strong>hate Sample 107<br />

4.37 20 Days BOD <strong>of</strong> <strong>th</strong>e Raw Le<strong>ac</strong>hate and Stripped Le<strong>ac</strong>hate 109<br />

4.38 20 Days BOD <strong>of</strong> <strong>th</strong>e YMBR and BMBR Effluents 109<br />

4.39 Molecular Weight Cut-<strong>of</strong>f <strong>of</strong> Raw Le<strong>ac</strong>hate, Stripped Le<strong>ac</strong>hate,<br />

B<strong>ac</strong>terial and Yeast Effluents 111<br />

4.40 Percent Contribution <strong>of</strong> Various Molecular Weight Compounds to<br />

<strong>th</strong>e Total COD 111<br />

4.41 Molecular Weight Cut-<strong>of</strong>f <strong>of</strong> Le<strong>ac</strong>hate (a) COD (mg/L) (b) COD (%) 113<br />

4.42 Molecular Weight Cut-<strong>of</strong>f <strong>of</strong> Le<strong>ac</strong>hate (a) BOD (mg/L) (b) BOD (%) 114<br />

xi

List <strong>of</strong> Abbreviations<br />

AAS Atomic Absorption Spectrophotometer<br />

AnSBR Anaerobic Sequencing Batch Re<strong>ac</strong>tors<br />

AOX Adsorbable Organic Halogens<br />

AS Activated Sludge<br />

BACFB Biological Activated Carbon Fluidized Bed Process<br />

BOD Biochemical Oxygen Demand<br />

BMBR B<strong>ac</strong>terial Membrane Biore<strong>ac</strong>tors<br />

C Carbon<br />

cm Centimeter<br />

COD Chemical Oxygen Demand<br />

CST Capillary Suction Time<br />

d Day<br />

Da Daltons<br />

DO Dissolved Oxygen<br />

DOC Dissolved Organic Carbon<br />

DSVI Diluted Sludge Volume Index<br />

EMBR Extr<strong>ac</strong>tive Membrane Biore<strong>ac</strong>tor<br />

EPS Extr<strong>ac</strong>ellular Polymeric Substances<br />

F/M Food/Microorganism ratio<br />

FS Fixed Solids<br />

g Gram<br />

G Mean velocity gradient<br />

GAC Granular Activated Carbon<br />

h Hour<br />

HRT Hydraulic Retention Time<br />

J Permeate flux<br />

k Substrate removal rate<br />

kDa Kilo Daltons<br />

kg Kilogram<br />

kPa Kilo Pascal<br />

kWh Kilowatt-hour<br />

kd Endogenous decay coefficient<br />

ke Mean re<strong>ac</strong>tion rate coefficient<br />

Ks Half-velocity constant<br />

L Liter<br />

m Meter<br />

m 2 Square meter<br />

m 3 Cubic meter<br />

m 3 /d Cubic meter per day<br />

mg/L Milligram per liter<br />

min Minute<br />

MAACFB Microorganism Att<strong>ac</strong>hed Activated Carbon Fluidized Bed Process<br />

MABR Membrane Aeration Biore<strong>ac</strong>tors<br />

MBR Membrane Biore<strong>ac</strong>tor<br />

MF Micr<strong>of</strong>iltration<br />

MLSS Mixed Liquor Suspended Solids<br />

MLVSS Mixed Liquor Volatile Suspended Solids<br />

MW Molecular Weight<br />

xii

MWCO Molecular Weight Cut-<strong>of</strong>f<br />

MWW Municipal Wastewater<br />

N Nitrogen<br />

NF Nan<strong>of</strong>iltration<br />

NH3-N Ammonia Nitrogen<br />

NH4-N Ammonium Nitrogen<br />

NO2-N Nitrite Nitrogen<br />

NO3-N Nitrate Nitrogen<br />

NOM Natural Organic Matter<br />

OLR Organic Loading Rate<br />

OUR Oxygen Uptake Rate<br />

P Phosphorus<br />

Pa Pascal<br />

PAC Powder Activated Carbon<br />

PS Pa<strong>th</strong>um<strong>th</strong>ani Landfill Site<br />

R Filtration resistance<br />

Rc Resistance due to cake layer<br />

Rm Intrinsic resistance<br />

Rn Resistance due to irreversible fouling<br />

Rt Total resistance<br />

RBC Rotating Biological Cont<strong>ac</strong>tor<br />

RIS Ram-indra Transfer Station<br />

RO Reverse Osmosis<br />

rpm Rotations per minute<br />

s Seconds<br />

So/Xo Substrate/Biomass ratio<br />

Ss Readily biodegradable organics<br />

SBR Sequencing Batch Re<strong>ac</strong>tor<br />

SCBP Suspended Carrier Bi<strong>of</strong>ilm Process<br />

SD Standard Deviation<br />

SRT Sludge Retention Time<br />

SS Suspended Solids<br />

SVI Sludge Volume Index<br />

T Temperature<br />

TDS Total Dissolved Solid<br />

TOC Total Organic Carbon<br />

TKN Total Kjedahl Nitrogen<br />

TMP Transmembrane Pressure<br />

TS Total Solids<br />

TVS Total Volatile Solids<br />

U Substrate Utilization Rate<br />

UASB Upflow Anaerobic Sludge Blanket<br />

UF Ultrafiltration<br />

USB/AF Upflow Hybrid Sludge Bed/Fixed Bed Anaerobic<br />

UV Ultraviolet<br />

VFA Volatile Fatty Acid<br />

VLR Volumetric Loading Rate<br />

VS Volatile Solids<br />

VSS Volatile Suspended Solids<br />

Xs Slowly biodegradable organics<br />

xiii

Y Yield coefficient<br />

YMBR Yeast Membrane Biore<strong>ac</strong>tor<br />

Өc Solid retention time<br />

o C Degree Celsius<br />

∆P Transmembrane Ppessure<br />

µ Vicosity<br />

µm Micrometer<br />

µmax Maximum specific grow<strong>th</strong> rate<br />

µS/cm Microsiemens per centimeter<br />

xiv

1.1 B<strong>ac</strong>kground<br />

Chapter 1<br />

Introduction<br />

Rapid industrialization and urbanization has resulted in an immense environmental<br />

degradation. Population grow<strong>th</strong> and poor environmental management pr<strong>ac</strong>tices have led to<br />

deterioration <strong>of</strong> environmental quality in most <strong>of</strong> <strong>th</strong>e developing countries. The<br />

composition <strong>of</strong> <strong>th</strong>e domestic refuse has radically changed in char<strong>ac</strong>ter over <strong>th</strong>e last fifty<br />

years, due to <strong>th</strong>e rise <strong>of</strong> an affluent society. In recent years, solid waste management has<br />

gained focus in many countries. Source reduction, reuse and recycling <strong>of</strong> waste,<br />

composting, incineration and landfill disposal are few <strong>of</strong> <strong>th</strong>e solid waste management<br />

appro<strong>ac</strong>hes pr<strong>ac</strong>ticed in different countries. The suitability <strong>of</strong> <strong>th</strong>ese appro<strong>ac</strong>hes differs from<br />

pl<strong>ac</strong>e to pl<strong>ac</strong>e. Municipal solid waste disposal in <strong>th</strong>e landfill is <strong>th</strong>e most common, cheap<br />

and easiest municipal solid waste management pr<strong>ac</strong>tice followed <strong>th</strong>roughout <strong>th</strong>e world.<br />

However, landfill requires a close environmental engineering surveillance in its design and<br />

operation as it is likely to generate le<strong>ac</strong>hate which would potentially contaminate nearby<br />

groundwater and surf<strong>ac</strong>e water. Wi<strong>th</strong> <strong>th</strong>e changing nature <strong>of</strong> domestic refuse composition<br />

over <strong>th</strong>e years, <strong>th</strong>e proportion <strong>of</strong> refuse available for decomposition has greatly increased<br />

and <strong>th</strong>us <strong>th</strong>e organic streng<strong>th</strong> <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate has increased, resulting in its greater potential<br />

to pollute water. A need exist to focus on <strong>th</strong>e environmental problems concerned wi<strong>th</strong><br />

domestic landfill disposal to protect <strong>th</strong>e environment and prevent adverse heal<strong>th</strong> affects.<br />

Surf<strong>ac</strong>e water <strong>th</strong>at percolates <strong>th</strong>rough <strong>th</strong>e landfill and le<strong>ac</strong>hes out organic and<br />

inorganic constituents from <strong>th</strong>e solid waste is termed le<strong>ac</strong>hate. Landfill le<strong>ac</strong>hate production<br />

starts at <strong>th</strong>e early stages <strong>of</strong> <strong>th</strong>e landfill and continues several decades even after landfill<br />

closure. Landfill le<strong>ac</strong>hate is mainly generated by <strong>th</strong>e infiltrating water, which passes<br />

<strong>th</strong>rough <strong>th</strong>e solid waste fill and f<strong>ac</strong>ilitates transfer <strong>of</strong> contaminants from solid phase to<br />

liquid phase. Due to <strong>th</strong>e inhomogeneous nature <strong>of</strong> <strong>th</strong>e waste and because <strong>of</strong> <strong>th</strong>e differing<br />

comp<strong>ac</strong>tion densities <strong>th</strong>at will be encountered, water will be able to percolate <strong>th</strong>rough and<br />

appear as le<strong>ac</strong>hate at <strong>th</strong>e base <strong>of</strong> <strong>th</strong>e site. If no remedial measures are taken to prevent<br />

continual inputs <strong>of</strong> water to <strong>th</strong>e wastes, <strong>th</strong>is could pose adverse environmental imp<strong>ac</strong>ts.<br />

Landfill le<strong>ac</strong>hate is high streng<strong>th</strong> wastewater which contains high concentrations <strong>of</strong><br />

organic matter and ammonium nitrogen. There is a fluctuation in <strong>th</strong>e composition <strong>of</strong><br />

organic, inorganic and heavy metal components in <strong>th</strong>e le<strong>ac</strong>hate making <strong>th</strong>em more difficult<br />

to be dealt wi<strong>th</strong>. The composition depends on <strong>th</strong>e landfill age, <strong>th</strong>e quality and quantity <strong>of</strong><br />

solid waste, <strong>th</strong>e biological and chemical processes occurring in <strong>th</strong>e landfill, and <strong>th</strong>e amount<br />

<strong>of</strong> precipitation and percolation. When <strong>th</strong>e le<strong>ac</strong>hate containing high streng<strong>th</strong> organic matter<br />

and ammonia is discharged wi<strong>th</strong>out treatment, it can stimulate algae grow<strong>th</strong> <strong>th</strong>rough<br />

nutrient enrichment, deplete dissolved oxygen, and cause toxic effects in <strong>th</strong>e surrounding<br />

water environment. Landfill design and operation have a major imp<strong>ac</strong>t and influence on <strong>th</strong>e<br />

le<strong>ac</strong>hate generation. This le<strong>ac</strong>hate varies from landfill to landfill and over time and sp<strong>ac</strong>e in<br />

a particular landfill wi<strong>th</strong> fluctuations apparent over short and long-term periods due to<br />

climatic, hydrogeology and waste composition variations (Keenan, et al., 1984). Generally,<br />

le<strong>ac</strong>hate contaminants are measured in terms <strong>of</strong> chemical oxygen demand (COD) and<br />

biological oxygen demand (BOD), halogenated hydrocarbons and heavy metals. In<br />

addition, le<strong>ac</strong>hate usually contains high concentrations <strong>of</strong> inorganic salts - mainly sodium<br />

1

chloride, carbonate and sulfate and is dependent on <strong>th</strong>e waste composition land-filled. An<br />

average fresh domestic refuse le<strong>ac</strong>hate can have a BOD <strong>of</strong> around 15,000 mg/L. When<br />

compared to an average raw sewage BOD <strong>of</strong> 200 mg/L, it can be seen <strong>th</strong>at landfill le<strong>ac</strong>hate<br />

is around 75 times as strong in terms <strong>of</strong> its polluting potential.<br />

Sufficient means have to be evolved to deal wi<strong>th</strong> landfill le<strong>ac</strong>hate so <strong>th</strong>at its imp<strong>ac</strong>t<br />

can be minimized. Le<strong>ac</strong>hate treatment and prevention or minimization <strong>of</strong> le<strong>ac</strong>hate<br />

generation is primarily <strong>th</strong>e two prime options available for landfill le<strong>ac</strong>hate management.<br />

Disposal <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate in <strong>th</strong>e sewer is an attr<strong>ac</strong>tive option, but <strong>th</strong>e variation in <strong>th</strong>e quality<br />

<strong>of</strong> <strong>th</strong>e sewage and le<strong>ac</strong>hate and remoteness <strong>of</strong> <strong>th</strong>e landfill sites make <strong>th</strong>is option difficult<br />

pr<strong>ac</strong>tically. Le<strong>ac</strong>hate treatment has inevitably become a much more widespread<br />

requirement at landfills. It is a technology which has only developed in 1980 in <strong>th</strong>e UK,<br />

but is now advancing rapidly as experience is being gained on full scale landfills<br />

(Robinson, et al., 1992).The main environmental problem experienced at landfills has<br />

resulted from a loss <strong>of</strong> le<strong>ac</strong>hate from <strong>th</strong>e site and <strong>th</strong>e subsequent contamination <strong>of</strong><br />

surrounding land and water. Improvements in landfill engineering has been aimed at<br />

reducing le<strong>ac</strong>hate production, collecting and treating le<strong>ac</strong>hate prior to discharge and<br />

<strong>th</strong>ereby limiting le<strong>ac</strong>hate infiltration to <strong>th</strong>e surrounding soil (Farquhar, 1989). However a<br />

need exists to develop reliable, sustainable options to effectively manage le<strong>ac</strong>hate<br />

generation and treatment. In designing a le<strong>ac</strong>hate treatment scheme, <strong>th</strong>e process must<br />

reflect <strong>th</strong>e possibility <strong>th</strong>at treatment techniques which work well for a young le<strong>ac</strong>hate may<br />

become wholly inadequate as <strong>th</strong>e landfill age increases.<br />

There are difficulties concerned wi<strong>th</strong> <strong>th</strong>e treatment <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate. First, <strong>th</strong>e<br />

variability and streng<strong>th</strong> <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate have important waste treatment application. Second,<br />

<strong>th</strong>e changes encountered from landfill to landfill are such <strong>th</strong>at waste treatment technology<br />

applicable at one site may not be directly transferable to o<strong>th</strong>er location. Third, fluctuations<br />

in <strong>th</strong>e le<strong>ac</strong>hate quality which occur over bo<strong>th</strong> short and long interval must be <strong>ac</strong>counted for<br />

in <strong>th</strong>e treatment design and long interval must be <strong>ac</strong>counted for in <strong>th</strong>e treatment design.<br />

Current treatment pr<strong>ac</strong>tices in developed countries advocate le<strong>ac</strong>hate minimization<br />

by operating landfills as dry as possible; <strong>th</strong>is poses <strong>th</strong>e problem <strong>of</strong> long-term landfill<br />

stabilization. The alternative <strong>of</strong> operating <strong>th</strong>e landfill as wet as possible by le<strong>ac</strong>hate recirculation<br />

does address <strong>th</strong>e problem <strong>of</strong> le<strong>ac</strong>hate treatment by reducing organics. However,<br />

<strong>th</strong>is me<strong>th</strong>od does not prove effective in treating “hard COD” or refr<strong>ac</strong>tory compounds and<br />

nitrogen. Therefore, it does not meet municipal discharge standards. Various biological<br />

treatment me<strong>th</strong>ods have been employed for <strong>th</strong>e treatment <strong>of</strong> le<strong>ac</strong>hate from municipal solid<br />

waste landfill. Extended aeration systems, sequencing batch re<strong>ac</strong>tors and aerated lagoons<br />

can <strong>ac</strong>t as robust, stable and reliable means <strong>of</strong> treating le<strong>ac</strong>hate. These treatment systems<br />

were found to be inefficient for le<strong>ac</strong>hate containing high streng<strong>th</strong> organic substances and<br />

ammonia nitrogen. In addition, <strong>th</strong>e organic loading and pH are significant in influencing<br />

<strong>th</strong>e grow<strong>th</strong> <strong>of</strong> nitrifying b<strong>ac</strong>teria in nitrification process (Aberling, et al., 1992; Bea, et al.,<br />

1997; Kabdasli, et al., 2000). Due to high ammonia concentrations in <strong>th</strong>e le<strong>ac</strong>hate,<br />

ammonia toxicity and sludge properties are affected in <strong>th</strong>e biological treatment systems. A<br />

reed bed treatment system can also be designed to treat effluent by passing it <strong>th</strong>rough <strong>th</strong>e<br />

rhizomes <strong>of</strong> <strong>th</strong>e reed. However, such treatment systems would not deal satisf<strong>ac</strong>torily<br />

because reed bed are poor in removing ammonia. Additionally, ammonium concentration<br />

as high as approximately 1,000 mg/L <strong>of</strong> untreated le<strong>ac</strong>hate feed, might be directly toxic<br />

(Robinson, et al., 1992). The physical treatment systems used for treatment <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate<br />

include <strong>ac</strong>tivated carbon adsorption, filtration, evaporation; etc. These processes are<br />

2

generally unsuccessful in removal <strong>of</strong> organic material from <strong>th</strong>e raw le<strong>ac</strong>hate. The chemical<br />

me<strong>th</strong>ods include coagulation and precipitation and oxidation <strong>of</strong> <strong>th</strong>e organics. The<br />

disadvantage <strong>of</strong> <strong>th</strong>e coagulation and precipitation is <strong>th</strong>at large amounts <strong>of</strong> sludge are<br />

produced which is difficult to manage. Nei<strong>th</strong>er biological nor chemical/physical treatment<br />

separately <strong>ac</strong>hieves high removal efficiency. Physical-chemical treatment is needed to<br />

remove <strong>th</strong>e metals and hydrolyze some <strong>of</strong> <strong>th</strong>e organics whilst biological treatment is<br />

necessary for stabilization and degradation <strong>of</strong> organic matter. Looking into <strong>th</strong>ese aspects,<br />

landfill le<strong>ac</strong>hate treatment requires some advanced treatment technique, to meet <strong>th</strong>e<br />

required effluent standards.<br />

Membrane biore<strong>ac</strong>tor systems are an example <strong>of</strong> an emerging advanced le<strong>ac</strong>hate<br />

treatment technology. Application <strong>of</strong> <strong>th</strong>e membrane coupled <strong>ac</strong>tivated sludge process in<br />

le<strong>ac</strong>hate treatment is very promising because <strong>of</strong> <strong>th</strong>e expected effluent quality. The design<br />

<strong>of</strong> <strong>th</strong>e membrane biore<strong>ac</strong>tor is becoming more affordable and <strong>th</strong>e equipment more reliable.<br />

Membrane biore<strong>ac</strong>tor systems are suspended grow<strong>th</strong> <strong>ac</strong>tivated sludge treatment systems<br />

<strong>th</strong>at rely upon <strong>th</strong>e membrane equipment for liquid/solid separation prior to <strong>th</strong>e discharge <strong>of</strong><br />

<strong>th</strong>e le<strong>ac</strong>hate. Two reasons <strong>th</strong>at exist for <strong>th</strong>e poor removal efficiency <strong>of</strong> <strong>th</strong>e individual<br />

treatment system is <strong>th</strong>e high percentage <strong>of</strong> high molecular weight organic material and<br />

ammonium concentration to be removed and biological inhibition caused by <strong>th</strong>e heavy<br />

metal which may be present in <strong>th</strong>e le<strong>ac</strong>hate.<br />

Sufficient knowledge about <strong>th</strong>e capability and <strong>th</strong>e performance <strong>of</strong> membrane<br />

biore<strong>ac</strong>tors plants for le<strong>ac</strong>hate treatment is yet to be found. Moreover, membrane systems<br />

are <strong>of</strong>ten subjected to clogging and <strong>th</strong>is poses serious problems for operation and<br />

maintenance. In order to reduce <strong>th</strong>e problems <strong>of</strong> frequent membrane clogging, <strong>th</strong>e<br />

application <strong>of</strong> yeast culture to treat wastewater can be considered. The membrane<br />

biore<strong>ac</strong>tor system wi<strong>th</strong> yeast can be employed to treat <strong>th</strong>e wastewater containing high<br />

amount <strong>of</strong> dissolved solids, high concentrations <strong>of</strong> organic matter and o<strong>th</strong>er substances,<br />

which are difficult to treat using conventional biological systems.<br />

Consequently, depending on <strong>th</strong>e char<strong>ac</strong>teristics <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate, a combination <strong>of</strong><br />

biological and physio-chemical processes can <strong>ac</strong>hieve high removal efficiencies. Thus, <strong>th</strong>e<br />

objective <strong>of</strong> <strong>th</strong>is study is introducing <strong>th</strong>e emerging technology <strong>of</strong> membrane biore<strong>ac</strong>tors<br />

and its role in le<strong>ac</strong>hate treatment. Thereafter, a rationale has been developed for <strong>th</strong>e<br />

treatment <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate produced under tropical conditions <strong>of</strong> Thailand. The experiments<br />

have been conducted in <strong>th</strong>e laboratory to find <strong>th</strong>e performance <strong>of</strong> membrane biore<strong>ac</strong>tor<br />

using yeast culture (YMBR) and b<strong>ac</strong>teria culture (BMBR) and coupled wi<strong>th</strong> ammonia<br />

stripping for removal <strong>of</strong> organic substances from <strong>th</strong>e landfill le<strong>ac</strong>hate. This treatment<br />

system could <strong>ac</strong>t as an innovative appro<strong>ac</strong>h in <strong>th</strong>e future wi<strong>th</strong> regard to <strong>th</strong>e landfill<br />

management pr<strong>ac</strong>tices.<br />

1.2 Objectives <strong>of</strong> <strong>th</strong>e Study<br />

The objectives <strong>of</strong> <strong>th</strong>is study are to investigate <strong>th</strong>e performance <strong>of</strong> membrane<br />

biore<strong>ac</strong>tor using yeast culture and b<strong>ac</strong>teria culture and to examine <strong>th</strong>e prospects <strong>of</strong><br />

applying membrane biore<strong>ac</strong>tor in landfill le<strong>ac</strong>hate treatment. The specific objectives are as<br />

follows:<br />

3

1. To investigate and evaluate <strong>th</strong>e performance <strong>of</strong> membrane biore<strong>ac</strong>tor using yeast<br />

culture (YMBR) and b<strong>ac</strong>teria culture (BMBR) for <strong>th</strong>e treatment <strong>of</strong> landfill le<strong>ac</strong>hate<br />

containing high organic and high ammonia concentrations;<br />

2. To investigate and evaluate <strong>th</strong>e performance <strong>of</strong> ammonia stripping coupled<br />

membrane biore<strong>ac</strong>tor process for <strong>th</strong>e landfill le<strong>ac</strong>hate treatment and to compare <strong>th</strong>e<br />

results wi<strong>th</strong> <strong>th</strong>e treatment performance wi<strong>th</strong>out pre-treatment;<br />

3. To evaluate <strong>th</strong>e respiratory inhibition effects <strong>of</strong> ammonia and lead concentrations on<br />

mixed yeast and mixed b<strong>ac</strong>teria culture;<br />

4. To investigate <strong>th</strong>e potential <strong>of</strong> ammonia stripping for ammonia removal and examine<br />

<strong>th</strong>e f<strong>ac</strong>tors influencing <strong>th</strong>e ammonia removal efficiency;<br />

5. To understand <strong>th</strong>e effect <strong>of</strong> membrane fouling <strong>th</strong>rough sludge char<strong>ac</strong>teristics.<br />

1.3 Scope <strong>of</strong> <strong>th</strong>e Study<br />

To <strong>ac</strong>hieve <strong>th</strong>e above mentioned objectives, <strong>th</strong>e following tasks are undertaken:<br />

1. Char<strong>ac</strong>terization and mixing <strong>of</strong> le<strong>ac</strong>hates obtained from Pa<strong>th</strong>um<strong>th</strong>ani landfill site<br />

(PS) and Ram-indra transfer station (RIS) was done to simulate a medium-aged<br />

le<strong>ac</strong>hate. The le<strong>ac</strong>hate COD concentration was maintained at 8,000±1,000 mg/L,<br />

BOD/COD ratio at 0.40±0.05, and TKN concentration at 1,900±100 mg/L. This<br />

laboratory simulated le<strong>ac</strong>hate was used to evaluate <strong>th</strong>e performance <strong>of</strong> <strong>th</strong>e treatment<br />

process.<br />

2. The yeast culture membrane biore<strong>ac</strong>tor (YMBR) and b<strong>ac</strong>teria culture based<br />

membrane biore<strong>ac</strong>tor (BMBR) were optimized varying <strong>th</strong>e HRT and MLSS<br />

concentrations. The optimum operational condition was evaluated in terms <strong>of</strong> organic<br />

and TKN removal efficiencies and membrane filtration performance.<br />

3. The removal <strong>of</strong> ammonia <strong>th</strong>rough ammonia stripping was carried out by varying <strong>th</strong>e<br />

pH, gradient velocity and cont<strong>ac</strong>t time. The process efficiency was evaluated in<br />

terms <strong>of</strong> ammonia removal efficiency. After <strong>th</strong>e optimization <strong>of</strong> <strong>th</strong>e operating<br />

conditions <strong>of</strong> <strong>th</strong>e ammonia stripping and <strong>th</strong>e membrane biore<strong>ac</strong>tor, <strong>th</strong>e optimum<br />

conditions were used to assess <strong>th</strong>e efficiency <strong>of</strong> <strong>th</strong>e membrane biore<strong>ac</strong>tor using <strong>th</strong>e<br />

b<strong>ac</strong>terial and yeast culture along wi<strong>th</strong> <strong>th</strong>e ammonia stripping.<br />

4. To evaluate <strong>th</strong>e inhibition effects <strong>of</strong> ammonium (NH4-N) and lead (Pb) on mixed<br />

yeast and mixed b<strong>ac</strong>teria sludge. The NH4-N concentration was varied from 200 to<br />

2,000 mg/L in bo<strong>th</strong> sludge. The lead nitrate (Pb(NO3)2) concentration in <strong>th</strong>e b<strong>ac</strong>teria<br />

system was varied from 20 to 100 mg/L while in <strong>th</strong>e yeast system was varied from 2<br />

to 25 mg/L. The inhibitory effect was measured in terms <strong>of</strong> oxygen uptake rate<br />

(OUR) using respirometric me<strong>th</strong>od.<br />

5. The sludge char<strong>ac</strong>teristics were analyzed to understand <strong>th</strong>eir relationship wi<strong>th</strong> <strong>th</strong>e<br />

EPS formation in <strong>th</strong>e membrane biore<strong>ac</strong>tor. The molecular weight cut-<strong>of</strong>f was also<br />

done in <strong>th</strong>e sludge along wi<strong>th</strong> <strong>th</strong>e fr<strong>ac</strong>tion causing COD.<br />

4

2.1 Introduction<br />

Chapter 2<br />

Literature Review<br />

A landfill is any form <strong>of</strong> waste land, ranging from an uncontrolled rubbish "dump" to<br />

a full "containment" site engineered wi<strong>th</strong> high standards to protect <strong>th</strong>e environment. The<br />

landfill is <strong>th</strong>e most economical form <strong>of</strong> solid waste disposal as adverse environmental<br />

effects and o<strong>th</strong>er risks and inconveniences are minimized, <strong>th</strong>ereby allowing waste to<br />

decompose under controlled conditions until it eventually transforms into relatively inert,<br />

stabilized material (Robinson and Maris, 1983). Most landfills can be operated<br />

satisf<strong>ac</strong>torily for at least some period in <strong>th</strong>eir lifetime in <strong>th</strong>is manner and in absence <strong>of</strong> any<br />

significant negative environmental imp<strong>ac</strong>t.<br />

Unfortunately, in warmer climates, <strong>th</strong>e increase in le<strong>ac</strong>hate production after<br />

precipitation is rapid (Lema, et al., 1988) due to rainfall exceeding <strong>th</strong>e amount which can<br />

be effectively evaporated during winter or rainy seasons. Hence, le<strong>ac</strong>hate generation needs<br />

to be controlled and effective le<strong>ac</strong>hate treatment options have to be identified in order to<br />

avoid negative imp<strong>ac</strong>ts caused by <strong>th</strong>e le<strong>ac</strong>hate.<br />

A common pr<strong>ac</strong>tice in controlling le<strong>ac</strong>hate generation is to control <strong>th</strong>e water<br />

infiltration in <strong>th</strong>e landfill by waste comp<strong>ac</strong>tion as it reduces <strong>th</strong>e infiltration rate. Fur<strong>th</strong>er, by<br />

designing water pro<strong>of</strong> covers and growing plants on <strong>th</strong>e soil covers <strong>of</strong> <strong>th</strong>e waste,<br />

infiltration can be minimized. Figure 2.1 presents a typical engineered landfill. The landfill<br />

le<strong>ac</strong>hate char<strong>ac</strong>teristic is controlled by solid waste char<strong>ac</strong>teristics, moisture content, pH,<br />

redox potential, temperature, etc. The presence <strong>of</strong> moisture is necessary for <strong>th</strong>e biological<br />

conversions wi<strong>th</strong>in <strong>th</strong>e landfill and for landfill stabilisation, which occurs when <strong>th</strong>ere is<br />

insufficient moisture. Degradation processes wi<strong>th</strong>in <strong>th</strong>e landfill are also temperature<br />

dependent. The pH and redox potential set <strong>th</strong>e conditions for <strong>th</strong>e different phases <strong>of</strong><br />

degradation and biological processes wi<strong>th</strong>in <strong>th</strong>e landfill. Thus, <strong>th</strong>e microbial composition<br />

wi<strong>th</strong>in <strong>th</strong>e landfill effectively contributes to <strong>th</strong>e landfill stabilization.<br />

After <strong>th</strong>e initial period <strong>of</strong> waste pl<strong>ac</strong>ement in a landfill, microbial processes proceed<br />

under anoxic conditions. Hydrolytic and fermentative microbial processes solubilize <strong>th</strong>e<br />

waste components during <strong>th</strong>e <strong>ac</strong>id fermentation phase producing organic <strong>ac</strong>ids, alcohols,<br />

ammonia, carbon dioxide and o<strong>th</strong>er low molecular weight compounds as major products.<br />

This process occurs at a low pH (typically around 5) and is enhanced by <strong>th</strong>e presence <strong>of</strong><br />

moisture wi<strong>th</strong>in <strong>th</strong>e landfill. After several mon<strong>th</strong>s, <strong>th</strong>e me<strong>th</strong>ane fermentation stage occurs.<br />

Me<strong>th</strong>anogenic le<strong>ac</strong>hate is neutral in pH and possesses moderate organic compounds which<br />

are not easily degradable and are fermented to yield me<strong>th</strong>ane, carbon dioxide and o<strong>th</strong>er<br />

gaseous end products (Harmsen, 1983; Farquhar, 1989).<br />

5

Perimeter<br />

Collection Pipe<br />

Cap Drainage<br />

System<br />

Filter<br />

Layer<br />

Comp<strong>ac</strong>ted<br />

soil<br />

Le<strong>ac</strong>hate Collection<br />

System<br />

Leak Detection<br />

System<br />

Figure 2.1 Schematic Representation <strong>of</strong> a Typical Engineered Landfill<br />

2.2 Solid Waste Management Pr<strong>ac</strong>tices<br />

The safe and reliable long-term disposal <strong>of</strong> solid waste is an important component in<br />

solid waste management. Municipal solid waste consists <strong>of</strong> inorganic substances such as<br />

boxes, grass clippings, furniture, clo<strong>th</strong>ing, bottles, food scraps, newspapers, and appliances<br />

along wi<strong>th</strong> organic waste. There are different me<strong>th</strong>ods employed in solid waste<br />

management. Few <strong>of</strong> <strong>th</strong>e management pr<strong>ac</strong>tices are as follows:<br />

(a) Reduction in <strong>th</strong>e exploitation <strong>of</strong> <strong>th</strong>e resources and <strong>th</strong>e minimization <strong>of</strong> waste<br />

(b) Increase in recovery/reuse by pl<strong>ac</strong>ing increased responsibility on <strong>th</strong>e producer<br />

(c) Incineration<br />

(d) Composting<br />

(e) Landfilling, etc.<br />

Landfilling or <strong>th</strong>e land disposal is today <strong>th</strong>e most commonly used me<strong>th</strong>od for waste<br />

disposal. Landfill has been <strong>th</strong>e most economical and environmentally <strong>ac</strong>ceptable me<strong>th</strong>od<br />

for <strong>th</strong>e disposal <strong>of</strong> solid waste <strong>th</strong>roughout <strong>th</strong>e world. Even wi<strong>th</strong> <strong>th</strong>e implementation <strong>of</strong><br />

waste reduction, recycling and transformation technologies, disposal <strong>of</strong> solid waste in <strong>th</strong>e<br />

landfill still remains an important component <strong>of</strong> <strong>th</strong>e solid waste management strategies.<br />

Concerns wi<strong>th</strong> <strong>th</strong>e landfilling <strong>of</strong> solid waste are related to (1) <strong>th</strong>e controlled release<br />

<strong>of</strong> landfill gases <strong>th</strong>at might migrate <strong>of</strong>f-site and cause odor and o<strong>th</strong>er potentially dangerous<br />

conditions, (2) <strong>th</strong>e imp<strong>ac</strong>t <strong>of</strong> <strong>th</strong>e uncontrolled discharge <strong>of</strong> landfill gases on <strong>th</strong>e green<br />

house effect in <strong>th</strong>e atmosphere , (3) <strong>th</strong>e uncontrolled release <strong>of</strong> le<strong>ac</strong>hate <strong>th</strong>at may migrate<br />

down to underlying groundwater or to surf<strong>ac</strong>e water, (4) <strong>th</strong>e breeding and harboring <strong>of</strong><br />

disease vectors in an improperly managed landfills, and (5) <strong>th</strong>e heal<strong>th</strong> and environmental<br />

imp<strong>ac</strong>ts associated wi<strong>th</strong> <strong>th</strong>e release <strong>of</strong> tr<strong>ac</strong>e gases arising from <strong>th</strong>e hazardous materials.<br />

2.3 Municipal Solid Waste Landfill<br />

Gas Vent<br />

Solid waste<br />

Drainage<br />

Layer<br />

Top Soil<br />

Drainage Layer<br />

Low Permeability Soil<br />

6<br />

Collection<br />

Pipes<br />

Collection<br />

Pipes<br />

Native Soil Foundation<br />

Final Soil Cover<br />

Filter Layer<br />

Barrier Layer<br />

(FML)<br />

Top Liner<br />

(FML)<br />

Upper<br />

Component<br />

Lower Component<br />

(Comp<strong>ac</strong>ted Soil)<br />

Protective Soil<br />

or Cover

In <strong>th</strong>e municipal solid waste landfill, biodegradable waste constituents are converted<br />

into intermediates and end products, primarily by initial hydrolysis to intermediate<br />

substrates which support <strong>ac</strong>idogenesis and product are subsequently utilized as precursor<br />

for gas formation during me<strong>th</strong>anogenesis in <strong>th</strong>e five degradation phases (Pohland and<br />

Harper, 1985; Pohland and Kim, 1999). Figure 2.2 represents variation in concentrations <strong>of</strong><br />

significant parameters during <strong>th</strong>e five degradation phases.<br />

High<br />

Concentration<br />

Low<br />

Redox<br />

Potential<br />

Figure 2.2 Changes in Significant Parameters during Different Phases <strong>of</strong> Landfill<br />

Stabilization (Pohland and Harper, 1985)<br />

The trend in <strong>th</strong>e degradation phase may not uniform <strong>th</strong>roughout <strong>th</strong>e landfill since<br />

<strong>th</strong>ere are certain regions in <strong>th</strong>e landfill which are dominated by a particular degradation<br />

phase. Hence, <strong>th</strong>e le<strong>ac</strong>hate generated is a combination <strong>of</strong> <strong>th</strong>e products <strong>of</strong> different<br />

microbial and physico-chemical processes taking pl<strong>ac</strong>e wi<strong>th</strong>in <strong>th</strong>e landfill.<br />

2.4 Municipal Solid Waste Landfill Le<strong>ac</strong>hate<br />

Landfill le<strong>ac</strong>hate is a high-streng<strong>th</strong> wastewater formed as a result <strong>of</strong> percolation <strong>of</strong><br />

rainwater and moisture <strong>th</strong>rough waste in a landfill. The liquid medium absorbs nutrients<br />

and contaminants from <strong>th</strong>e waste and <strong>th</strong>us posing hazard to <strong>th</strong>e receiving water bodies.<br />

Le<strong>ac</strong>hate contains many substances, depending upon <strong>th</strong>e types <strong>of</strong> waste disposed into <strong>th</strong>e<br />

landfill. Le<strong>ac</strong>hate may be toxic to life or may simply alter <strong>th</strong>e ecology <strong>of</strong> <strong>th</strong>e stream<br />

watercourse, if not removed by treatment.<br />

Depending on <strong>th</strong>e geographical and geological nature <strong>of</strong> a landfill site, le<strong>ac</strong>hate may<br />

seep into <strong>th</strong>e ground and possibly enter groundwater sources. Though part <strong>of</strong> <strong>th</strong>e<br />

contaminants from <strong>th</strong>e le<strong>ac</strong>hate can be removed by natural processes wi<strong>th</strong>in <strong>th</strong>e ground,<br />

groundwater contamination can be hazardous as drinking water sources may be affected.<br />

The simplest me<strong>th</strong>od <strong>of</strong> le<strong>ac</strong>hate treatment is disposal into <strong>th</strong>e public sewer. However,<br />

as <strong>th</strong>ere is considerable difference between <strong>th</strong>e le<strong>ac</strong>hate and domestic wastewater<br />

char<strong>ac</strong>teristics, <strong>th</strong>e volume <strong>of</strong> le<strong>ac</strong>hate discharged is limited. Fur<strong>th</strong>er, depending on<br />

7<br />

Heavy Metal<br />

Emission<br />

Carbon<br />

Emission<br />

Aerobic Acidogenic Me<strong>th</strong>anogenic Oxidation Wea<strong>th</strong>ering<br />

Degradation Phases

le<strong>ac</strong>hate char<strong>ac</strong>teristics, it may be necessary to pre-treat le<strong>ac</strong>hate prior to discharge in<br />

wastewater treatment plants so <strong>th</strong>at it does not upset <strong>th</strong>e biological process nor cause any<br />

operational and maintenance problems in <strong>th</strong>e treatment plant. In determining a treatment<br />

scheme for le<strong>ac</strong>hate treatment, it is also necessary to determine whe<strong>th</strong>er <strong>th</strong>e le<strong>ac</strong>hate<br />

effluent meets sewer or water body discharge standards.<br />

2.5 Le<strong>ac</strong>hate Composition and Char<strong>ac</strong>teristics<br />

During <strong>th</strong>e first few years (< 5 years), <strong>th</strong>e landfill is in <strong>ac</strong>idogenic phase and <strong>th</strong>e<br />

le<strong>ac</strong>hate generated is generally referred to as “young” or carbon-based le<strong>ac</strong>hate due to <strong>th</strong>e<br />

high concentration <strong>of</strong> organic carbon present. Landfill greater <strong>th</strong>an 10 years old are<br />

generally in <strong>th</strong>e me<strong>th</strong>anogenic phase and <strong>th</strong>e le<strong>ac</strong>hate generated is referred to as “old” or<br />

nitrogen-based le<strong>ac</strong>hate (Mavinic, 1998). Table.2.1 gives <strong>th</strong>e char<strong>ac</strong>teristic <strong>of</strong> le<strong>ac</strong>hate<br />

present in <strong>ac</strong>idogenic and me<strong>th</strong>anogenic phases.<br />

Table 2.1 Le<strong>ac</strong>hate Char<strong>ac</strong>teristic in Acidogenic and Me<strong>th</strong>anogenic Phase in a Landfill<br />

(Ehrig, 1998)<br />

Parameter Unit Average Range<br />

Acidogenic Phase<br />

pH 6.1 4.5 to 7.5<br />

BOD5 mg/L 13,000 4,000 to 40,000<br />

COD mg/L 22,000 6,000 to 60,000<br />

BOD5/COD 0.58 -<br />

SO4 mg/L 500 70 to 1,750<br />

Ca mg/L 1,200 10 to 2,500<br />

Mg mg/L 470 50 to 1,150<br />

Fe mg/L 780 20 to 2,100<br />

Mn mg/L 25 0.3 to 65<br />

Zn mg/L 5 0.1 to 120<br />

Me<strong>th</strong>anogenic Phase<br />

pH 8 7.5 to 9<br />

BOD5 mg/L 180 20 to 550<br />

COD mg/L 3,000 500 to 4,500<br />

BOD5/COD 0.06 -<br />

SO4 mg/L 80 10 to 420<br />

Ca mg/L 60 20 to 600<br />

Mg mg/L 180 40 to 350<br />

Fe mg/L 15 3 to 280<br />

Mn mg/L 0.7 0.03 to 45<br />

Zn mg/L 0.6 0.03 to 4<br />

The differences in le<strong>ac</strong>hate quality can be due to varied reasons, which can be<br />

categorised into four major divisions, namely <strong>th</strong>e waste (type <strong>of</strong> waste, degree <strong>of</strong><br />

decomposition, and possible seasonal variance), landfill environment (phase <strong>of</strong> degradation,<br />

humidity, temperature etc.), filling technique (comp<strong>ac</strong>ting, cover, height <strong>of</strong> landfill layers,<br />

etc.) and sampling (me<strong>th</strong>od <strong>of</strong> analysis and point <strong>of</strong> sample collection).<br />

The f<strong>ac</strong>tors affecting <strong>th</strong>e le<strong>ac</strong>hate quality is inter-related and affects <strong>th</strong>e overall<br />

variance in le<strong>ac</strong>hate quality and char<strong>ac</strong>terization. The changes in <strong>th</strong>e BOD/COD,<br />

8

COD/TOC, VS/FS and VFA/TOC ratios <strong>of</strong> le<strong>ac</strong>hate are depends greatly on <strong>th</strong>e age <strong>of</strong> <strong>th</strong>e<br />

landfill (Chian and DeWalle, 1976; Kylefors, 1997). Figure 2.3 represents <strong>th</strong>e trend <strong>of</strong><br />

le<strong>ac</strong>hate variation and over <strong>th</strong>e period <strong>of</strong> time in <strong>th</strong>e landfill. During <strong>th</strong>e initial stages, <strong>th</strong>e<br />

landfill is aerobic rich in biodegradable organic content. As <strong>th</strong>e landfill age increases, <strong>th</strong>e<br />

microorganism present in <strong>th</strong>e landfill tend to degrade <strong>th</strong>ese organic compounds into<br />

inorganic components. When anaerobic phase begins, <strong>th</strong>e COD starts increasing causing a<br />

decrease in BOD/COD ratio. This decrease in BOD/COD ratio observed, suggests <strong>th</strong>e<br />

change in biodegradability <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate wi<strong>th</strong> time. For young landfill, <strong>th</strong>e ratio is around<br />

0.5-0.8 while it re<strong>ac</strong>hes almost 0.1 in <strong>th</strong>e old landfill. The reason for low biodegradability<br />

in <strong>th</strong>e old landfill could be due to <strong>th</strong>e presence <strong>of</strong> humic and fluvic <strong>ac</strong>ids.<br />

Figure 2.3 Variation in Significant Pollutant Ratios wi<strong>th</strong> Increase in Age <strong>of</strong> <strong>th</strong>e Landfill<br />

(Chian and DeWalle, 1976)<br />

The ammonium concentration in <strong>th</strong>e le<strong>ac</strong>hate also varies wi<strong>th</strong> age <strong>of</strong> <strong>th</strong>e landfill, wi<strong>th</strong><br />

young le<strong>ac</strong>hate having a high COD (>5,000 mg/L) and low nitrogen content (< 400 mg<br />

N/L) and old le<strong>ac</strong>hate having a high concentrations <strong>of</strong> ammonia (> 400 mg N/L) and<br />

recalcitrant compounds and a low biodegradable organic fr<strong>ac</strong>tion (BOD5/COD = 0.1).<br />

Municipal solid waste landfill in Asia (except Japan) is char<strong>ac</strong>terized by 60 to 90 %<br />

organic waste and 3 to 18 % plastic (Agamu<strong>th</strong>u, 1999). Le<strong>ac</strong>hate char<strong>ac</strong>teristics <strong>of</strong> landfills<br />

surveyed in Asia including Thailand, Europe, and America are presented in Table 2.2. The<br />

char<strong>ac</strong>teristic <strong>of</strong> le<strong>ac</strong>hate from different landfill site as reported show a great variation. It is<br />

dependent on <strong>th</strong>e solid waste composition, landfill site location, and local climate. The<br />

BOD and COD concentrations decrease as <strong>th</strong>e landfill age increases.<br />

9

Table 2.2 Comparison <strong>of</strong> Le<strong>ac</strong>hate Char<strong>ac</strong>teristics <strong>of</strong> Landfills Surveyed in Asia, Europe and America<br />

Thailand 1,2 Malaysia 3<br />

Parameter<br />

Air Sabak Taman HongKong<br />

Phitsanuklok Pa<strong>th</strong>um<strong>th</strong>ani Nakhonpa<strong>th</strong>om Pa<strong>th</strong>um<strong>th</strong>ani On-Nutch Hitam Bernam Beringin<br />

4<br />

USA 5<br />

Europe 6<br />

Years in<br />

operation 1 3 4 9 20 5 7 16 6 10 1 5 16 -<br />

1,540- 1,200- 3,750- 10,700- 3,230- 800-<br />

300-<br />

Alkalinity 300-4,700 918-4,250 960-2,740 6,620 - 9,000 1,550 9,375 11,700 4,940 4,000 5,810 2,250 11,500<br />

pH 7.1-8.3 8.2-8.9 8.2-8.5 8.1 7.5 7.6-8.8 8.0-801 7.8-8.7 8.1-8.6 7.6-8.1 5.2-6.4 6.3 - 5.3-8.5<br />

1,625- 420-<br />

2,320-<br />

Chloride - 1,220-5,545 655-2,200 2,530 - 3,200<br />

410-<br />

1,820 875-2,875 2,740 522-853 600-800 1,330 70 -<br />

SS 1,950 29-110 8.4-15.7 12.5 488 1,250 111-920 420-1,150 40-53 3-124 - - - -<br />

13,930-<br />

10,300-<br />

TS 6,700 350-1,598 274-1,200 848 11,320 15,380 - 13,680 - - 100-700 - - -<br />

1,724- 1,250- 1,960- 2,460-<br />

10,000-<br />

150-<br />

COD 4,900-11,000 1,488-3,200 800-3,575 3,200 1,200 7,038 2,570 5,500 2,830 641-873 40,000 8,000 400 100,000<br />

1,120- 726-<br />

7,500-<br />

100-<br />

BOD 3,000-7,150 198-260 100-240 280 130 1,800 1,210 562-1,990 - - 28,000 4,000 80 90,000<br />

2,219- 889-<br />

TKN - 240-452 64-1,260 1,256 700 131-930 - 104-1,014 2,860 1,180 - - - 50-5,000<br />

1,190- 784-<br />

NH3-N 150-1,250 - - - - 2-32 3-8 2-47 2,700 1,156 56-482 - - 1-1500<br />

Ni 0.02-1.56 0.01-0.42 0.1 0.25 0.035 0.13-0.95 - 0-0.6 - - - - - 0.02-2.05<br />

Cd 0.037 0.02 0.001 0.002 - 0-0.23 0-0.001 0-0.15 - - -

Table 2.3 presents <strong>th</strong>e general le<strong>ac</strong>hate char<strong>ac</strong>teristics wi<strong>th</strong> age and suitability <strong>of</strong><br />

treatment options in terms <strong>of</strong> biodegradable, intermediate and stabilized landfill le<strong>ac</strong>hate.<br />

As <strong>th</strong>e young landfill is rich in organic, biological treatment is more appropriate <strong>th</strong>an<br />

physico-chemical which is suitable for <strong>th</strong>e old landfill. However, effectiveness <strong>of</strong><br />

combined treatment process for <strong>th</strong>e treatment <strong>of</strong> a le<strong>ac</strong>hate produced at specific landfill age<br />

has not been considered. Individual treatment options cannot be a long-term solution for<br />

le<strong>ac</strong>hate treatment as <strong>th</strong>ey are not effective in treating le<strong>ac</strong>hate generated at different period<br />

<strong>of</strong> time and do not adapt to changing le<strong>ac</strong>hate char<strong>ac</strong>teristics.<br />

Table 2.3 Relation between Landfill Age, Le<strong>ac</strong>hate Char<strong>ac</strong>teristics and Treatments<br />

(Amokrane, et al., 1997)<br />

Landfill Age (years) < 5 (young) 5 to 10 (medium) > 10 (old)<br />

Le<strong>ac</strong>hate Type I (biodegradable) II (intermediate) III (stabilized)<br />