Evaluation of Plastic Waste Management in Thailand Using Material ...

Evaluation of Plastic Waste Management in Thailand Using Material ...

Evaluation of Plastic Waste Management in Thailand Using Material ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

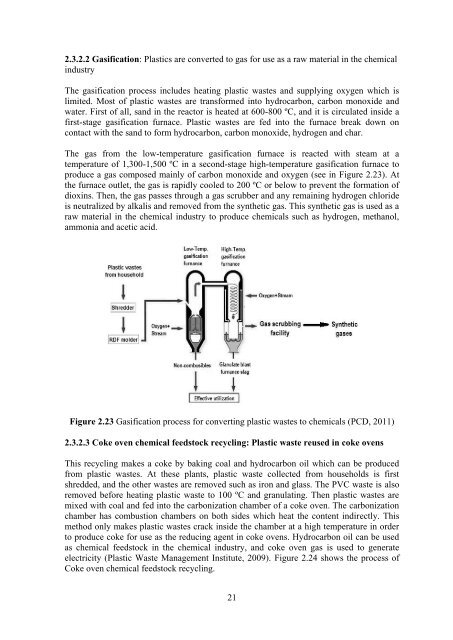

2.3.2.2 Gasification: <strong>Plastic</strong>s are converted to gas for use as a raw material <strong>in</strong> the chemical<br />

<strong>in</strong>dustry<br />

The gasification process <strong>in</strong>cludes heat<strong>in</strong>g plastic wastes and supply<strong>in</strong>g oxygen which is<br />

limited. Most <strong>of</strong> plastic wastes are transformed <strong>in</strong>to hydrocarbon, carbon monoxide and<br />

water. First <strong>of</strong> all, sand <strong>in</strong> the reactor is heated at 600-800 ºC, and it is circulated <strong>in</strong>side a<br />

first-stage gasification furnace. <strong>Plastic</strong> wastes are fed <strong>in</strong>to the furnace break down on<br />

contact with the sand to form hydrocarbon, carbon monoxide, hydrogen and char.<br />

The gas from the low-temperature gasification furnace is reacted with steam at a<br />

temperature <strong>of</strong> 1,300-1,500 ºC <strong>in</strong> a second-stage high-temperature gasification furnace to<br />

produce a gas composed ma<strong>in</strong>ly <strong>of</strong> carbon monoxide and oxygen (see <strong>in</strong> Figure 2.23). At<br />

the furnace outlet, the gas is rapidly cooled to 200 ºC or below to prevent the formation <strong>of</strong><br />

diox<strong>in</strong>s. Then, the gas passes through a gas scrubber and any rema<strong>in</strong><strong>in</strong>g hydrogen chloride<br />

is neutralized by alkalis and removed from the synthetic gas. This synthetic gas is used as a<br />

raw material <strong>in</strong> the chemical <strong>in</strong>dustry to produce chemicals such as hydrogen, methanol,<br />

ammonia and acetic acid.<br />

Figure 2.23 Gasification process for convert<strong>in</strong>g plastic wastes to chemicals (PCD, 2011)<br />

2.3.2.3 Coke oven chemical feedstock recycl<strong>in</strong>g: <strong>Plastic</strong> waste reused <strong>in</strong> coke ovens<br />

This recycl<strong>in</strong>g makes a coke by bak<strong>in</strong>g coal and hydrocarbon oil which can be produced<br />

from plastic wastes. At these plants, plastic waste collected from households is first<br />

shredded, and the other wastes are removed such as iron and glass. The PVC waste is also<br />

removed before heat<strong>in</strong>g plastic waste to 100 ºC and granulat<strong>in</strong>g. Then plastic wastes are<br />

mixed with coal and fed <strong>in</strong>to the carbonization chamber <strong>of</strong> a coke oven. The carbonization<br />

chamber has combustion chambers on both sides which heat the content <strong>in</strong>directly. This<br />

method only makes plastic wastes crack <strong>in</strong>side the chamber at a high temperature <strong>in</strong> order<br />

to produce coke for use as the reduc<strong>in</strong>g agent <strong>in</strong> coke ovens. Hydrocarbon oil can be used<br />

as chemical feedstock <strong>in</strong> the chemical <strong>in</strong>dustry, and coke oven gas is used to generate<br />

electricity (<strong>Plastic</strong> <strong>Waste</strong> <strong>Management</strong> Institute, 2009). Figure 2.24 shows the process <strong>of</strong><br />

Coke oven chemical feedstock recycl<strong>in</strong>g.<br />

21