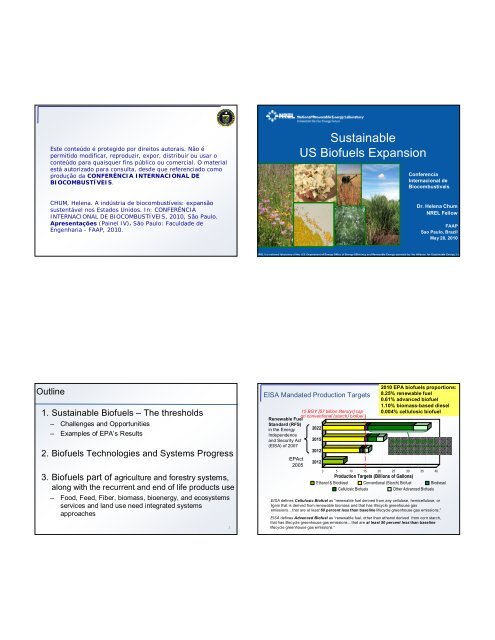

Sustainable US Biofuels Expansion - Faap

Sustainable US Biofuels Expansion - Faap Sustainable US Biofuels Expansion - Faap

Este conteúdo é protegido por direitos autorais. Não é permitido modificar, reproduzir, expor, distribuir ou usar o conteúdo para quaisquer fins público ou comercial. O material está autorizado para consulta, desde que referenciado como produção da CONFERÊNCIA INTERNACIONAL DE BIOCOMBUSTÍVEIS. CHUM, Helena. A indústria de biocombustíveis: expansão sustentável nos Estados Unidos. In: CONFERÊNCIA INTERNACIONAL DE BIOCOMBUSTÍVEIS, 2010, São Paulo. Apresentações (Painel IV). São Paulo: Faculdade de Engenharia - FAAP, 2010. Outline 1. Sustainable Biofuels – The thresholds – Challenges and Opportunities – Examples of EPA’s Results 2. Biofuels Technologies and Systems Progress 3. Biofuels part of agriculture and forestry systems, along with the recurrent and end of life products use – Food, Feed, Fiber, biomass, bioenergy, and ecosystems services and land use need integrated systems approaches 3 Sustainable US Biofuels Expansion Conferencia Internacional de Biocombustiveis Dr. Helena Chum NREL Fellow FAAP Sao Paulo, Brazil May 28, 2010 NREL is a national laboratory of the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy operated by the Alliance for Sustainable Energy, LLC EISA Mandated Production Targets 15 BGY [57 billion liters/yr] cap on conventional (starch) biofuel Renewable Fuel Standard (RFS) in the Energy 2022 Independence and Security Act 2015 (EISA) of 2007 2012 EPAct 2005 2012 2010 EPA biofuels proportions: 8.25% renewable fuel 0.61% advanced biofuel 1.10% biomass-based diesel 0.004% cellulosic biofuel Advanced Biofuels (include cellulosic biofuels other than starch-based ethanol) 0 5 10 15 20 25 30 35 40 Production Targets (Billions of Gallons) Ethanol & Biodiesel Conventional (Starch) Biofuel Biodiesel Cellulosic Biofuels Other Advanced Biofuels EISA defines Cellulosic Biofuel as “renewable fuel derived from any cellulose, hemicellulose, or lignin that is derived from renewable biomass and that has lifecycle greenhouse gas emissions…that are at least 60 percent less than baseline lifecycle greenhouse gas emissions.” EISA defines Advanced Biofuel as “renewable fuel, other than ethanol derived from corn starch, that has lifecycle greenhouse gas emissions…that are at least 50 percent less than baseline lifecycle greenhouse gas emissions.”

- Page 3 and 4: Multiple Simultaneous Advances in T

- Page 5 and 6: Key Recent Accomplishments and Deli

- Page 7 and 8: Grand Challenge: Next-Generation Bi

- Page 9 and 10: Chum, 12/2009 Chum, 12/2009 Summary

- Page 11: EPA, 2010, Renewable Fuel Standard

Este conteúdo é protegido por direitos autorais. Não é<br />

permitido modificar, reproduzir, expor, distribuir ou usar o<br />

conteúdo para quaisquer fins público ou comercial. O material<br />

está autorizado para consulta, desde que referenciado como<br />

produção da CONFERÊNCIA INTERNACIONAL DE<br />

BIOCOMB<strong>US</strong>TÍVEIS.<br />

CHUM, Helena. A indústria de biocombustíveis: expansão<br />

sustentável nos Estados Unidos. In: CONFERÊNCIA<br />

INTERNACIONAL DE BIOCOMB<strong>US</strong>TÍVEIS, 2010, São Paulo.<br />

Apresentações (Painel IV). São Paulo: Faculdade de<br />

Engenharia - FAAP, 2010.<br />

Outline<br />

1. <strong>Sustainable</strong> <strong>Biofuels</strong> – The thresholds<br />

– Challenges and Opportunities<br />

– Examples of EPA’s Results<br />

2. <strong>Biofuels</strong> Technologies and Systems Progress<br />

3. <strong>Biofuels</strong> part of agriculture and forestry systems,<br />

along with the recurrent and end of life products use<br />

– Food, Feed, Fiber, biomass, bioenergy, and ecosystems<br />

services and land use need integrated systems<br />

approaches<br />

3<br />

<strong>Sustainable</strong><br />

<strong>US</strong> <strong>Biofuels</strong> <strong>Expansion</strong><br />

Conferencia<br />

Internacional de<br />

Biocombustiveis<br />

Dr. Helena Chum<br />

NREL Fellow<br />

FAAP<br />

Sao Paulo, Brazil<br />

May 28, 2010<br />

NREL is a national laboratory of the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy operated by the Alliance for <strong>Sustainable</strong> Energy, LLC<br />

EISA Mandated Production Targets<br />

15 BGY [57 billion liters/yr] cap<br />

on conventional (starch) biofuel<br />

Renewable Fuel<br />

Standard (RFS)<br />

in the Energy 2022<br />

Independence<br />

and Security Act 2015<br />

(EISA) of 2007<br />

2012<br />

EPAct<br />

2005<br />

2012<br />

2010 EPA biofuels proportions:<br />

8.25% renewable fuel<br />

0.61% advanced biofuel<br />

1.10% biomass-based diesel<br />

0.004% cellulosic biofuel<br />

Advanced <strong>Biofuels</strong><br />

(include cellulosic biofuels other<br />

than starch-based ethanol)<br />

0 5 10 15 20 25 30 35 40<br />

Production Targets (Billions of Gallons)<br />

Ethanol & Biodiesel Conventional (Starch) Biofuel Biodiesel<br />

Cellulosic <strong>Biofuels</strong> Other Advanced <strong>Biofuels</strong><br />

EISA defines Cellulosic Biofuel as “renewable fuel derived from any cellulose, hemicellulose, or<br />

lignin that is derived from renewable biomass and that has lifecycle greenhouse gas<br />

emissions…that are at least 60 percent less than baseline lifecycle greenhouse gas emissions.”<br />

EISA defines Advanced Biofuel as “renewable fuel, other than ethanol derived from corn starch,<br />

that has lifecycle greenhouse gas emissions…that are at least 50 percent less than baseline<br />

lifecycle greenhouse gas emissions.”

Multiple Simultaneous Advances in Technologies for<br />

Feedstocks --- Conversion --- End Use<br />

Goal: Drive towards an<br />

economic integrated<br />

multistep process<br />

DuPont Danisco<br />

Cellulose Ethanol<br />

<strong>US</strong>DA Data: 5-fold increase since 1940<br />

Can industry reach these yields?<br />

80 new hybrids in 2010

Exploring Routes to Convert Biomass<br />

Feedstock<br />

Production<br />

& Logistics<br />

• Energy<br />

crops<br />

• Forest<br />

Residue<br />

• Agricultural<br />

wastes<br />

• Algae<br />

Integrated Biorefineries<br />

Biochemical Conversion<br />

Pretreatment &<br />

Conditioning<br />

Distillation<br />

Enzymatic<br />

Hydrolysis<br />

Sugars Fermentation<br />

Enzyme<br />

By-Products<br />

Production<br />

Wastes/Residue<br />

Thermochemical Conversion<br />

Upgrading<br />

Fast Liquid Zeolite Cracking<br />

Pyrolysis Bio-oil Hydrogenolysis<br />

Gasification Syngas<br />

Lipid (Oil)<br />

Extraction<br />

Algal<br />

Oil<br />

Fischer Tropsch<br />

Alcohol Synthesis<br />

Transesterification<br />

Upgrading<br />

R E F I N I N G<br />

Research on multiple conversion pathways aims to improve the<br />

efficiency and economics of biofuels production.<br />

DDGS (corn)<br />

Lignin<br />

(for power)<br />

Ethanol<br />

Butanol<br />

Olefins<br />

Gasoline<br />

Diesel<br />

Others<br />

Program Areas & Key Challenges<br />

Feedstock<br />

Systems<br />

– Diverse regional<br />

biomass<br />

resources<br />

– Yield & price<br />

– Water & fertilizer<br />

– Land use<br />

– Metrics &<br />

standards<br />

Sustainability<br />

Research & Development Demonstration & Deployment<br />

Conversion Technologies<br />

Biochemical<br />

– Cost & Efficiency<br />

• Pretreatments<br />

• Enzymes/yields<br />

– Fermentation<br />

Thermochemical<br />

– Cost & Efficiency<br />

– Gasification Process<br />

– Fuel Stabilization<br />

• GHG emissions<br />

• Water quality<br />

• Land use<br />

• Socioeconomics<br />

Integrated<br />

Biorefineries<br />

– Integrating<br />

process<br />

technologies<br />

– Financing<br />

– Technical<br />

expertise<br />

– Profit potential<br />

Product Development<br />

− Fuel purity & cost<br />

− By-products/markets<br />

− Infrastructure compatibility<br />

Major DOE <strong>Biofuels</strong> Project Locations<br />

Pacific Ethanol<br />

(Boardman, OR)<br />

Nov ozymes<br />

(Dav is, CA)<br />

Genencor<br />

(Palo Alto, CA)<br />

Ceres, Inc<br />

(Thousand Oaks, CA)<br />

Verenium Corp (2)<br />

(San Diego, CA)<br />

BlueFire Ethanol<br />

(Mecca, CA)<br />

Eight Small-Scale Biorefinery Projects<br />

Four Commercial-Scale Biorefinery Projects<br />

Four Improved Enzyme Projects<br />

Emery Energy<br />

(Salt Lake City, UT)<br />

Five Projects for Fermentation Organisms<br />

Five Thermochemical Syngas Projects<br />

DOE Joint Solicitation Biomass Projects<br />

Five Thermochemical Bio-Oil Projects<br />

Six University Conversion Projects<br />

Montana State University<br />

(Bozeman, MT)<br />

Lignol<br />

(Grand Junction, CO)<br />

Abengoa<br />

(Hugoton, KS )<br />

Cargill Inc<br />

(Minneapolis, MN)<br />

Flambeau Riv er<br />

(Park Falls, WI)<br />

NewPage<br />

(Wisconsin Rapids, WI)<br />

Poet<br />

(Emmetsburg, IA)<br />

Office of Science Bioenergy<br />

Centers<br />

DOE Great Lakes, Madison, WI<br />

DOE Joint Bioenergy Institute, Berkeley,<br />

CA<br />

DOE Bioenergy Science Center, Oak<br />

Ridge, TN<br />

Univ ersity of Minnesota<br />

(Minneapolis, MN)<br />

Iowa State (3) Univ ersity<br />

(Ames, IA)<br />

UOP, LLC<br />

(De s Plaines, IL)<br />

Infrastructure<br />

– Transport<br />

– Storage<br />

– Codes &<br />

Standards<br />

(Blend wall)<br />

– Demand/<br />

markets<br />

– Compatibility<br />

• Predictive Modeling<br />

• International<br />

Purdue Univ ersity (2)<br />

(West Lafaye tte, IN)<br />

Alltech<br />

Env irofine<br />

(Washington<br />

County, KY)<br />

Southern Research<br />

Institute<br />

(Birmingham, AL)<br />

Mascoma<br />

(Kinross, MI)<br />

Gas Technology Institute<br />

(Des Plaines, IL)<br />

Verenium <strong>Biofuels</strong> Corp.<br />

(Jennings, LA)<br />

Georgia Tech<br />

(Atlanta, GA)<br />

Range Fuels<br />

(Soperton, GA)<br />

Mascoma<br />

(Lebanon, NH)<br />

Univ ersity of Georgia<br />

(Athens, GA)<br />

Univ ersity of Maine<br />

(Orono, ME)<br />

Regional<br />

Partnerships<br />

South Dakota State Univ., Brookings, SD<br />

Cornell University, Ithaca, NY<br />

Univ. of Tennessee, Knoxville, TN<br />

Oklahoma State Univ., Stillwater, OK<br />

Oregon State Univ., Corvallis, OR<br />

RSE Pulp &<br />

Chemical, LLC<br />

(Old Town, ME)<br />

Cornell Univ ersity Univ ersity of Mass<br />

(Ithaca, NY)<br />

(Amherst, MA)<br />

GE Global Research<br />

(Niskayuna, NY)<br />

Stevens Institute of<br />

Technology<br />

(Hoboken NJ)<br />

Univ eristy of<br />

Toledo<br />

(Toldeo, OH)<br />

Virginia Tech<br />

(Blacksburg, VA)<br />

DSM Innovation Center<br />

(Parsippany, NJ)<br />

Dupont<br />

(Wilmington, DE )<br />

Research Triangle Institute (2)<br />

(Research Triangle Park, NC)<br />

Modified 10/1/2008

Key Recent Accomplishments and Deliverables<br />

EPACT Section 932 “Commercial-Scale” Biorefineries<br />

DOE investments in cellulosic biofuels will accelerate commercialization<br />

and help create a biofuels market based on non-food feedstocks.<br />

Performers<br />

Poet<br />

Emmetsburg, IA<br />

Range Fuels<br />

Soperton, GA<br />

Abengoa<br />

Hugoton, KS<br />

Bluefire<br />

Fulton, MS<br />

Feedstock<br />

Type<br />

Corn Cob<br />

Corn Fiber<br />

Woody<br />

Waste<br />

Agricultural<br />

Residue<br />

Conversion<br />

Technology<br />

Fuel Type Status<br />

Biochemical Ethanol Engineering and construction in<br />

progress. Cobs feedstock<br />

infrastructure set up<br />

Gasification + Mixed<br />

Alcohol synthesis<br />

Mixed<br />

alcohols<br />

Engineering and construction in<br />

progress.<br />

Biochemical Ethanol NEPA EIS process initiated. Corn<br />

stover infrastructure set up<br />

Sorted MSW Biochemical-<br />

Concentrated Acid<br />

Hydrolysis<br />

Ethanol Lease and NEPA issues being<br />

resolved.<br />

Key Recent Accomplishments and Deliverables<br />

Demonstration-Scale Biorefineries: FY08 Award One, Under Negotiation<br />

Alltech-Envirofine<br />

Washington County, KY<br />

Lignol Innovations<br />

Grand Junction, CO<br />

Mascoma<br />

Upper Peninsula, MI<br />

NewPage<br />

Wisconsin Rapids, WI<br />

Pacific Ethanol<br />

Boardman, OR<br />

RSA<br />

Old Town, ME<br />

Performers Feedstock Type<br />

Verenium <strong>Biofuels</strong> Corp.<br />

Jennings, LA<br />

Flambeau River <strong>Biofuels</strong> LLC<br />

Park Falls, WI<br />

Corn Cobs, Corn<br />

Fiber<br />

Conversion<br />

Technology<br />

Biochemical-Solid<br />

State Fermentation<br />

Woody Biomass Biochemical-<br />

Organisolve<br />

Ethanol<br />

Ethanol<br />

Woody Biomass Biochemical Ethanol<br />

Woody Biomass<br />

- Mill Residue<br />

Wheat Straw,<br />

Stover, Poplar<br />

Residuals<br />

Woody Biomass<br />

- Mill residues<br />

Energy Cane and<br />

Bagasse<br />

Forest residues<br />

and wood waste<br />

Thermochemical-<br />

Fischer-Tropsch<br />

Biochemical-Biogasol Ethanol<br />

Biochemical-Pentose<br />

Extraction<br />

Biochemical Process Ethanol<br />

Thermochem to<br />

Fischer-Tropsch<br />

Fuel Type<br />

Fischer-Tropsch liquids<br />

To be determined<br />

Fischer-Tropsch liquids<br />

Pilot Plant, Scotland, South Dakota<br />

Key Stakeholder Relationships<br />

Regional Biomass Energy Feedstock Partnership Bioenergy Crop Trials<br />

In 2008, the Biomass Program, Sun Grant Initiative universities, and <strong>US</strong>DA selected, and<br />

in some cases established the first round of replicated field trials of corn stover<br />

removal and dedicated herbaceous energy crops.<br />

This map shows<br />

the selected<br />

locations and<br />

types of crops.

DOE<br />

Office of<br />

Science<br />

Advanced<br />

Feedstock &<br />

Conversion<br />

Technologies

Grand Challenge: Next-Generation Bioenergy Crops Center Strategies<br />

• GLBRC – Engineer “model” plants and potential energy crops to produce new forms of lignin and more<br />

starches and oils, which are more easily processed into fuels.<br />

• JBEI – Enhance lignin degradation in “model” plants by changing cross-links among lignin subunits;<br />

improve deconstruction and subsequent fermentation by altering linkages between lignin and other cellwall<br />

components; translate genetic developments to switchgrass.<br />

• BESC – Decrease or eliminate harsh chemical pretreatments by engineering plant cell walls in poplar<br />

and switchgrass to be less recalcitrant; simultaneously increase total biomass produced per acre.<br />

Grand Challenge: Discovery and Design of Enzymes and Microbes with Novel<br />

Biomass-Degrading Capabilities Center Strategies<br />

• GLBRC – Identify combinations of enzymes and pretreatment needed to digest specific biomass types;<br />

express biomass-degrading enzymes in the stems and leaves of corn and other plants.<br />

• JBEI – Develop new ionic liquid pretreatments that can completely solubilize and fractionate biomass<br />

components; improve performance and stability of enzymes obtained from the rainforest floor and<br />

other environments; engineer, through directed evolution, highly efficient cellulase enzymes.<br />

• BESC – Screen natural thermal springs to identify enzymes and microbes that effectively break down<br />

and convert biomass at high temperatures; understand and engineer cellulosomes (multifunctional<br />

enzyme complexes for degrading cellulose).<br />

Grand Challenge: Development of Transformational Microbe-Mediated Strategies<br />

for Biofuel Production Center Strategies<br />

• GLBRC – Start with an ethanol-producing microbe and add lignocellulose-degrading capabilities to<br />

substantially reduce costs.<br />

• JBEI – Connect diverse biological parts and pathways to create entirely new organisms that produce<br />

fuels other than ethanol; engineer organisms to produce and withstand high concentrations of biofuels;<br />

derive useful chemical products from lignin degradation.<br />

• BESC – Start with a lignocellulose-degrading microbe and add ethanol-producing capabilities to<br />

substantially reduce costs; develop a knowledgebase and pathway analysis tools to aid this manipulation.<br />

Chum, 12/2009 Chum, 12/2009

Chum, 12/2009<br />

NSF. 2008. Breaking the Chemical and Engineering Barriers to Lignocellulosic <strong>Biofuels</strong>: Next Generation Hydrocarbon<br />

Biorefineries. Ed. George W. Huber, University of Massachusetts Amherst. National Science Foundation. Chemical,<br />

Bioengineering, Environmental, and Transport Systems Division. Washington D.C. 180 p.<br />

http://www.ecs.umass.edu/biofuels/Images/Roadmap2-08.pdf<br />

Chum, 12/2009

Chum, 12/2009<br />

Chum, 12/2009<br />

Summary<br />

• Promises<br />

– Increased Understanding from Advances in Science and<br />

Engineering Leading the Possibility of Designed Systems<br />

– Recognized the Need for Integration of Technologies along the<br />

Supply Chain, Systems and Uses – Buying Down Risk<br />

• Challenges<br />

– Technology Development and Learning Curves - timing<br />

– Uncertainties and Risks – Financial, Regulatory, Security…<br />

– Complexity of systems, families of technologies, multiplicity of<br />

choices with no clear winner<br />

• Innovation and Leadership<br />

– Required for the Development of Integrated <strong>Sustainable</strong> Biomass<br />

Systems

37<br />

Update on EPA RFS2<br />

Type of Model Example Explanation<br />

General equilibrium models represent the<br />

whole economy and the main interactions<br />

between economic sectors of a single<br />

region or multiple regions.<br />

Partial equilibrium models give a detailed<br />

description of a specific economic sector.<br />

Optimization models aim to allocate<br />

resources by maximizing or minimizing an<br />

objective function, generally an economic<br />

objective function of profit or utility.<br />

Agent-based models focus on the<br />

simulation of actors’ decisions<br />

System Dynamics models simulate timedependent<br />

phenomena such as land-use<br />

change and account for feedbacks in the<br />

system<br />

GTAP Global Trade Analysis Project model, a multi-region, multi-sector, computable<br />

general equilibrium model that estimates changes in world agricultural<br />

production. Maintained through Purdue University, GTAP projects international<br />

land use change based on the economics of land conversion. Website:<br />

https://www.gtap.agecon.purdue.edu/default.asp<br />

FAPRI Integrated Food and Agricultural Policy and Research Institute with the<br />

international models, as maintained by the Center for Agricultural and Rural<br />

Development (FAPRI-CARD) at Iowa State University. Website:<br />

http://www.fapri.iastate.edu/<br />

FASOM Forestry and Agriculture Optimization Model (FASOM) of Texas A&M University<br />

with a much more detailed economic description of the agriculture and<br />

forestry sector. Website: http://agecon2.tamu.edu/people/faculty/mccarlbruce/FASOM.html<br />

Carnegie- Linking global and local dynamics and modeling indirect land use change from<br />

Stanford <strong>Biofuels</strong> biofuel demand (e.g., simulate sugarcane expansion dynamics in the Brazilian<br />

project<br />

agricultural frontier) .Work presented at Roundtable on <strong>Sustainable</strong> <strong>Biofuels</strong>,<br />

Sao Paulo, November, 2008.<br />

http://cgse.epfl.ch/webdav/site/cgse/shared/<strong>Biofuels</strong>/Regional<br />

%20Outreaches%20&%20Meetings/LUC%20Workshop%20Sao%20Paulo/<br />

Presentations%20day%202/Fernandez.pdf<br />

STELLA-based<br />

SheehanBoyce<br />

The Systems Thinking Experimental Learning Laboratory with<br />

Animation (STELLA) simulate the biofuel production chain in the<br />

U.S. accounting for land in the feedstock-production phase and the<br />

greenhouse-gas emissions from indirect land-use changes.<br />

http://www.bio.org/letters/CARB_LCFS_Sheehan_200904.pdf<br />

Lifecycle Assessment (LCA) GREET Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation<br />

Model, developed by Argonne National Laboratory. Website:<br />

http://www.transportation.anl.gov/modeling_simulation/GREET/

EPA, 2010, Renewable Fuel Standard Program (RFS2)<br />

Regulatory Impact Analysis, EPA-420-R-10-006,<br />

February 2010,<br />

http://www.epa.gov/otaq/renewablefuels/420r10006.pdf<br />

CARB, 2010. January 10, 2010, FINAL REGULATION ORDER,<br />

Subchapter 10. Climate Change, Article 4. Regulations to<br />

Achieve Greenhouse Gas Emission Reductions, Subarticle 7.<br />

Low Carbon Fuel Standard,<br />

http://www.arb.ca.gov/regact/2009/lcfs09/lcfs09.htm<br />

For information on current DOE Biomass<br />

Program Activities see:<br />

http://www.obpreview2009.govtools.us/review/<br />

Support from the DOE Office of the Biomass Program is<br />

greatly acknowledged<br />

Helena.Chum@nrel.gov.<br />

Visit us online at www.nrel.gov .<br />

National Renewable<br />

Energy Laboratory<br />

Operated Innovation for the U.S. for Department Our Energy of Energy Office of Energy Efficiency and Renewable Energy by Midwest Research Institute • Battelle<br />

Future