ExxonMobil and Abu Dhabi

ExxonMobil and Abu Dhabi

ExxonMobil and Abu Dhabi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

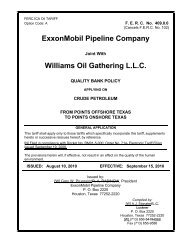

The <strong>Abu</strong> <strong>Dhabi</strong> Technology Center promotes research <strong>and</strong> collaboration<br />

between United Arab Emirates <strong>and</strong> <strong>ExxonMobil</strong> professionals.<br />

ervoir rock, you don’t know what<br />

will happen when you drill. We use<br />

<strong>ExxonMobil</strong>’s 3-D seismic technology<br />

to get the picture we need.”<br />

The next step is to create models,<br />

using <strong>ExxonMobil</strong>’s proprietary<br />

EM power reservoir-simulation<br />

technology, which helps predict<br />

how the reservoirs will perform.<br />

“Then,” says Kemnetz, “we<br />

apply our decision-making tools<br />

to determine how to maximize<br />

recovery at the lowest cost <strong>and</strong><br />

risk. Technology adds value by<br />

reducing costs <strong>and</strong> enhancing<br />

resource recovery. It opens the<br />

door to more options.”<br />

A first for <strong>ExxonMobil</strong><br />

To open that door further,<br />

<strong>ExxonMobil</strong> has established a<br />

unique technology center in<br />

<strong>Abu</strong> <strong>Dhabi</strong>.<br />

“The center’s mission is twofold,”<br />

says <strong>ExxonMobil</strong>’s Ram<br />

Rajagopalan, the center’s operations<br />

manager. “We want to apply<br />

high-impact technology that<br />

benefits Upper Zakum while still<br />

protecting our proprietary technology.<br />

And we want to promote<br />

a good working relationship<br />

between ZADCO <strong>and</strong> <strong>ExxonMobil</strong><br />

professionals.”<br />

19<br />

The technology center is the<br />

first to be established at an<br />

<strong>ExxonMobil</strong> joint-interest facility.<br />

It’s managed <strong>and</strong> operated by<br />

<strong>ExxonMobil</strong> staff.<br />

“The technology center<br />

provides a window into the<br />

<strong>ExxonMobil</strong> world,” says<br />

Rajagopalan. “It enables ZADCO<br />

to pair the best technology with<br />

a state-of-the-art computing<br />

environment to achieve its development<br />

targets.”<br />

Employees of <strong>ExxonMobil</strong><br />

work closely with members of<br />

the ZADCO team that manages<br />

the Upper Zakum field. Together,<br />

they seek to meet the field’s<br />

development challenges.<br />

The center places a strong<br />

emphasis on training. From<br />

2007 through 2008, it conducted<br />

11 courses for more<br />

than 122 people. In addition,<br />

about 25 <strong>ExxonMobil</strong> employees<br />

were “seconded,” or temporarily<br />

assigned, to ZADCO to further<br />

enable the transfer of technical<br />

expertise. The center also hired<br />

<strong>and</strong> trained UAE nationals in line<br />

with a strategy set out by the<br />

government.<br />

In addition to making technology<br />

<strong>and</strong> expertise available in<br />

Photo by Keith Wood<br />

<strong>Abu</strong> <strong>Dhabi</strong>, <strong>ExxonMobil</strong> brings<br />

ZADCO’s Emirati nationals to the<br />

United States for training, <strong>and</strong> has<br />

accepted a number of individuals<br />

for developmental assignments<br />

within the company.<br />

“The technology center allows<br />

us to bring technological expertise<br />

to our co-venturer’s facility so we<br />

can work together applying it to<br />

Upper Zakum’s challenges,” says<br />

Rajagopalan.<br />

Innovation with s<strong>and</strong> <strong>and</strong> rock<br />

Technological advances come in a<br />

variety of ways. Some are results<br />

of years of intensive research.<br />

Some arise from ideas inspired by<br />

work in other areas.<br />

Abi Modavi, an engineer with<br />

<strong>ExxonMobil</strong> Production Company<br />

who was temporarily assigned to<br />

ZADCO as the field development<br />

planning leader, suggested that artificial<br />

isl<strong>and</strong>s, rather than the more<br />

expensive steel platforms, be used<br />

as drilling <strong>and</strong> production sites.<br />

“When I first joined ZADCO, I<br />

noticed how shallow the water<br />

was – about 15 to 80 feet,” says<br />

Modavi, “<strong>and</strong> I started thinking<br />

about ways to use artificial isl<strong>and</strong>s<br />

for drilling <strong>and</strong> production.”<br />

<strong>ExxonMobil</strong> <strong>and</strong> ZADCO agreed<br />

that the technical <strong>and</strong> economic<br />

value of the concept held merit,<br />

<strong>and</strong> Movadi’s staff of three<br />

quickly grew to more than 100<br />

during the assessment stage,<br />

completed one year ago. The<br />

project team now is conducting<br />

detailed engineering design <strong>and</strong><br />

tendering construction bids.<br />

Frank Kemnetz says that artificial<br />

isl<strong>and</strong>s can reduce costs <strong>and</strong><br />

achieve long-term environmental<br />

benefits. He points out that the<br />

isl<strong>and</strong>s would not be feasible<br />

without the “enabling technology”<br />

of <strong>ExxonMobil</strong>’s expertise<br />

in extended-reach drilling, which<br />

allows wells to be drilled vertically<br />

at first, then turned horizontally<br />

to target reservoirs up to several<br />

miles away.<br />

“With artificial isl<strong>and</strong>s <strong>and</strong><br />

extended-reach technology, we<br />

anticipate building fewer isl<strong>and</strong>s<br />

instead of having to install a<br />

larger number of steel platforms<br />

to accommodate a comparable<br />

number of wells, along with the<br />

miles of pipelines to connect<br />

them all together,” says Kemnetz.<br />

“The cost savings could be in the<br />

billions of dollars, <strong>and</strong> the isl<strong>and</strong>s<br />

are a better long-term option for<br />

the marine environment.”<br />

The oval-shaped isl<strong>and</strong>s will<br />

be made of s<strong>and</strong> <strong>and</strong> rock <strong>and</strong><br />

measure 2,000 to 2,600 feet<br />

in diameter. The rocks, some<br />

weighing several tons, are<br />

barged from quarries in the UAE.<br />

The isl<strong>and</strong>s are expected to<br />

outlast the very long producing<br />

life of the Upper Zakum field.<br />

A multinational drilling group<br />

ZADCO has embarked on a<br />

major development program<br />

to boost daily production in<br />

the Upper Zakum by nearly 40<br />

percent. Reaching that goal<br />

requires a significant increase in