Flexitemp Instructions - Euroheat

Flexitemp Instructions - Euroheat

Flexitemp Instructions - Euroheat

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Euroheat</strong> Distributors<br />

(H.B.S.) Ltd.,<br />

Unit 2, Court Farm<br />

Business Park,<br />

Bishops Frome,<br />

Worcestershire,<br />

WR6 5AY.<br />

<strong>Flexitemp</strong> <strong>Instructions</strong><br />

BM and Toby<br />

Pass this Manual to the User After Installation<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. Nov. 2004 1 Operating <strong>Instructions</strong> Part number IN1051 Edition B

Oil Control<br />

Type<br />

B M<br />

C I<br />

TOBY<br />

Visual Identification<br />

<strong>Flexitemp</strong><br />

Installation of <strong>Flexitemp</strong> and suggested uses.<br />

For System Centre 2 Installation see Stove and Boiler Management Systems Documentation<br />

Suitable <strong>Flexitemp</strong>s for different Oil Control valves<br />

There are 3 types of oil control valves used on the Efel stoves. Use only the <strong>Flexitemp</strong> or System centre listed<br />

below for each type of oil control valve.<br />

<strong>Flexitemp</strong><br />

Part Number<br />

Document<br />

Instruction<br />

Information<br />

Page<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 2004 2<br />

Operating <strong>Instructions</strong> Part number IN1051 Edition B

The <strong>Flexitemp</strong> unit is an electrically operated device<br />

designed to control the stove’s heat output. It does so<br />

by holding the oil metering valve at its minimum setting<br />

when de-energized, and when energized allows the<br />

valve to deliver oil to the burner at any chosen setting.<br />

It operates by heating a coil around the actuating rod<br />

which then extends its length and causes the operating<br />

Because the <strong>Flexitemp</strong> allows the stove to be<br />

controlled by electrical switching devices, such as<br />

timers or thermostats, it can form the heart of many<br />

Two types of <strong>Flexitemp</strong> are available<br />

A) BM for BM & CI Oil Control Valves<br />

B) Toby for Toby oil Control Valves<br />

Electrical connection for simple mains failure or remote<br />

switching mechanism.<br />

1 2 3 4<br />

L N E<br />

240 Volts a.c<br />

Fused at 3 amps<br />

The <strong>Flexitemp</strong> Oil<br />

Valve Controller<br />

1 2 3 4<br />

N 240V L<br />

A) BM <strong>Flexitemp</strong> Part Number MS9036 Electrical Connection<br />

Electrical connection for remote thermostat control<br />

directly connected to <strong>Flexitemp</strong><br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. Nov. 2004 3 Operating <strong>Instructions</strong> Part number IN1051 Edition B<br />

1<br />

C<br />

1 2 3 4<br />

L N E<br />

240 Volts a.c<br />

Fused at 3 amps<br />

2

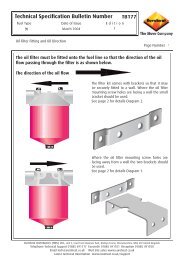

Installing the <strong>Flexitemp</strong> to BM and CI Oil Control<br />

The wiring of all electrical components fi tted to a stove should allow for the stove’s surface and radiated heat,<br />

no electrical wiring should be undertaken by anyone not suitably qualifi ed and conversant with any regulations,<br />

and necessary precautions applicable to the installation of the <strong>Flexitemp</strong> unit. All planned electrical connections<br />

should be installed prior to the attachment of the <strong>Flexitemp</strong> to the Oil Control valve.<br />

The stove must be cold and all electrical and fuel supplies should be isolated when fi tting any components to<br />

the stove.<br />

The three top-plate mounting screws which will be covered by the <strong>Flexitemp</strong> unit should be removed. The<br />

cover of the <strong>Flexitemp</strong> unit should be removed, placed over the valve so that the <strong>Flexitemp</strong> operating arm pad<br />

is concentric with the valve fi ring rate pin and the three holes in the <strong>Flexitemp</strong> body allow the top-plate screws<br />

to be refi tted, passing through, and securing the <strong>Flexitemp</strong> body. Ensure the valve control knob will not foul<br />

against the <strong>Flexitemp</strong> cover when replaced and that the auto/manual lever is set to automatic.<br />

Turn the valve to its minimum “on” position and adjust the <strong>Flexitemp</strong> low position limit screw to cause the<br />

operating arm pad to rest on, but not infl uence the valve fi ring rate pin.<br />

The <strong>Flexitemp</strong> and its control should be subjected to a full mechanical and electrical operation test.<br />

Note:<br />

See <strong>Flexitemp</strong> commissioning instructions to complete installation.<br />

CI Oil Control Valves<br />

remove low setting location<br />

clicker<br />

Valve fi ring rate pin<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 2004 4<br />

Operating <strong>Instructions</strong> Part number IN1051 Edition B<br />

6<br />

OFF<br />

5<br />

Override<br />

1<br />

3<br />

Automatic<br />

Low position<br />

Limit screw

Commissioning the BM <strong>Flexitemp</strong><br />

Once the installation has been completed the <strong>Flexitemp</strong> requires adjusting to correctly control the minimum<br />

oil flow rate when the <strong>Flexitemp</strong> is de-energized.<br />

The protruding control lever of the <strong>Flexitemp</strong> presses down on the valve firing rate pin. The degree to which<br />

this is pressed determines the flow rate to the burner. To correctly adjust the <strong>Flexitemp</strong> the appliance must be<br />

fully installed and normal stove commissioning completed.<br />

Two checks and possible adjustments need to be completed for correct operation.<br />

A<br />

Remove the coal effect from the appliance.<br />

Light the appliance as described in the operation<br />

instructions.<br />

Once the stove has reached operational temperature<br />

turn the main control knob to the number “1”<br />

position.<br />

The control to the <strong>Flexitemp</strong> must be calling for heat<br />

so that the <strong>Flexitemp</strong> control lever is not touching the<br />

valve firing rate pin.<br />

Observe the flame size.<br />

Remove the electrical power from the <strong>Flexitemp</strong> by<br />

switching off the connecting time clock or other control<br />

system.<br />

The <strong>Flexitemp</strong> control lever should now drop and press<br />

on to the Valve firing rate pin.<br />

The flame size should not change. If the flame reduces<br />

in size the <strong>Flexitemp</strong> control lever is pressing to greatly<br />

on the Valve firing pin.<br />

BM <strong>Flexitemp</strong>, Adjust the low position limit screw<br />

clockwise in small increments until the flame size<br />

returns to the originally observed size.<br />

B<br />

Once section “A” of <strong>Flexitemp</strong> commissioning has<br />

been completed section “B” checks that the <strong>Flexitemp</strong><br />

control lever will reduce the oil flow rate to the number<br />

“1 “ setting and not for example to the number “2” oil<br />

control setting.<br />

With the <strong>Flexitemp</strong> de-energized turn the oil control<br />

knob to the number “4” setting. The flame size should<br />

not change. If The flame size increases the <strong>Flexitemp</strong><br />

oil control lever is not pressing sufficiently on to the<br />

valve firing pin.<br />

BM <strong>Flexitemp</strong>, Turn the low position limit screw<br />

anticlockwise in small increments until the flame<br />

returns to the number “1” setting.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. Nov. 2004 5 Operating <strong>Instructions</strong> Part number IN1051 Edition B<br />

FIG82A<br />

Minimum for low fire<br />

setting<br />

E x c e p t a b l e<br />

Flame Patterns<br />

Valve Firing Rate Pin<br />

Maximum for low<br />

fire setting<br />

Unacceptable Flame Pattern<br />

Caution after adjusting wait 3-4 minutes<br />

for the flame pattern to settle before<br />

continuing commissioning.

B) Toby <strong>Flexitemp</strong> Part Number MS10040<br />

Electrical oil valve control with the <strong>Flexitemp</strong>.<br />

1 2 3 4 5 6<br />

The <strong>Flexitemp</strong> allows the oil valve to be controlled automatically, and can be used to govern the firing rate of a<br />

stove with a boiler as illustrated in the two following drawings. High and low limit thermostats are incorporated<br />

to protect the boiler from condensation by not allowing it to run at too low a temperature and dissipating<br />

excess heat should the control thermostat fail. The high limit and control thermostat should be fitted at the<br />

boiler flow outlet and the low limit thermostat should be fitted to the boiler return inlet. All pipe thermostats<br />

must be fitted using heat conducting paste between the thermostat’s monitoring face and the pipe to ensure<br />

reliable thermal transmission. High temperature cables must be used to wire components in contact with or<br />

in close proximity to the stove. All wiring must be in accordance with whatever regulations may be applicable<br />

at the time of installation.<br />

Schematic electrical diagram for system with gravity D.H.W. and pumped space heating circuit.<br />

L<br />

N<br />

Pump<br />

1<br />

C<br />

90 C<br />

o<br />

2 1<br />

C<br />

2<br />

50 C<br />

o<br />

High Limit Low Limit<br />

Room<br />

Thermostat<br />

1 2 3 4 5 6<br />

<strong>Flexitemp</strong> unit.<br />

Control<br />

Thermostat<br />

Schematic electrical diagram for system with gravity D.H.W. and pumped space heating circuit, where no<br />

room thermostat is fitted.<br />

L<br />

N<br />

Pump<br />

1<br />

C<br />

90 C<br />

o<br />

2 1<br />

C<br />

2<br />

50 C<br />

o<br />

High Limit Low Limit<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 2004 6<br />

Operating <strong>Instructions</strong> Part number IN1051 Edition B<br />

1<br />

C<br />

2<br />

<strong>Flexitemp</strong> unit.<br />

1<br />

C<br />

2<br />

1 2 3 4 5 6<br />

Control<br />

Thermostat<br />

CH<br />

HW<br />

CH<br />

HW

Schematic electrical diagram for system with<br />

both D.H.W. and space heating circuit being<br />

pumped.<br />

N<br />

Pump<br />

1<br />

C<br />

90 C<br />

o<br />

2 1<br />

C<br />

2<br />

50 C<br />

o<br />

High Limit Low Limit<br />

Room 1 2 3 4 5 6<br />

Thermostat<br />

<strong>Flexitemp</strong> unit.<br />

Schematic electrical diagram for system with no boiler but where it is required to control<br />

stove’s heat output with a room thermostat and a time switch.<br />

N<br />

1 2 3 4 5 6<br />

<strong>Flexitemp</strong> unit.<br />

Control by single Pipe thermostat to maintain control temperature<br />

N<br />

<strong>Flexitemp</strong> unit.<br />

1<br />

C<br />

2<br />

1 2 3 4 5 6<br />

Control<br />

Thermostat<br />

Control<br />

Thermostat<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. Nov. 2004 7 Operating <strong>Instructions</strong> Part number IN1051 Edition B<br />

L<br />

1<br />

C<br />

2<br />

L<br />

HW

Installing the <strong>Flexitemp</strong> to Toby Valve<br />

Isolate all electrical supplies before working on the stove or its controls.<br />

1<br />

Loosen screw “A” and slide off<br />

terminal cover.<br />

3 4<br />

5<br />

C<br />

TO B Y<br />

D V R<br />

The <strong>Flexitemp</strong> is attached to the<br />

Toby valve with two screws. The screw<br />

passing through the <strong>Flexitemp</strong> body “B” is<br />

captive, the other, “C” is taken<br />

from the valve.<br />

TO B Y<br />

D VR<br />

+<br />

+<br />

_<br />

B<br />

A<br />

+<br />

_<br />

Remove these two screws from the<br />

Toby valve, One screw “C” is reused<br />

to mount the <strong>Flexitemp</strong> unit.<br />

Mount <strong>Flexitemp</strong> using the captive screw “B”<br />

and the screw “C” in the hole shown. These should be<br />

screwed into the fixing points on the valve vacated by<br />

the two screws removed.. Note:- The <strong>Flexitemp</strong> is offset Ensure the <strong>Flexitemp</strong> sits flat on the<br />

when mounted.<br />

Valve body. Refit terminal cover.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 2004 8<br />

Operating <strong>Instructions</strong> Part number IN1051 Edition B<br />

6<br />

2<br />

T O B Y<br />

D V R<br />

Wire in cable, or cables to <strong>Flexitemp</strong> unit,<br />

ensuring you are wiring to the correct<br />

terminals for your control system, and<br />

and the earth wires are connected to the<br />

earthing terminal of the metal body.<br />

Cables must be secured by the cable<br />

clamp tightened onto the outer sheaths.<br />

TO B Y<br />

D V R<br />

+<br />

_<br />

+<br />

+<br />

_<br />

C

Commissioning and operation of the Toby <strong>Flexitemp</strong><br />

The valve contains and controls a reservoir of oil, maintained at the height marked on the valve body. The<br />

delivery rate of the valve is governed by a slotted barrel at the valve’s exit being raised or lowered within a sleeve<br />

to expose more or less of this slot to the reservoir of oil. The position of the barrel is controlled by a cam, in<br />

the form of an adjustable track, attached to the control knob shaft. When the valve is in the “off “ position the<br />

track causes the barrel to be pushed down within the sleeve so that none of the slot is exposed and so no oil<br />

flows out from the valve. As the control knob turns from the “off” position to position “6” the track rotates over<br />

the barrel allowing the barrel to raise progressively to expose the full length of its slot. The final calibration of<br />

the valve’s flow rate is made by adjustment of the two screws holding the ends of the track, so that the height<br />

of the track and the position of the barrel, when the control knob is at position “1” and “6”, is determined. The<br />

barrel movement necessary to give the flow rates from low to high flow is approximately one mm.<br />

Above the flow regulating barrel is a pin, which protrudes through the valve cover plate, and it is this pin that<br />

the <strong>Flexitemp</strong> arm operates. When the <strong>Flexitemp</strong> unit is not energized the arm pushes down the pin and lowers<br />

the barrel to position ”1”. When energized, the <strong>Flexitemp</strong> arm lifts clear of the pin to allow the barrel to rise to<br />

whatever position is set on the control knob. The <strong>Flexitemp</strong> arm is actuated by heating an expanding metal<br />

rod which causes the arm to lift or lower very slowly, about three minutes. This slow operation allows more<br />

time for the flue draught to stabilize as the stove’s firing rate changes.<br />

Minimum flow rate<br />

adjustment screw<br />

T O B Y<br />

D V R<br />

+<br />

+<br />

_<br />

_<br />

+<br />

+<br />

_<br />

Maximum flow rate<br />

adjustment screw<br />

Pin operated by <strong>Flexitemp</strong><br />

If the <strong>Flexitemp</strong> arm does not lift<br />

clear of the pin when energized and<br />

the valve control setting is at “6”,<br />

the hexagon pad should be screwed<br />

higher into the operating arm.<br />

6 MM<br />

_<br />

NOTE:- All valves are supplied precalibrated;<br />

if it is necessary<br />

to re-calibrate, all adjustments<br />

to the flow rate screws should<br />

be in increments of no more<br />

than a quarter turn at a time.<br />

Allow at least four minutes for stabilizing<br />

after each adjustment<br />

The pin is located within a tube nut If the <strong>Flexitemp</strong><br />

pushes the pin to give a lower fuel rate than “position<br />

1” the nut should be turned<br />

anticlockwise to provide a higher stop for the <strong>Flexitemp</strong>.<br />

If the minimum flow setting has been adjusted, this<br />

adjustment will be necessary.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. Nov. 2004 9 Operating <strong>Instructions</strong> Part number IN1051 Edition B