EASB - Eurocopter

EASB - Eurocopter

EASB - Eurocopter

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

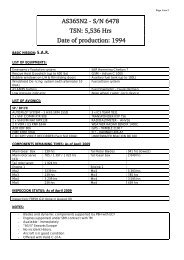

<strong>EASB</strong><br />

2) If you need to perform a flight of more than 3 flying hours and less than 10 flying hours, between 2<br />

VHM data downloading operations, perform an Eddy current check of the component before flight,<br />

to make sure that there is no crack in the area of the weld according to paragraph 3.B.2.<br />

CAUTION<br />

ONLY LEVEL II AND LEVEL III OPERATORS CERTIFIED IN THE EDDY<br />

CURRENT DETECTION METHOD IN THE AERONAUTICS SECTOR<br />

ACCORDING TO THE EN4179 OR NAS410 STANDARD ARE<br />

AUTHORIZED TO CARRY OUT THE INSPECTION.<br />

MOREOVER, EACH OPERATOR HAS TO ATTEND AN ADDITIONAL<br />

TRAINING PERFORMED UNDER EUROCOPTER RESPONSIBILITY.<br />

THIS TRAINING WILL INCLUDE PRACTICING ON DEFECTS<br />

GENERATED ON REAL VERTICAL SHAFT AND ON REPRESENTATIVE<br />

COUPONS.<br />

NOTE 2<br />

AS THIS SPECIFIC EDDY CURRENT PROCEDURE HAS<br />

BEEN VALIDATED BY THE EC QUALITY LABORATORY<br />

TO DETECT POSSIBLE CRACKS IN THIS PARTICULAR<br />

AREA, IT IS POSSIBLE TO USE THIS METHOD AS AN<br />

ADDITIONAL SAFETY BARRIER.<br />

Revision 0 2012-06-27 Page 7/15<br />

Revision 2 2012-11-21 This document is available on the internet: www.eurocopter.com/techpub