Background Information Document - Eskom

Background Information Document - Eskom

Background Information Document - Eskom

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

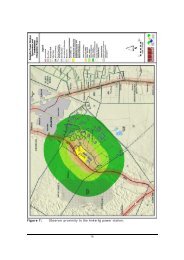

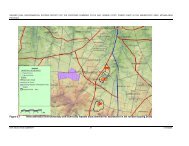

Proposed location of the LNG terminal and CCGT Power Plant within the Port of Ngqura and Coega IDZ<br />

ABOUT THE PROJECT<br />

<strong>Eskom</strong> Holdings (<strong>Eskom</strong>) and the South African Gas<br />

Development Company (iGas, a national gas infrastructure<br />

company) have been investigating the feasibility of developing<br />

an integrated power project within the Coega Industrial<br />

Development Zone (IDZ) near Port Elizabeth. The project is<br />

referred to as the Coega Integrated LNG-to-Power Project (CIP).<br />

The CIP is proposed within the Port of Ngqura which is an<br />

integral component of the Coega IDZ, located within the<br />

Nelson Mandela Metropolitan Municipality (NMMM) in the<br />

Eastern Cape Province, approximately 15 km north-east<br />

of Port Elizabeth. Phase 1 of the port construction is<br />

nearing completion. The project will ultimately consist of the<br />

following components:<br />

• A liquefied natural gas 1 (LNG) terminal, consisting of a<br />

berth with off-loading arms within the Port of Ngqura,<br />

cryogenic pipelines, storage and handling facilities and<br />

re-gasification modules (covered in this EIA);<br />

• A combined cycle gas turbine (CCGT) power plant, to<br />

generate electricity by burning natural gas or diesel<br />

(covered in this EIA);<br />

• Gas pipelines for the transmission, distribution and<br />

reticulation of natural gas within the Coega IDZ and Port of<br />

Ngqura (to be covered in a separate EIA process); and<br />

• Electricity transmission lines to transmit electricity into<br />

the national grid (being covered in a separate EIA for<br />

transmission lines, currently in progress).<br />

Coega Integrated LNG-to-Power Project<br />

NEED AND JUSTIFICATION FOR THE PROJECT<br />

South Africa is an energy intensive country, largely as a result<br />

of our historic economic focus on energy intensive industries<br />

such as mining and primary metal processing. With current<br />

energy and electricity demands projected to continue<br />

increasing, new investments in electricity generation<br />

capacity are required. Future increases in electricity<br />

demand are particularly expected for the regions around the<br />

Nelson Mandela Metropolitan Municipality and Southern<br />

Cape, the Western Cape and KwaZulu-Natal.<br />

1 LNG is a natural gas associated with oil extraction that has been liquefied (i.e. changed<br />

into a liquid by subjecting it to very low temperatures) for easier transportation and storage.<br />

What is your role as a stakeholder?<br />

The EIA process provides you with the opportunity to:<br />

• Attend meetings and obtain information (such as this<br />

<strong>Background</strong> <strong>Information</strong> <strong>Document</strong>) to find out more<br />

about the proposed project and the EIA process;<br />

• Raise any issues or concerns which you may have<br />

regarding the proposed project;<br />

• Provide us with additional information which should be<br />

taken into account in the assessment of impacts and the<br />

decision-making process;<br />

• Comment on the EIA process and contents of the reports<br />

prior to submission of these reports to the authorities for<br />

decision-making; and<br />

• Appeal the Record of Decision issued by the authorities.<br />

How can you get involved?<br />

• By responding to our invitation for your involvement,<br />

which will be advertised in local, regional and national<br />

newspapers, and by registering as an I&AP;<br />

• By mailing or faxing a comment form to the public<br />

participation consultant indicated below;<br />

• By attending the public meetings which will be held<br />

during the EIA process;<br />

• By telephonically contacting the public participation<br />

consultant if you have a query, comment, or require<br />

further project information;<br />

• By reviewing the Draft Reports within the timeframes<br />

provided.<br />

All registered I&APs will be sent personal newsletters with<br />

information updates on the EIA process and invitations to<br />

attend public meetings. The meeting dates will also be<br />

advertised in local and regional newspapers.<br />

Should you consider yourself to be an interested and / or<br />

affected party we encourage you to ensure you are registered<br />

on the project database by providing your contact details to<br />

the participation consultants indicated below. Registration will<br />

ensure that you are kept informed of developments relating to the<br />

EIA process, are invited to attend meetings and are informed of<br />

the location and availability of draft reports for comment.<br />

Where can I find <strong>Information</strong> on this project?<br />

Relevant project and EIA information is included on the EIA<br />

website at: http://eia.csir.co.za/cip as well as on the <strong>Eskom</strong><br />

website at: www.eskom.co.za/eia.<br />

WHO SHOULD YOU CONTACT?<br />

Public Process Consultants - Coega Integrated Project EIA<br />

120 Diaz Road, Adcockvale, Port Elizabeth 6001<br />

PO Box 27688, Greenacres, 6057<br />

Phone: 041 - 374 8426 • Fax: 041 - 373 2002<br />

E-mail: sandy@publicprocess.co.za<br />

<strong>Background</strong><br />

information<br />

document<br />

for the Scoping and Environmental Impact Assessments (EIAs)<br />

for the proposed Coega Integrated<br />

LNG-to-Power Project<br />

Eastern Cape, South Africa<br />

August 2006<br />

Prepared on behalf of: <strong>Eskom</strong> and iGas<br />

Prepared by: CSIR and Public Process Consultants

Electricity planning in the national context<br />

The South African Energy Policy, published in December<br />

1998 by the Department of Minerals and Energy (DME),<br />

identifies five key objectives, namely:<br />

• Increasing access to affordable energy services;<br />

• Improving energy sector governance;<br />

• Stimulating economic development;<br />

• Managing energy-related environmental impacts; and<br />

• Securing supply through diversity.<br />

The Department of Minerals and Energy’s Integrated Energy<br />

Plan (IEP) projected that the current growth in electricity<br />

demand would require that additional electricity generation<br />

capacity would be required by approximately 2007, with further<br />

base load generating capacity required by 2010. The IEP<br />

recognises that South Africa is likely to be reliant on coal for<br />

the next 20 years as the predominant source of energy.<br />

The National Energy Regulator’s second National Integrated<br />

Resource Plan (NIRP), which focussed on planning options<br />

for meeting the long term increases in electricity demand,<br />

confirmed that coal-fired power options were still required<br />

over the next 20 years.<br />

In order to meet these objectives and the developmental and<br />

socio-economic objectives in South Africa, the country needs<br />

to optimally use the available energy resources. The South<br />

African Government, through the Department of Minerals and<br />

Energy, the National Electricity Regulator of South Africa<br />

(NERSA) and <strong>Eskom</strong> are required to address what can be<br />

done to meet these electricity needs both in the short- and<br />

long-term.<br />

The Department of Minerals and Energy performs Integrated<br />

Energy Planning (IEP) to identify future energy demand and<br />

supply requirements. The National Energy Regulator performs<br />

National Integrated Resource Planning (NIRP) to identify the<br />

future electricity demand and supply requirements. Similarly,<br />

<strong>Eskom</strong> continually assesses the projected electricity demand<br />

and supply through a process called the Integrated Strategic<br />

Electricity Plan (ISEP).<br />

Through these assessment and planning processes, the<br />

most likely future electricity demand based on long-term<br />

Southern African economic scenarios is forecasted, and provides<br />

the framework for <strong>Eskom</strong> and South Africa to investigate a<br />

wide range of supply and demand-side technologies and<br />

options. <strong>Eskom</strong>’s ISEP provides strategic projections of<br />

supply-side and demand-side options to be implemented in<br />

order to meet these long-term load forecasts. It provides the<br />

framework for <strong>Eskom</strong> to investigate a wide range of new<br />

supply-side and demand-side technologies, with a view to<br />

optimising investments and returns.<br />

The most attractive supply-side option identified is to Returnto-Service<br />

three mothballed coal-fired Simunye Power<br />

Stations, i.e. Camden, Komati and Grootvlei. These stations<br />

are currently being returned to service. A variety of supplyside<br />

options are being investigated, including conventional<br />

pulverised fuel power plants (i.e. coal-based power), pumped<br />

storage schemes, gas-fired power plants, nuclear plants (eg.<br />

PBMR), greenfield fluidised bed combustion technologies,<br />

renewable energy technologies (mainly wind and solar projects),<br />

and import options within the Southern African Power<br />

Pool. As older <strong>Eskom</strong> power plants reach the end of their<br />

design life from approximately 2025, the use of all available<br />

technologies will need to be exploited in order to supply the<br />

country’s growing electricity demand.<br />

The demand for electricity in South Africa has grown, on<br />

average, at more than 4% over the past few years, with a<br />

concomitant reduction in the surplus generating capacity.<br />

The DME, NERSA and <strong>Eskom</strong> planning processes all indicate<br />

that South Africa will require an additional 5000 MW of<br />

electricity within the next 5 years, with this consisting of both<br />

base load electricity generating capacity 2 and peaking electricity<br />

generating capacity 3 . The planning processes also indicate that<br />

new base load capacity will be required by approximately 2010.<br />

In 2004, the South African Cabinet took the decision that<br />

<strong>Eskom</strong> will build approximately 70% of the new capacity<br />

required in South Africa. The balance is expected to come from<br />

Independent Power Producers (IPPs).<br />

Hence as part of the increased electricity supply plan, <strong>Eskom</strong><br />

is considering a combined cycle gas turbine (CCGT) in the<br />

Coega IDZ. CSIR has been appointed by <strong>Eskom</strong> and iGas as<br />

independent consultants to undertake an Environmental<br />

Impact Assessment (EIA) process for the proposed new facility.<br />

Electricity Planning: Eastern Cape region<br />

At present, the bulk of power used in the Eastern Cape is<br />

generated predominantly in Mpumalanga and Limpopo<br />

provinces and transported via transmission lines to the<br />

region. The amount of power currently being provided to the<br />

Eastern Cape - approximately 1400 Megawatts (MW) - is<br />

approaching the maximum limit that the existing infrastructure<br />

can deliver. Yet it is expected that power demand will increase<br />

significantly in the next 5 to 25 years. The NMMM area is predicted<br />

to experience a growth in power demand from current<br />

levels of approximately 730 MW to in the order of 5000 MW,<br />

largely as a result of energy intensive industrial developments<br />

located within the Coega IDZ. This will require additional<br />

power generation capacity, in which the proposed CIP would<br />

play a crucial role. The location of a major source of power<br />

2 “Base load electricity generating capacity” refers to power station technology designed specifically<br />

to generate electricity continuously for all hours of the day and night (i.e. 24 hours per day).<br />

3 “Peaking electricity generating capacity” refers to power station technology designed specifically<br />

to generate electricity during periods of very high demand for electricity, normally on weekday<br />

mornings around 07:00 to 09:00 and weekday evenings around 18:00 to 20:00.<br />

generation within the Eastern Cape will assist in stabilizing the<br />

power grid. It will also avoid energy losses that would occur if<br />

additional power was generated elsewhere (eg. Mpumalanga<br />

and Limpopo Provinces) and transmitted to the Eastern Cape.<br />

The CIP is therefore proposed within the context of the need<br />

for additional national and local electricity generating capacity.<br />

There is a need for additional electricity generation capacity to<br />

meet increasing electricity demands within the Eastern Cape,<br />

and specifically the NMMM.<br />

WHAT DOES THIS PROJECT ENTAIL?<br />

The proposed CIP would involve importing 1.7 million tonnes<br />

per annum (mtpa) of liquefied natural gas (LNG) via ship<br />

(referred to as an LNG carrier) to the Port of Ngqura, and the<br />

storage, re-gasification and utilization of 1.4 mtpa in a 2400<br />

MW CCGT power plant. The remaining 0.3 mtpa LNG would be<br />

available, if required in the future, for distribution to gas users in<br />

the Port and IDZ via a gas reticulation network. This amount<br />

could then increase in step with the demands of the IDZ. The<br />

maximum imported LNG will be limited by the port shipping<br />

constraints. The LNG imported may rise over a long period to 5<br />

mtpa. This EIA is based on a proposed LNG import of 1.7 mtpa<br />

and additional import would need to be covered in a separate<br />

future EIA process should the need arise.<br />

The LNG terminal and CCGT power plant are both predicted<br />

to operate for a minimum of 35 years. The approximate area<br />

required for the project is 60 hectares, including options for<br />

expansion. Construction of the LNG terminal and CCGT plant<br />

concurrently is estimated to take 3 years, with 2 years<br />

required prior to construction for design, approvals and<br />

financing. Direct investments associated with the CIP are<br />

estimated in the region of US$ 1 billion.<br />

The following provides more detailed information on each of<br />

the various components that make up the project.<br />

LNG berth and terminal<br />

The LNG berth is being designed to accommodate LNG carriers<br />

up to 300 m long and 50 m wide, with a maximum draft of 12 m<br />

and an LNG capacity of approximately 160 000 cubic metres.<br />

Based on current assumptions, an LNG off-take of 1.4 mtpa for<br />

the CCGT plant will require one LNG carrier at berth approximately<br />

every 14 days (or 26 times per year). The LNG is transported<br />

and stored at atmospheric temperature and is kept at<br />

minus 160 degrees Celsius in order to keep it in a liquid form.<br />

During offloading, the LNG will be transferred in cryogenic<br />

pipelines (i.e. insulated pipes that keep the LNG cold) from the<br />

berth to the LNG storage tanks. It is planned that there will be two<br />

LNG storage tanks each approximately 50m high and 80m in<br />

diameter and with a capacity of approximately 165 000 cubic<br />

metres. From there, the LNG is sent to the re-gasification plant<br />

where the temperature of the LNG is raised in a warming process<br />

using sea water to convert the liquid back to gas. The key infrastructural<br />

components of the proposed LNG terminal are:<br />

• LNG berth, with offloading arms<br />

• Cryogenic pipelines from the berth to the on-land<br />

storage tanks<br />

• On-land terminal facilities, including storage tanks and a<br />

loading facility for future LNG distribution using trucks<br />

• Re-gasification plant.<br />

LNG berths and activities worldwide are governed by strict<br />

safety zones and codes of practice. During offloading, a safety<br />

zone of up to 200m radius is required around the LNG carrier<br />

manifold offloading arm (i.e. where the offloading pipe couples<br />

to the vessel); or 50m from the side of the vessel itself.<br />

CCGT power plant<br />

A combined cycle gas turbine (CCGT) plant uses a cycle<br />

configuration of combustion turbines, heat recovery steam<br />

generators (HRSG), and steam turbines, to generate<br />

electricity. In the combustion turbine component, air is<br />

compressed to a high pressure and thereafter mixed with<br />

natural gas or liquid fuel (eg. diesel), which is subsequently<br />

ignited to develop mechanical energy that drives an electrical<br />

generator. When run in open cycle mode, the excess heat<br />

from the combustion turbines is released via the exhaust<br />

stacks. In the combined cycle mode, hot exhaust gases from<br />

the combustion turbine are used to produce steam, which<br />

drives a steam turbine coupled to an electrical generator.<br />

Because of this composite thermodynamic process, CCGT’s<br />

have thermal efficiencies far greater than other generation<br />

technology options.<br />

The proposed CCGT plant consists of two power blocks<br />

each producing 1200 MW in CCGT mode. The facility will<br />

have dual fuel capacity, i.e. be able to run off either liquid fuel<br />

(diesel) or natural gas. The CCGT plant includes the following<br />

key components:<br />

• Combustion turbines located in two power blocks and<br />

producing approximately 800 MW per power block<br />

• Heat recovery steam generators with associated chimneys<br />

• Steam turbines located in two power blocks and<br />

producing approximately 400 MW per power block, with<br />

associated sea water cooling system<br />

• Electrical generator<br />

• On-site liquid fuels storage tanks totalling approximately<br />

13.5 million litres<br />

• Desalination plant for production of potable water for<br />

use in the CIP facility<br />

• Administration buildings.<br />

The LNG terminal takes longer to construct than the CCGT<br />

power plant. Due to the need to provide the power to the grid<br />

before the completion date for the LNG terminal, the CCGT<br />

power plant is planned to run on diesel for the first approximately<br />

two years of operation. Diesel will be imported by ship via the<br />

bulk liquids berth at the Port of Ngqura and stored within the<br />

vicinity of the port, in diesel storage tanks with a total storage<br />

capacity of approximately 47.7 million litres.<br />

Integration of the CIP into the national grid<br />

The proposed CCGT power plant will transfer power into the<br />

national grid via the Grassridge substation (located on the northern<br />

boundary of the IDZ approximately 10 km north-west of<br />

the proposed CIP site) and the proposed Dedisa substation<br />

(within the IDZ). Currently 3 x 400 kV and 4 x 132 kV transmission<br />

lines are being planned between the new proposed<br />

power station and the new proposed Dedisa substation. This<br />

high voltage transmission infrastructure is the subject of a separate<br />

EIA currently being conducted jointly by <strong>Eskom</strong><br />

Transmission and the Coega Development Corporation<br />

(CDC). Further information on this particular EIA can be<br />

obtained from: www.eskom.co.za/eia.<br />

OVERVIEW OF THE ENVIRONMENTAL<br />

IMPACT ASSESSMENT PROCESS<br />

On 21st April 2006, new EIA Regulations were published under<br />

Chapter 5 of the National Environmental Management Act<br />

(NEMA, Act 107 of 1998). The regulations commenced on 3rd<br />

July 2006. Government Notices published in terms of NEMA list<br />

activities that require either a basic assessment or scoping and<br />

environmental assessment (i.e. a “full EIA”). The proposed CIP<br />

requires a “full EIA”, in particular because it includes inter alia the<br />

following activities listed under Activity Number 1 in GN R 387<br />

in Government Gazette No 28753 of 21 April 2006:<br />

“The construction of facilities or infrastructure, including<br />

associated structures or infrastructure, for -<br />

(a) the generation of electricity where -<br />

(i) the electricity output is 20 megawatts or more; or<br />

(ii) the elements of the facility cover a combined area in<br />

excess of 1 hectare; ....<br />

(c) the above ground storage of a dangerous good,<br />

including petrol, diesel, liquid petroleum gas or paraffin, in<br />

containers with a combined capacity of 1 000 cubic metres<br />

or more at any one location or site including the storage of<br />

one or more dangerous goods, in a tank farm;...”<br />

The EIA process is used as a planning, design and decisionmaking<br />

tool in order to identify the biophysical, social and<br />

economic impacts (positive and negative) and consequences<br />

of the proposed project upfront in order to support more<br />

informed decision-making. If the project is authorised to<br />

proceed, the EIA process provides recommendations for<br />

management actions which will minimise potential negative<br />

impacts and maximise the benefits associated with the project.<br />

This EIA is being conducted as one integrated process that<br />

covers two applications in terms of the EIA Regulations; an<br />

application by iGas for the LNG component; and from <strong>Eskom</strong><br />

for the CCGT component.<br />

The EIA process is planned to be undertaken in five phases:<br />

(1) Project initiation and scoping (June to December 2006)<br />

(2) Specialist studies (July 2006 to January 2007)<br />

(3) Preparation of the integrative Environmental Impact<br />

Report (December 2006 to May 2007)<br />

(4) Preparation of a draft Environmental Management Plan<br />

(December 2006 to May 2007)<br />

(5) Authority decision-making (approximately May to August<br />

2007).<br />

The following key environmental issues have been identified<br />

for further investigation:<br />

• Impact of atmospheric emissions<br />

• Impacts of water consumption, wastewater generation<br />

and implications for integrated water management<br />

• Impact of water discharges to the marine environment<br />

• Impacts of materials handling and solid and chemical<br />

waste management<br />

• Impact of noise<br />

• Visual impacts<br />

• Socio-economic impacts<br />

• Heritage impacts (eg. archaeology)<br />

• Macro-economic impacts.<br />

PUBLIC PARTICIPATION PROCESS<br />

Proactive engagement with stakeholders forms a key component<br />

of the entire EIA process. The public and key stakeholders<br />

will be informed via newspaper adverts, letters and a public<br />

meeting about the proposed project at the outset of the EIA<br />

process and invited to register as stakeholders. Stakeholders will<br />

be consulted during the Scoping phase to identify issues and<br />

concerns which should be addressed through the EIA process,<br />

identify additional information which will be of value to the EIA<br />

process and assist in defining the scope and terms of reference<br />

for the EIA specialist studies. The draft Scoping Report and draft<br />

Environmental Impact Report will be presented to stakeholders<br />

with the opportunity to submit comments on the draft version<br />

prior to the submission of the final reports to the authorities for<br />

decision-making. Responses to all issues raised and comments<br />

made will be included in the reports submitted to the authorities.