PDF format (503 kB) - ECN

PDF format (503 kB) - ECN

PDF format (503 kB) - ECN

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

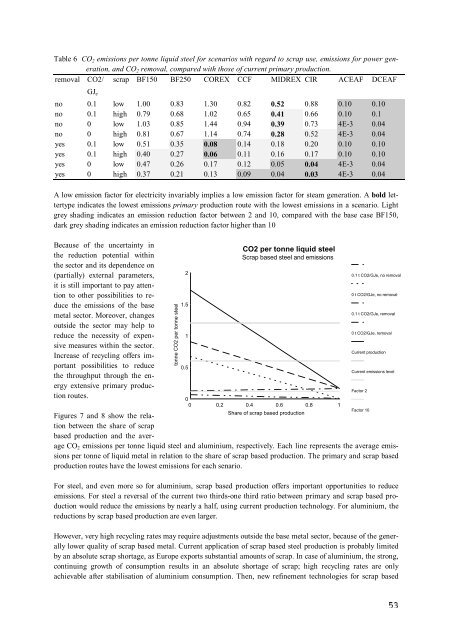

Table 6 CO2 emissions per tonne liquid steel for scenarios with regard to scrap use, emissions for power generation,<br />

and CO2 removal, compared with those of current primary production.<br />

removal CO2/ scrap BF150 BF250 COREX CCF MIDREX CIR ACEAF DCEAF<br />

no<br />

GJe<br />

0.1 low 1.00 0.83 1.30 0.82 0.52 0.88 0.10 0.10<br />

no 0.1 high 0.79 0.68 1.02 0.65 0.41 0.66 0.10 0.1<br />

no 0 low 1.03 0.85 1.44 0.94 0.39 0.73 4E-3 0.04<br />

no 0 high 0.81 0.67 1.14 0.74 0.28 0.52 4E-3 0.04<br />

yes 0.1 low 0.51 0.35 0.08 0.14 0.18 0.20 0.10 0.10<br />

yes 0.1 high 0.40 0.27 0.06 0.11 0.16 0.17 0.10 0.10<br />

yes 0 low 0.47 0.26 0.17 0.12 0.05 0.04 4E-3 0.04<br />

yes 0 high 0.37 0.21 0.13 0.09 0.04 0.03 4E-3 0.04<br />

A low emission factor for electricity invariably implies a low emission factor for steam generation. A bold lettertype<br />

indicates the lowest emissions primary production route with the lowest emissions in a scenario. Light<br />

grey shading indicates an emission reduction factor between 2 and 10, compared with the base case BF150,<br />

dark grey shading indicates an emission reduction factor higher than 10<br />

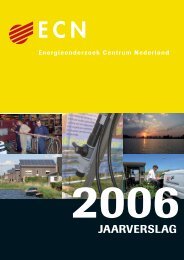

Because of the uncertainty in<br />

the reduction potential within<br />

the sector and its dependence on<br />

(partially) external parameters,<br />

it is still important to pay attention<br />

to other possibilities to reduce<br />

the emissions of the base<br />

metal sector. Moreover, changes<br />

outside the sector may help to<br />

reduce the necessity of expensive<br />

measures within the sector.<br />

Increase of recycling offers important<br />

possibilities to reduce<br />

the throughput through the energy<br />

extensive primary production<br />

routes.<br />

tonne CO2 per tonne steel<br />

2<br />

1.5<br />

1<br />

0.5<br />

CO2 per tonne liquid steel<br />

Scrap based steel and emissions<br />

0<br />

0 0.2 0.4 0.6 0.8 1<br />

Share of scrap based production<br />

0.1 t CO2/GJe, no removal<br />

0 t CO2/GJe, no removal<br />

0.1 t CO2/GJe, removal<br />

0 t CO2/GJe, removal<br />

Current production<br />

Current emissions level<br />

Figures 7 and 8 show the relation<br />

between the share of scrap<br />

based production and the average<br />

CO2 emissions per tonne liquid steel and aluminium, respectively. Each line represents the average emissions<br />

per tonne of liquid metal in relation to the share of scrap based production. The primary and scrap based<br />

production routes have the lowest emissions for each senario.<br />

For steel, and even more so for aluminium, scrap based production offers important opportunities to reduce<br />

emissions. For steel a reversal of the current two thirds-one third ratio between primary and scrap based production<br />

would reduce the emissions by nearly a half, using current production technology. For aluminium, the<br />

reductions by scrap based production are even larger.<br />

However, very high recycling rates may require adjustments outside the base metal sector, because of the generally<br />

lower quality of scrap based metal. Current application of scrap based steel production is probably limited<br />

by an absolute scrap shortage, as Europe exports substantial amounts of scrap. In case of aluminium, the strong,<br />

continuing growth of consumption results in an absolute shortage of scrap; high recycling rates are only<br />

achievable after stabilisation of aluminium consumption. Then, new refinement technologies for scrap based<br />

Factor 2<br />

Factor 10