10089_001.pdf - Load set calculation - ECN

10089_001.pdf - Load set calculation - ECN

10089_001.pdf - Load set calculation - ECN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Load</strong> <strong>set</strong> <strong>calculation</strong> DOWEC 6MW H. Efdé<br />

5 Design variations.<br />

By altering Phatas IV input files and/or executables by <strong>ECN</strong> and Stentec, design variations are<br />

created. These are compared with the baseline DOWEC turbine. Not the whole load <strong>set</strong> is used, but<br />

just the load cases that have caused the highest loads. The following load cases are chosen to<br />

calculate the design variations: 012, 018, 024, 1B-5Vo, E50025, E50335, EcdVrb, Eog50-12,<br />

GrEog1Voc.<br />

5.1 Cost of energy.<br />

To clarify the results, the cost of energy per design is calculated according ref. [9], chapter 5.<br />

The cost of a wind turbine can be broken down in cost per component. Important design (and cost)<br />

drivers of a component are the extreme and fatigue loads it has to withstand. A further break down is<br />

achieved by weighing the several loads. By comparing load changes with the baseline configuration<br />

an estimation can be made about the change in cost of the wind turbine.<br />

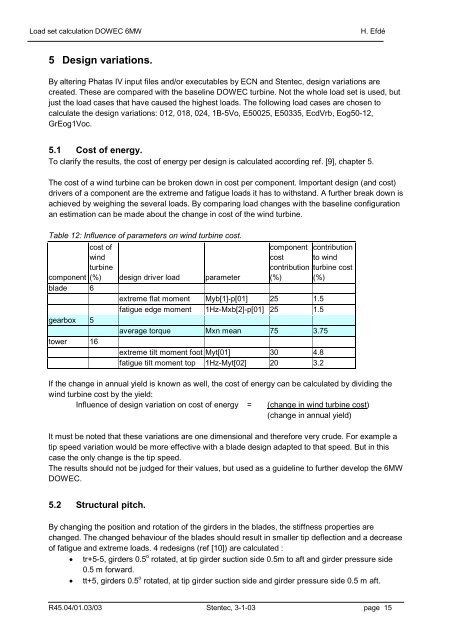

Table 12: Influence of parameters on wind turbine cost.<br />

cost of<br />

component contribution<br />

wind<br />

cost to wind<br />

turbine<br />

contribution turbine cost<br />

component (%) design driver load parameter (%) (%)<br />

blade 6<br />

extreme flat moment Myb[1]-p[01] 25 1.5<br />

fatigue edge moment 1Hz-Mxb[2]-p[01] 25 1.5<br />

gearbox 5<br />

average torque Mxn mean 75 3.75<br />

tower 16<br />

extreme tilt moment foot Myt[01] 30 4.8<br />

fatigue tilt moment top 1Hz-Myt[02] 20 3.2<br />

If the change in annual yield is known as well, the cost of energy can be calculated by dividing the<br />

wind turbine cost by the yield:<br />

Influence of design variation on cost of energy = (change in wind turbine cost)<br />

(change in annual yield)<br />

It must be noted that these variations are one dimensional and therefore very crude. For example a<br />

tip speed variation would be more effective with a blade design adapted to that speed. But in this<br />

case the only change is the tip speed.<br />

The results should not be judged for their values, but used as a guideline to further develop the 6MW<br />

DOWEC.<br />

5.2 Structural pitch.<br />

By changing the position and rotation of the girders in the blades, the stiffness properties are<br />

changed. The changed behaviour of the blades should result in smaller tip deflection and a decrease<br />

of fatigue and extreme loads. 4 redesigns (ref [10]) are calculated :<br />

• tr+5-5, girders 0.5 o rotated, at tip girder suction side 0.5m to aft and girder pressure side<br />

0.5 m forward.<br />

• tt+5, girders 0.5 o rotated, at tip girder suction side and girder pressure side 0.5 m aft.<br />

R45.04/01.03/03 Stentec, 3-1-03 page 15