SILAC® Siemens Industrial Linear Accelerator

SILAC® Siemens Industrial Linear Accelerator

SILAC® Siemens Industrial Linear Accelerator

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

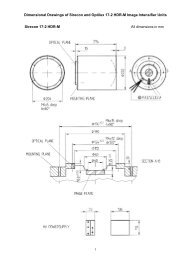

.75<br />

F<br />

4T Dia. 1T Dia.<br />

A<br />

E<br />

2T Dia.<br />

FE<br />

T<br />

±10%<br />

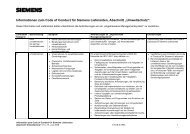

Figure 3: Test device acc. ASTM E1742-00 Diagram 1: Test result acc. ASTM E1742-00<br />

<strong>SILAC®</strong><br />

<strong>Siemens</strong> <strong>Industrial</strong> <strong>Linear</strong> <strong>Accelerator</strong><br />

ASTM E1742-00:<br />

The following unit mold is placed between 2 plates made<br />

on 80 mm thick steel (Figure 3).<br />

The diagram shows the result which is generated with the<br />

6 MeV <strong>SILAC®</strong> (Diagram 1).<br />

D. System interface<br />

Control of the whole system is possible via an external<br />

user interface. This system software can be operated on a<br />

standard Windows computer at the customer site or by<br />

SPS System (24V TTL).<br />

All relevant parameters like energy, dose, repetition rate<br />

or pulse length are variable within the system limits.<br />

In order to start the beam pulse the user can choose<br />

between external triggering and internal trigger control.<br />

The system control is fully integrated and shows the<br />

user all status messages regarding time stamps, status of<br />

system and safety loops and system errors (Figure 4).<br />

E. Safety circuits<br />

The “beam off“ safety switch is realized by an emergency<br />

stop switch of cat. 4, which has to be lined in the radiation<br />

safety loop at the user site.<br />

The system has an interlock system. When activated<br />

the errors are shown on the user monitor and the affected<br />

components stop operation.<br />

After solving the problem, the beam operation can be<br />

continued.<br />

D<br />

C<br />

B<br />

3.0 FE – 80 mm steel<br />

F. Mechanical design<br />

The main design elements are made of aluminum<br />

or stainless steel.<br />

The standard configuration can be operated in the<br />

horizontal position only.<br />

Cooling system<br />

The system needs a DI water supply. This can be provided<br />

at the user end or by the supplier. The recommended<br />

indoor cooling system has the following dimensions:<br />

Width 480 mm, length 510 mm, height 560 mm<br />

Figure 4: Screenshot of user interface<br />

4